Radiator and LED lamp

A heat sink and LED light source technology, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problem of high difficulty in controlling the thickness of heat sinks, different production molds for heat sinks, and LED heat sinks. Scrapped and other issues, to achieve the effect of reducing weight and consumables, good heat dissipation effect, high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

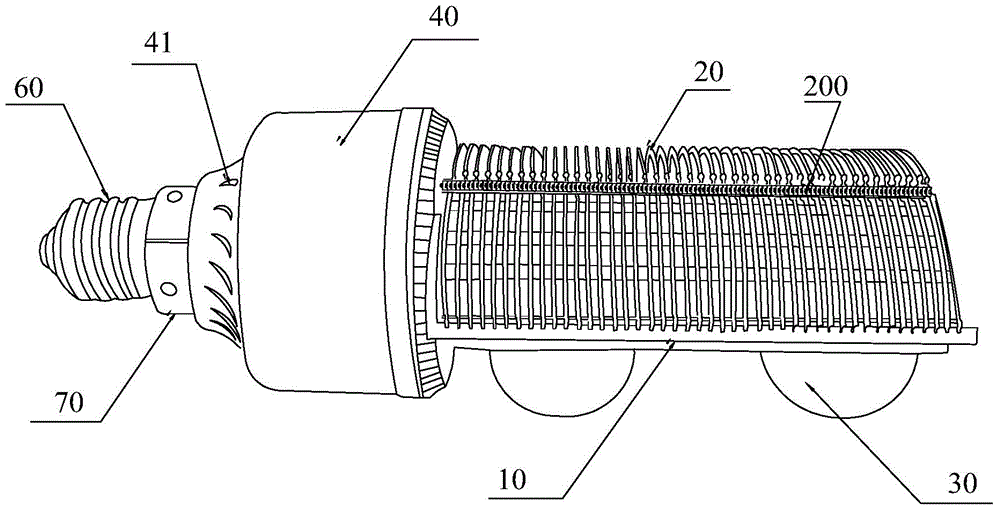

[0036] refer to Figure 1 to Figure 5 , propose an embodiment of the radiator of the present invention:

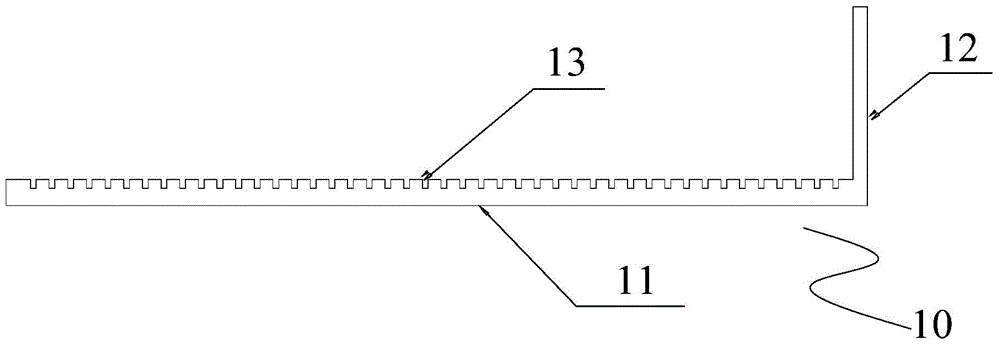

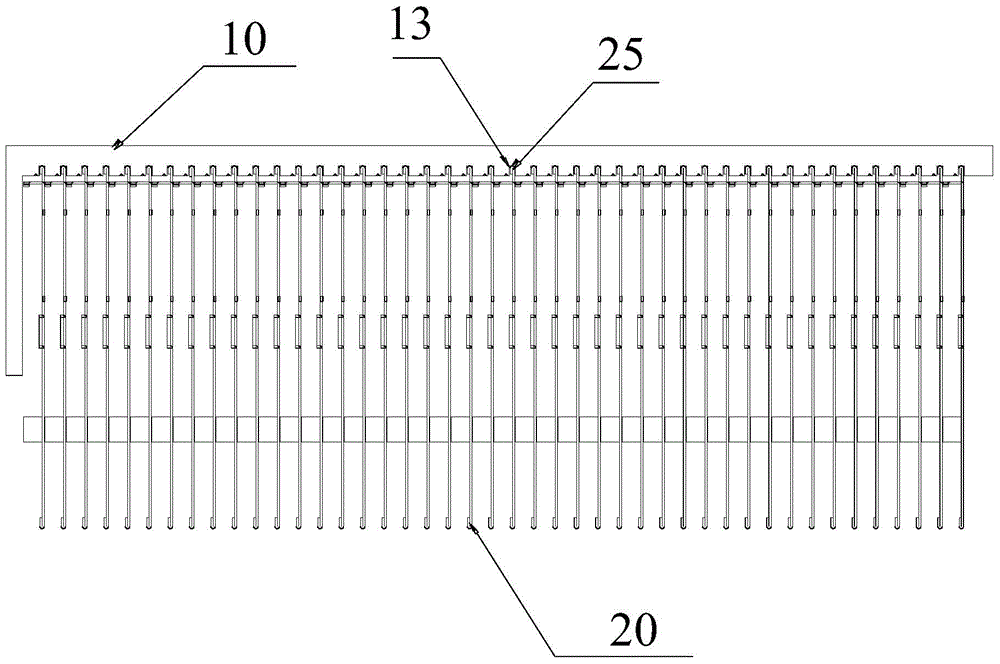

[0037] A heat sink includes a heat conduction plate 10 for installing an LED light source 30 and a plurality of heat dissipation fins 20, the heat conduction plate 10 and the heat dissipation fins 20 are made of aluminum. The heat conduction plate 10 has a straight dihedral design and includes two mutually perpendicular panels—a first panel 11 and a second panel 12 , and the length of the first panel 11 is longer than that of the second panel 12 . The cooling fins 20 are arranged in columns to form heat dissipation columns, and the heat dissipation columns are installed on the back of the first panel 11 of the heat conduction plate 10, and the front surface of the first panel 11 is used to install the LED light sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com