Motor and hydraulic pressure combined drive in-situ test device for structure properties of materials

A driving method and technology of tissue properties, applied in the field of in-situ testing devices for material properties The requirements of sample preparation and the effect of shortening the experimental time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing.

[0034] The invention is an in-situ observation device capable of simultaneously realizing the material structure under two kinds of mechanical performance experiments of tension and compression on the X-ray diffraction experiment equipment. The device can be used for both in-situ observation of tension experiments and in-situ observation of compression experiments. It can be used alone or in combination with X-ray diffraction equipment.

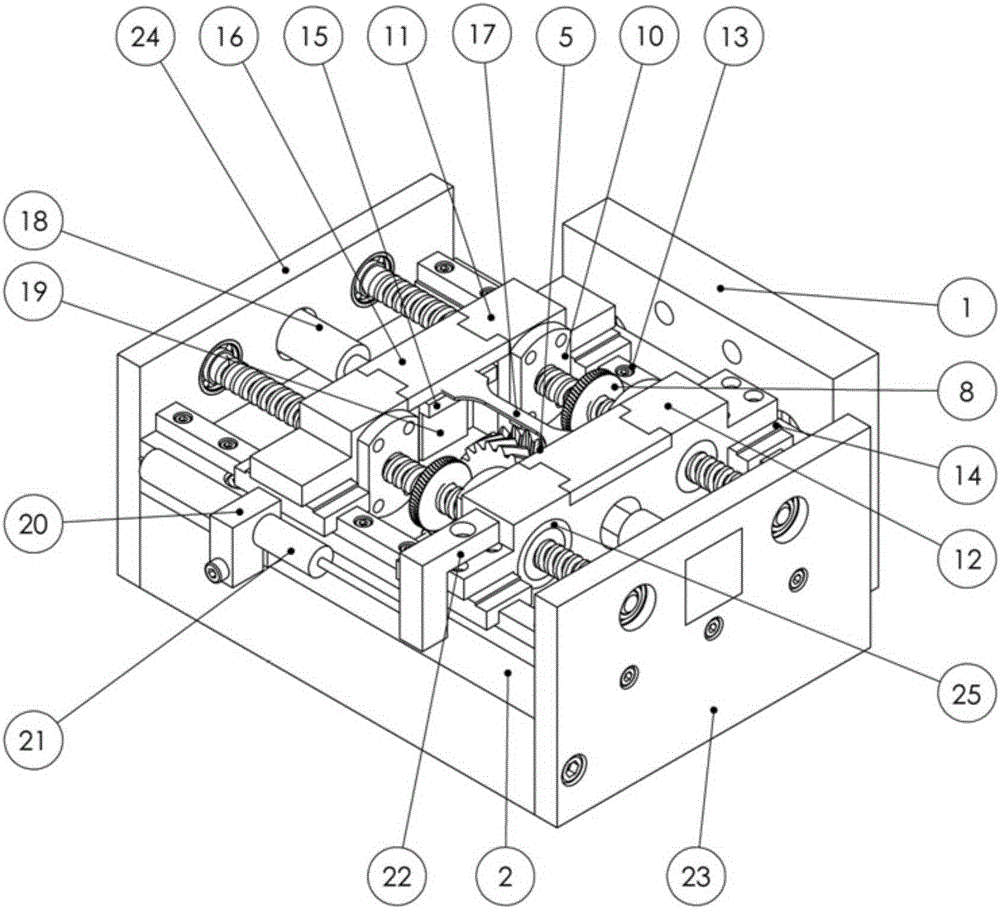

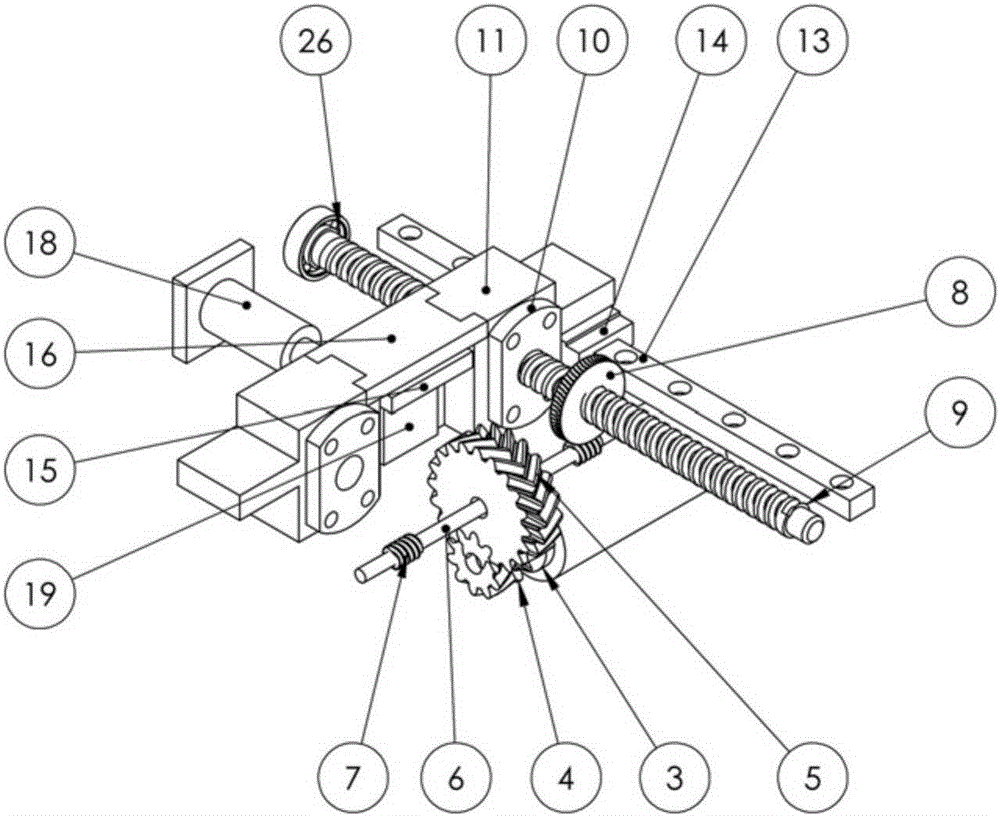

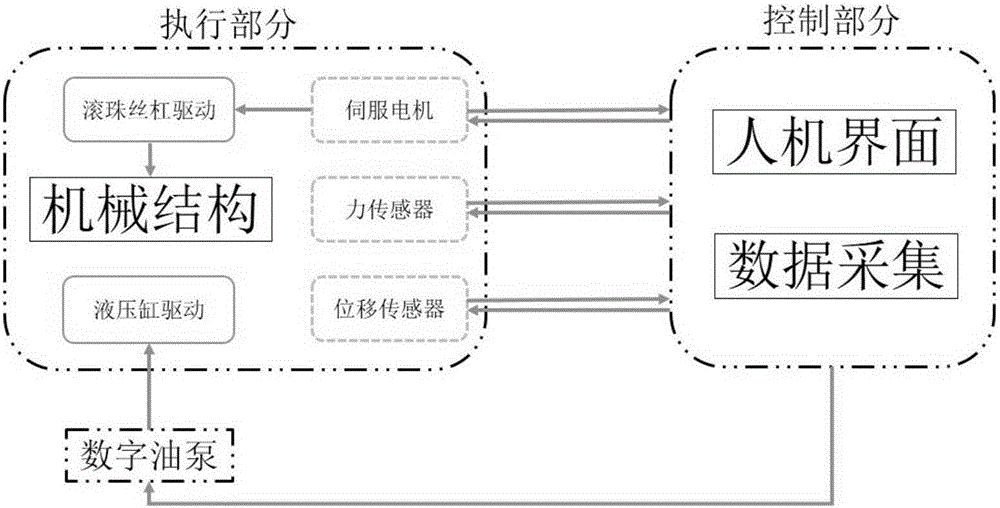

[0035] like figure 1 As shown in -4, the device of the present invention adopts a servo motor and a hydraulic dual drive mode, and the two drive modes can be switched seamlessly. The unit can also be paused at any time. The test device of the present invention comprises the following parts:

[0036] 1. Executing part (located inside the machine)

[0037] The execution part is combined with servo motor drive and hydraulic drive, which rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com