Grinding body for corrosion-resistant high-hardness high-toughness ball mill

A high-hardness, high-toughness technology, applied in the field of grinding bodies, can solve problems affecting the normal operation and production progress of equipment, premature scrapping, wear loss, etc., and achieve good wear resistance, good wear resistance, and excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

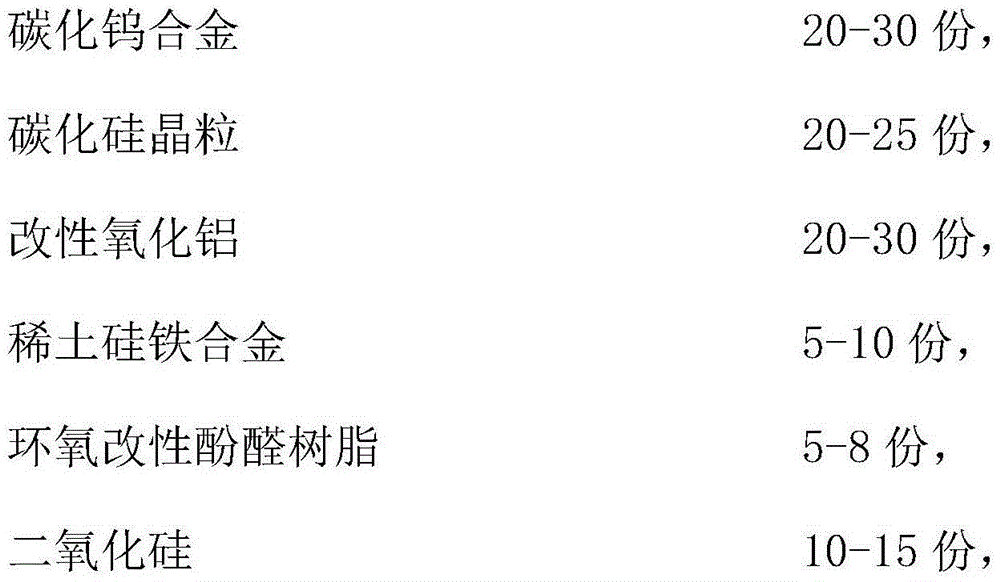

[0016] A grinding body for a corrosion-resistant, high-hardness, high-toughness ball mill, the raw materials of which include by weight:

[0017]

[0018] Wherein, the modified alumina is a product obtained by sintering, quenching and tempering at 1285°C;

[0019] In the diamond powder, 15-35 μm accounts for 35 parts, 40-50 μm accounts for 27 parts, 70-80 μm accounts for 8 parts, and 85-95 μm accounts for 9 parts;

[0020] The preparation process of the cubic boron nitride is as follows: 87.5% hexagonal boron nitride and 12.5% magnesium-based alloy are uniformly mixed according to the weight percentage, and then the temperature is 1965 ℃, the pressure is 5.2×10 6 Cubic boron nitride converted under the condition of K Pa.

Embodiment 2

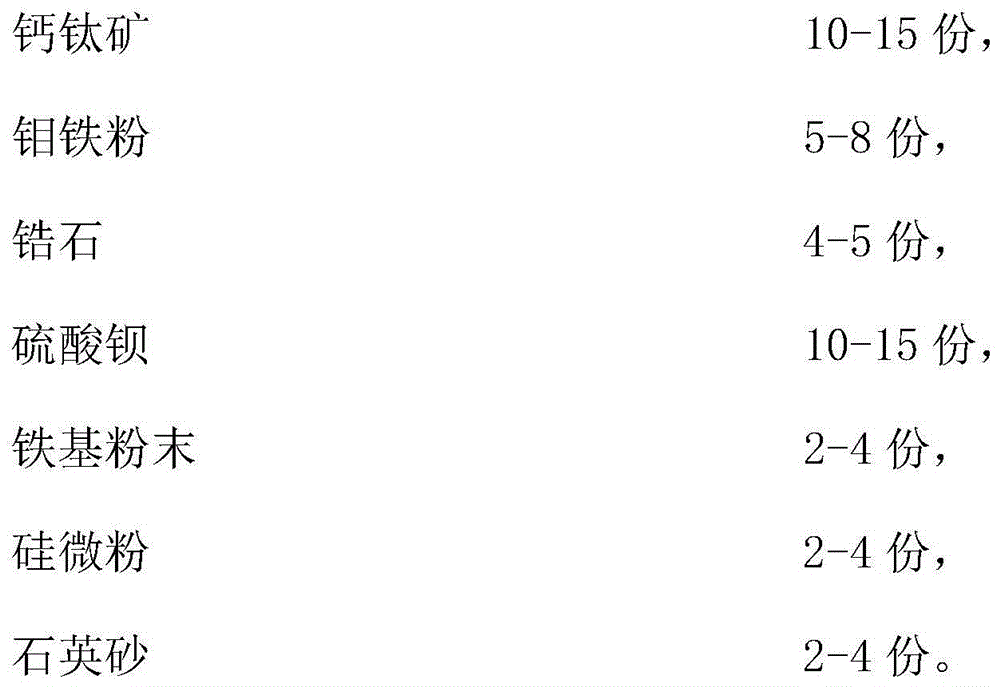

[0022] A grinding body for a corrosion-resistant, high-hardness, high-toughness ball mill, the raw materials of which include by weight:

[0023]

[0024] Wherein, the modified alumina is a product obtained by sintering, quenching and tempering at 1300°C;

[0025] In the diamond powder, 15-35 μm accounts for 20 parts, 40-50 μm accounts for 30 parts, 70-80 μm accounts for 5 parts, and 85-95 μm accounts for 10 parts;

[0026] The preparation process of the cubic boron nitride is as follows: 87.5% hexagonal boron nitride and 12.5% magnesium-based alloy are uniformly mixed according to the weight percentage, and then the temperature is 1965 ℃, the pressure is 5.2×10 6 Cubic boron nitride converted under the condition of K Pa.

Embodiment 3

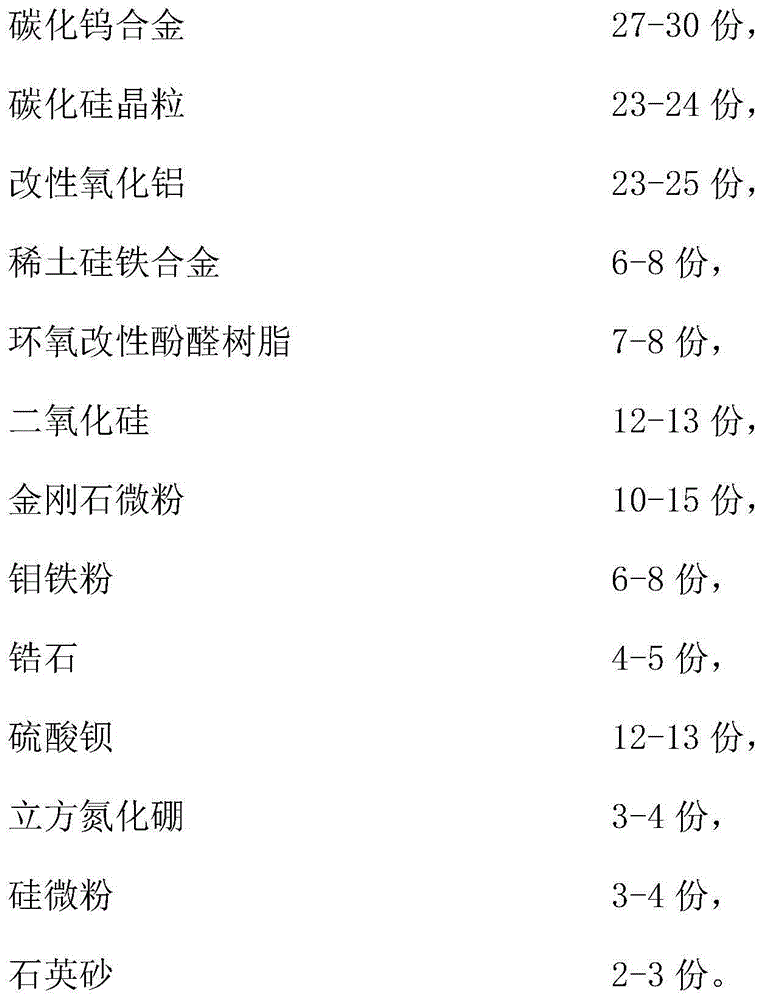

[0028] A grinding body for a corrosion-resistant, high-hardness, high-toughness ball mill, the raw materials of which include by weight:

[0029]

[0030] Wherein, the modified alumina is a product obtained by sintering, quenching and tempering at 1270°C;

[0031] In the diamond powder, 15-35 μm accounts for 40 parts, 40-50 μm accounts for 20 parts, 70-80 μm accounts for 10 parts, and 85-95 μm accounts for 5 parts;

[0032] The preparation process of the cubic boron nitride is as follows: 87.5% hexagonal boron nitride and 12.5% magnesium-based alloy are uniformly mixed according to the weight percentage, and then the temperature is 1965 ℃, the pressure is 5.2×10 6 Cubic boron nitride converted under the condition of K Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com