Patents

Literature

34results about How to "Reduce axial displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

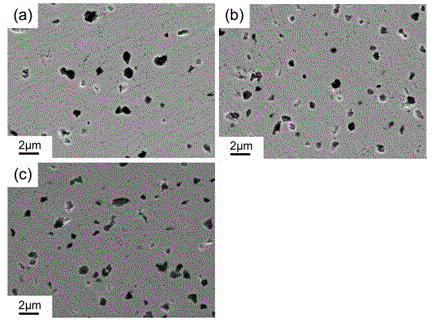

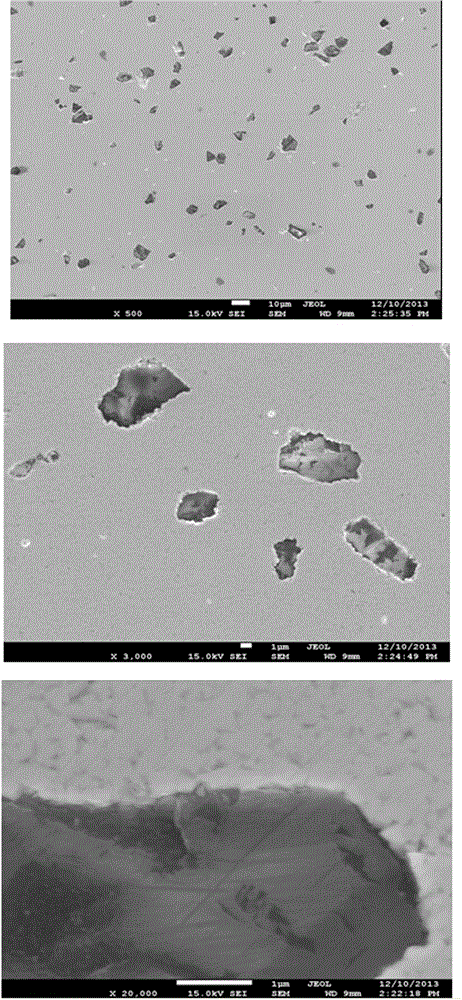

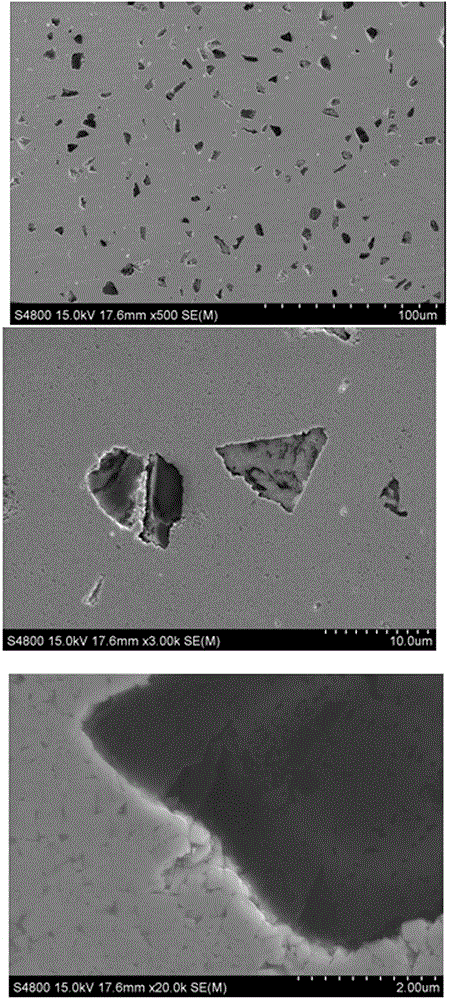

Preparation method of WC-Co-cBN composite material

The invention belongs to the technical field of material preparation and in particular relates to a preparation method of a WC-Co-cBN composite material. The preparation method of the WC-Co-cBN composite material comprises the following steps: firstly weighing WC, metal Co powder and cBN raw material in proportion, uniformly mixing, mixing by carrying out ball milling, drying the mixed raw materials in a drying oven at the temperature of 50-200 DEG C, then sieving with a sieve of 100-300 meshes, putting the dried raw materials into a mould, then placing the mould into a hot-pressing sintering furnace, heating the sintering furnace to 1200-1400 DEG C at a speed of 30-50 DEG C / min, insulating for 5-30 minutes, and maintaining pressure to be 20-50MPa, so that the WC-Co-cBN composite material is obtained. The preparation method of the WC-Co-cBN composite material has the advantages that the hot-pressing method is adopted, the sintering temperature is low, sintering time is short, and no phase transformation of cBN can be guaranteed while the WC-Co-cBN composite material has high shrinkage percentage and high volume density; meanwhile, hot pressing energy consumption is low, cost is low, operation is easy, and safety coefficient is high.

Owner:NORTHEASTERN UNIV

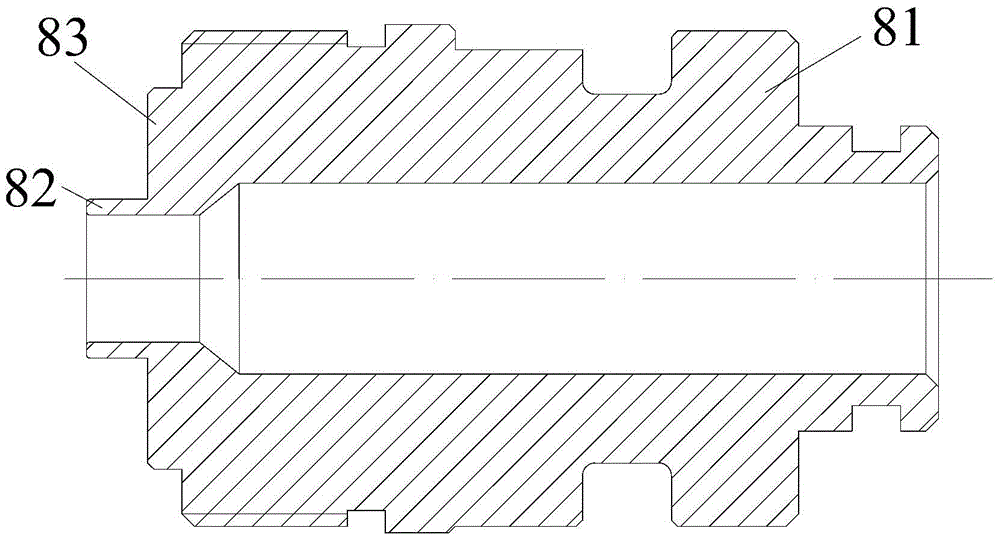

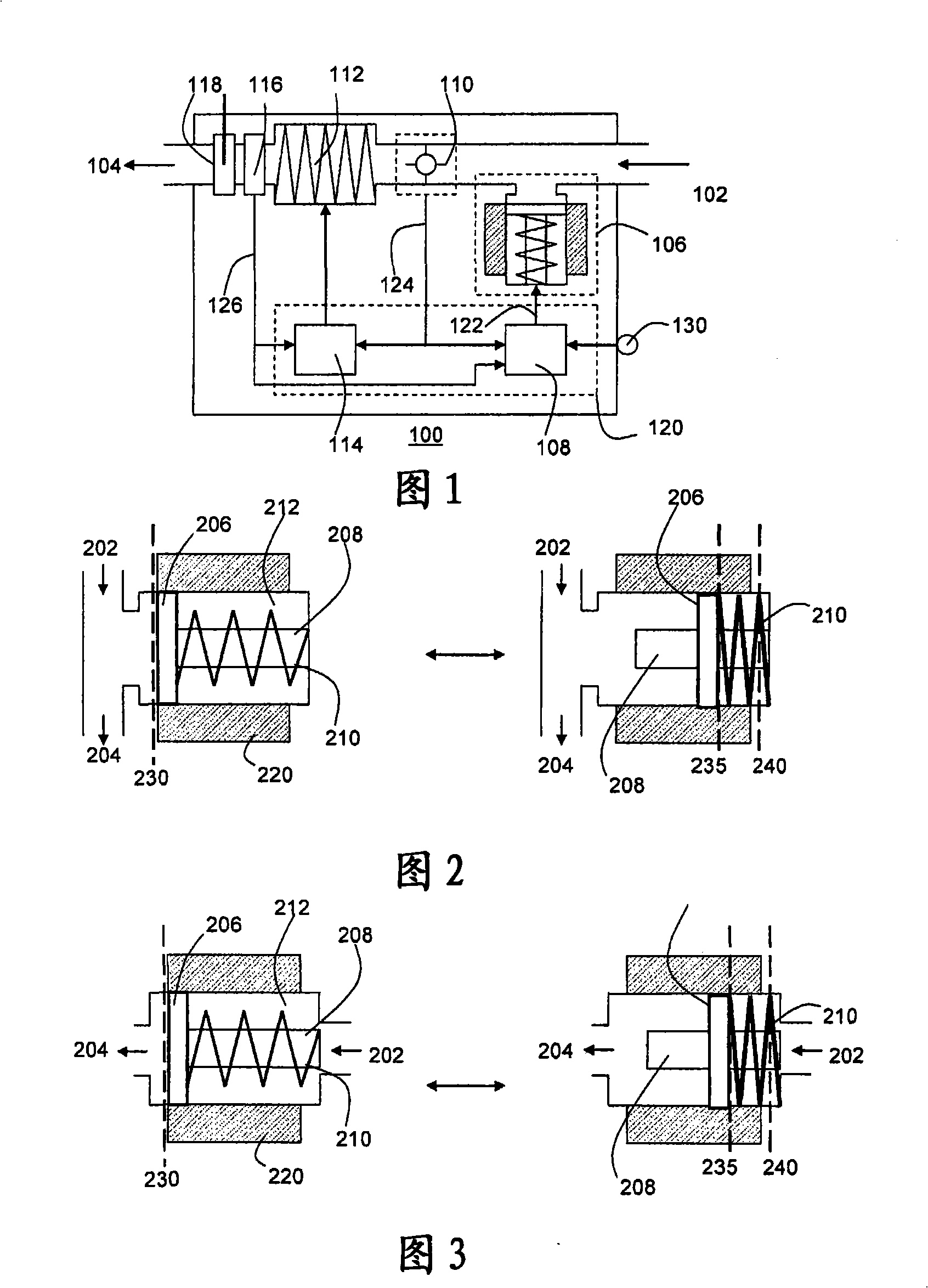

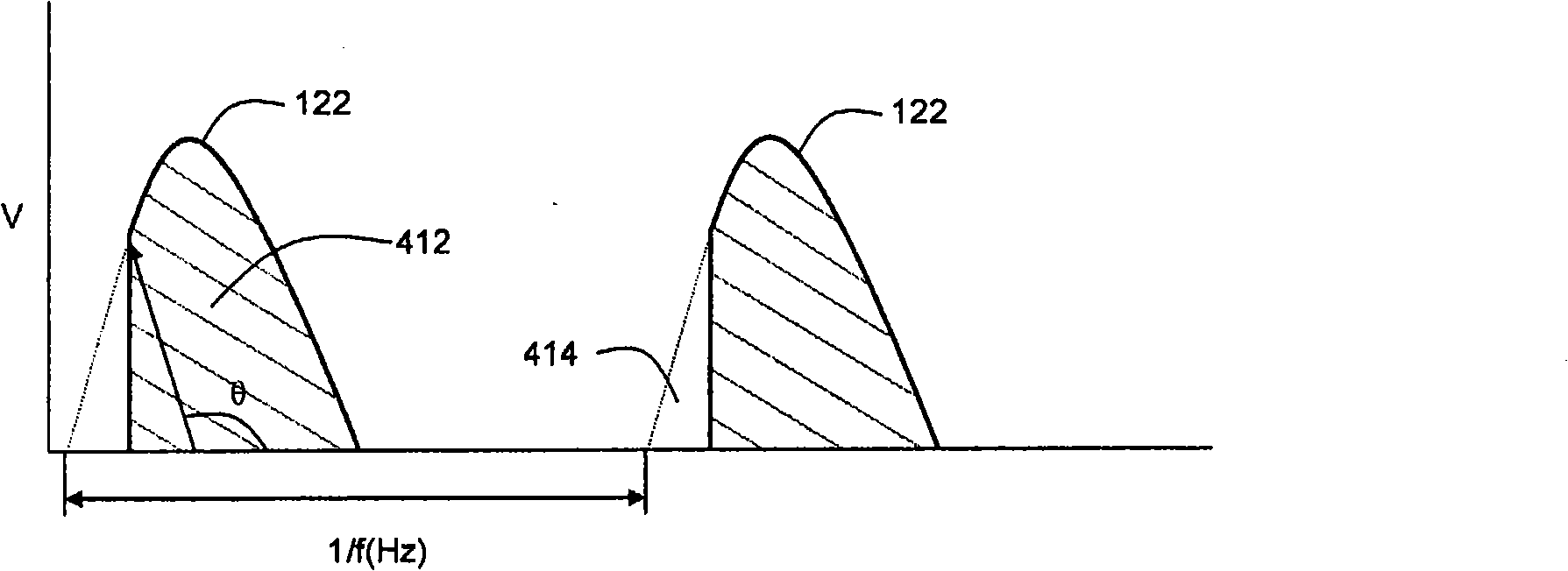

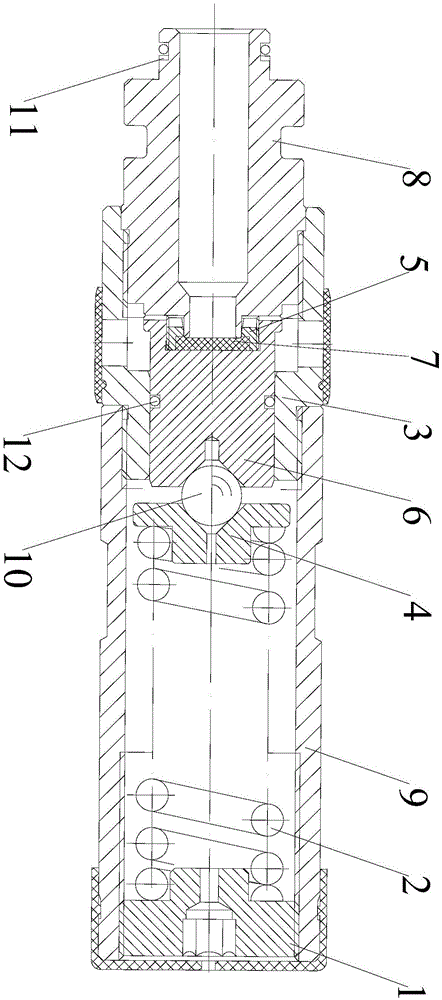

Beverage dispensing apparatus and method

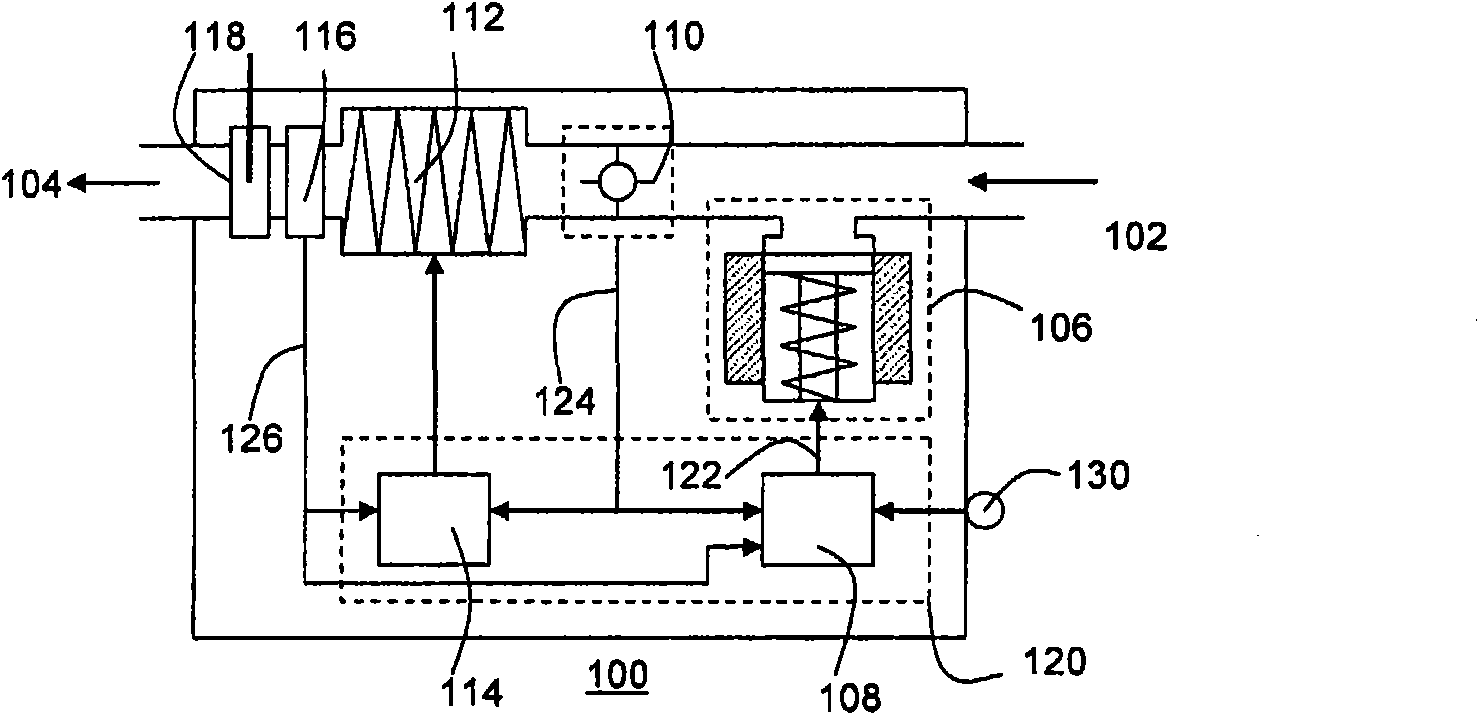

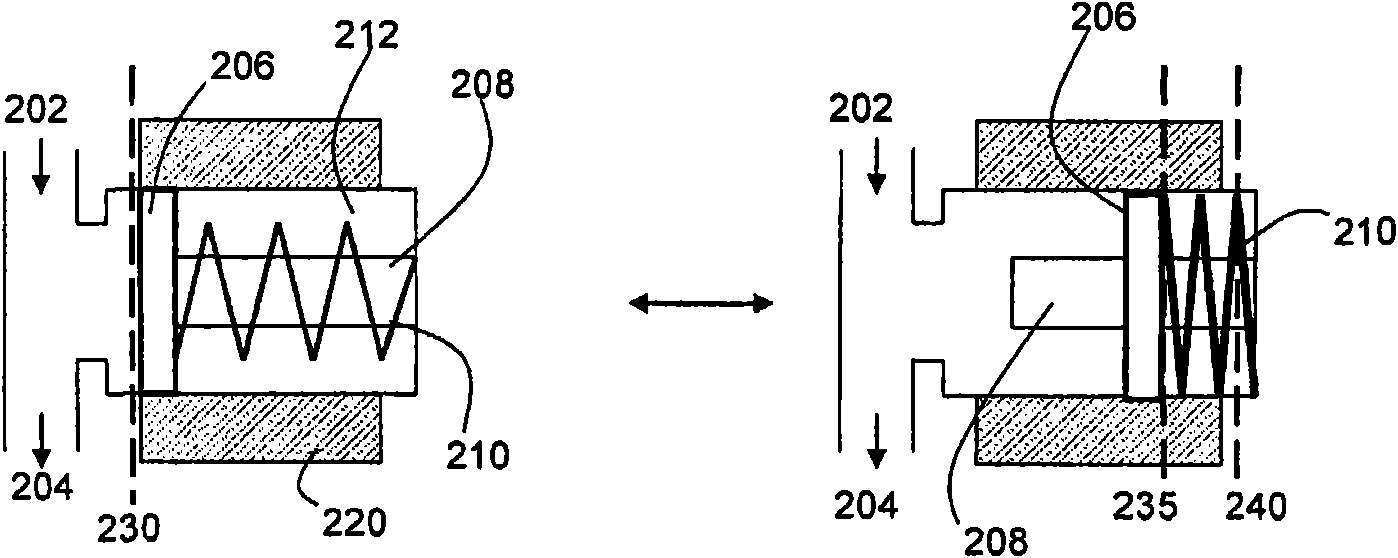

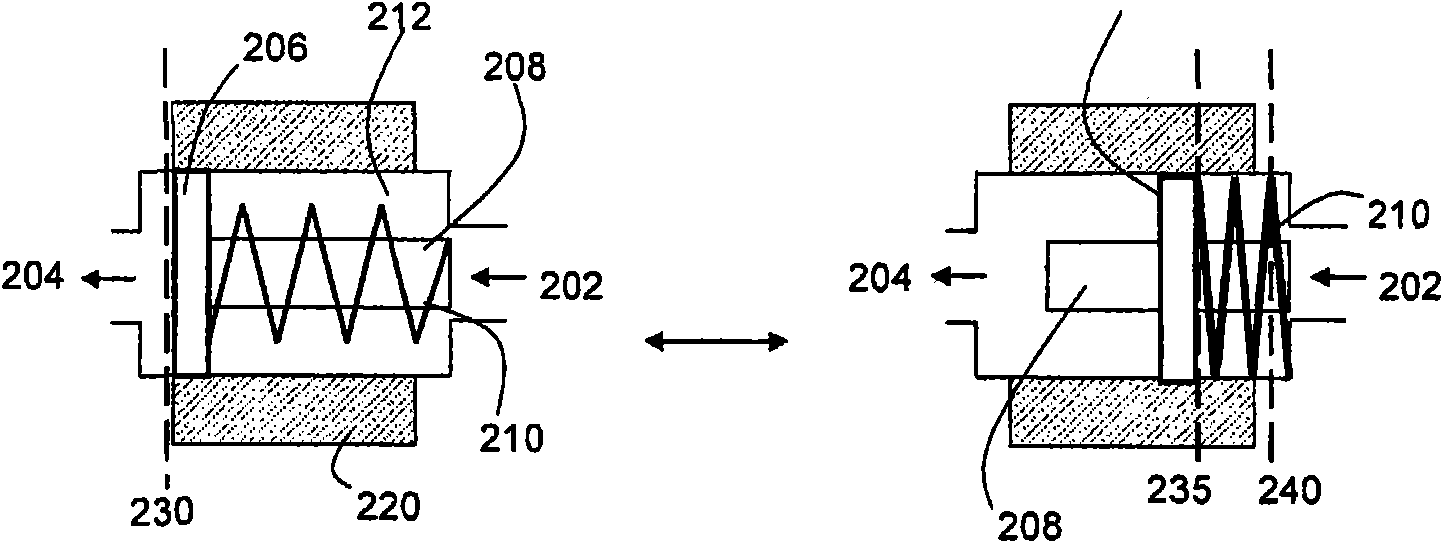

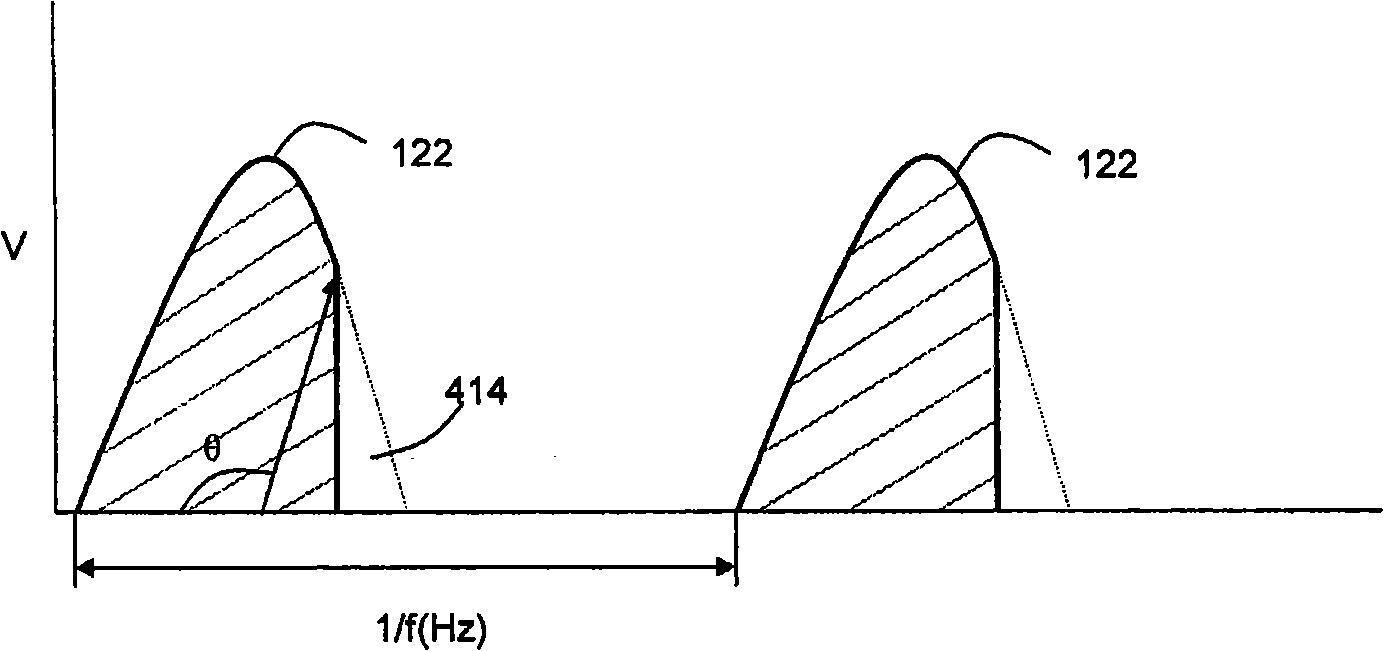

InactiveCN101554986AReduce noise levelReduce axial displacementPositive displacement pump componentsLiquid transferring devicesBiomedical engineeringElectromagnetic pump

A beverage dispensing apparatus (100) is disclosed, comprising a solenoid pump (106) coupled between a fluid inlet (102) and a fluid outlet (104) for pumping the fluid from said inlet to said outlet, said pump comprising a spring-loaded linear pumping member (206) axially displaceable between a spring-loaded position (240) and a spring-released end position (230) and a controller (108) for the solenoid pump (106), said controller being arranged to energize the pumping member (206) into an intermediate position (235) between the spring-released end position (230) and the spring-loaded position(240). Consequently, the solenoid pump (106) has improved noise characteristics and can be used to control the flow rate of the fluid whilst still being energized in substantially every cycle of an alternating current.

Owner:NESTEC SA

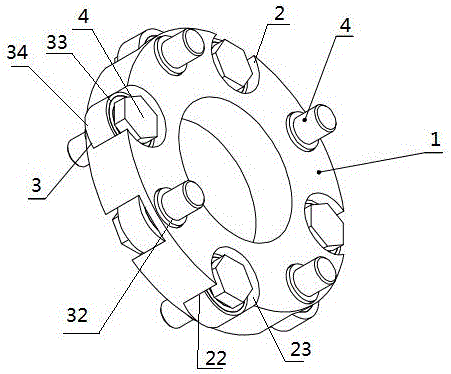

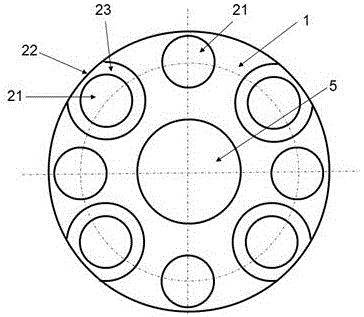

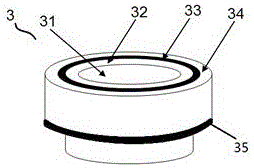

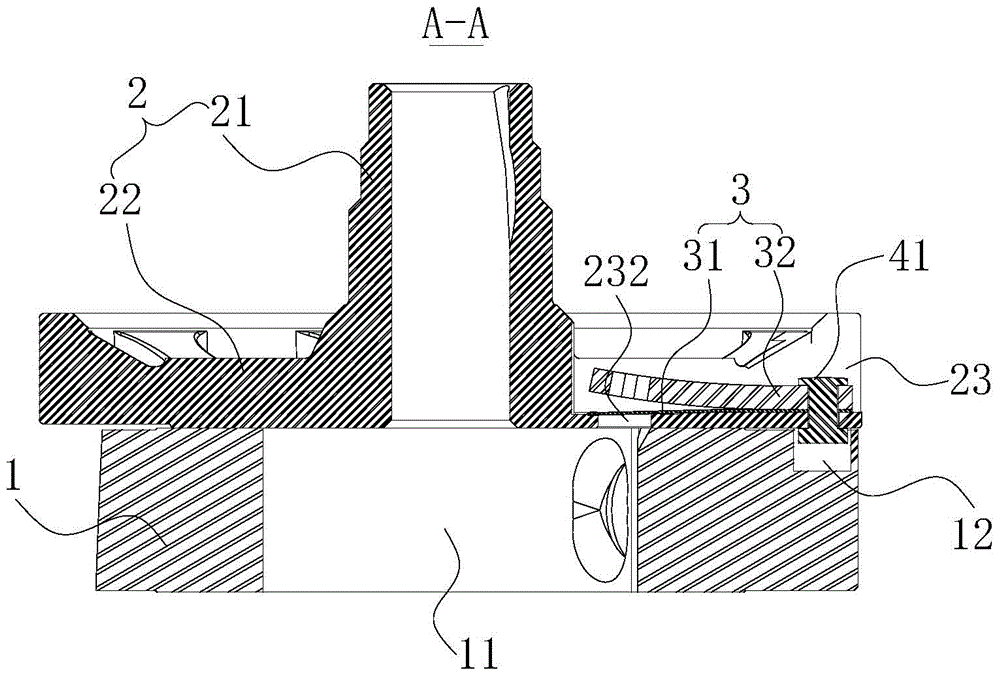

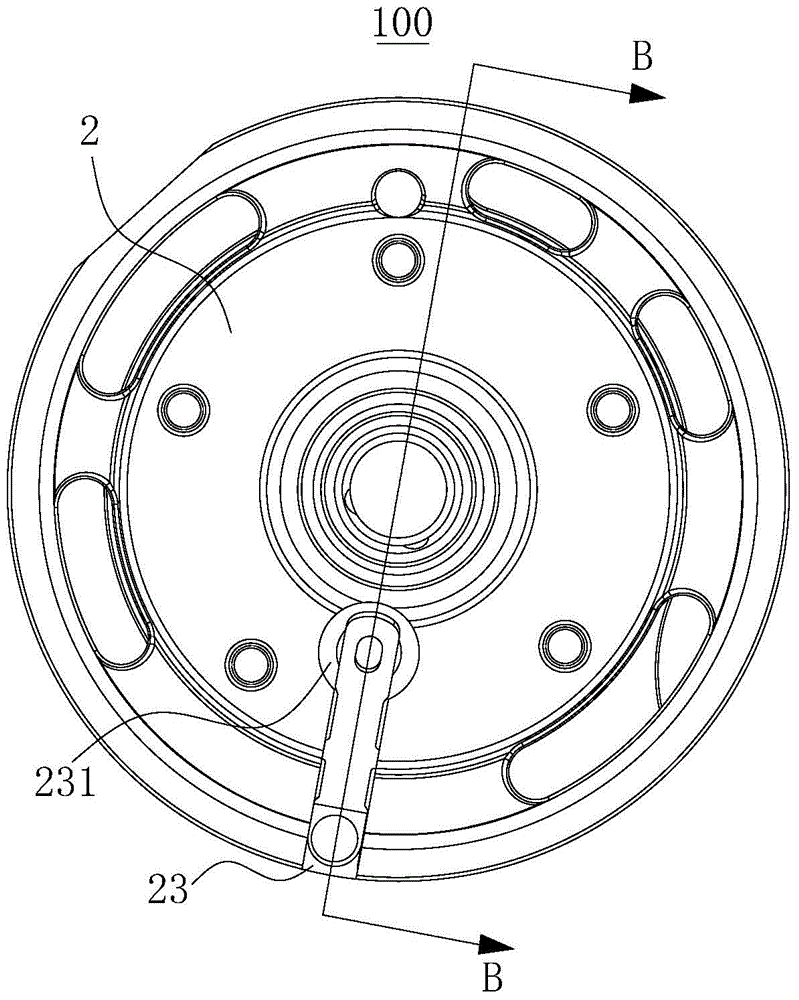

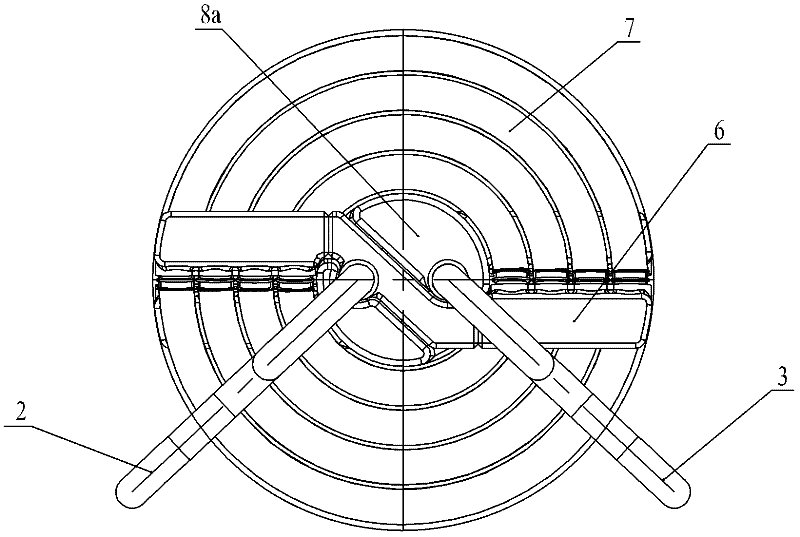

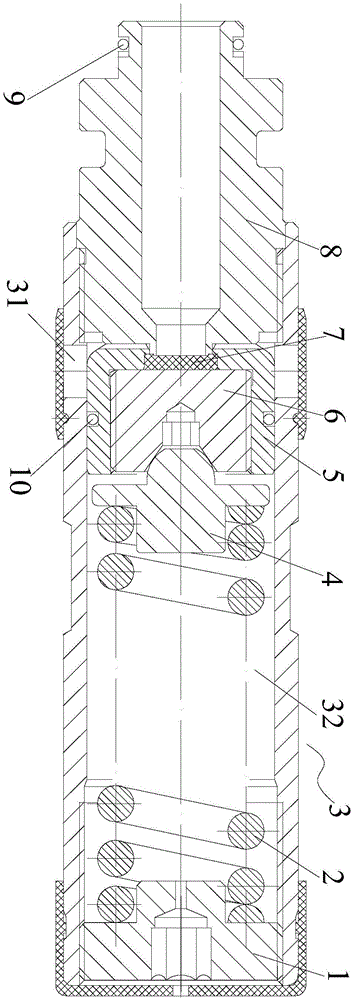

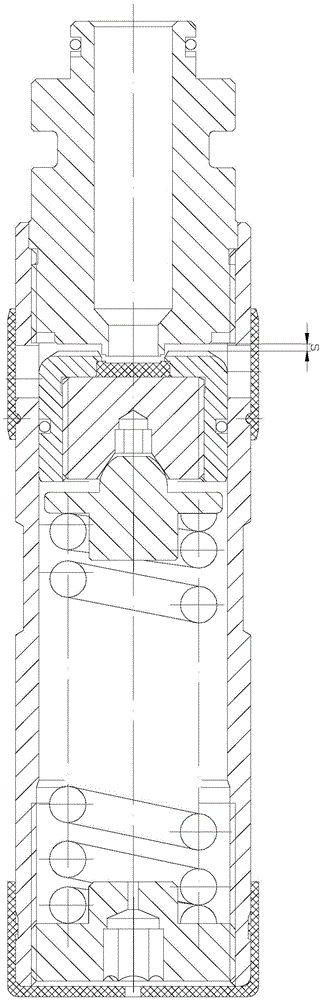

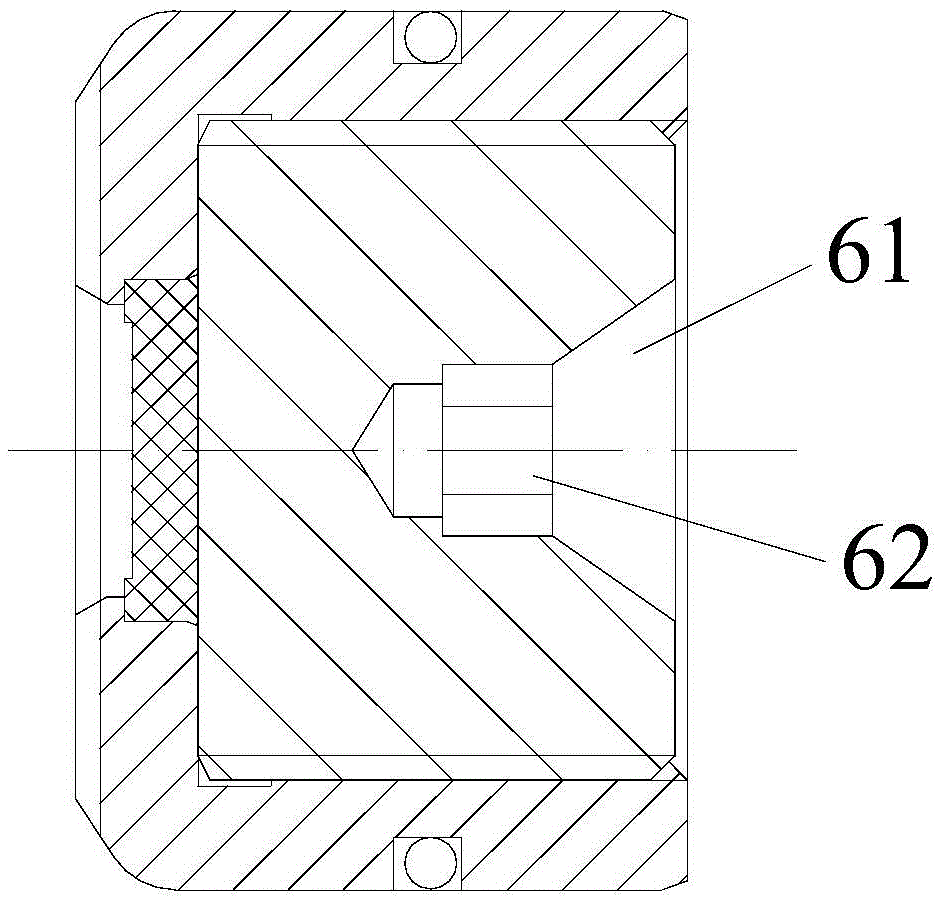

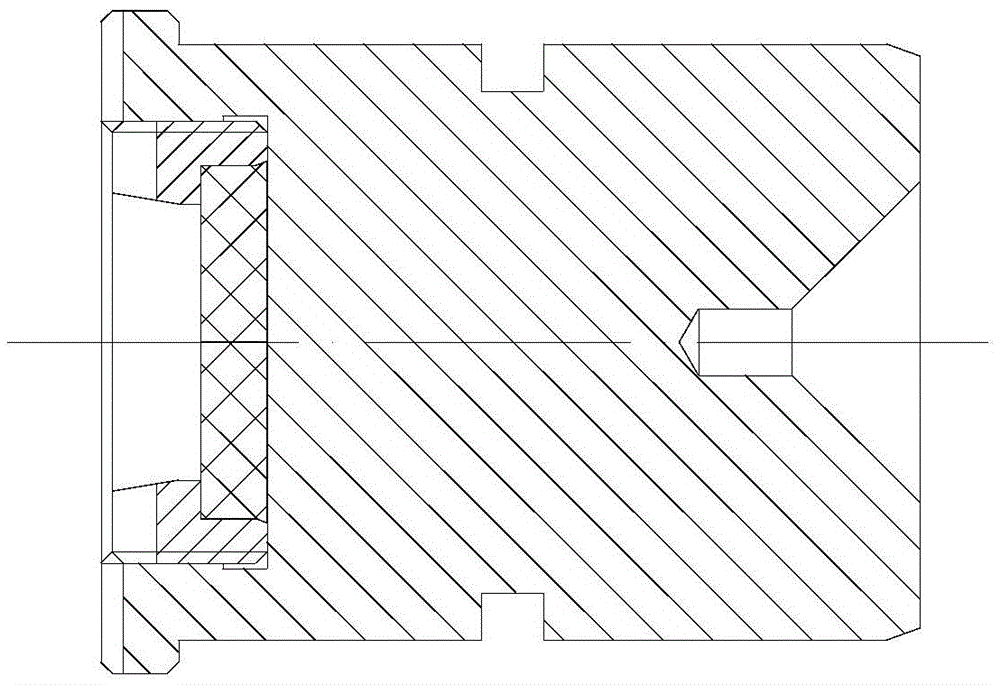

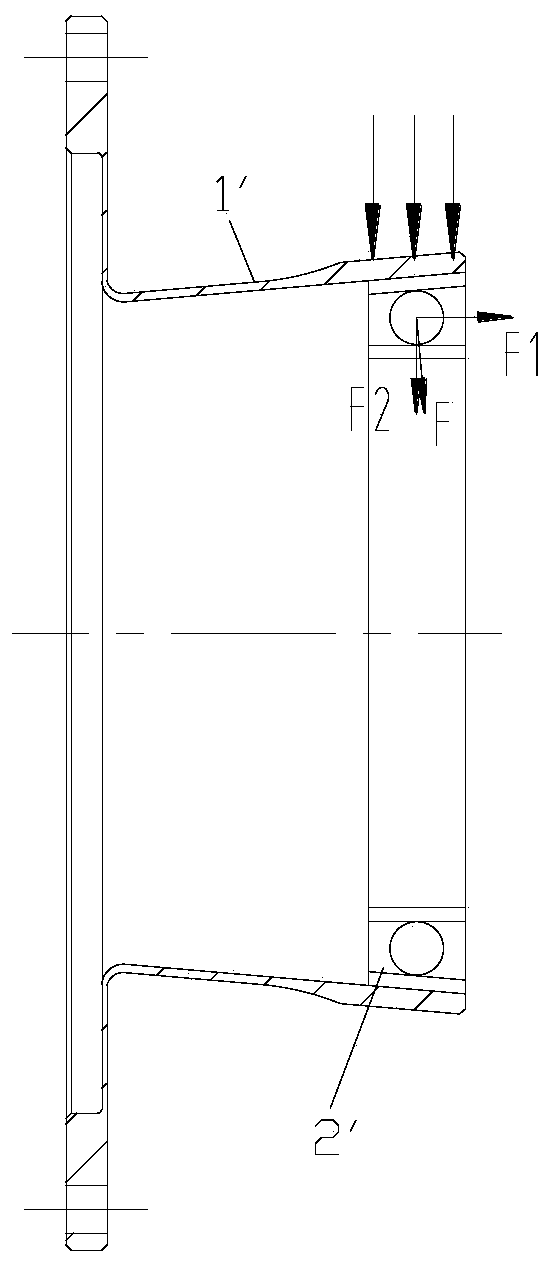

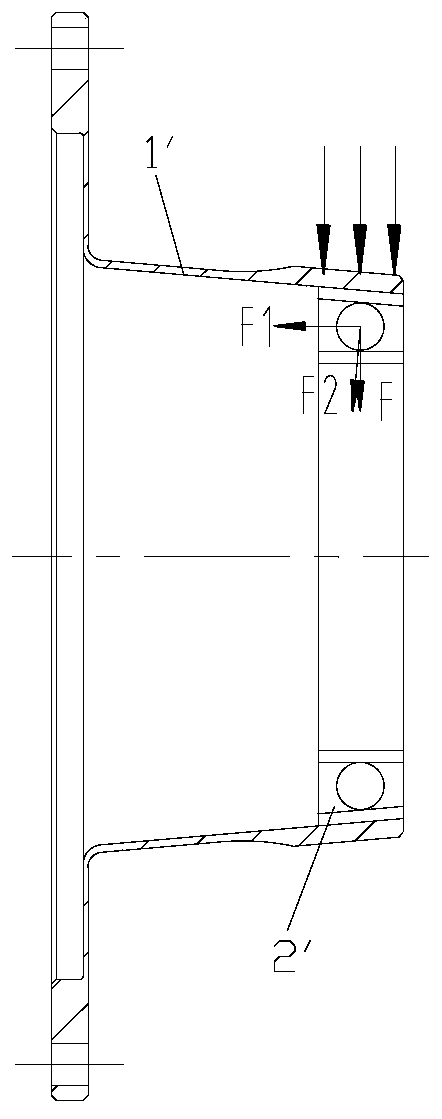

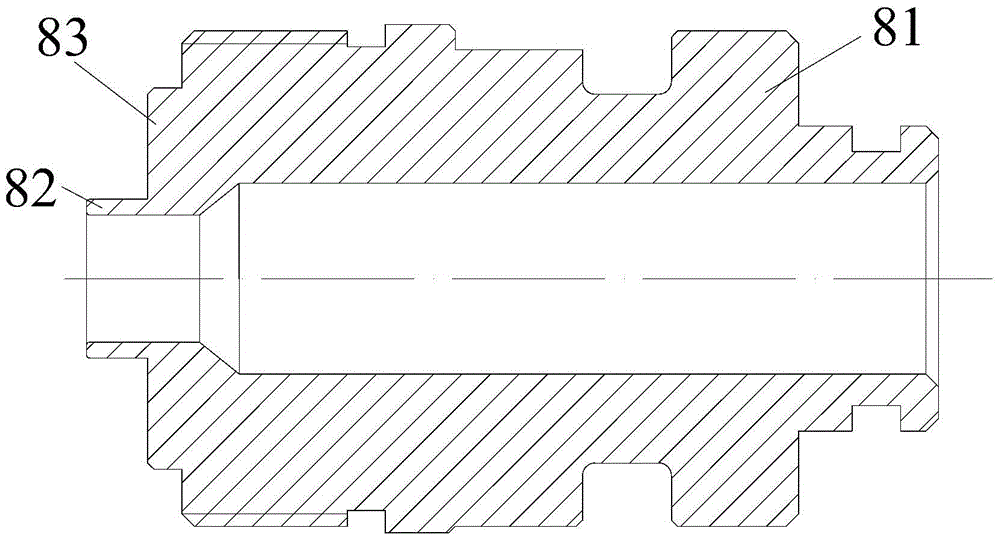

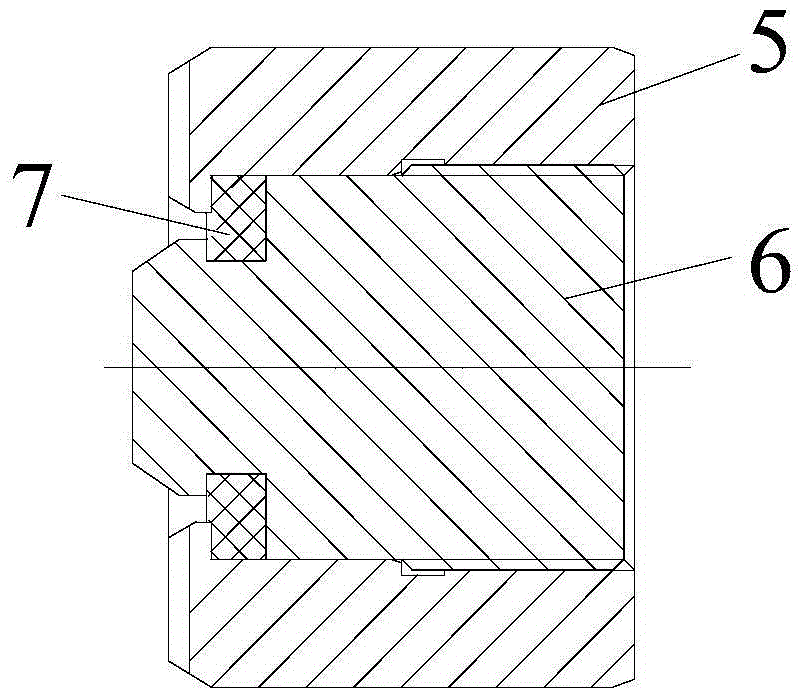

Vibration and noise reduction flange

PendingCN106050946ACut off the delivery pathReduce axial displacementNon-rotating vibration suppressionCouplings for rigid shaftsAxial displacementEngineering

The invention discloses a flange. The flange comprises a flange plate and a first connecting unit, wherein the flange plate comprises a flange hole formed in the center of a circle and at least one connecting groove, the first connecting unit is positioned in the connecting groove and is used for connecting a first element to one side surface of the flange plate, the first connecting unit comprises a bolt and a shock absorber which is positioned on the outer side of the bolt, the shock absorber is used for reducing axial displacement and axial vibration, and additionally, a noise transmission path can be cut off, so that the noise amplitude is reduced.

Owner:NINGBO HAITONG AUTO PARTS

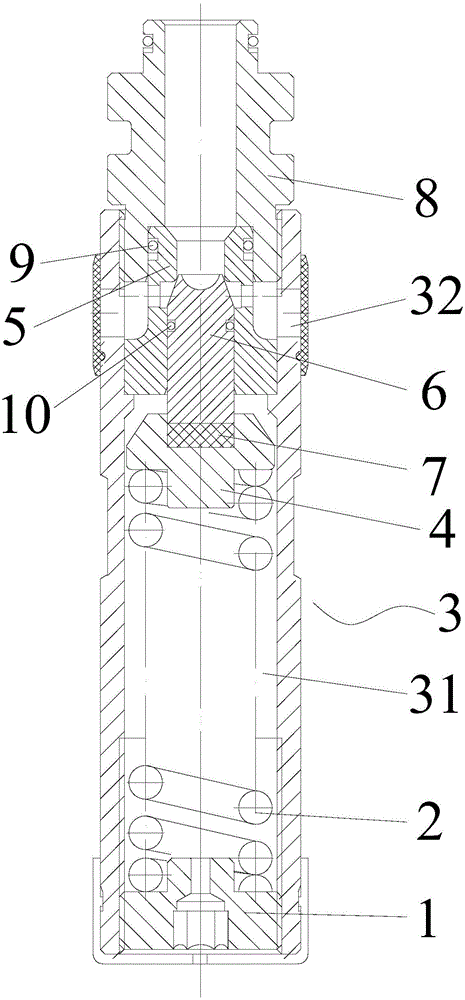

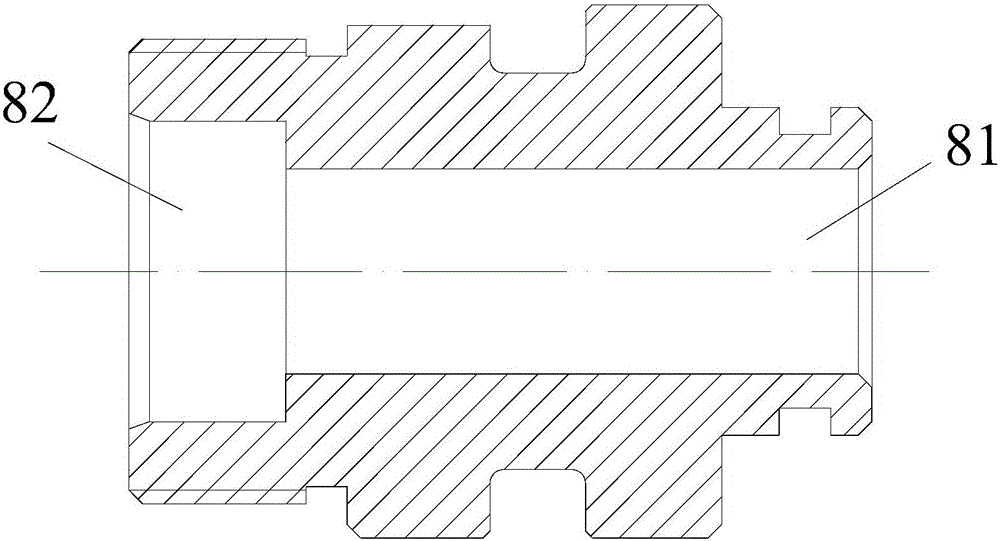

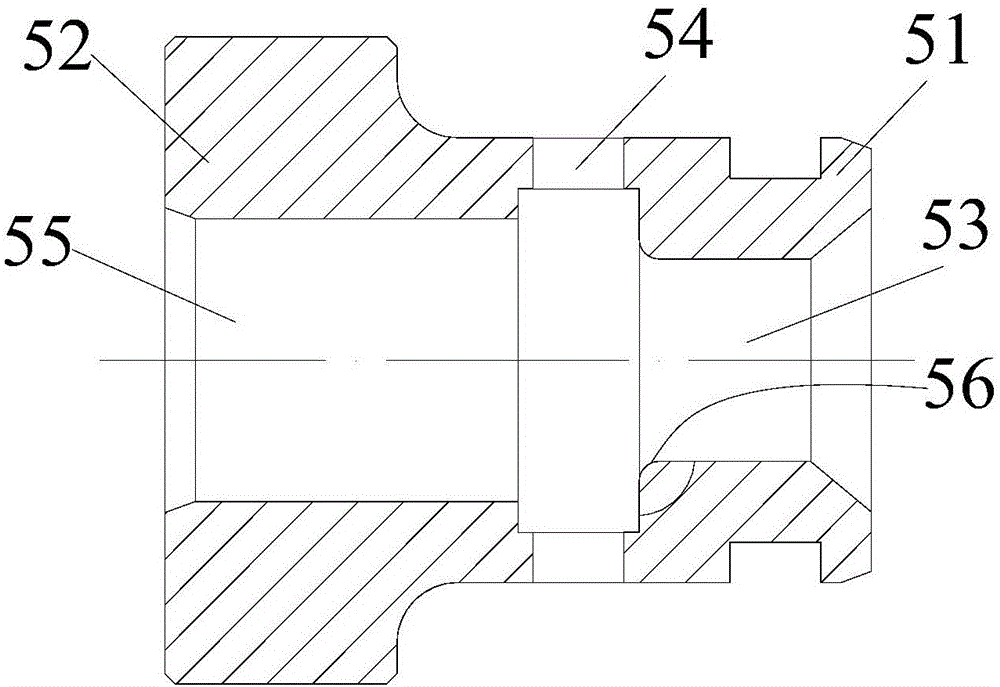

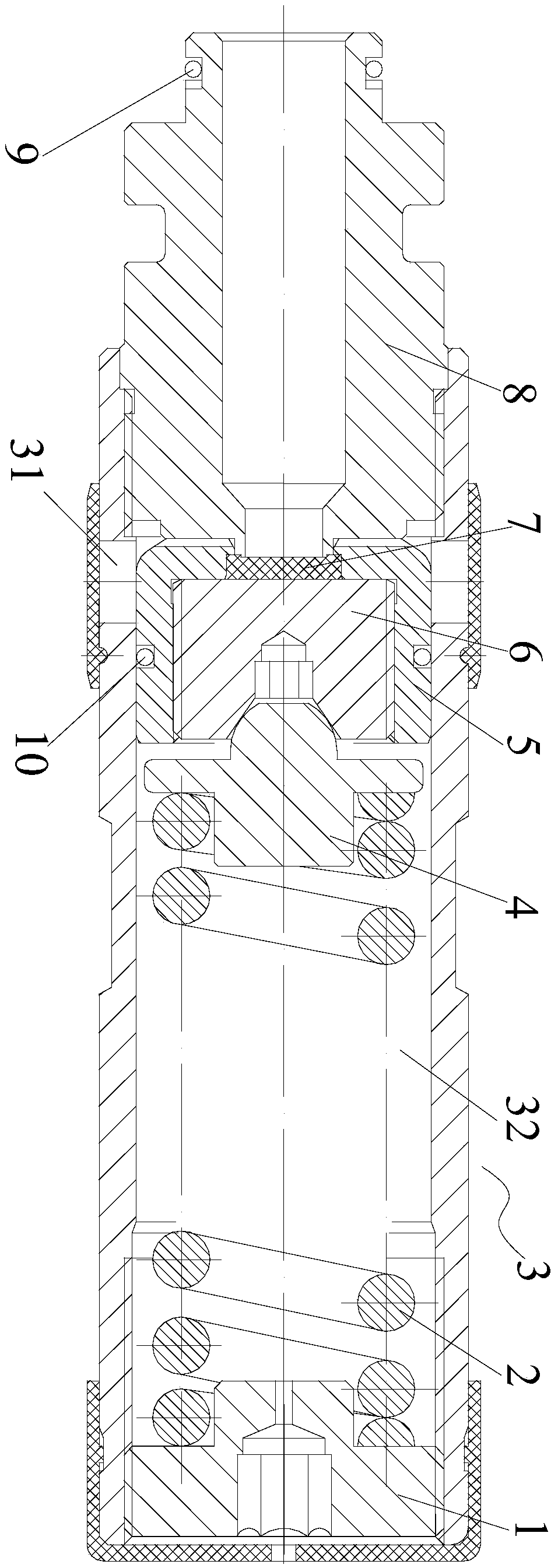

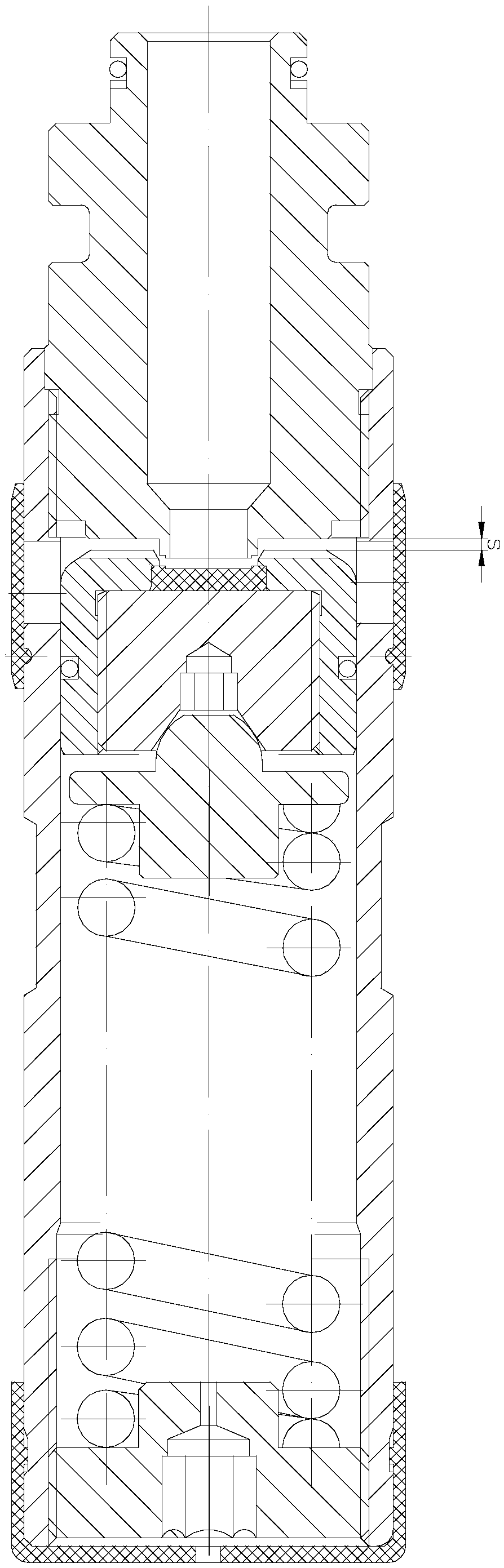

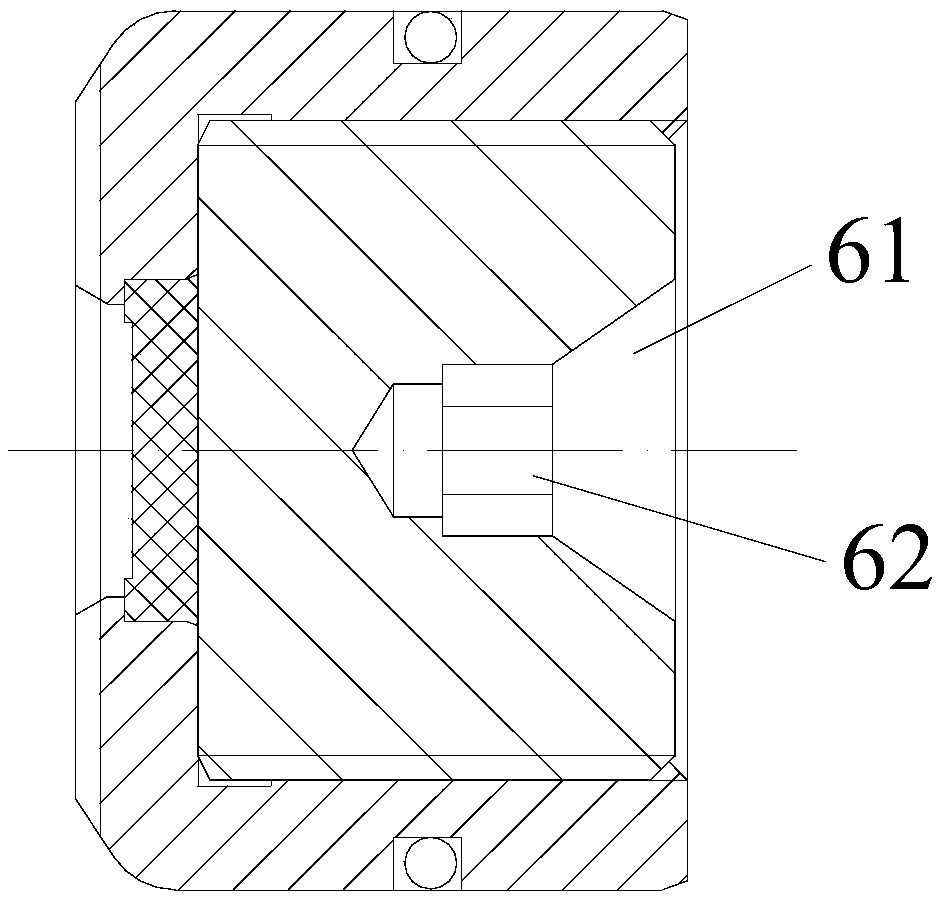

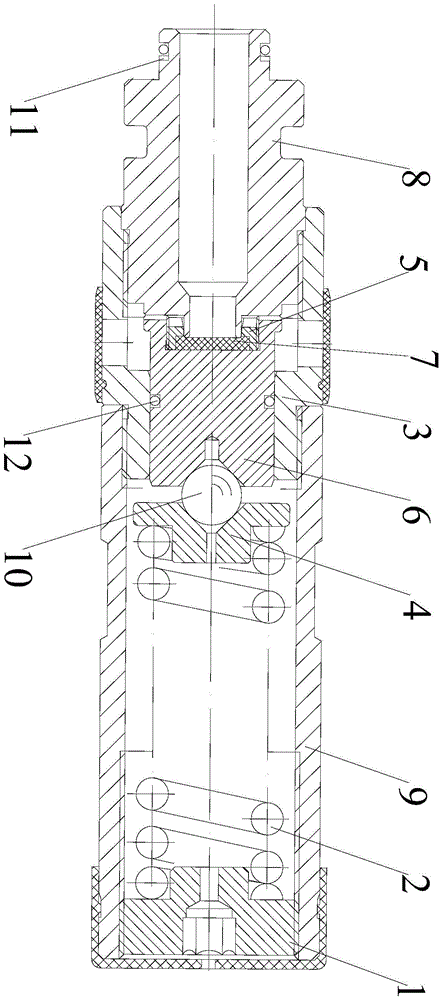

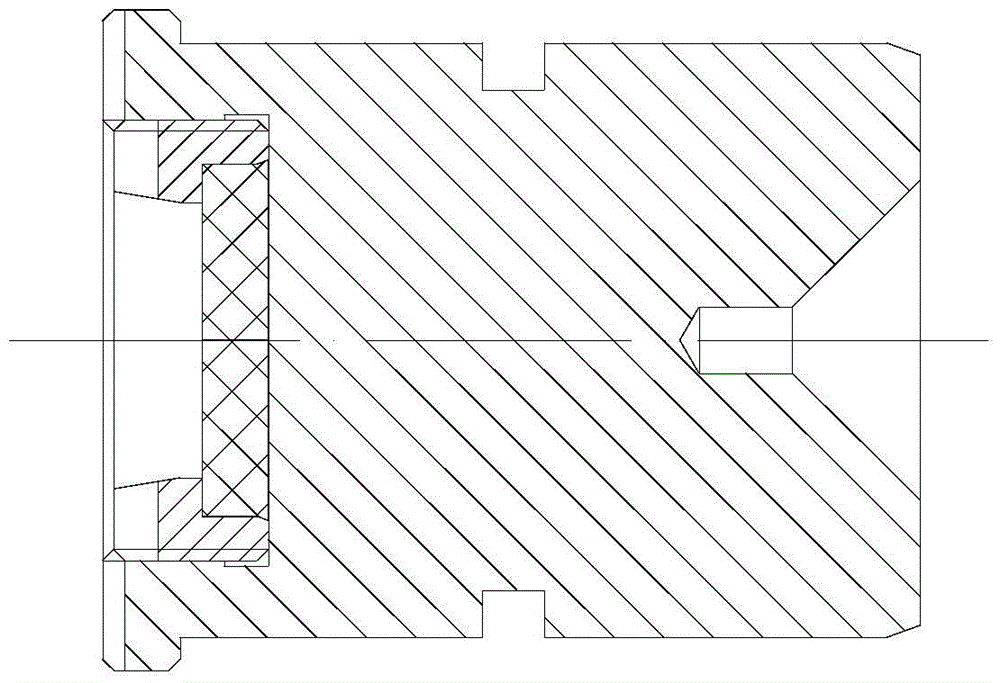

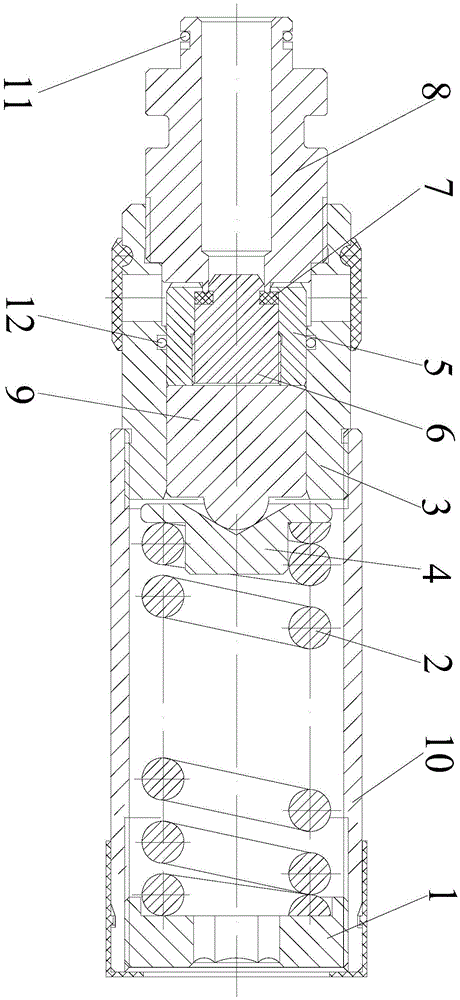

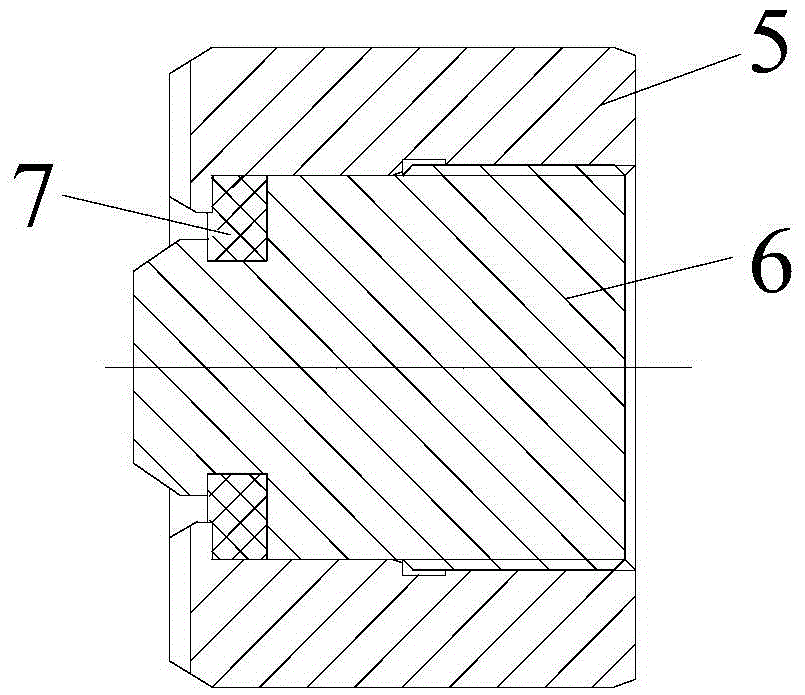

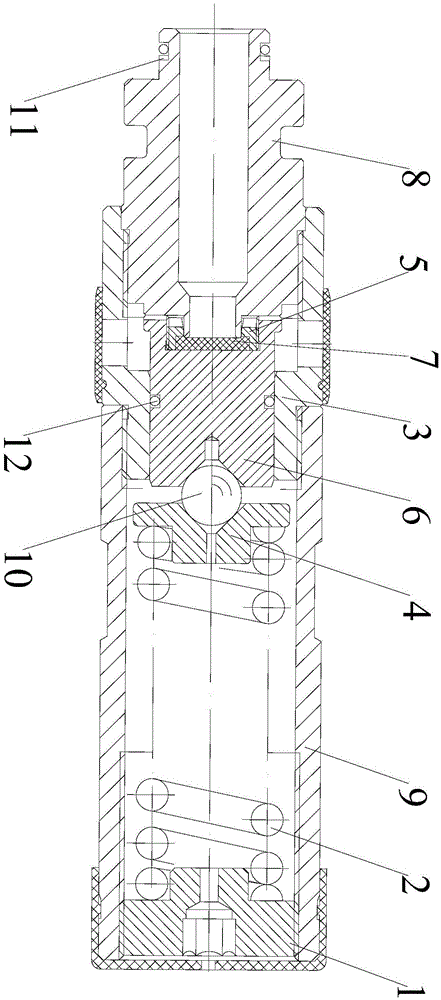

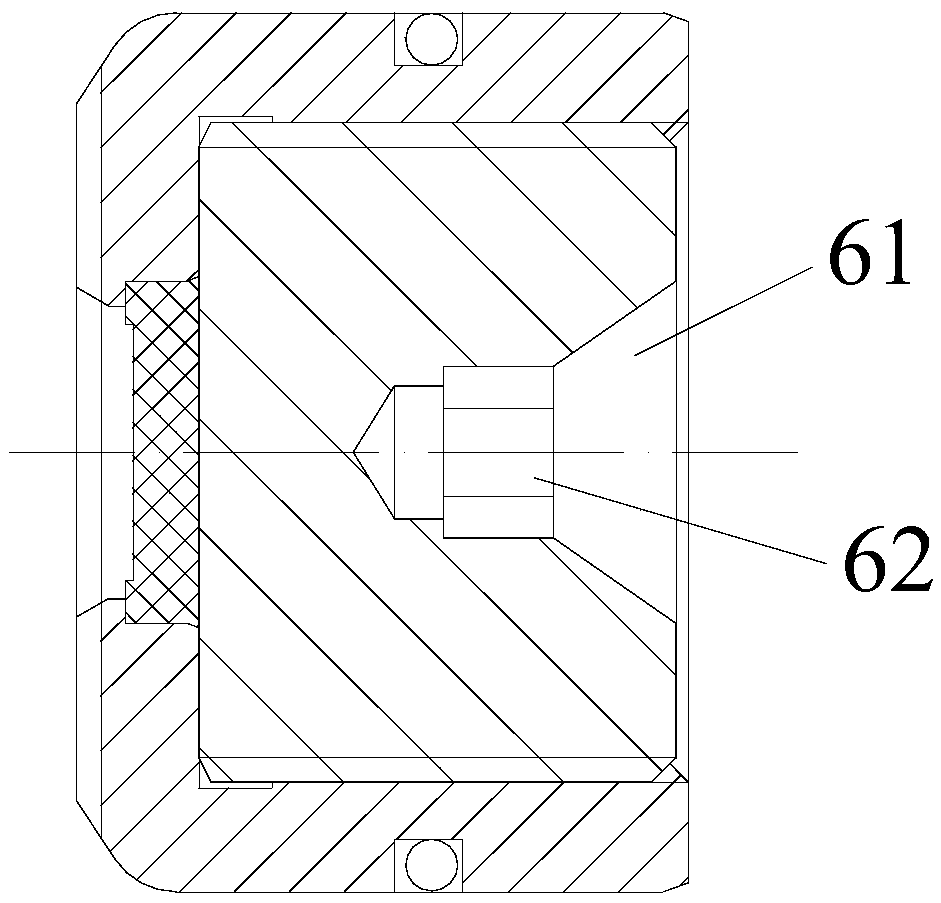

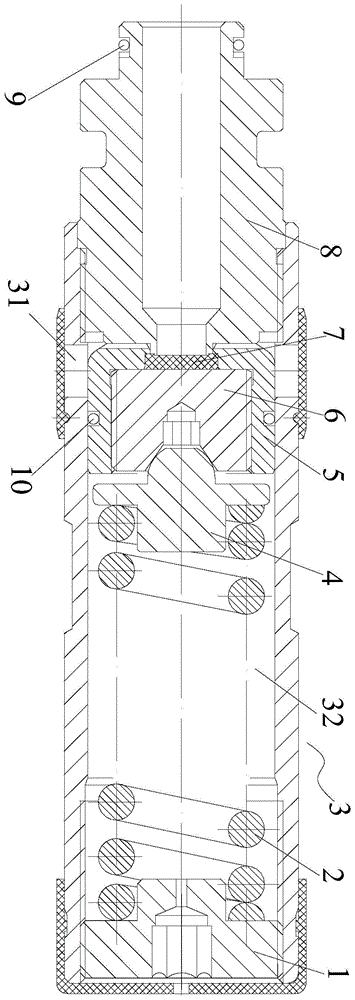

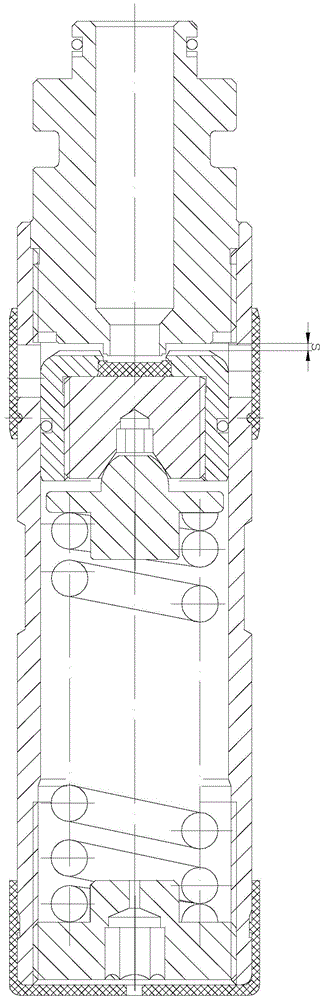

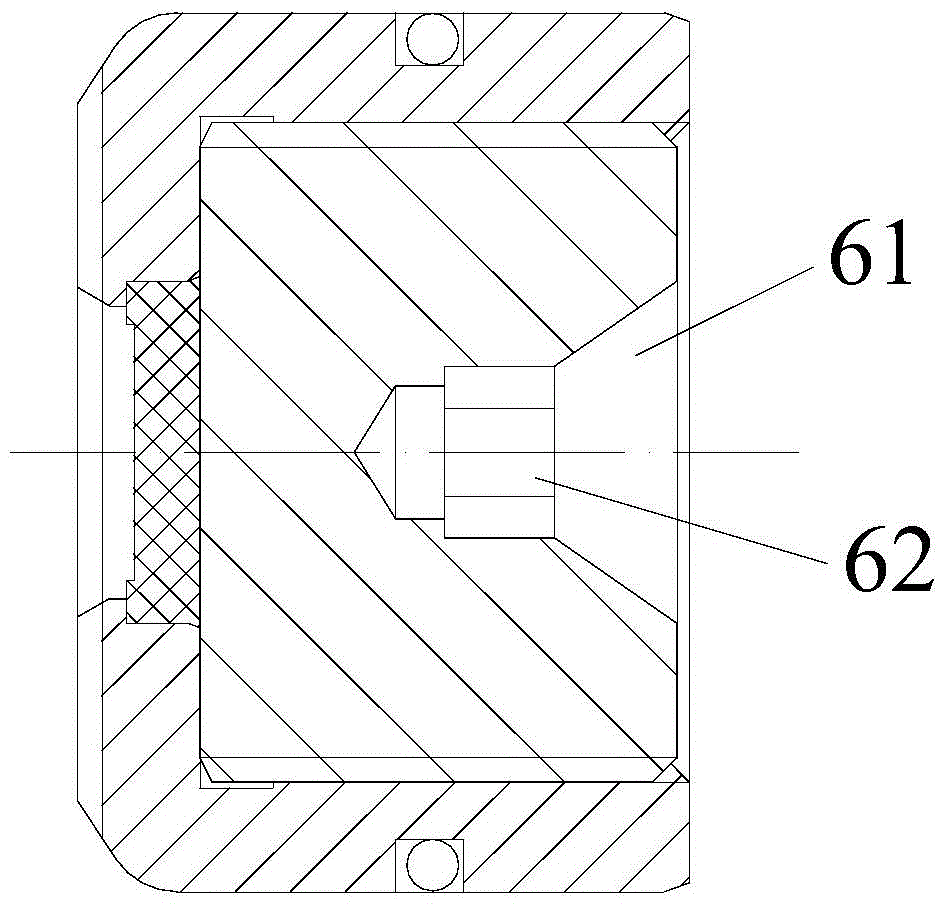

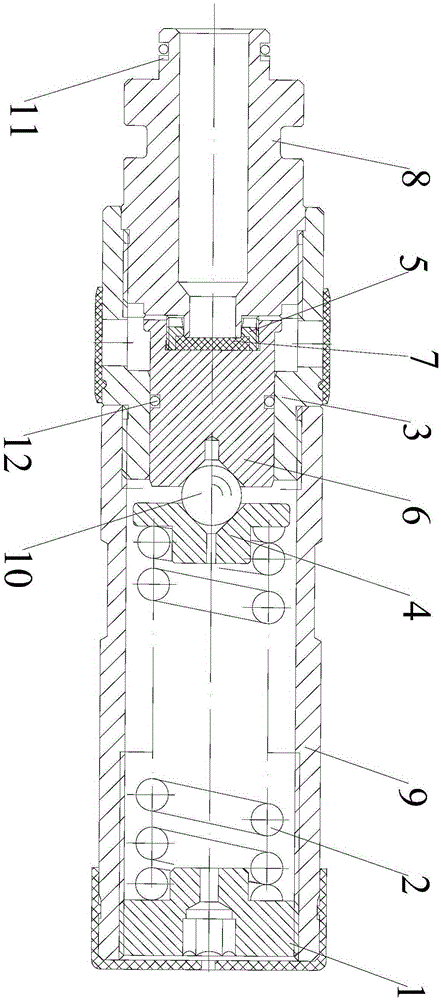

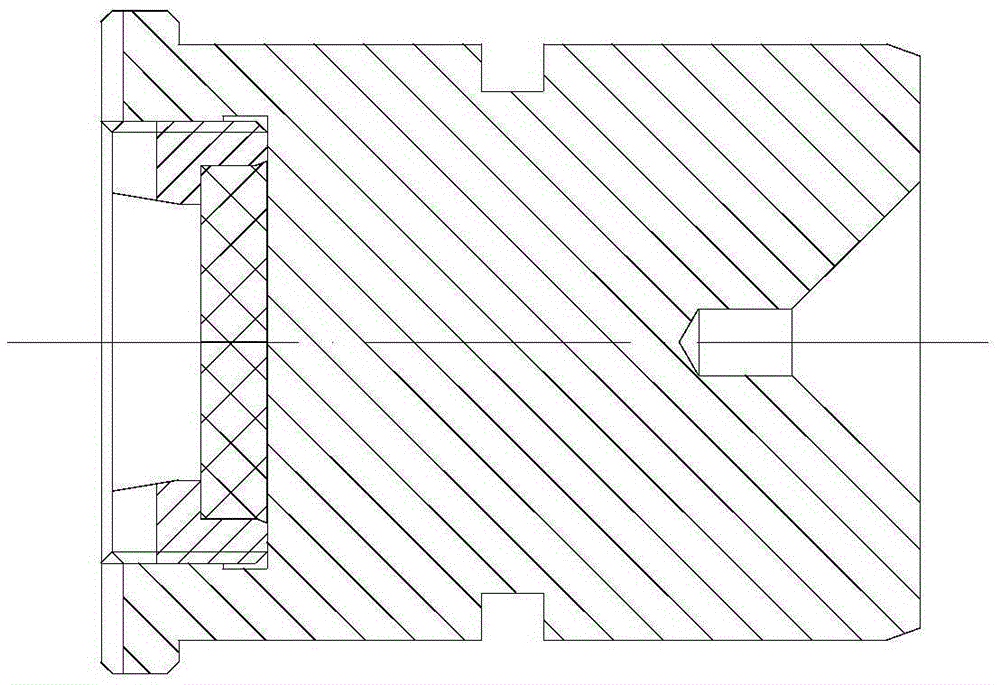

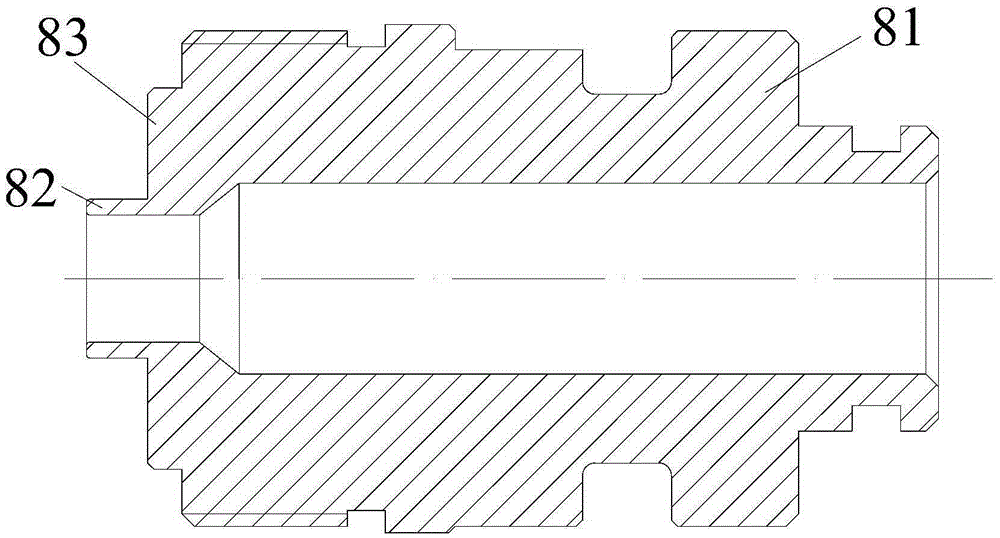

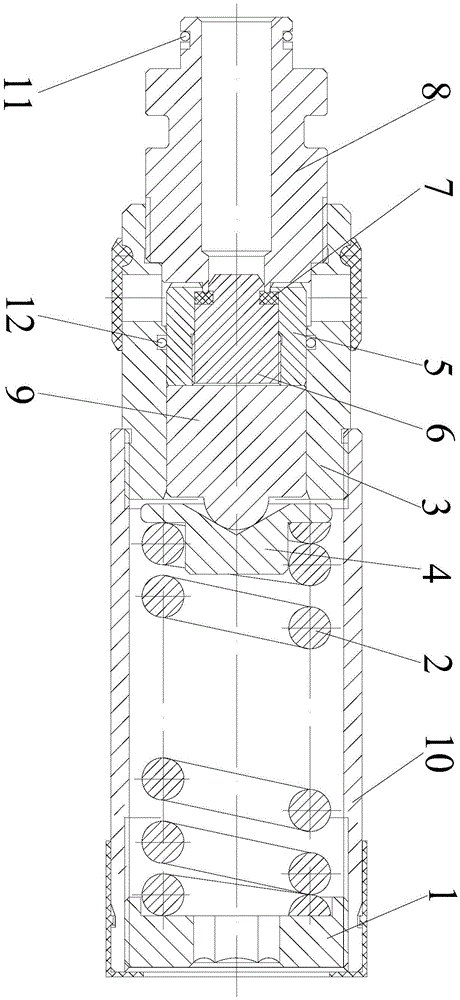

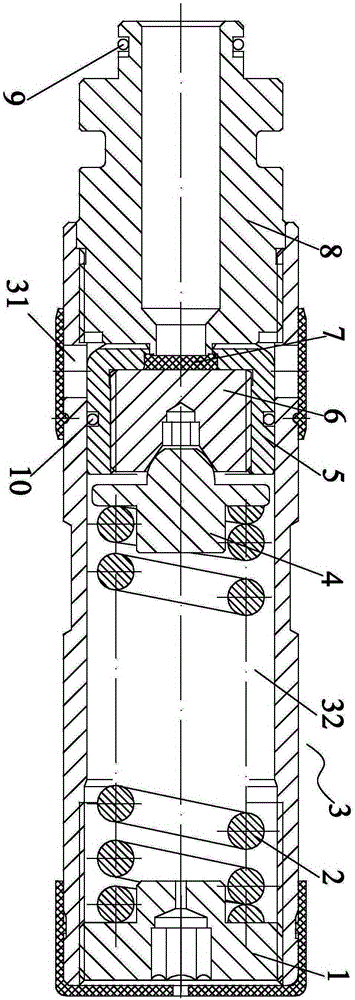

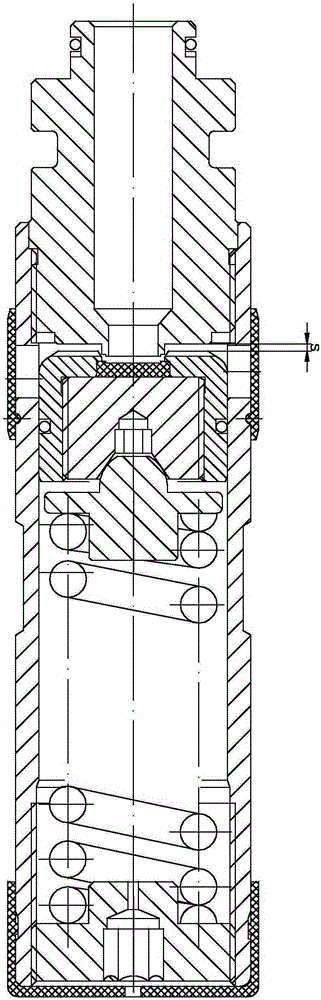

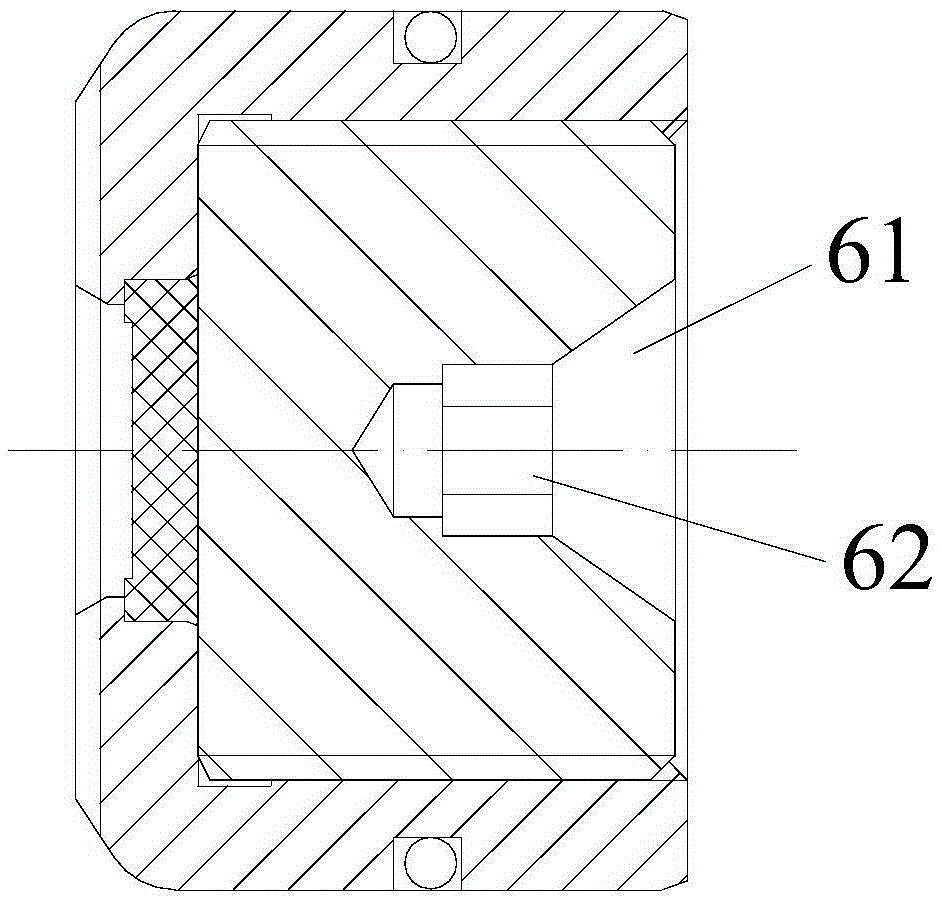

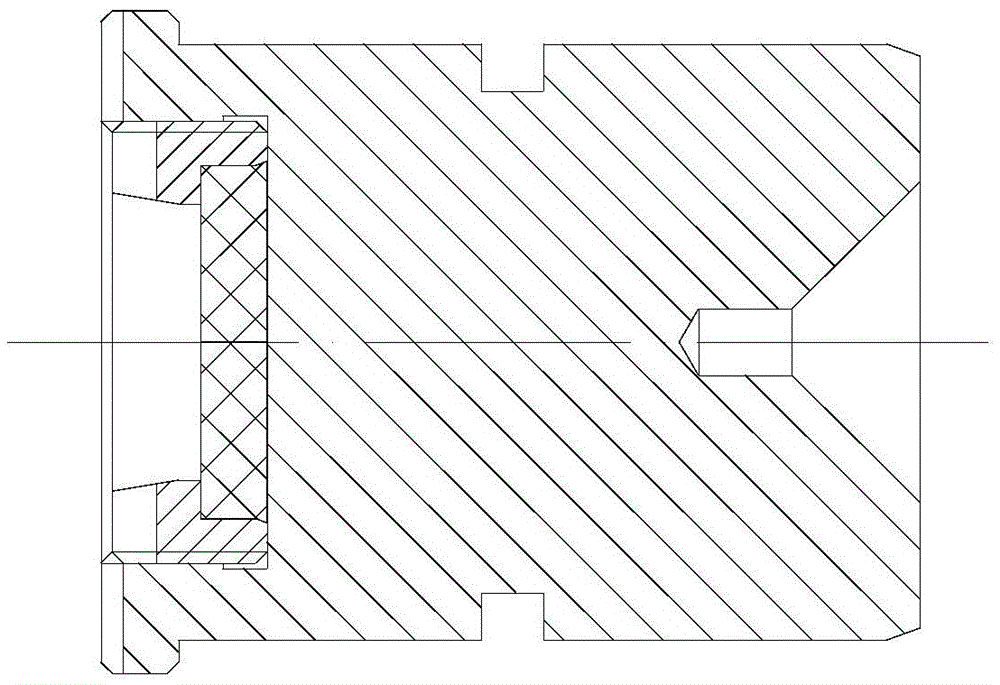

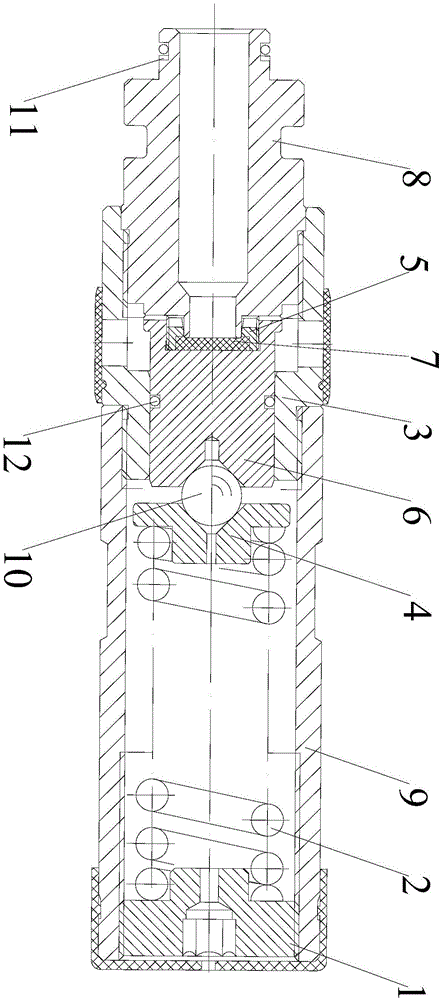

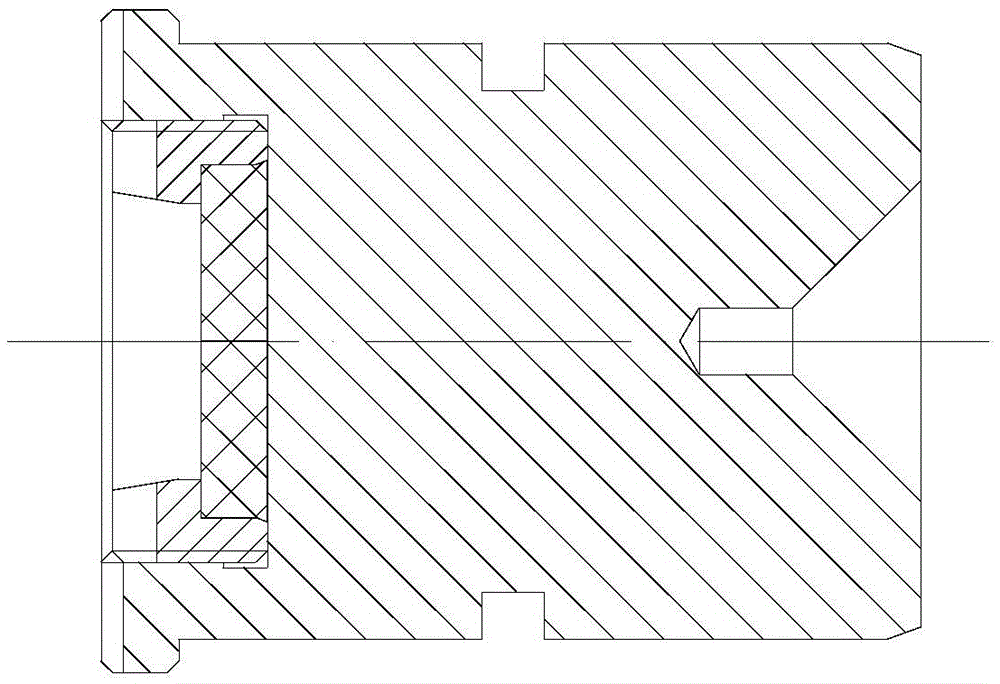

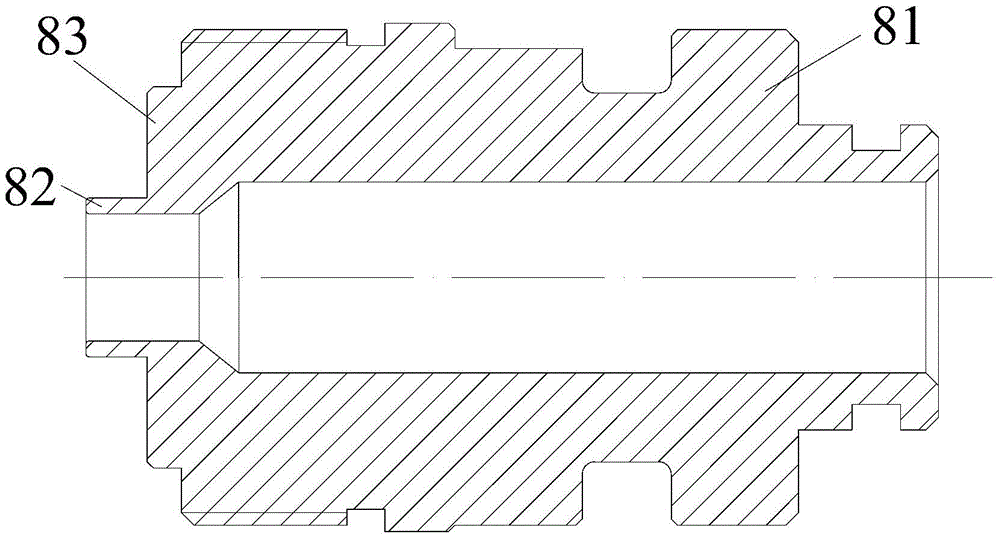

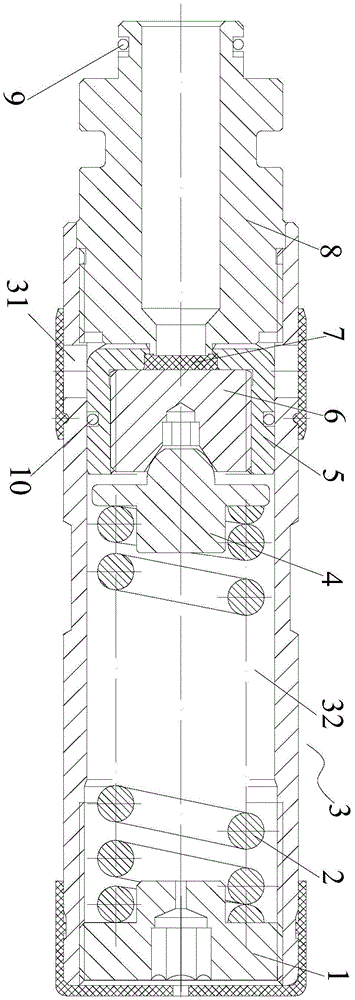

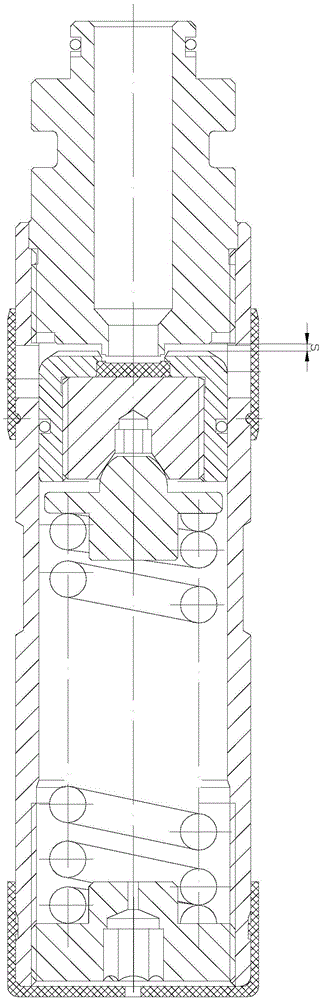

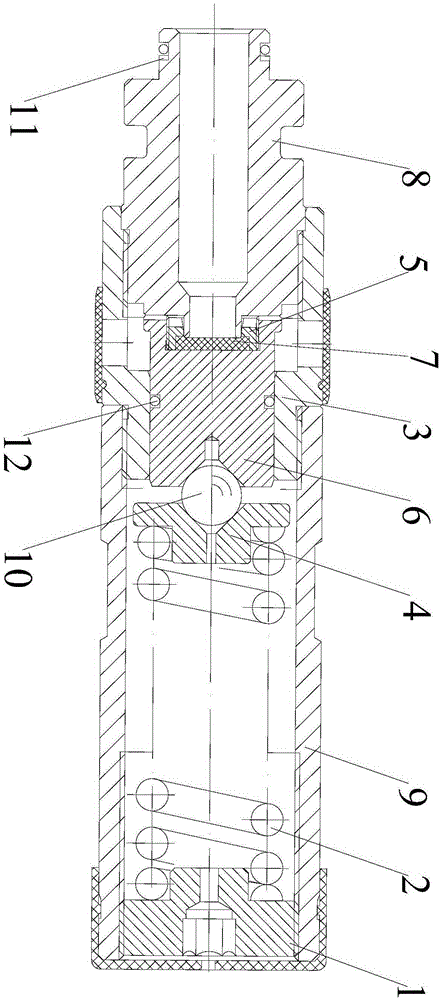

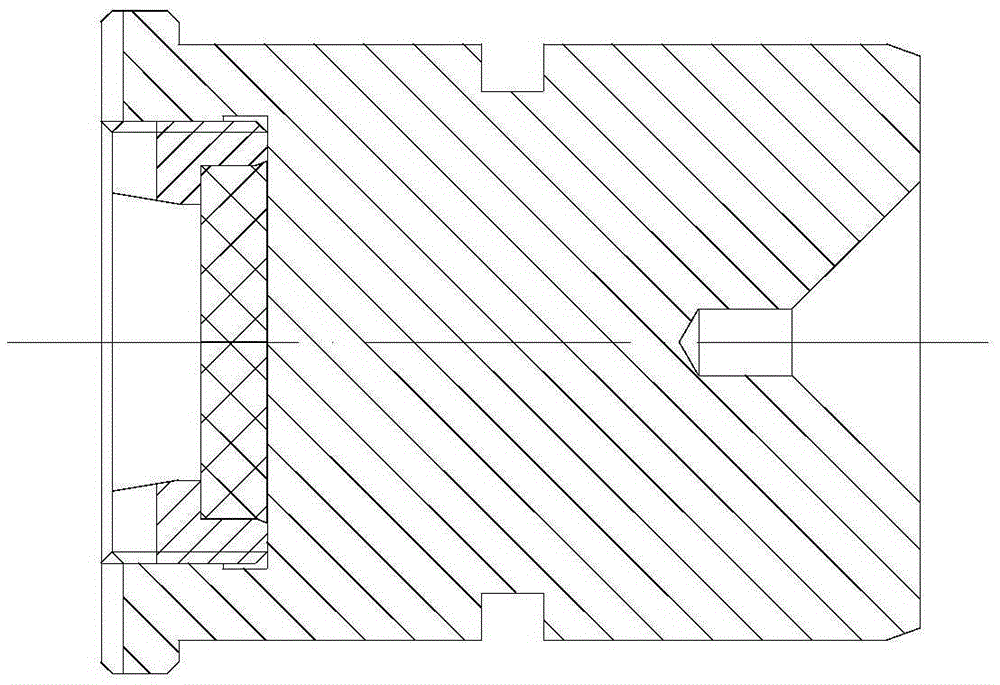

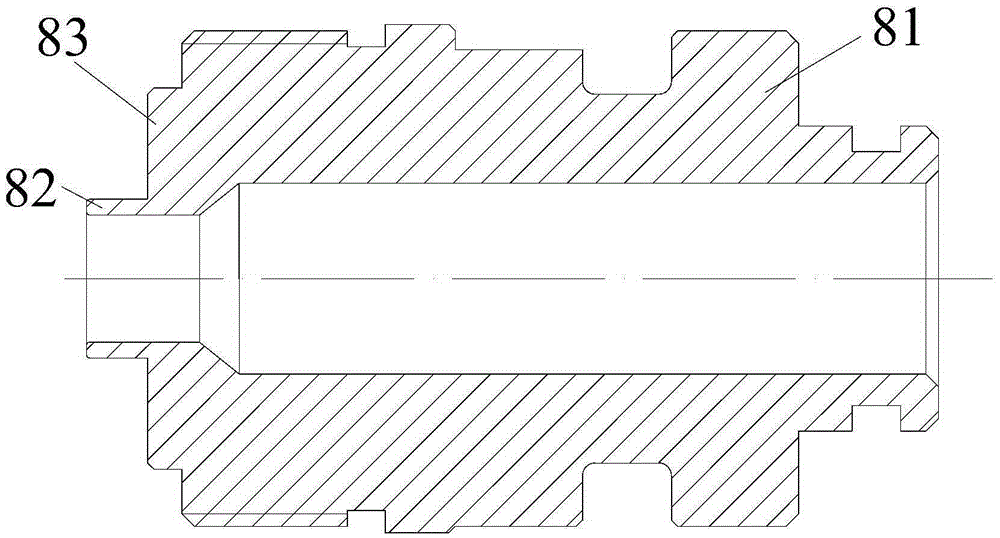

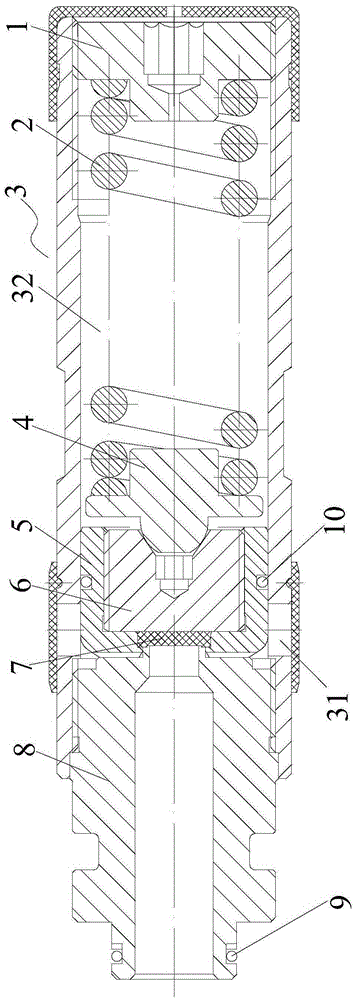

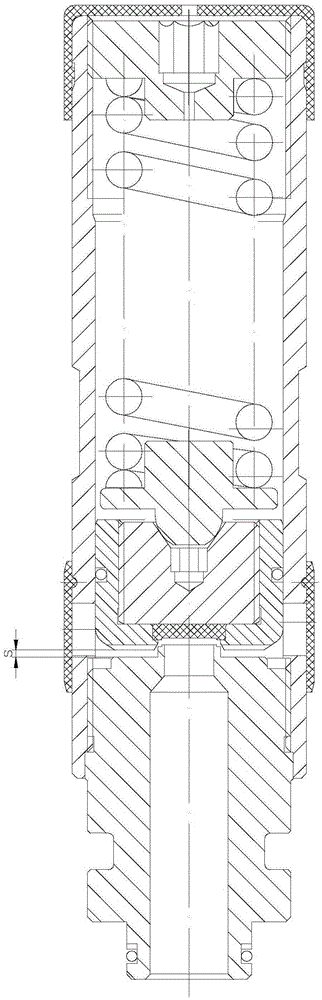

Hard sealing safety valve

The invention discloses a hard sealing safety valve which comprises a valve shell and a liquid inlet connector as well as a valve element component, wherein a liquid inlet is formed in the liquid inlet connector; the valve element component is arranged inside the valve shell; a liquid discharge hole is formed in the valve shell; the valve element component comprises a valve seat and a valve element made of a metal material; a liquid through hole for communicating the liquid inlet and the liquid discharge hole is formed in the valve seat; the valve element is moveably arranged inside the valve seat and is used for controlling opening and closure of the liquid through hole. As the valve element and the valve seat of the hard sealing safety valve disclosed by the invention are both made of the metal material, metallic annular hard sealing contact of the valve element and the valve seat is achieved, the sealing reliability is greatly improved, and the sealing property is good; moreover, due to adoption of the valve element component, on / off of an oil path from the liquid inlet to the liquid discharge hole can be controlled, large-amount overflowing can be achieved, the flow of the hard sealing safety valve is greatly increased, the axial displacement of the valve element component can be reduced due to rapid overflowing within a short time, the axial deformation of a return spring can be reduced when the axial displacement of the valve element component is reduced, and ultimately pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Safety valve

InactiveCN105507932AHigh trafficReduce axial displacementMine roof supportsAxial displacementEngineering

The invention discloses a safety valve, comprising a valve shell and a liquid incoming connector having a liquid inlet and also comprising a valve element component movably disposed in the valve shell and used for controlling the liquid inlet to open or close. The valve shell is provided with a liquid outlet. The valve element component comprises a nut and a valve washer disposed in the nut, and the valve washer has a recessed structure. The overflow safety valve of the invention is provided with the valve element component movably disposed within the valve shell, the valve element component may be used for controlling connection and disconnection of an oil circuit from the liquid inlet to the liquid outlet, high-capacity overflow may be provided when the valve element component is far away from the liquid incoming connector, safety valve flow is greatly increased, short-term quick overflow may reduce axial displacement of the valve element component, the reduction in the axial displacement of the valve element component may reduce axial deformation of a return spring, and finally pressure fluctuation may be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Switching on and switching off mechanism of safety valve

InactiveCN105715284AReduce axial displacementHigh trafficMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses a switching on and switching off mechanism of a safety valve.The mechanism comprises a liquid inlet connector with a liquid inlet, the mechanism further comprises a valve element assembly which can move relative to the liquid inlet connector and is used for controlling opening and closing of the liquid inlet, the valve element assembly comprises a sliding base, a thread sleeve and a valve pad, the thread sleeve is arranged in the sliding base, the valve pad is arranged in the thread sleeve, and a spherical groove is formed in the valve pad.According to the switching on and switching off mechanism of the safety valve, the movable valve element assembly is matched with the liquid inlet connector, the valve element assembly can be used for controlling on and off of an oil path from the liquid inlet to a drainage hole, large flow overflow can be realized when the valve element assembly is away from the liquid inlet connector, the flow of the safety valve is increased greatly, axial displacement of the valve element assembly can be reduced by the aid of short-time rapid overflow, axial deformation of a reset spring can be reduced by reducing the axial displacement of the valve element assembly, and finally pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

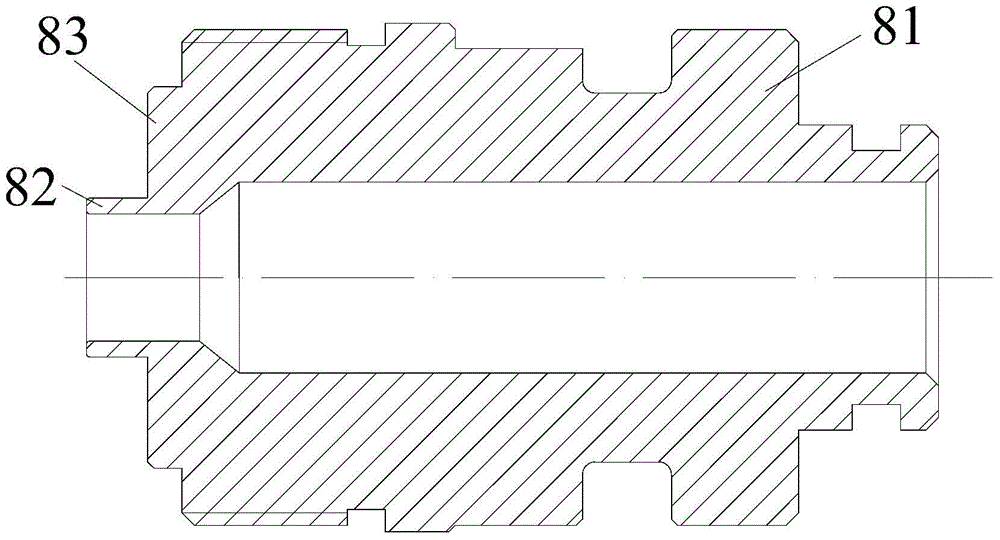

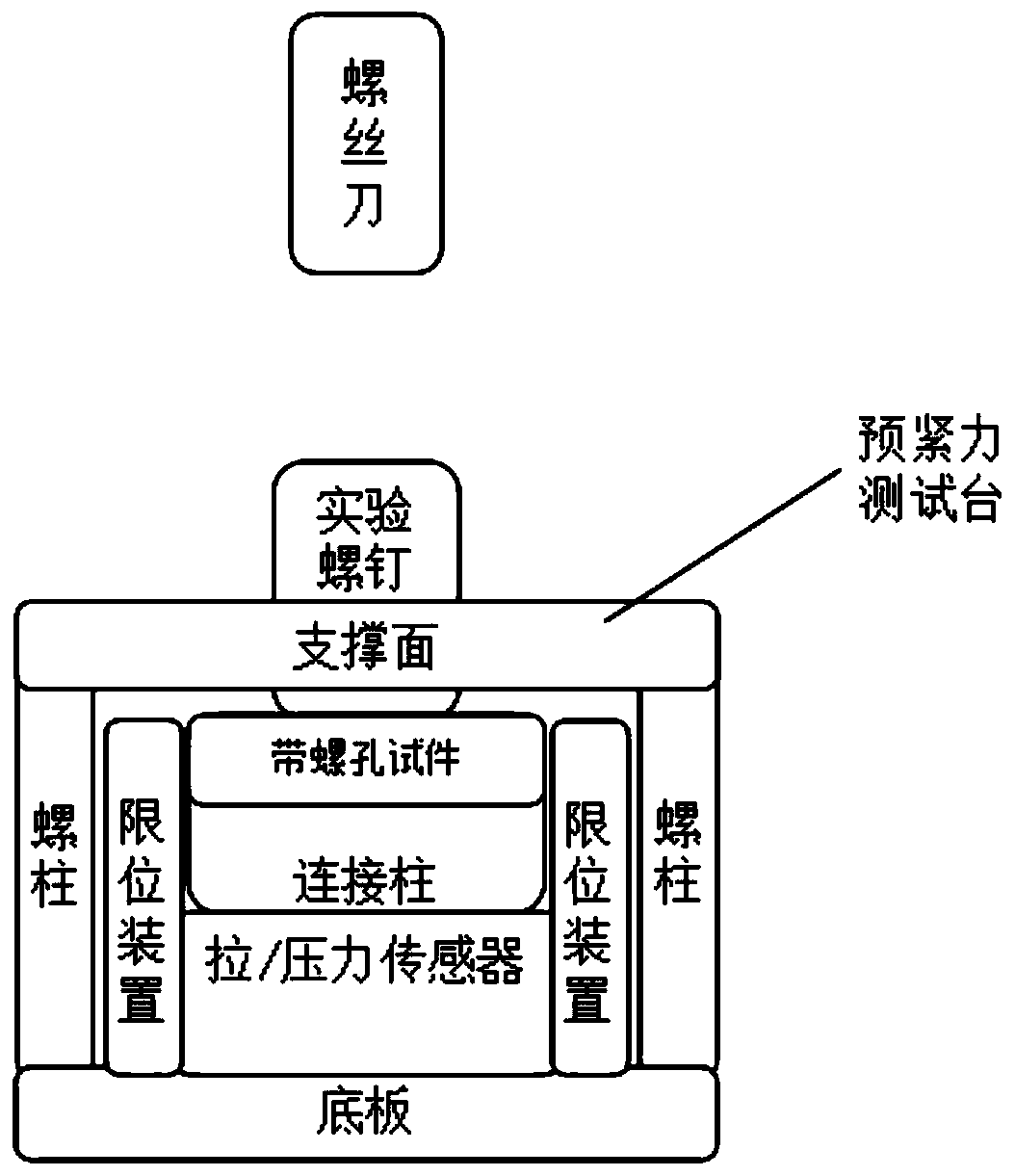

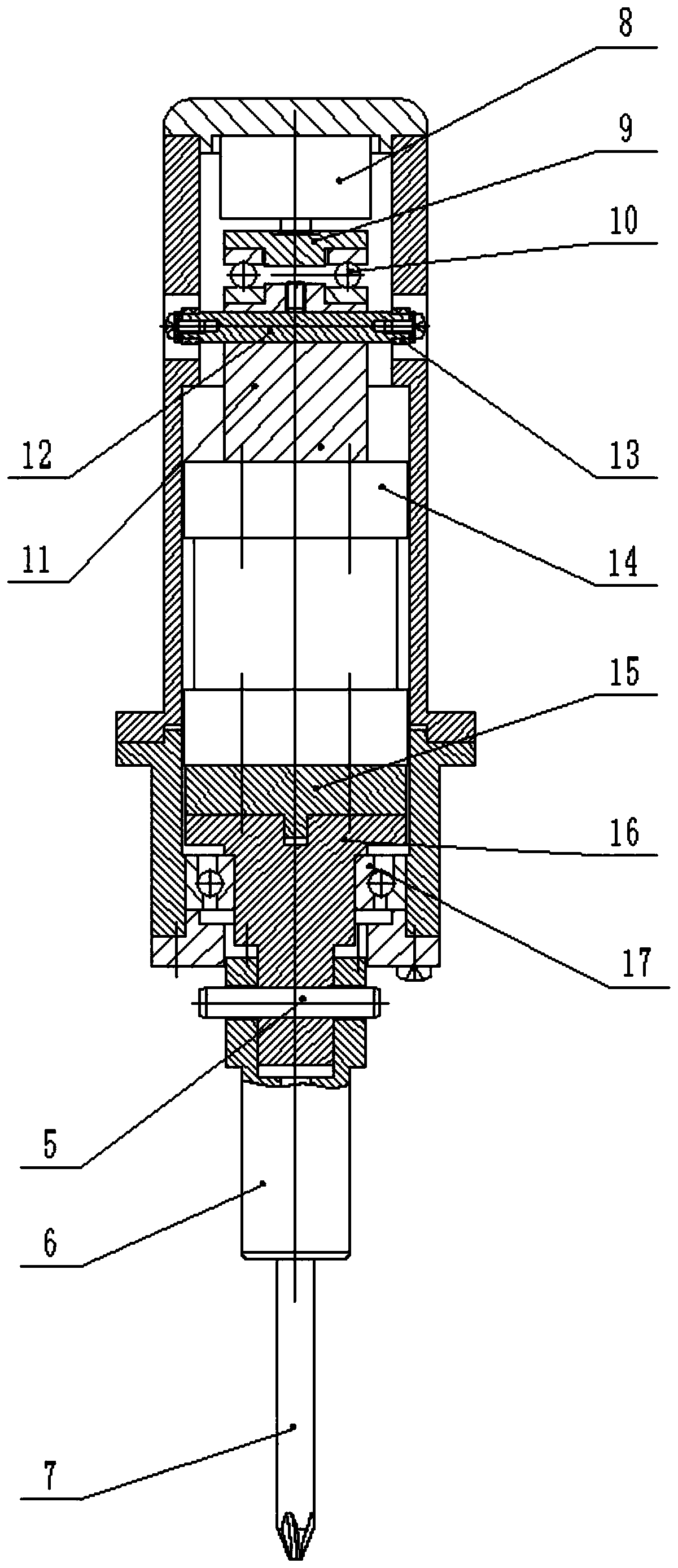

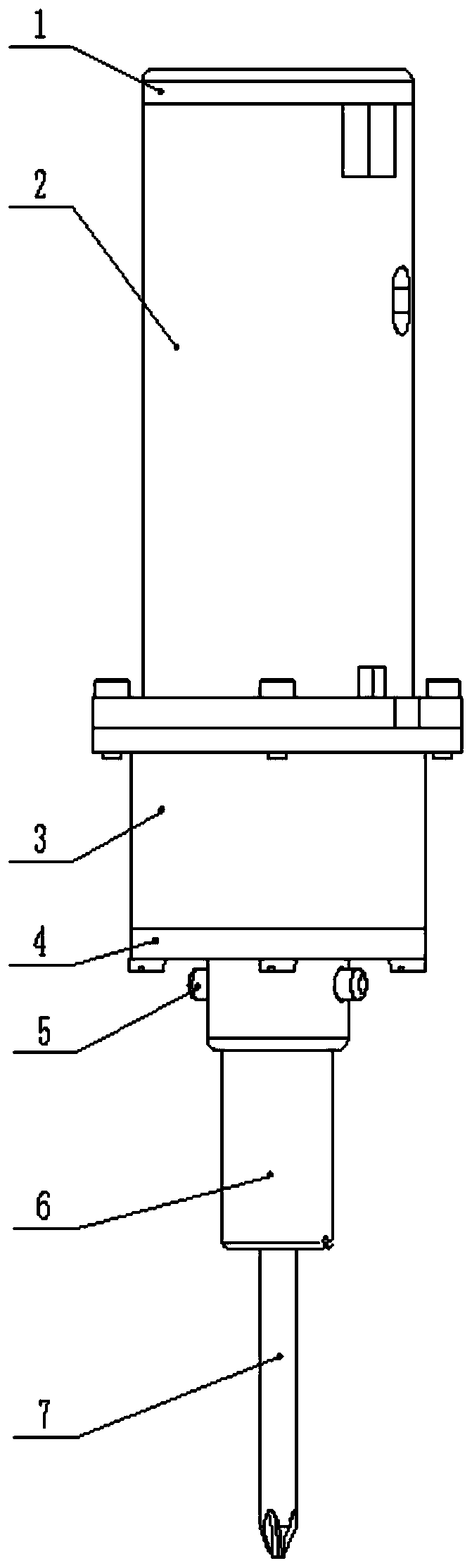

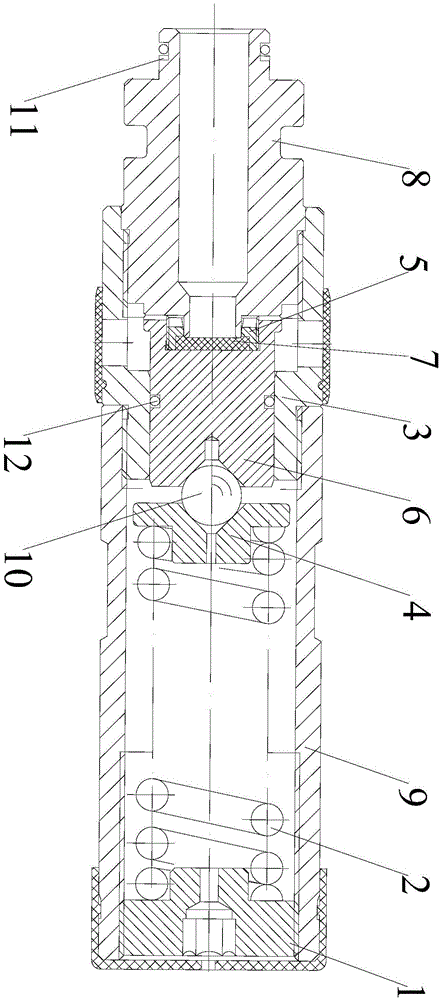

A measuring device and method for studying the effect of compression force on torque coefficient

ActiveCN109186843BRealize real-time monitoringHigh measurement accuracyMeasurement of torque/twisting force while tighteningMeasuring instrumentTorque transmission

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

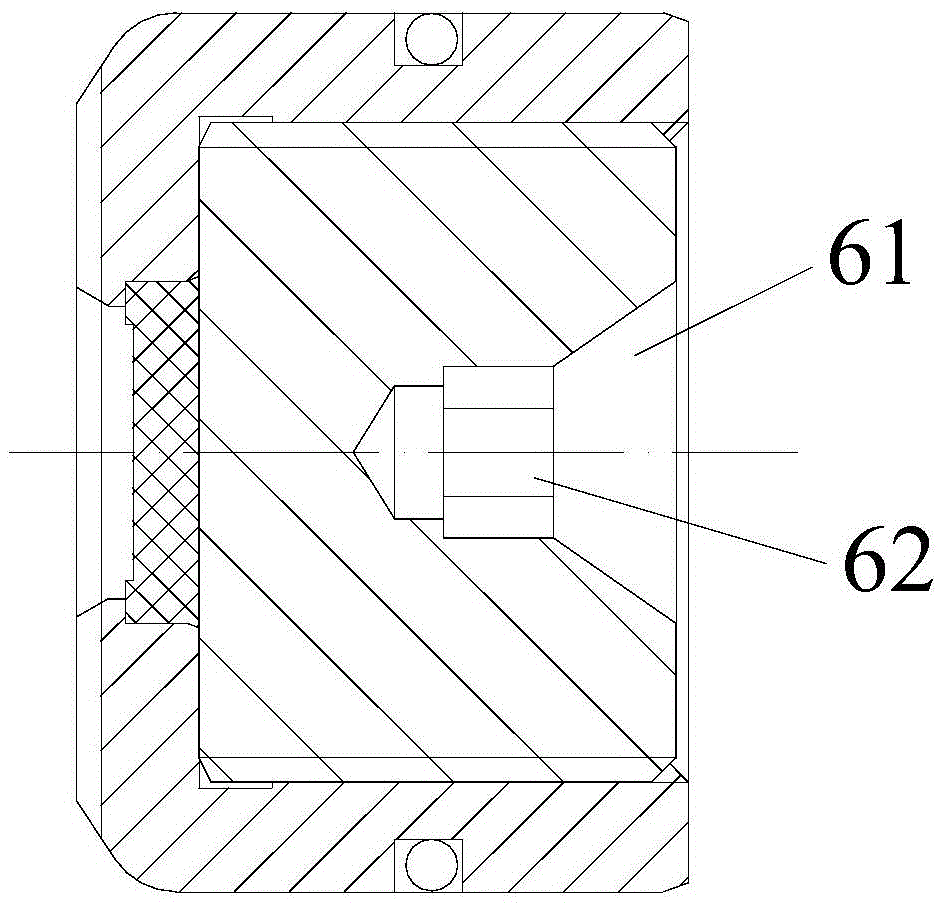

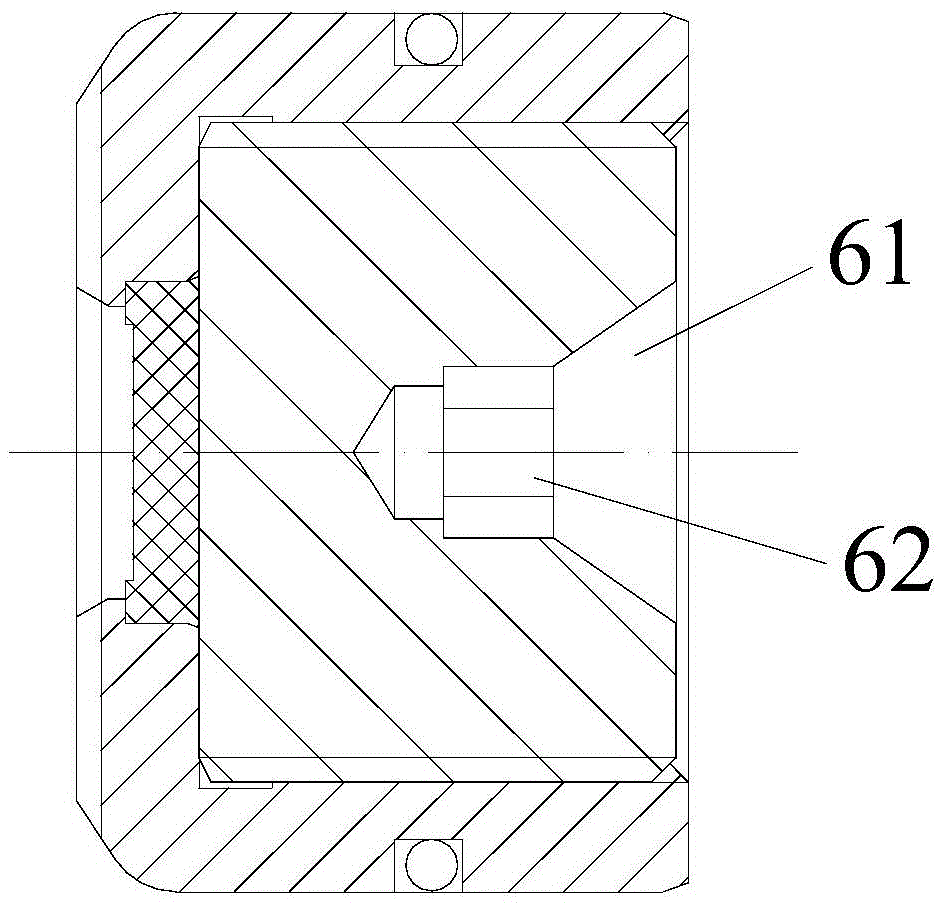

Valve element assembly of safety valve

InactiveCN105605255AReduce axial displacementHigh trafficEqualizing valvesSafety valvesAxial displacementSafety valve

The invention discloses a valve element assembly of a safety valve. The valve element assembly comprises a movable nut and a valve element which is arranged in the nut and is used for controlling the on / off of a liquid feeding hole of the safety valve; the valve element is provided with a plug capable of being inserted into the liquid feeding hole of the safety valve. The valve element assembly disclosed by the invention is applied to the safety valve, and can be used for controlling the on / off of an oil path from the liquid feeding hole to a liquid discharging hole; when the valve element assembly is far away from a liquid feeding connector, large-flow overflowing can be realized and the flow of the safety valve is greatly improved; axial displacement of the valve element assembly can be shortened by rapid overflowing within short time; the axial displacement of the valve element assembly is shortened so that axial deformation of a resetting spring can be reduced; finally, pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

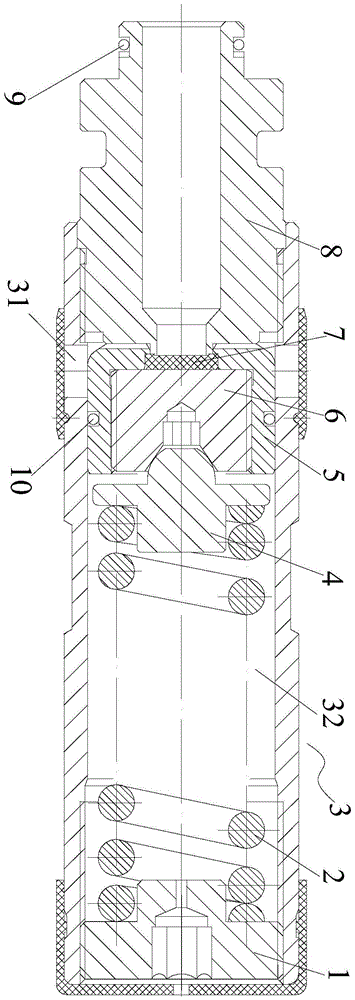

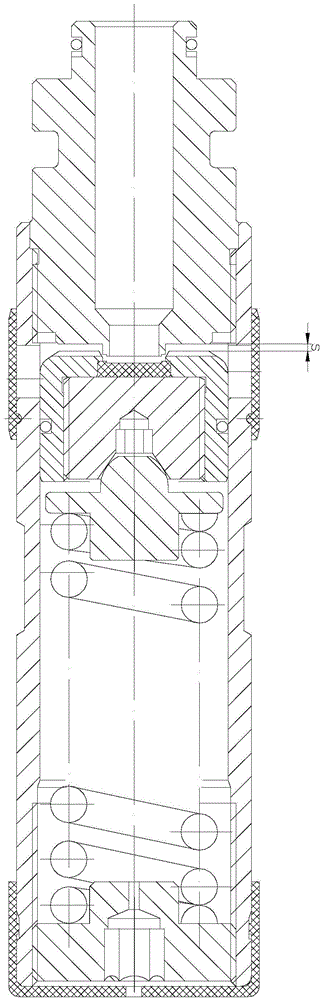

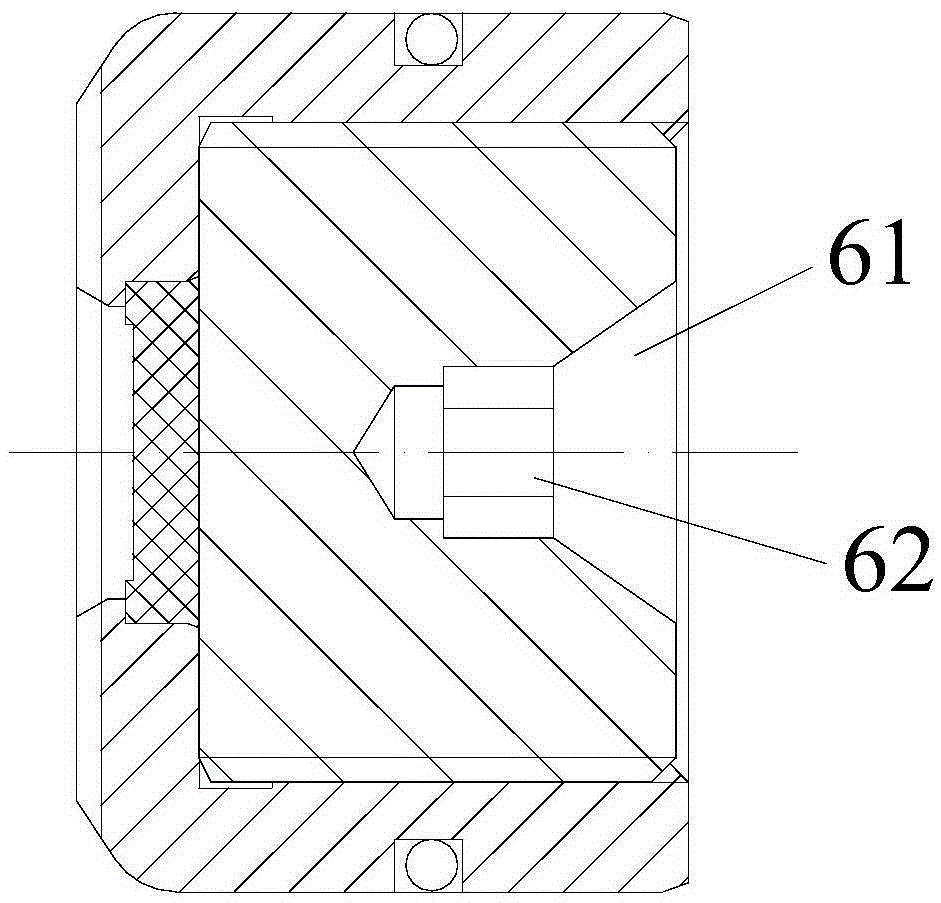

Compression mechanism for rotary compressor and rotary compressor with same

InactiveCN104481882AImprove performanceImprove rigidityRotary/oscillating piston pump componentsLiquid fuel engine componentsAxial displacementInterference fit

The invention discloses a rotary compressor and a compression mechanism of the rotary compressor. The compression mechanism comprises an air cylinder assembly, a bearing and an exhaust device, wherein the air cylinder assembly comprises an air cylinder, the air cylinder is provided with a compression cavity, a mounting slot is formed in the bearing, a vent hole is formed in the inner wall of the mounting slot and is communicated with the compression cavity, the mounting slot is formed in a sector-shaped area formed by the fact that a reference line takes the center of the vent hole as a rotation center and rotates towards the two sides at a preset angle respectively, the preset angle is 45 degrees, and the reference line is a connection line between the center of the bearing and the center of the vent hole; the exhaust device is arranged in the mounting slot and comprises an exhaust valve plate, and one end of the exhaust valve plate covers the vent hole. According to the compression mechanism, the rigidity of the bearing is improved; when the compression mechanism is applied to the rotary compressor, the radial displacement of a rotor of a motor, caused by magnetic pull force, can be reduced, the abrasion of a crankshaft can be reduced, and meanwhile, the axial displacement, caused by the interference fit of a muffler and the operation temperature rise of the rotary compressor, of the end surface of the bearing is reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR

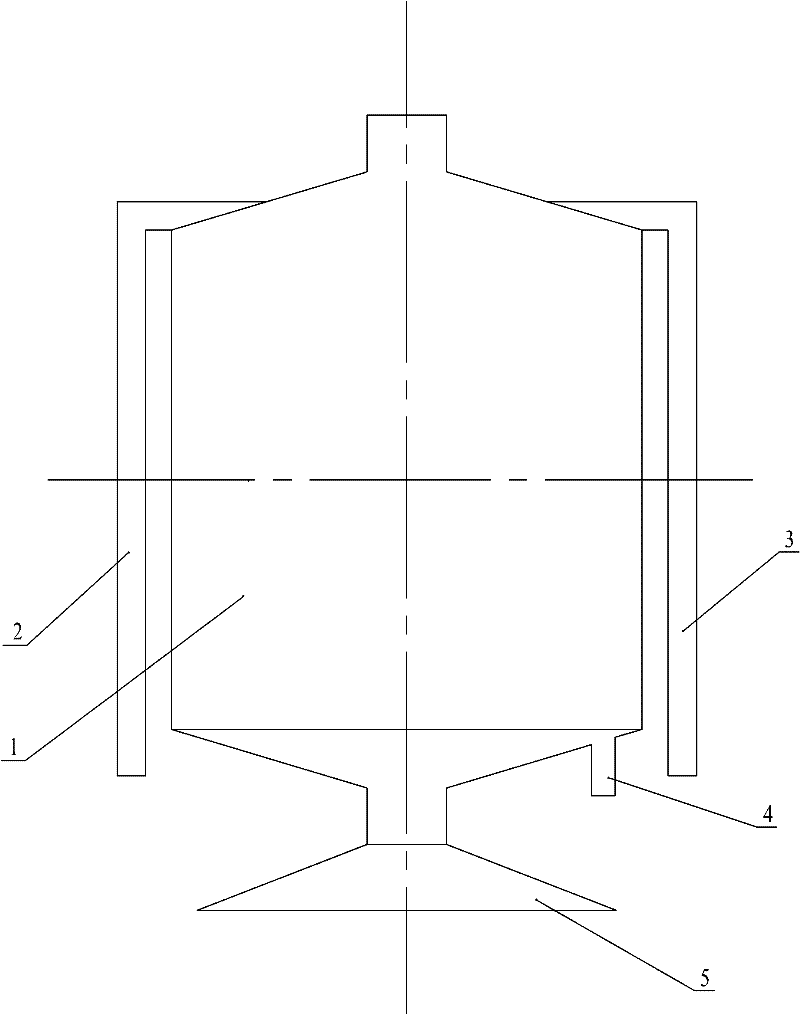

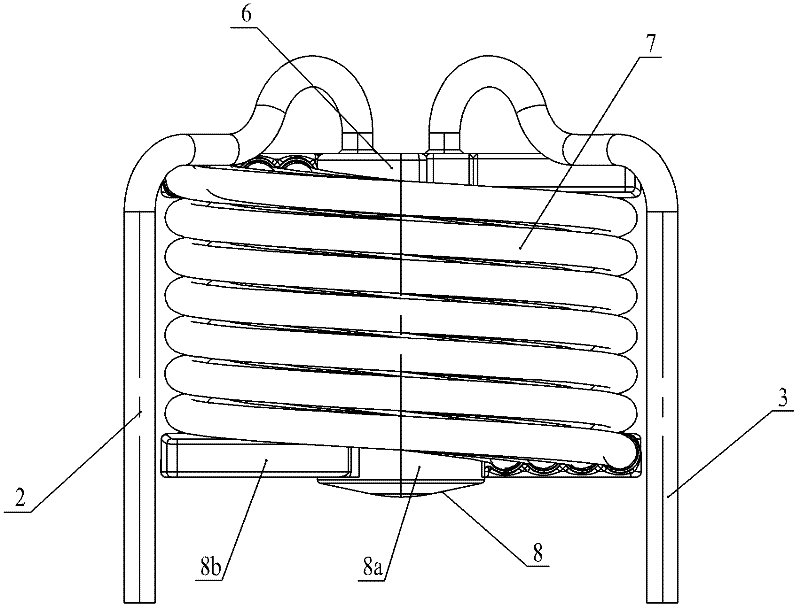

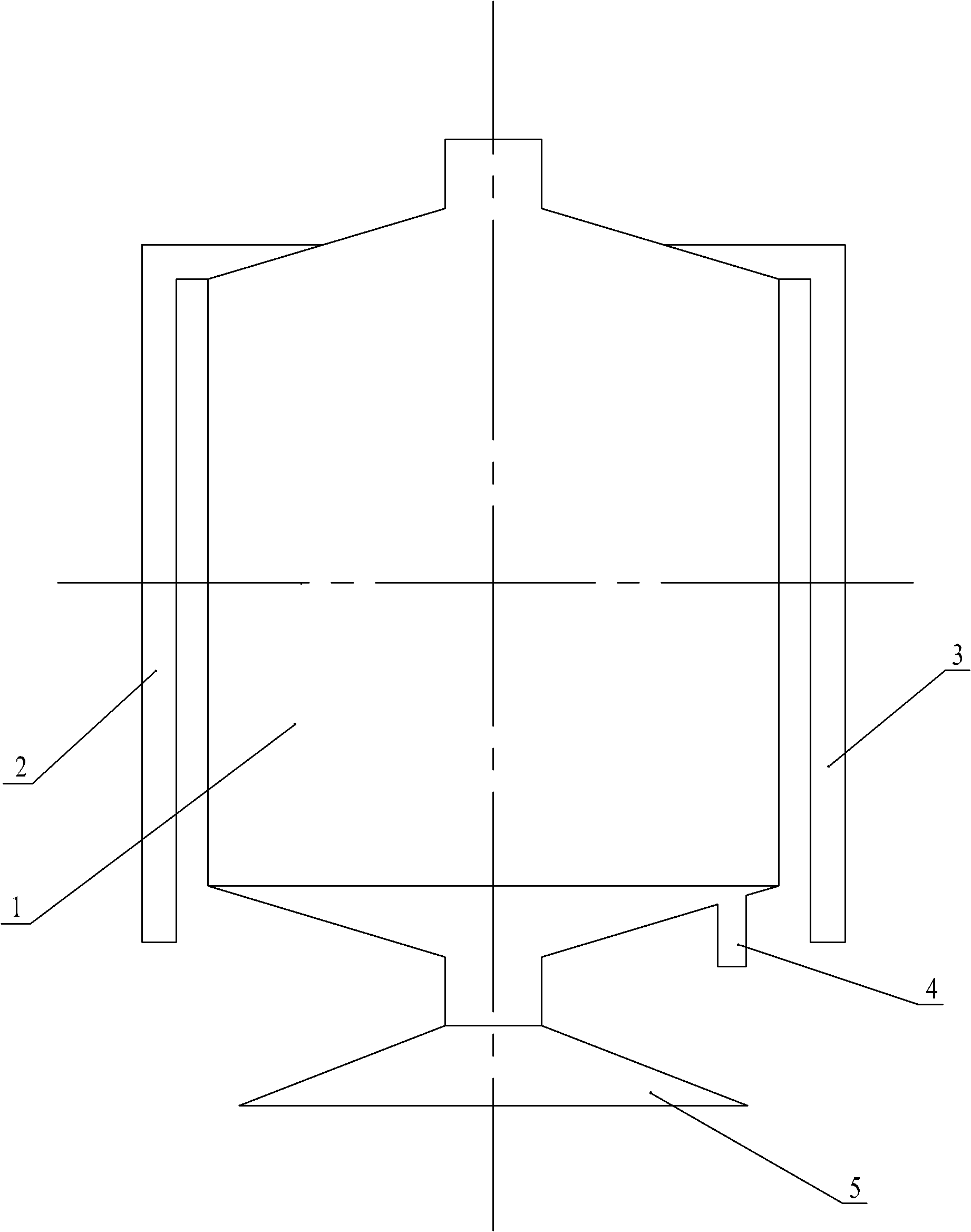

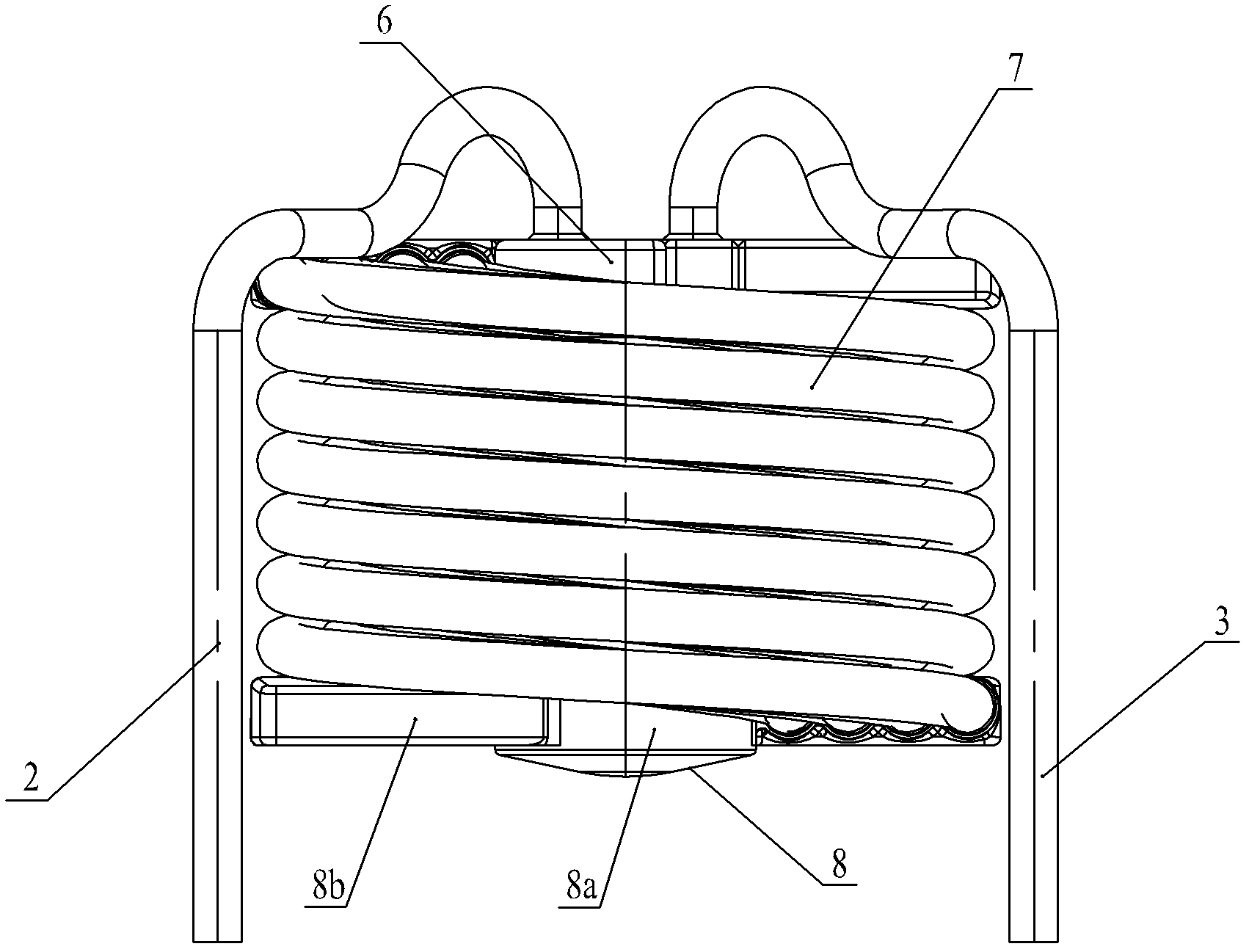

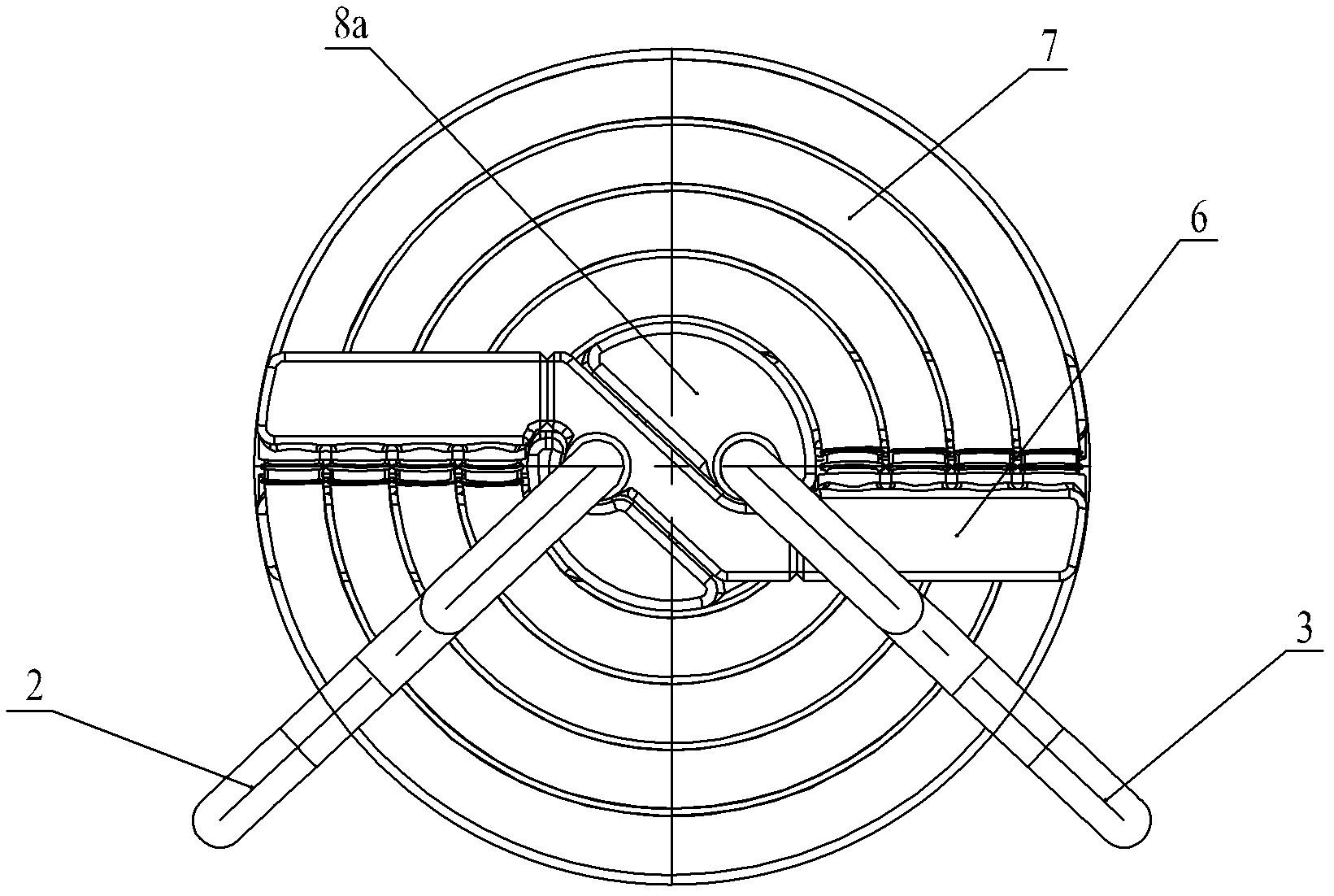

Flue gas waste heat recovery device

ActiveCN102410631AReduce pipe axial displacementReduce the impactEnergy efficient heating/coolingAir heatersCondensed waterProcess engineering

The invention relates to a flue gas waste heat recovery device, which comprises a main cylinder, wherein the main cylinder is hollow inside; a heat conversion unit is arranged in the main cylinder; and the bottom end of the main cylinder is connected with a flue gas inlet device. The flue gas waste heat recovery device is characterized in that: the main cylinder is cylindrical, wherein the bottomof the main cylinder is provided with a flue gas distributor, the flue gas distributor is communicated with the flue gas inlet device, and the heat conversion unit is arranged above the flue gas distributor; the heat conversion unit comprises a cold water storage body, a hot water storage body and a heat exchange component, wherein the cold water storage body is externally connected with a water inlet pipeline, and a hot water outlet is externally connected with a water outlet pipeline; and the bottom of the main cylinder is provided with a condensed water outlet. The flue gas waste heat recovery device is suitable for non-industrial occasions, such as families, markets, hosts, restaurants and the like and has the advantages of simple structure, wide application range and capability of deeply utilizing heat in flue gas and potential heat energy in the flue gas; and core components of the flue gas waste heat recovery device are made of stainless steel materials, so that not only scale prevention capability of the product can be enhanced, service life is prolonged, but also quality of domestic water can be ensured.

Owner:WUXI XIZHOU MACHINERY

Valve core assembly of safety valve

InactiveCN105587327AReduce axial displacementHigh trafficMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses a valve core assembly of a safety valve. The valve core assembly comprises a screw cap and a valve pad, wherein the valve pad is arranged in the screw cap and is used for being matched with a liquid inlet joint of an overflow safety valve. The valve core assembly is applied to the safety valve, and can be used for controlling the make-and-break state of an oil path from a liquid inlet hole to a liquid discharge hole; when the valve core assembly goes far away from the liquid inlet joint, the high-flow-rate overflow can be realized; the flow rate of the safety valve is greatly improved; the axial displacement of the valve core assembly can be reduced through short-time fast overflow; when the axial displacement of the valve core assembly is reduced, the axial deformation of reset springs can be reduced; and finally, the pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Valve element assembly of safety valve

InactiveCN105465437AReduce axial displacementHigh trafficFluid-pressure actuator safetyEqualizing valvesAxial displacementSafety valve

The invention discloses a valve element assembly of a safety valve. The valve element assembly comprises a sliding seat, a thread sleeve arranged in the sliding seat, and a valve pad which is arranged in the thread sleeve and used for being matched with a liquid inlet connector of the safety valve, and the valve pad is provided with a conical groove. The valve element assembly is applied to the safety valve and can be used for controlling connection and disconnection of an oil path from a liquid inlet hole to a liquid discharge hole; after the valve element assembly is far away from the liquid inlet connector, large-flow overflow can be achieved, the flow of the safety valve is greatly increased, and the axial displacement of the valve element assembly can be reduced through short-time rapid overflow; by means of reduction of the axial displacement of the valve element assembly, the axial deformation of a reset spring can be reduced, and finally pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

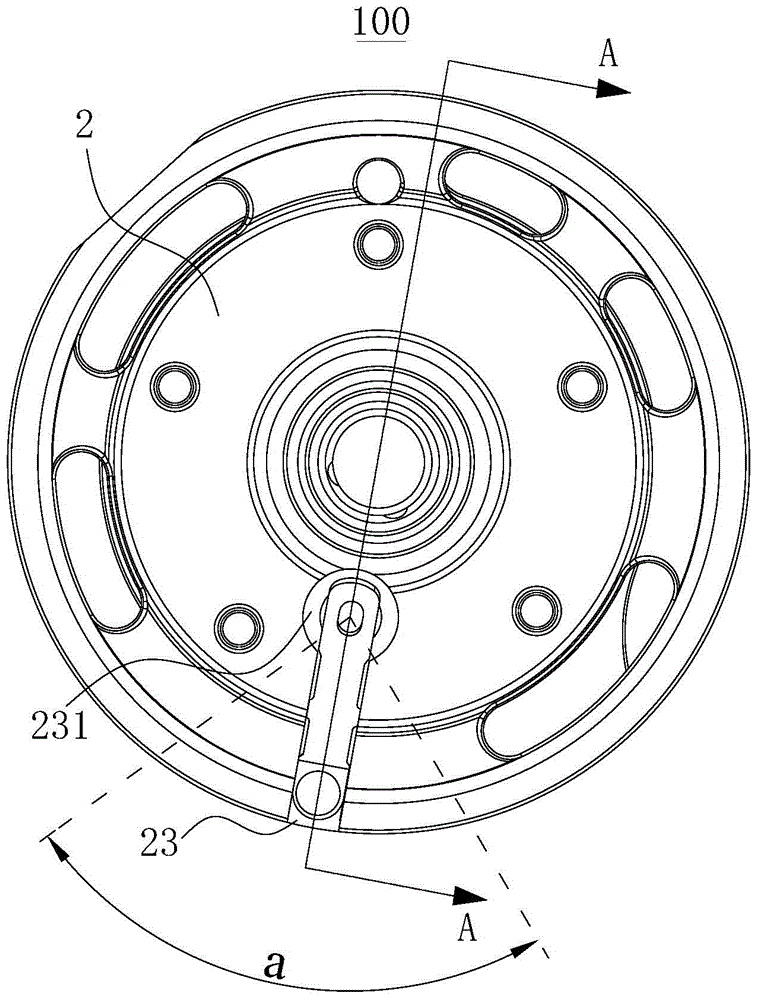

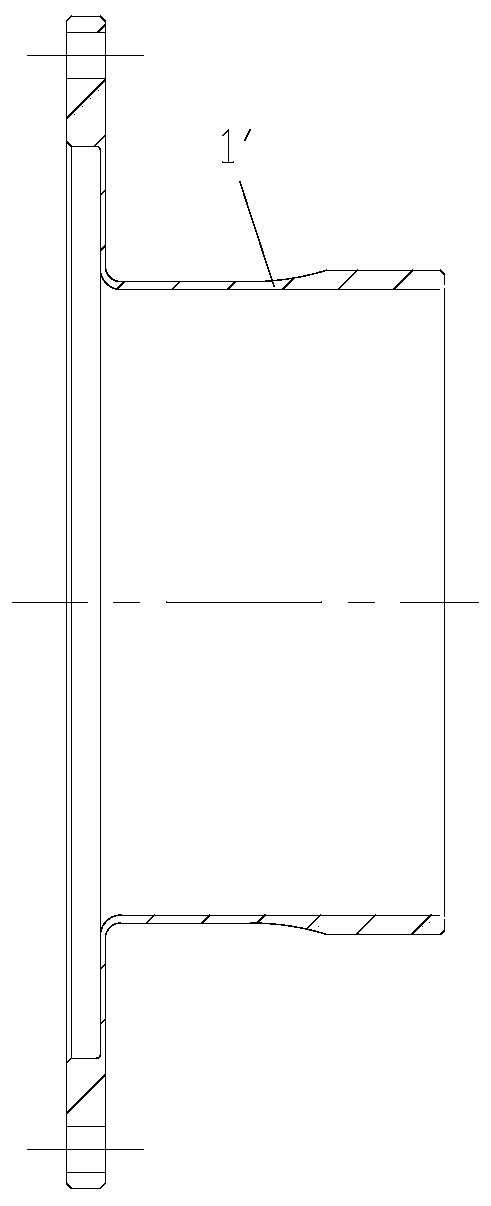

Flexible wheel, harmonic transmission and robot

PendingCN109751393AReduce axial forceExtended service lifeGearingPortable liftingEngineeringAxial force

The invention provides a flexible wheel, a harmonic transmission and a robot. The flexible wheel comprises a matching part (1) arranged at the open end of a flexible wheel body and used for cooperating with a wave generator, wherein the matching part (1) is provided with a first inner hole (2), and an angle of inclination alpha is formed between the hole wall of the first inner hole (2) and the central axis of the flexible wheel body. According to the flexible wheel, the axial force applied to the wave generator can be reduced, and the service life of the wave generator is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

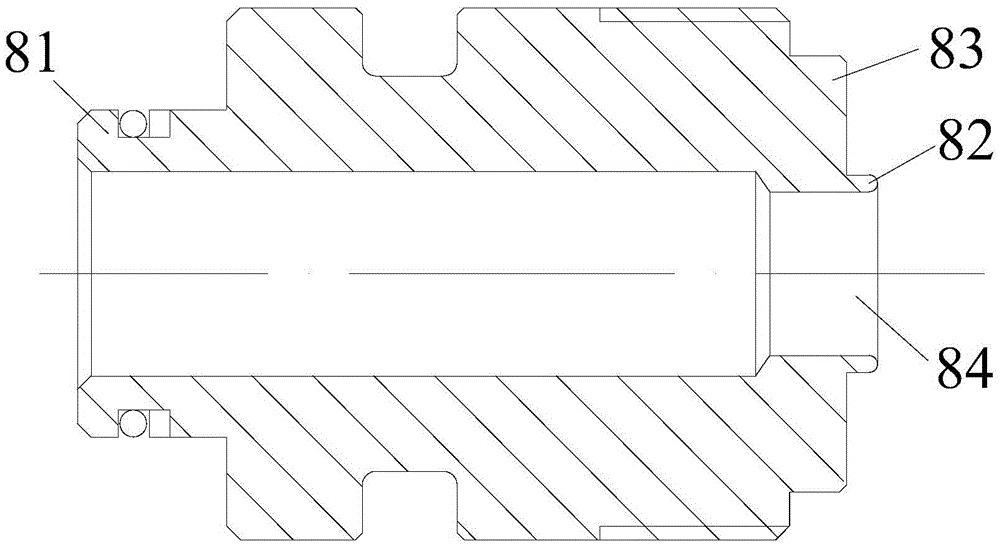

Safety valve

The invention discloses a safety valve. The safety valve comprises a valve body, a liquid inlet connector with a liquid inlet hole, a spring seat and a reset spring and further comprises a valve element assembly which is movably arranged inside the valve body and used for controlling the liquid inlet hole to be opened and closed, the valve body is provided with a liquid discharging hole, the valve element assembly comprises a sliding base, a threaded sleeve arranged inside the sliding base and a valve gasket arranged inside the threaded sleeve, and the spring seat is provided with a first boss inserted into the reset spring. Through arranging the movable valve element assembly inside a valve shell, the valve element assembly can be used for controlling on-off of an oil path from the liquid inlet hole to the liquid discharging hole; when the valve element assembly gets away from the liquid inlet connector, large-flow overflowing can be achieved, the flow of the safety valve is greatly improved, and rapid overflowing within short time can reduce the axial displacement of the valve element assembly; in this way, axial deformation of the reset spring can be reduced, and finally pressure fluctuations can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

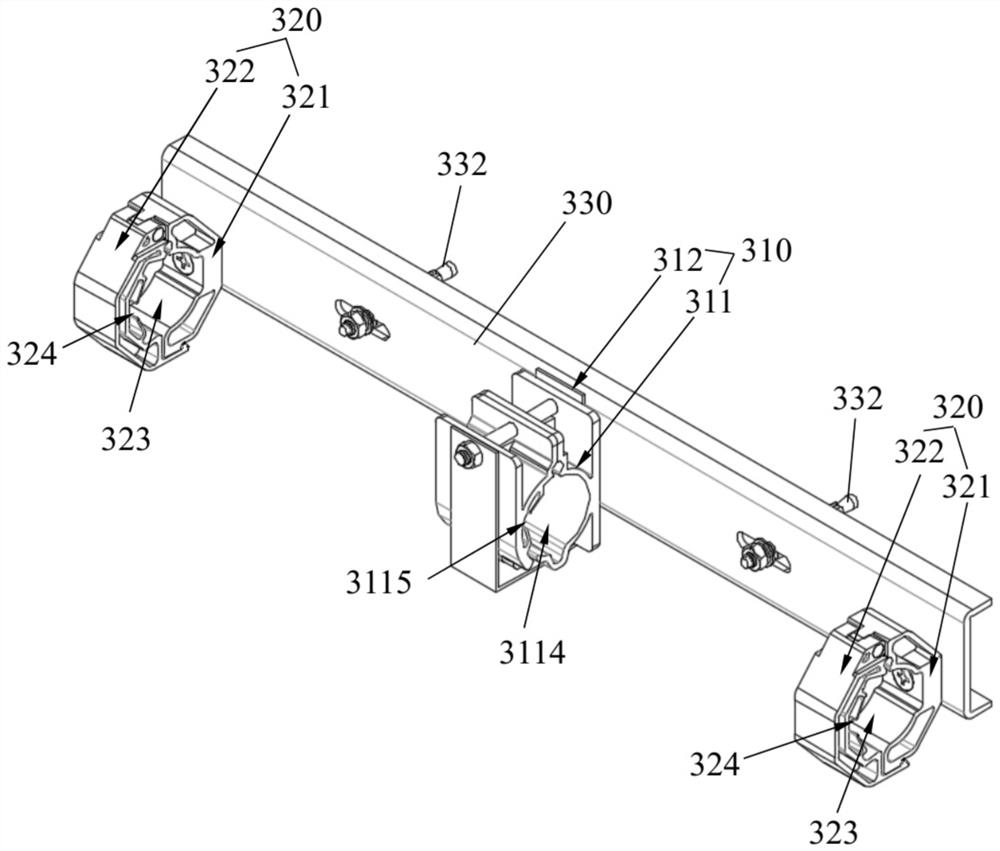

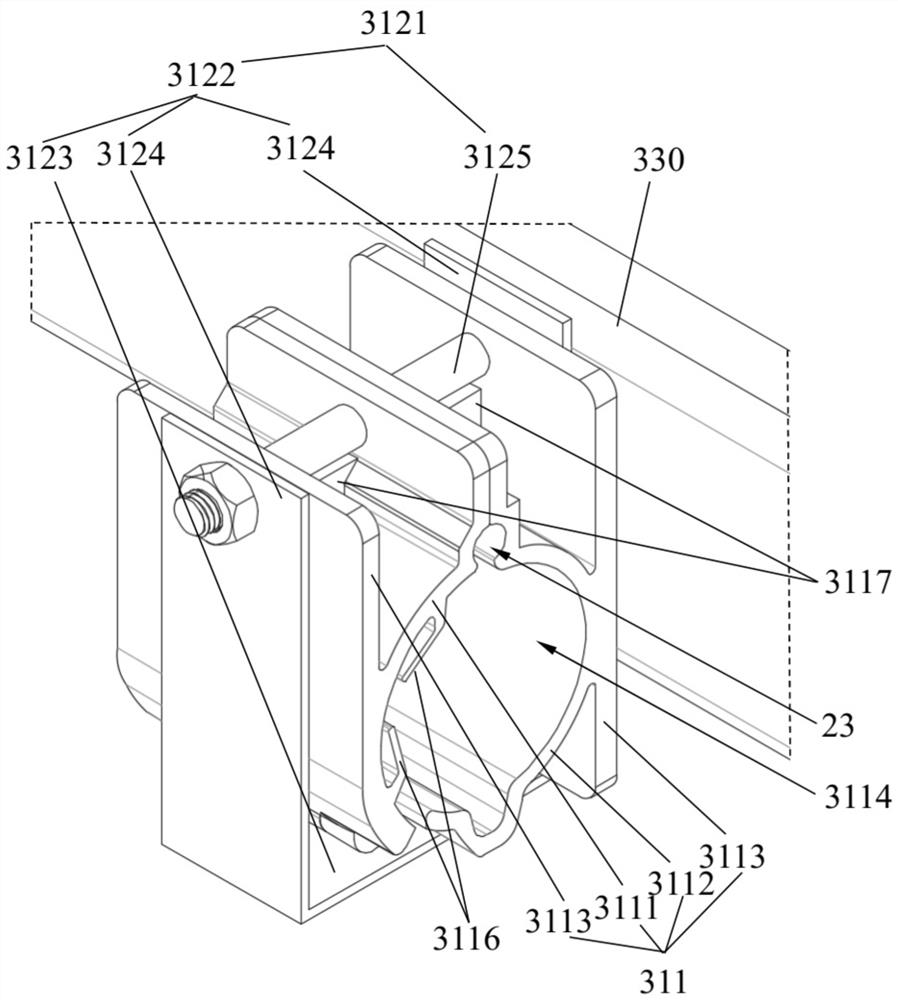

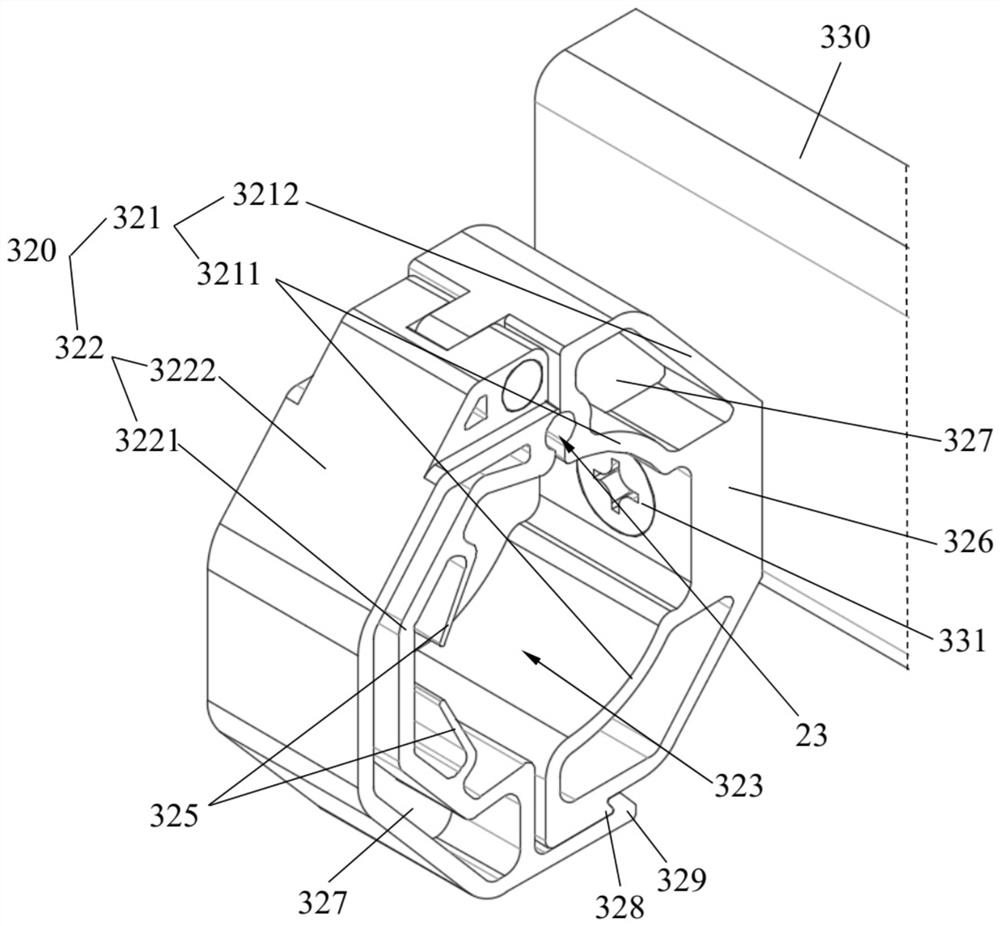

Leaky coaxial cable clamp mechanism and leaky coaxial cable bearing system

ActiveCN114696271AReduce axial displacementReduce or eliminate axial displacementNon-rotating vibration suppressionCable installations in tunnelsAxial displacementCoaxial cable

The invention discloses a leaky coaxial cable clamp mechanism and a leaky coaxial cable bearing system.The leaky coaxial cable clamp mechanism comprises a bearing support, a main clamp and at least two auxiliary clamps, the bearing support is fixed to an installation wall body, the main clamp and the at least two auxiliary clamps are all fixed to the bearing support, the at least two auxiliary clamps are arranged on the two sides of the main clamp at intervals, and the main clamp and the at least two auxiliary clamps are fixed to the bearing support. The auxiliary clamp can generate elastic deformation in the vibration state of the leaky coaxial cable so as to have a damping and buffering effect, and the main clamp is fixed relative to the bearing support in the vibration state of the leaky coaxial cable. According to the leaky coaxial cable clamp, the bearing requirement of the leaky coaxial cable can be met, the installation number of the leaky coaxial cable clamp mechanisms is effectively reduced, the situation that the bearing support is loosened due to the fact that the stress between the bearing support and the installation wall body is influenced by vibration can be avoided, the influence of the vibration on the stress between the main clamp and the leaky coaxial cable can be relieved or eliminated, larger clamping force can be applied to the leaky coaxial cable, and the leaky coaxial cable is prevented from being damaged. Therefore, the leaky coaxial cable is prevented from loosening, the safety performance is effectively improved, and axial displacement of the leaky coaxial cable under the action force of the tunnel wind tunnel effect is reduced or eliminated.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD +1

A kind of preparation method of wc-co-cbn composite material

The invention belongs to the field of material preparation technology, and particularly relates to a method for preparing WC-Co-cBN composite materials. In the present invention, WC, metallic Co powder and cBN raw materials are first weighed in proportion and mixed evenly, and the ball mill is used for mixing. After the ball-milled mixed raw materials are dried in an oven at 50~200°C, they are then sieved through 100~300 mesh. After processing, put the dried raw materials into the mold and place them in a hot-pressing sintering furnace. The sintering furnace heats up to 1200~1400℃ at a speed of 30~50℃ / min and keeps it warm for 5~30 minutes. The pressure is maintained at 20 ~50MPa, WC-Co-cBN composite material was obtained. The present invention adopts the hot-pressing sintering method, with low sintering temperature and short sintering time, which can ensure that the cBN does not phase change, and can also make the material have a large shrinkage rate and high volume density, and the hot-pressing sintering energy consumption is small and the cost is low. Low, easy to operate, high safety factor.

Owner:NORTHEASTERN UNIV LIAONING

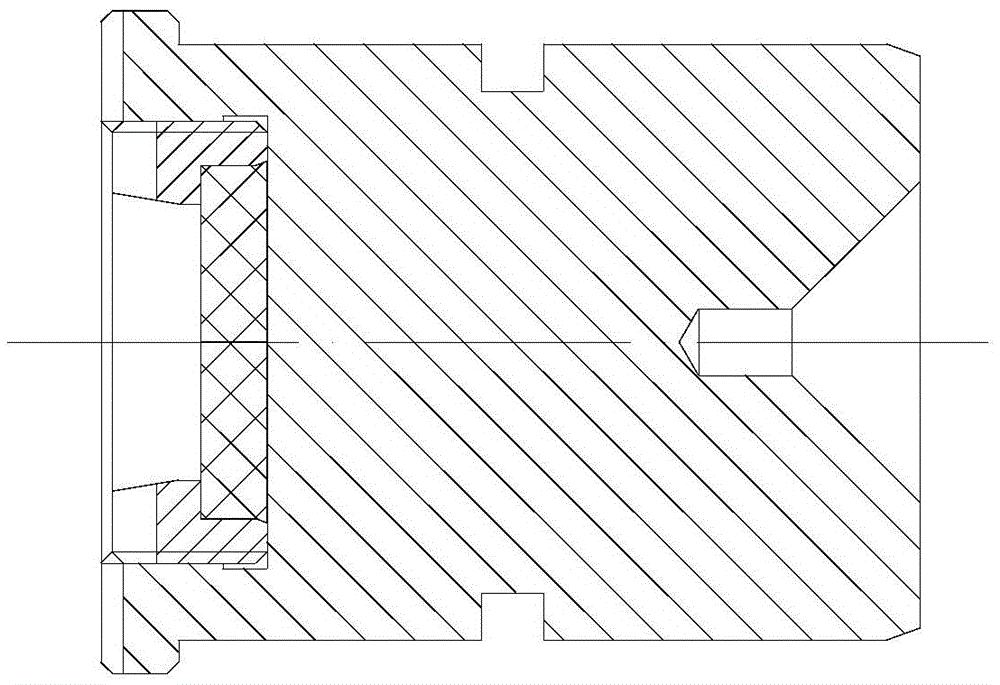

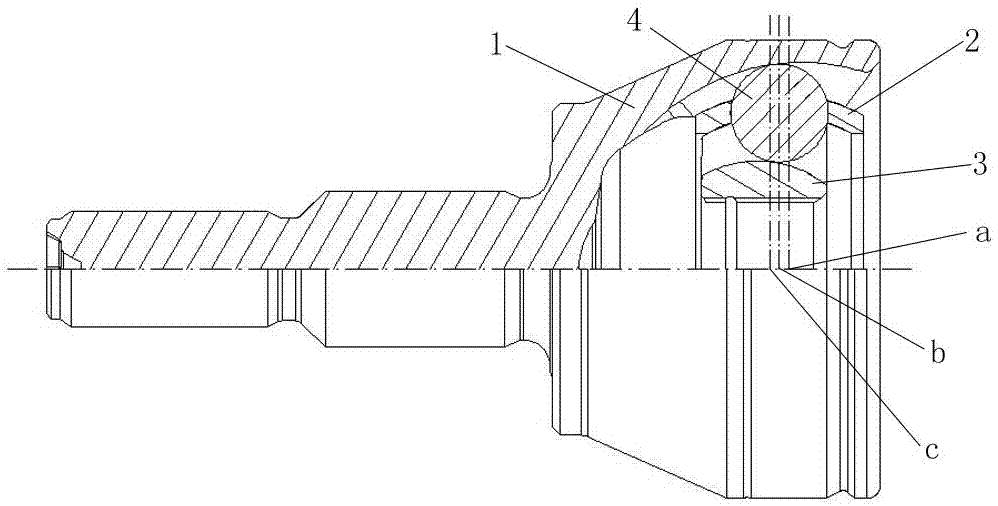

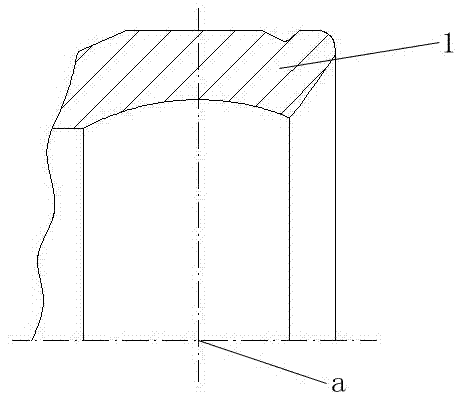

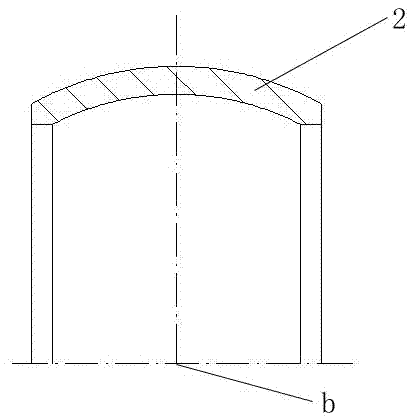

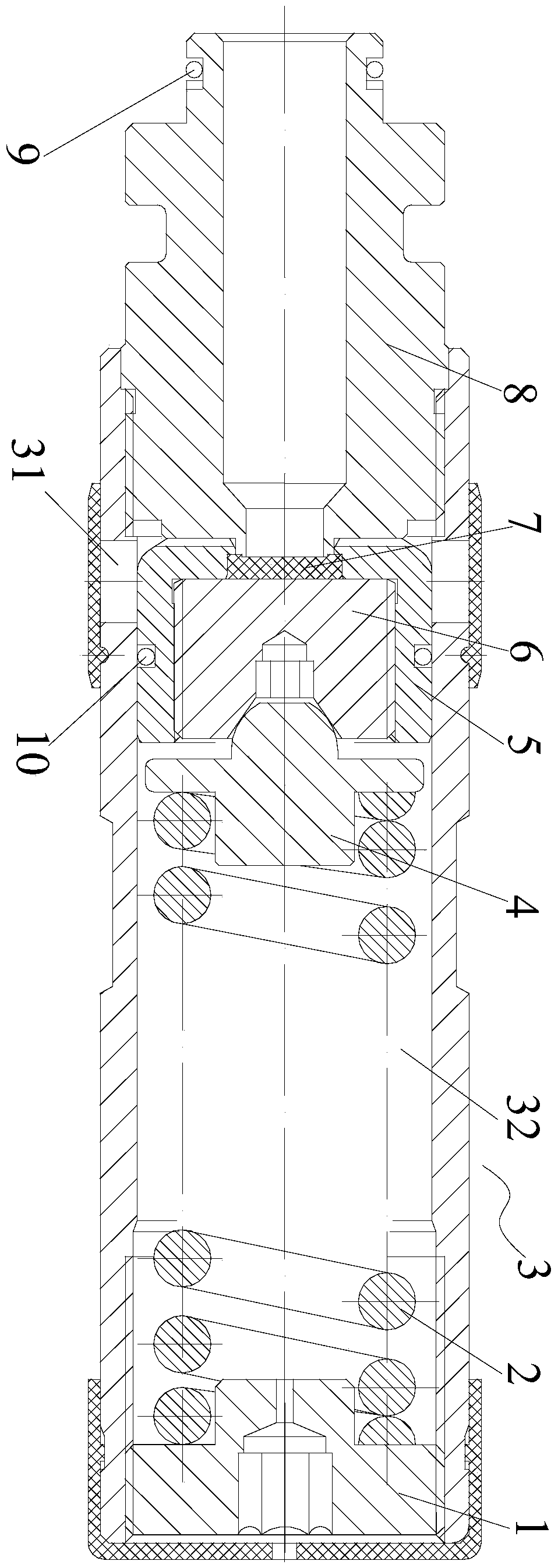

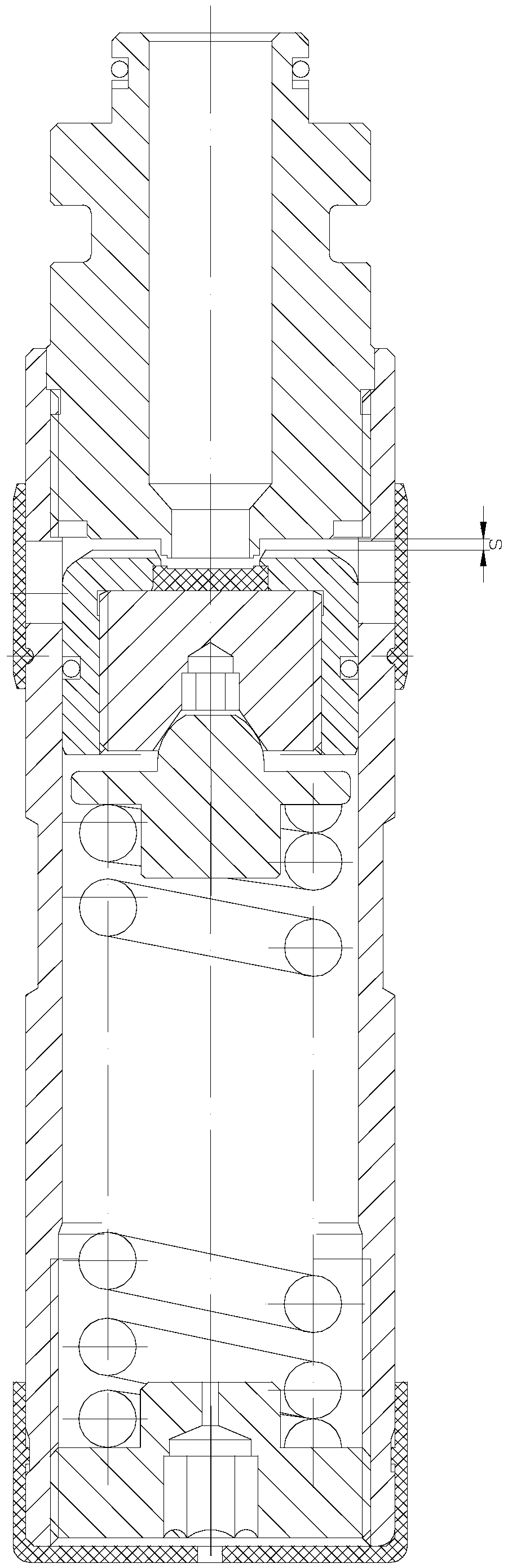

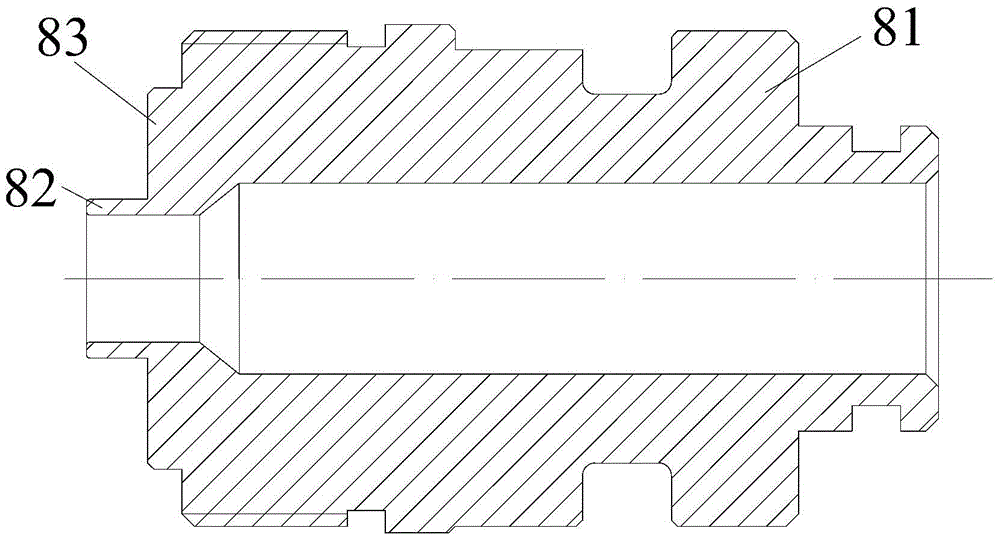

A fixed end constant velocity joint

ActiveCN104806650BReduce arc curvatureReduce radial clearanceYielding couplingAxial displacementGreat circle

The invention discloses a new fixed-end constant velocity universal joint, which includes a bell-shaped shell, a cage, a star sleeve and steel balls. The spherical center a' of the inner spherical surface of the bell-shaped shell is vertically displaced upwards based on the axis line and The connection line between the original center a and the center a' is located on the vertical center line of the great circle perpendicular to the axis line; the center b1' of the outer spherical surface of the cage is offset vertically downward based on the axis line and the original center b The connection line with the center of the sphere b1' is located on the vertical center line of the great circle perpendicular to the axis line, the center of the spherical surface b2' in the cage is offset vertically upward based on the axis line, and the original center of the sphere b and the center of the sphere b2' The connection line of is located on the vertical center line of the great circle perpendicular to the axis line; the center c' of the outer spherical surface of the star-shaped sleeve is offset vertically downward based on the axis line, and the connection line between the original center c and the center c' On the vertical centerline of a great circle perpendicular to the axis. This structure reduces the axial displacement between the parts, reduces the impact force between the parts, and prolongs the service life.

Owner:WANXIANGQIANCHAO CO LTD +1

Switching mechanism for large-flow overflow safety valve

InactiveCN105545339AReduce axial displacementHigh trafficMine roof supportsAxial displacementEngineering

The invention discloses a switching mechanism for a large-flow overflow safety valve. The switching mechanism comprises a liquid inlet joint with a liquid inlet hole and further comprises a valve element assembly which can move relative to the liquid inlet joint and is used for controlling opening and closing of the liquid inlet hole, the valve element assembly comprises a nut and a valve pad arranged in the nut, and the valve pad is provided with a seal surface used for being matched with the liquid inlet joint, wherein a conical surface is adopted as the seal surface. According to the switching mechanism for the valve element assembly, by arranging the movable valve element assembly to be matched with the liquid inlet joint, the valve element assembly can be used for controlling connection and disconnection of an oil way from the liquid inlet hole to a liquid outlet hole, large-flow overflowing can be achieved when the valve element assembly is far away from the liquid inlet joint, the safety valve flow is greatly increased, axial displacement of the valve element assembly can be reduced through short-time quick overflowing, axial deformation of a reset spring can be reduced through axial displacement reduction of the valve element assembly, and pressure fluctuation can be reduced finally.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Valve element assembly of overflow safety valve

InactiveCN105715285AReduce axial displacementHigh trafficMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses a valve element assembly of an overflow safety valve.The valve element assembly comprises a nut and a valve pad arranged in the nut and matched with a liquid inlet connector of the overflow safety valve.The valve element assembly is applied to the overflow safety valve, and can be used for controlling on-off of an oil path from a liquid inlet hole to a liquid discharging hole, large-flow overflow can be achieved after the valve element assembly is away from the liquid inlet connector, the flow of the safety valve is greatly increased, the axial displacement of the valve element assembly can be reduced through short-time quick overflowing, the axial deformation of a reset spring can be relieved due to reduction of the axial displacement of the valve element assembly, and finally pressure fluctuation can be relieved.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Safety valve

InactiveCN105422157AHigh trafficReduce axial displacementMine roof supportsAxial displacementEngineering

The invention discloses a safety valve, comprising a valve body, a liquid inlet connector with a liquid inlet hole, and a valve element assembly movably arranged in the valve body and used for controlling the opening and closing of the liquid inlet hole, wherein the valve body is provided with a liquid discharge hole, the valve element assembly comprises a sliding seat, a swivel nut arranged in the sliding seat, and a valve pad arranged in the swivel nut, and the valve pad is provided with a spherical groove. According to the safety valve, the movable valve element assembly is arranged inside a valve casing; the valve element assembly can be used for controlling the on-off of an oil path from the liquid inlet hole to the liquid discharge hole, after the valve element assembly is far away from the liquid inlet connector, mass-flow overflow can be realized, the flow rate of the safety valve is greatly increased, quick overflow in a short time can reduce the axial displacement of the valve element assembly, the axial displacement reduction of the valve element assembly can decrease the axial deformation of a reset spring, and finally pressure surge can be lowered.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Safety valve

InactiveCN105626105AHigh trafficReduce axial displacementMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses a safety valve, which comprises a valve pocket, a spring seat, a liquid inlet joint, and also comprises a valve core assembly and a push rod, wherein the liquid inlet joint is provided with a liquid inlet hole; the valve core assembly is movably arranged in the valve pocket and is further used for controlling the opening and the closing of the liquid inlet hole; the push rod is located between the valve core assembly and the spring seat; the valve pocket is provided with a liquid discharge hole. According to the safety valve provided by the invention, by arranging the movable valve core assembly inside a valve body, the valve core assembly can be used for controlling the on / off of an oil way from the liquid inlet hole to the liquid discharge hole; the mass-flow overflow can be realized after the valve core assembly is far away from the liquid inlet joint; the flow of the safety valve is greatly improved; the axial displacement of the valve core assembly can be shortened by short-time quick overflow; the axial deformation of a reset spring can be reduced when the axial displacement of the valve core assembly is shortened; finally, the pressure fluctuation can be decreased.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

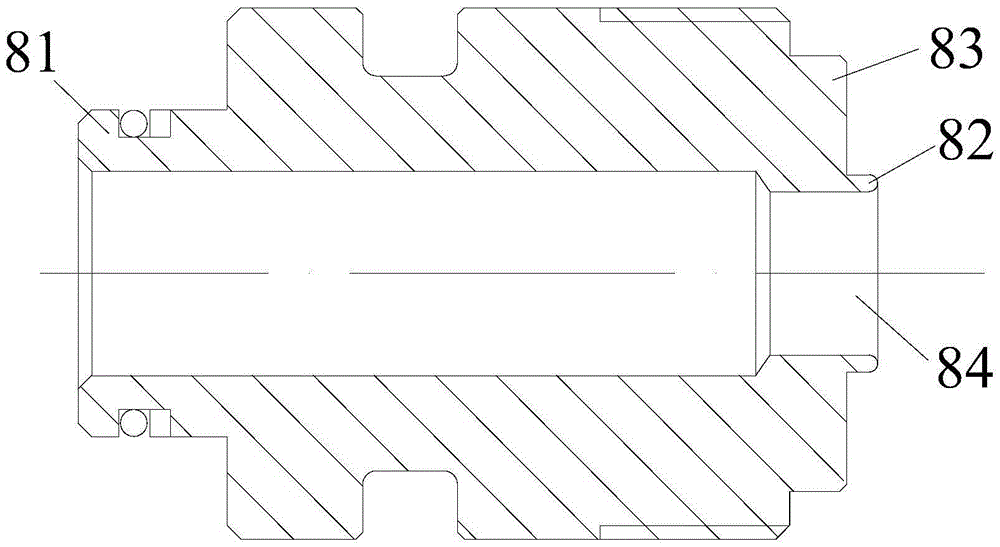

Beverage dispensing apparatus and method

InactiveCN101554986BReduce axial displacementReduce impactPositive displacement pump componentsLiquid transferring devicesEngineeringAlternating current

A beverage dispensing apparatus (100) is disclosed, comprising a solenoid pump (106) coupled between a fluid inlet (102) and a fluid outlet (104) for pumping the fluid from said inlet to said outlet, said pump comprising a spring-loaded linear pumping member (206) axially displaceable between a spring-loaded position (240) and a spring-released end position (230) and a controller (108) for the solenoid pump (106), said controller being arranged to energize the pumping member (206) into an intermediate position (235) between the spring-released end position (230) and the spring-loaded position (240). Consequently, the solenoid pump (106) has improved noise characteristics and can be used to control the flow rate of the fluid whilst still being energized in substantially every cycle of an alternating current.

Owner:NESTEC SA

Overflow safety valve

InactiveCN105386782AHigh trafficReduce axial displacementMine roof supportsProps/chocksAxial displacementCore component

The invention discloses an overflow safety valve. The overflow safety valve comprises a valve shell and a liquid inlet joint with a liquid inlet hole, and further comprises a valve core component movably arranged in the valve shell and used for controlling the opening and the closing of the liquid inlet hole, wherein the valve shell has a drain hole. The overflow safety valve is provided with the movable valve core component in the valve shell; the valve core component can be used for controlling the connection and the disconnection of an oil way from the liquid inlet hole to the drain hole; after the valve core component is far from the liquid inlet joint, the high-flow overflow can be realized; the flow of the safety valve is largely increased; the axial displacement of the valve core component can be shortened through quick overflow in a shorter time; the axial deformation of a return spring can be decreased through shortening the axial displacement of the valve core component; and finally, the pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Flue gas waste heat recovery device

ActiveCN102410631BReduce axial displacementExtended stayEnergy efficient heating/coolingAir heatersWater storageFlue gas

The invention relates to a flue gas waste heat recovery device, which comprises a main cylinder, wherein the main cylinder is hollow inside; a heat conversion unit is arranged in the main cylinder; and the bottom end of the main cylinder is connected with a flue gas inlet device. The flue gas waste heat recovery device is characterized in that: the main cylinder is cylindrical, wherein the bottomof the main cylinder is provided with a flue gas distributor, the flue gas distributor is communicated with the flue gas inlet device, and the heat conversion unit is arranged above the flue gas distributor; the heat conversion unit comprises a cold water storage body, a hot water storage body and a heat exchange component, wherein the cold water storage body is externally connected with a water inlet pipeline, and a hot water outlet is externally connected with a water outlet pipeline; and the bottom of the main cylinder is provided with a condensed water outlet. The flue gas waste heat recovery device is suitable for non-industrial occasions, such as families, markets, hosts, restaurants and the like and has the advantages of simple structure, wide application range and capability of deeply utilizing heat in flue gas and potential heat energy in the flue gas; and core components of the flue gas waste heat recovery device are made of stainless steel materials, so that not only scale prevention capability of the product can be enhanced, service life is prolonged, but also quality of domestic water can be ensured.

Owner:WUXI XIZHOU MACHINERY

Safety valve

InactiveCN105604585AHigh trafficReduce axial displacementMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses a safety valve, which comprises a valve body, a liquid inlet joint, a spring seat and a reset spring, wherein the liquid inlet joint is provided with a liquid inlet hole. The safety valve also comprises a valve core assembly; the valve core assembly is movably arranged in the valve body and is used for controlling the liquid inlet hole to be opened or closed; the valve body is provided with a liquid discharge hole; the valve core assembly comprises a sliding seat, a screw sleeve and a valve pad; the screw sleeve is arranged in the sliding seat; the valve pad is arranged in the screw sleeve, and is provided with a spherical groove; the spring seat is provided with a first lug boss inserted into the reset spring. The safety valve has the advantages that the movable valve core assembly is arranged in a valve case; the valve core assembly can be used for controlling the make-and-break state of an oil path from the liquid inlet hole to the liquid discharge hole; after the valve core assembly leaves far away from the liquid inlet joint, the high-flow-rate overflow can be realized; the flow rate of the safety valve is greatly improved; the axial displacement of the valve core assembly can be reduced through the short-time fast overflow; the axial displacement of the valve core assembly is reduced, so that the axial deformation of the reset spring is reduced; the pressure fluctuation can be finally reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Opening/closing mechanism of safety valve

InactiveCN105604587AReduce axial displacementHigh trafficMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses an opening / closing mechanism of a safety valve. The opening / closing mechanism comprises a liquid feeding connector provided with a liquid feeding hole, and further comprises a valve element assembly which can move relative to the liquid feeding connector and is used for controlling the on / off of the liquid feeding hole, wherein the valve element assembly comprises a nut and a valve pad arranged in the nut; the valve pad is provided with a sealing surface matched with the liquid feeding connector; the valve pad has a concave structure. According to the opening / closing mechanism of the safety valve, provided by the invention, the movable valve element assembly is matched with the liquid feeding connector, and the movable valve element assembly can be used for controlling the on / off of an oil path from the liquid feeding hole to a liquid discharging hole; when the valve element assembly is far away from the liquid feeding connector, large-flow overflowing can be realized and the flow of the safety valve is greatly improved; axial displacement of the valve element assembly can be shortened by rapid overflowing within short time; the axial displacement of the valve element assembly is shortened so that axial deformation of a resetting spring can be reduced; finally, pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Valve core assembly of safety valve

InactiveCN105484785AReduce axial displacementHigh trafficMine roof supportsAxial displacementEngineering

The invention discloses a valve core assembly of a safety valve. The valve core assembly comprises a sliding seat, a thread sleeve arranged in the sliding seat and a valve pad which is arranged in the thread sleeve and matched with a liquid inlet connector of the safety valve, wherein the valve part is provided with a spherical groove. The valve core assembly is applied to the safety valve and can be used for controlling on-off of an oil line from a liquid inlet hole to a liquid discharge hole, high-flow overflowing can be realized when the valve core assembly is far away from the liquid inlet connector, the flow of the safety valve is greatly increased, axial displacement of the valve core assembly can be reduced through short-term fast overflowing, axial deformation of a reset spring can be reduced through reduction of the axial displacement of the valve core assembly, and pressure fluctuation can be reduced finally.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Switching mechanism of overflow safety valve

InactiveCN105626119AReduce axial displacementHigh trafficMine roof supportsAxial displacementCore component

The invention discloses a switching mechanism of an overflow safety valve. The switching mechanism comprises a liquid inlet connector and a valve core component, wherein a liquid inlet hole is formed in the liquid inlet connector; the valve core component is removable relative to the liquid inlet connector and is used for controlling the switching on and off of the liquid inlet hole; the valve core component comprises a nut and a valve pad which is arranged in the nut; the valve pad is provided with a sealing surface which is matched with the liquid inlet connector; the sealing surface is a spherical surface. According to the switching mechanism of the overflow safety valve, disclosed by the invention, through matching of the removable valve core component and the liquid inlet connector, the valve core component can be used for controlling the switching on and off of an oil way from the liquid inlet hole to a liquid outlet hole, large-flow overflow can be realized after the valve core component is far away from the liquid inlet connector, the flow of the overflow safety valve is greatly increased, the axial displacement of the valve core component can be lessened by fast overflow in a short time, the axial deformation of a reset spring is reduced when the axial displacement of the valve core component is lessened, and the pressure fluctuation can be finally reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Switching mechanism of safety valve

InactiveCN105422158AReduce axial displacementHigh trafficMine roof supportsAxial displacementSafety valve

The invention discloses a switching mechanism of a safety valve. The switching mechanism comprises a liquid inlet connector with a liquid inlet hole, and a valve element assembly capable of moving relative to the liquid inlet connector and used for controlling the opening and closing of the liquid inlet hole, wherein the valve element assembly comprises a sliding seat, a swivel nut arranged in the sliding seat, and a valve pad arranged in the swivel nut. According to the switching mechanism of the safety valve, the movable valve element assembly is arranged to be matched with the liquid inlet connector; the valve element assembly can be used for controlling the on-off of an oil path from the liquid inlet hole to a liquid discharge hole, after the valve element assembly is far away from the liquid inlet connector, mass-flow overflow can be realized, the flow rate of the safety valve is greatly increased, quick overflow in a short time can reduce the axial displacement of the valve element assembly, the axial displacement reduction of the valve element assembly can decrease the axial deformation of a reset spring, and finally pressure surge can be lowered.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Valve core assembly of overflow safety valve

InactiveCN105386783AReduce axial displacementHigh trafficMine roof supportsProps/chocksAxial displacementEngineering

The invention discloses a valve core assembly of an overflow safety valve. The valve core assembly comprises a nut and a valve pad which is arranged in the nut and is used for being matched with a liquid inlet joint of the overflow safety valve. The valve core assembly disclosed by the invention is applied to the overflow safety valve and can be used for controlling the opening and closing of an oil line from a liquid inlet hole to a liquid drainage hole. After the valve core assembly is far away from the liquid inlet joint, the large flow overflow can be realized, and the flow of the safety valve is greatly increased. The rapid overflow within a short time can reduce the axial displacement of the valve core assembly, the reduction of the axial displacement of the valve core assembly enables the reduction of axial deformation of a reset spring, and ultimately the pressure fluctuation can be reduced.

Owner:JULONG GROUP WUHU XINGLONG HYDRAULIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com