A fixed end constant velocity joint

A technology of constant velocity universal joint and fixed end, which is applied in the field of auto parts, can solve problems such as limited degree, and achieve the effects of reducing abnormal noise, easy processing, reducing force and possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

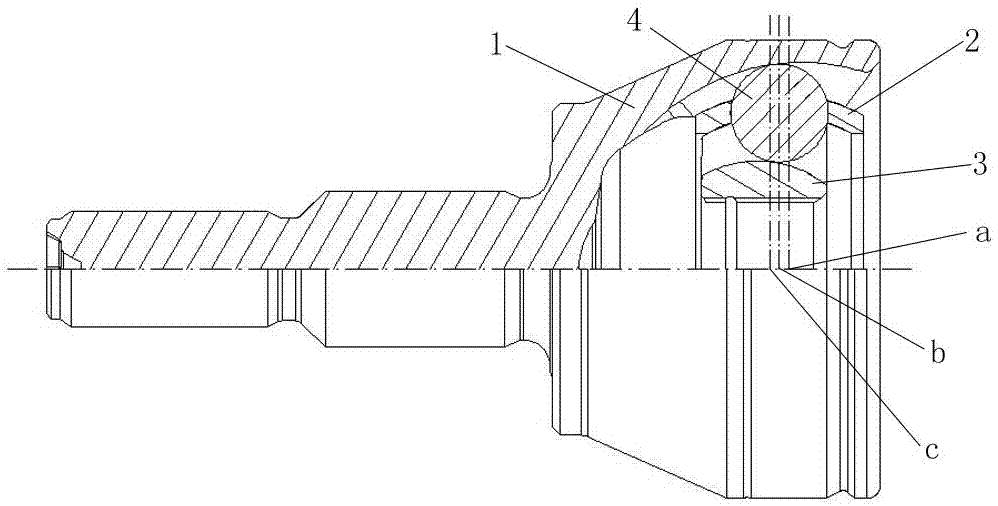

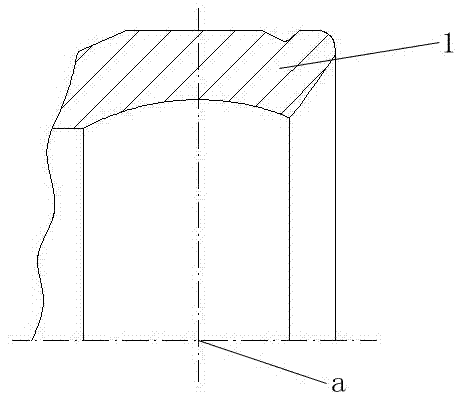

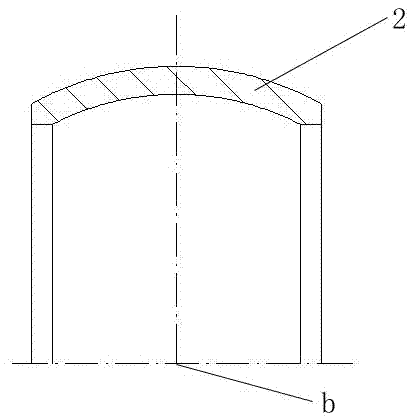

[0028] Such as figure 1 As shown in the structural diagram of the prior art, the present invention, as a new type of fixed-end constant velocity universal joint, also includes a bell shell 1 , a cage 2 , a star sleeve 3 and steel balls 4 . As a structural improvement relative to the prior art, first of all, as Figure 7 As shown, the center a' of the inner sphere of the bell-shaped shell 1 is shifted vertically upward based on the axis line, and the line connecting the original center a and the center a' is located on the vertical center line of the great circle perpendicular to the axis line ; Next as Figure 8 As shown, the center b1' of the outer spherical surface of the cage 2 is offset vertically downward based on the axis line and the line connecting the original center b and the center b1' is located on the vertical center line of the great ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com