Magnet-containing brush-type sealing structure capable of adjusting radial clearance between brush wire beams and rotor surface

A brush seal, radial clearance technology, applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve the problem of the gap between the brush bundle and the rotor surface cannot be adjusted, etc., to facilitate disassembly, replacement and maintenance, reduce leakage flow, The effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

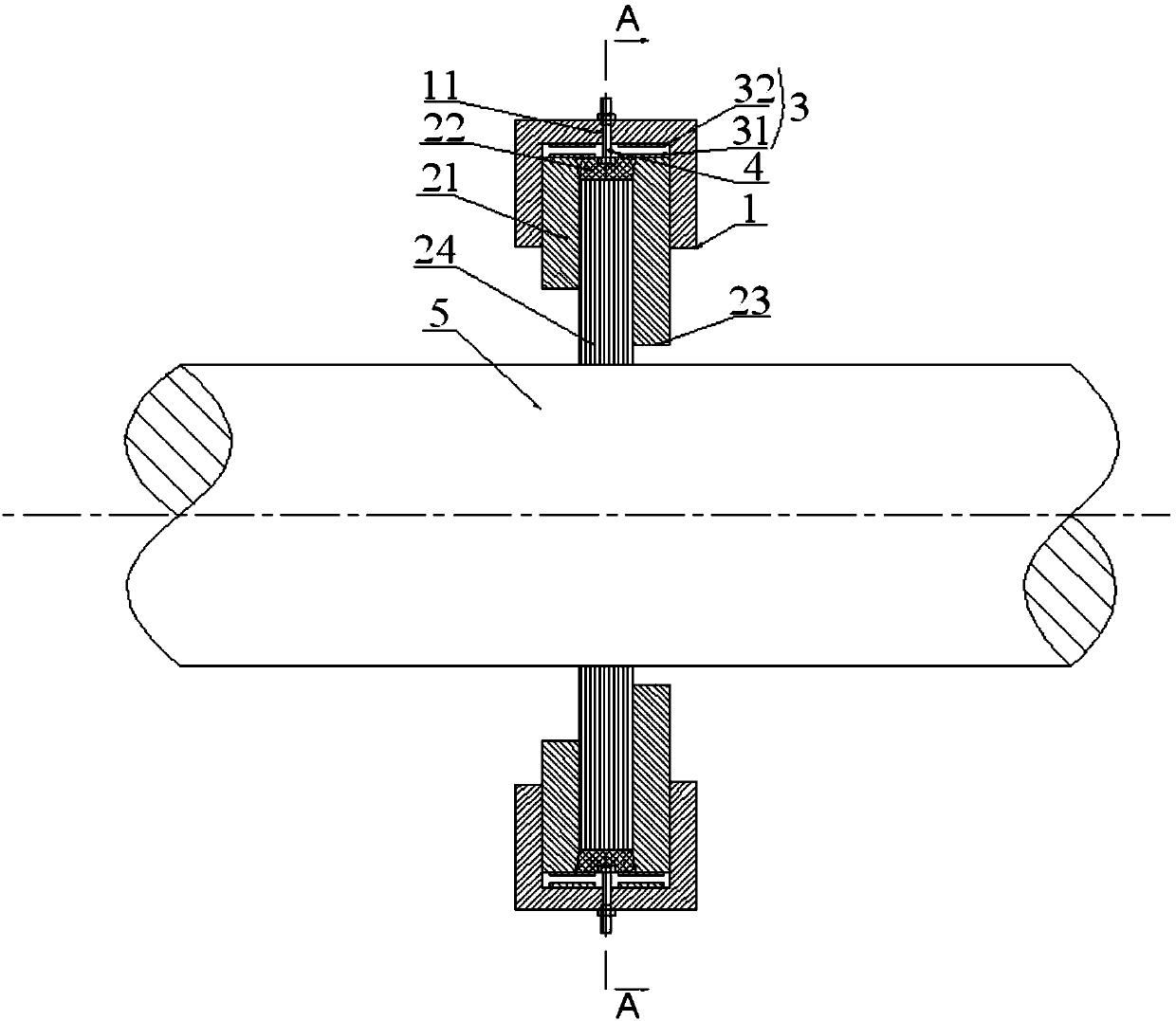

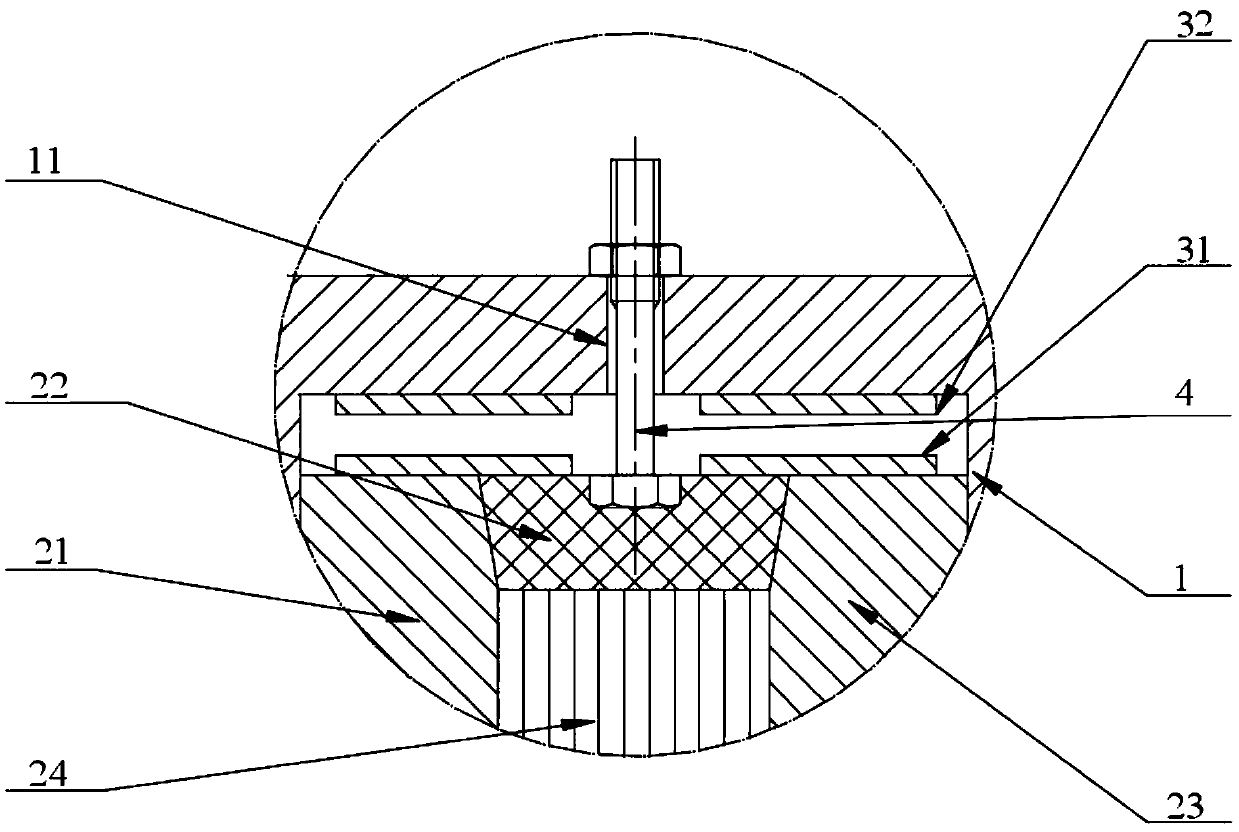

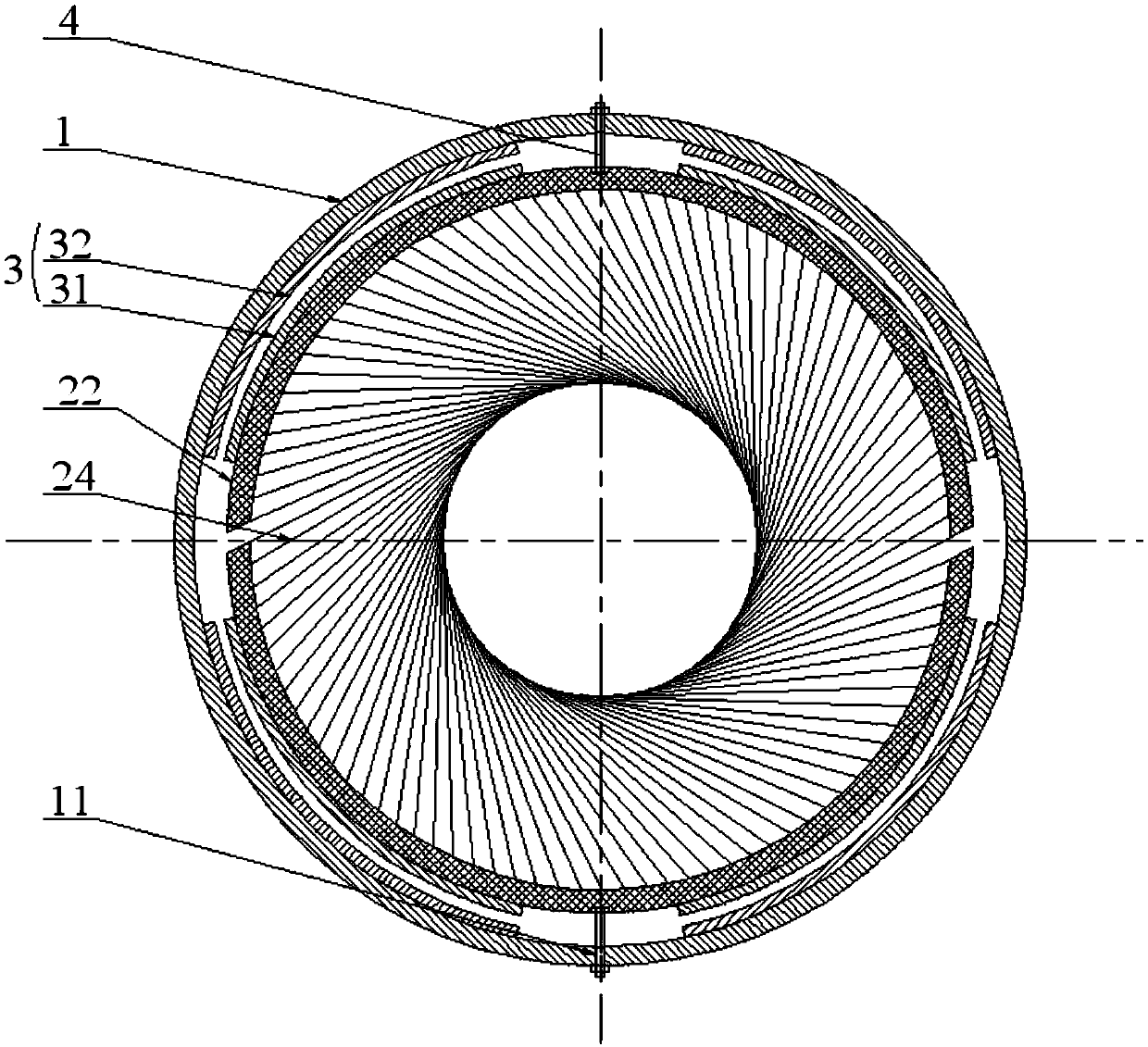

[0024] Such as Figure 1 to Figure 3 As shown, the present invention provides a brush seal structure containing magnets to adjust the radial gap between the brush filament bundle and the rotor surface, including: a stator 1, a brush seal and a tile-shaped magnet 3, wherein the brush seal cooperates It is arranged on the inner circumference of the stator 1 and can move radially along the rotor 5 inside the stator. The brush seal includes an upper brush seal and a lower brush seal with the same structure and the upper brush seal and the lower brush seal. The brush seals all include a front baffle 21, a welding zone 22, a rear baffle 23 and a brush wire bundle 24, the front baffle 21 and the rear baffle 23 are connected through the welding zone 22, and the root of the brush wire bundle 24 is fixed on On the welding zone 22, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com