Flexible wheel, harmonic transmission and robot

A transmission and flexible wheel technology, applied in the field of robotics, can solve problems such as bearing damage, flexible bearing axial displacement, etc., to achieve the possible effects of increasing service life, improving service life, reducing axial displacement or bearing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

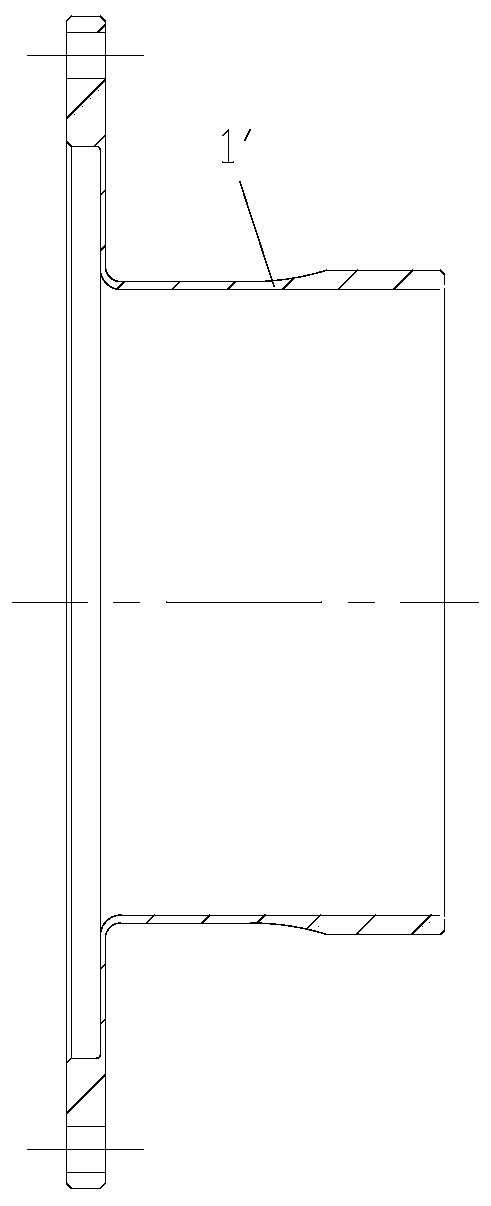

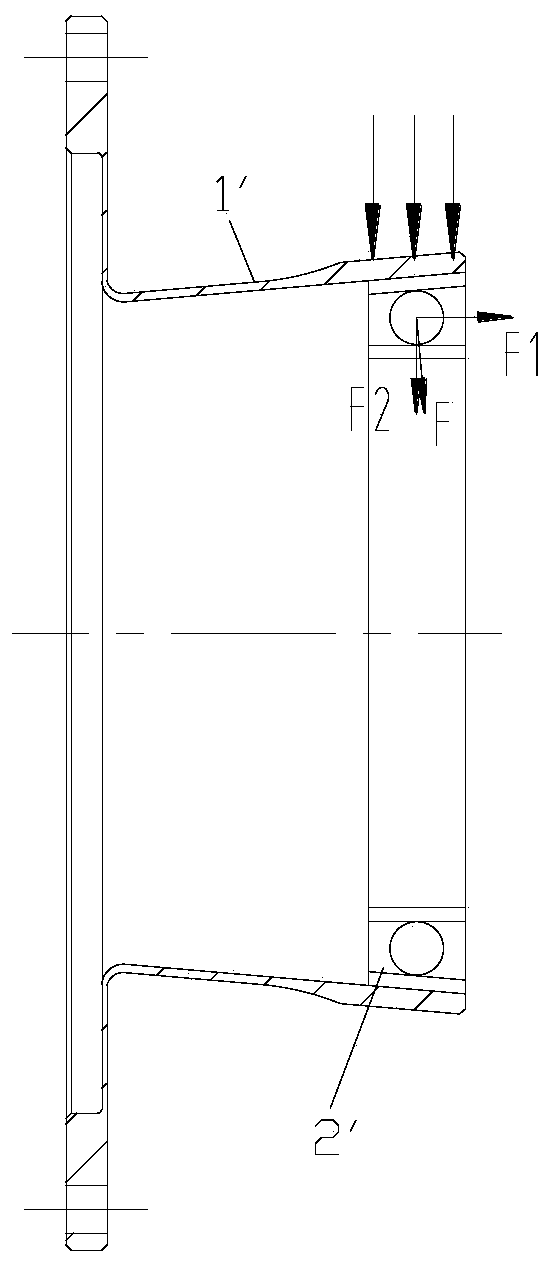

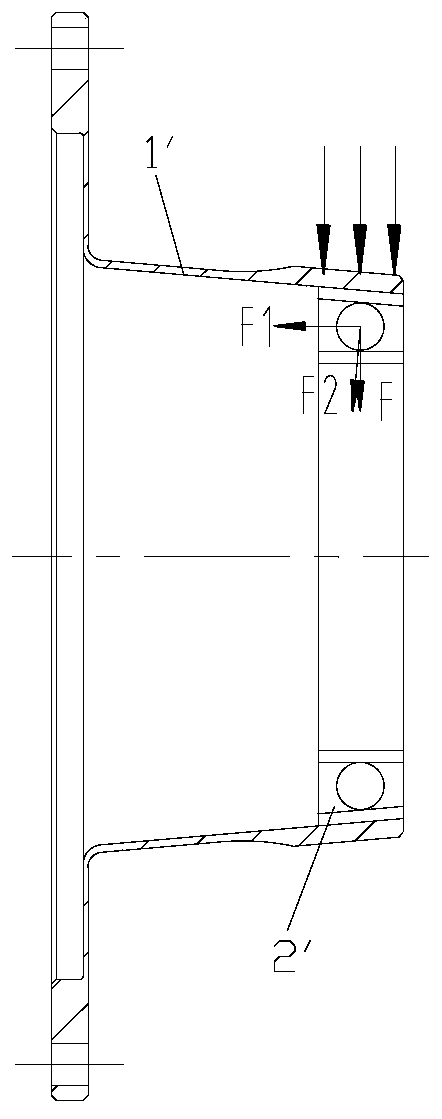

[0028] see in conjunction Figure 5 to Figure 6 As shown, according to the embodiment of the present application, the flexspline includes a matching part 1 arranged at the open end of the flexspline and used to cooperate with the wave generator. The matching part 1 has a first inner hole 2, and the hole wall of the first inner hole 2 An inclination α is formed with the central axis of the flexspline.

[0029] The flexspline sets the first inner hole 2 of the matching part 1 that cooperates with the wave generator as a hole with a taper, which can compensate the deformation of the flexspline during the switching process of flexspline expansion or contraction. Before the sudden point when the contraction state is switched to the expansion state, a certain axial force is pre-applied between the flexspline and the wave generator through the taper of the first inner hole 2, so that when the flexspline reaches the state switching point, it can be reduced. During the switching proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com