Flue gas waste heat recovery device

A recovery device and flue gas waste heat technology, applied in the direction of air heaters, fluid heaters, climate sustainability, etc., can solve the problems of ineffective recovery of water vapor condensation latent heat, narrow application range, waste of heat energy, etc., to achieve good environmental protection Effect, improve heat conversion efficiency, prolong the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

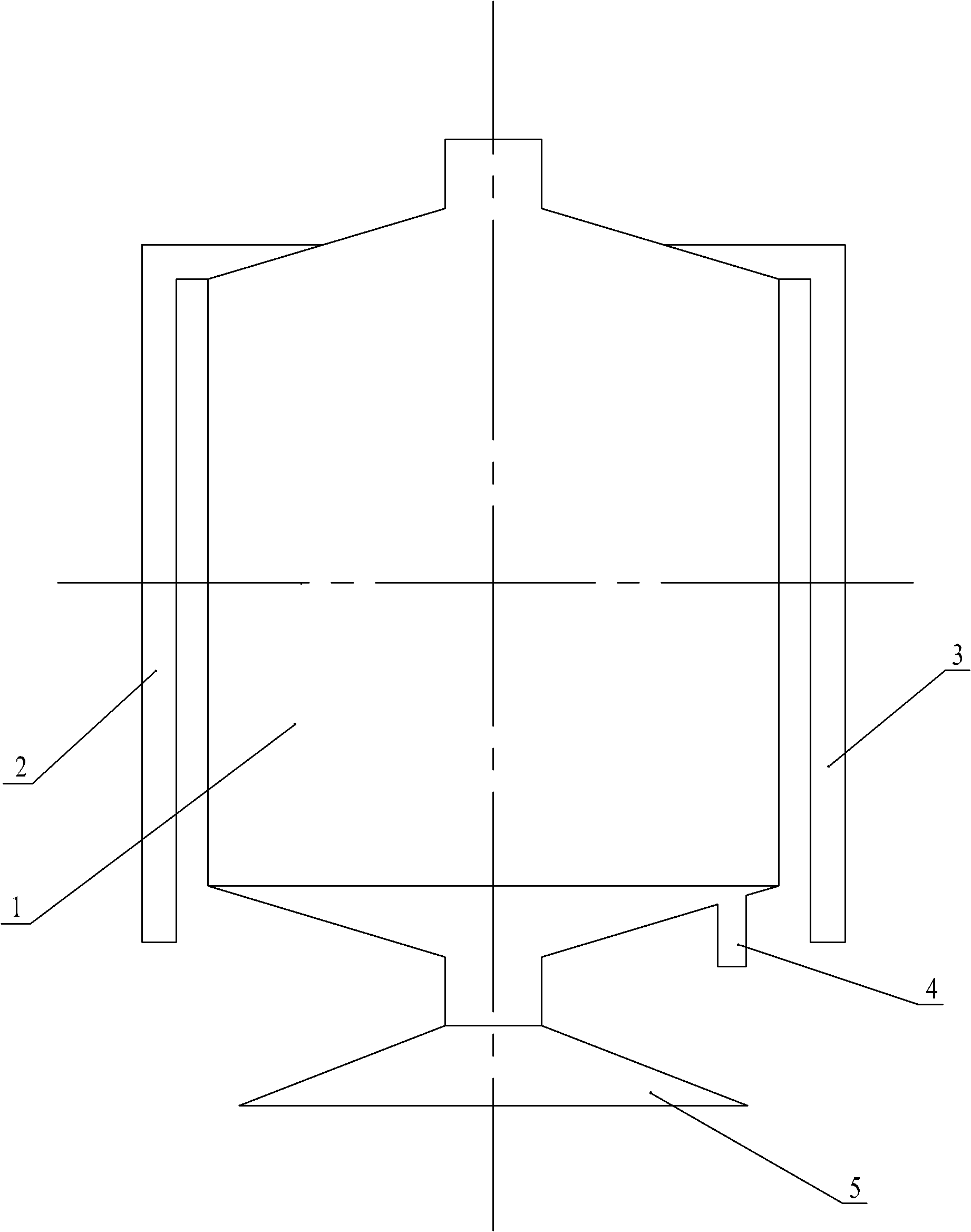

[0018] As shown in the figure: the flue gas waste heat recovery device in the embodiment mainly includes three parts: the main cylinder body 1, the heat conversion unit and the flue gas distributor 9. The main cylinder body 1 is a hollow cylindrical structure, and the main cylinder body A smoke distributor 9 is arranged at the bottom, and the smoke distributor 9 communicates with the smoke inlet device 5 below it, and the heat conversion unit is arranged above the smoke distributor 9.

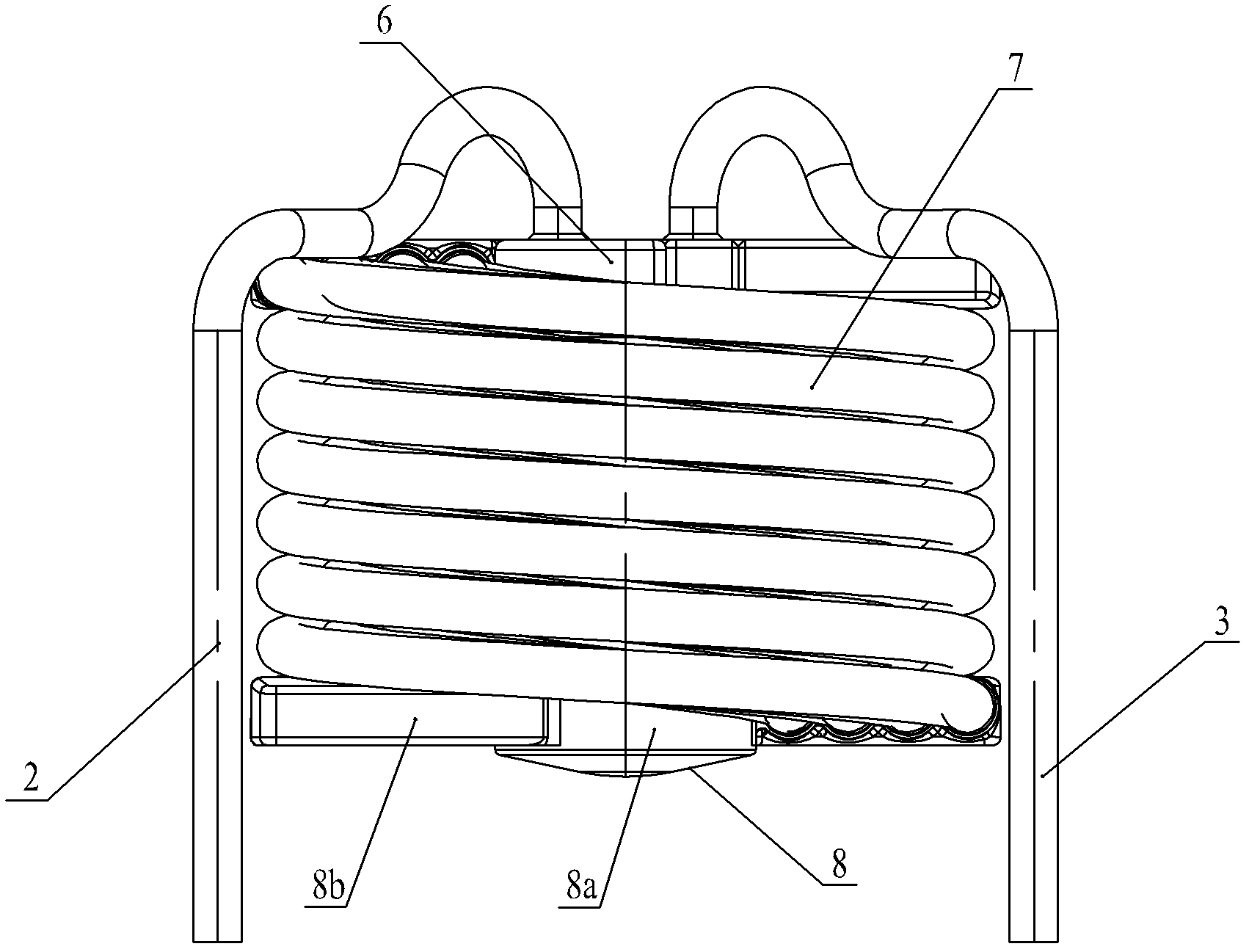

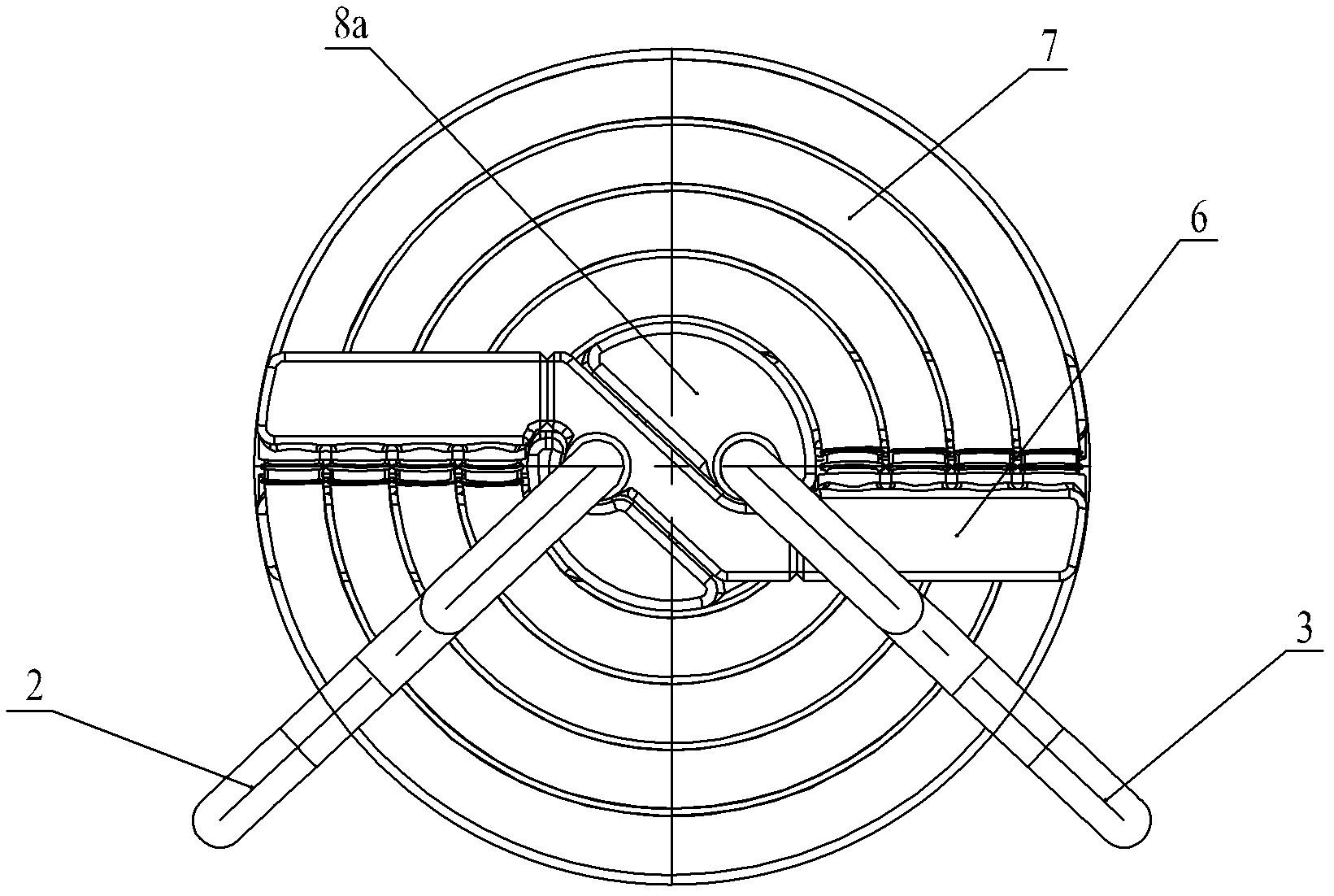

[0019] Such as figure 2 , image 3 As shown, the heat conversion unit is mainly composed of a cold water storage body 6, a hot water storage body 8 and heat exchange components. The heat exchange components in the embodiment are composed of eight concentrically arranged spiral coils 7, and the eight spiral coils 7 are equally divided into four groups according to different ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com