Vibration and noise reduction flange

A vibration and noise reduction, flange technology, applied in the direction of non-rotational vibration suppression, rigid shaft coupling, mechanical equipment, etc., can solve the problem of unable to reduce the displacement and vibration of the inner ring and outer ring of the flange, and the flexible pad detached from the flange Disk, high cost of manufacturing process, etc., to avoid complex manufacturing process, reduce installation difficulty, reduce the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

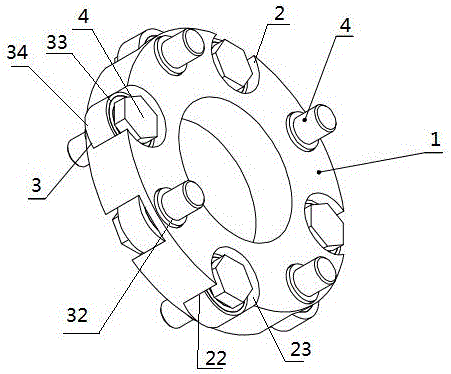

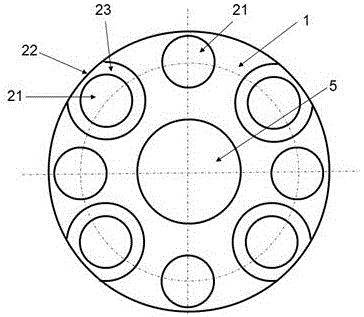

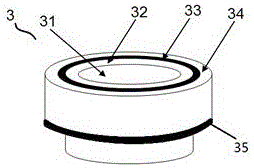

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] In order to solve the above technical problems, the present invention provides a flange, which can reduce radial and axial displacement, reduce torsional and axial vibration, cut off the noise transmission path, and reduce the noise amplitude. Moreover, the cost of the manufacturing process of the flange is lower than that of the prior art, and the installation procedure is simpler when the flange is used for component installation.

[0034] In the following description, in order to clearly show the structure and working method of the present invention, many directional words will be used to describe, but "front", "rear", "left", "right", "outer", "inner" should be used Words such as ", "outward", "inward", "upper" and "lower" are to be understood as convenient terms, and should not be understood as restrictive terms. In addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com