Leaky coaxial cable clamp mechanism and leaky coaxial cable bearing system

A bearing system and leaky cable card technology, which is applied in the installation of cables, cables in tunnels, electrical components, etc., can solve problems such as time-consuming and labor-intensive fixture displacement, leaky cable loosening, etc., to improve safety performance, Elimination of axial displacement and reduction in the number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

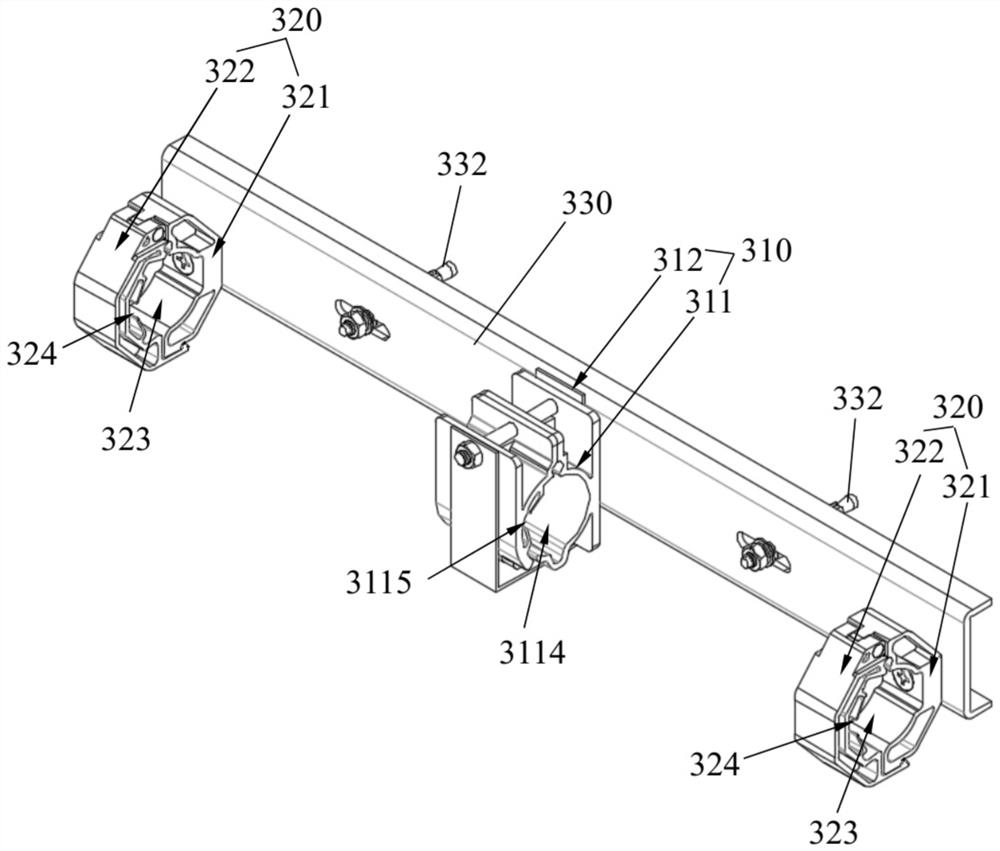

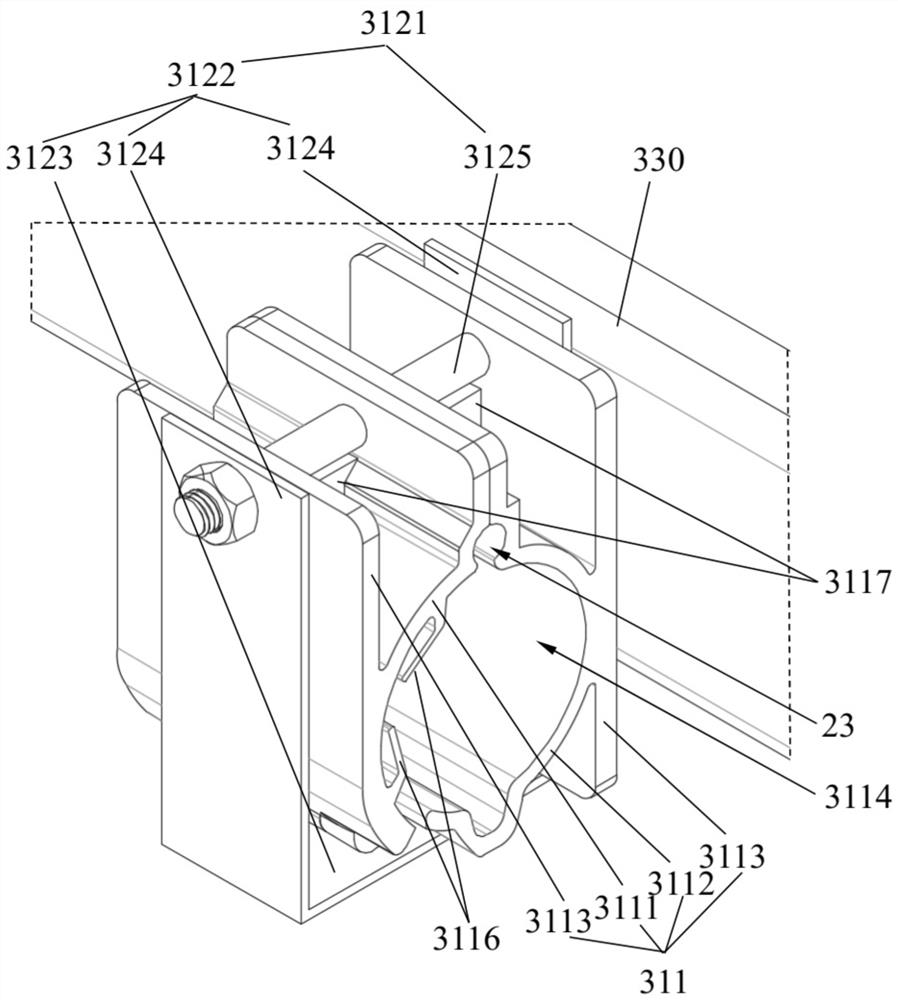

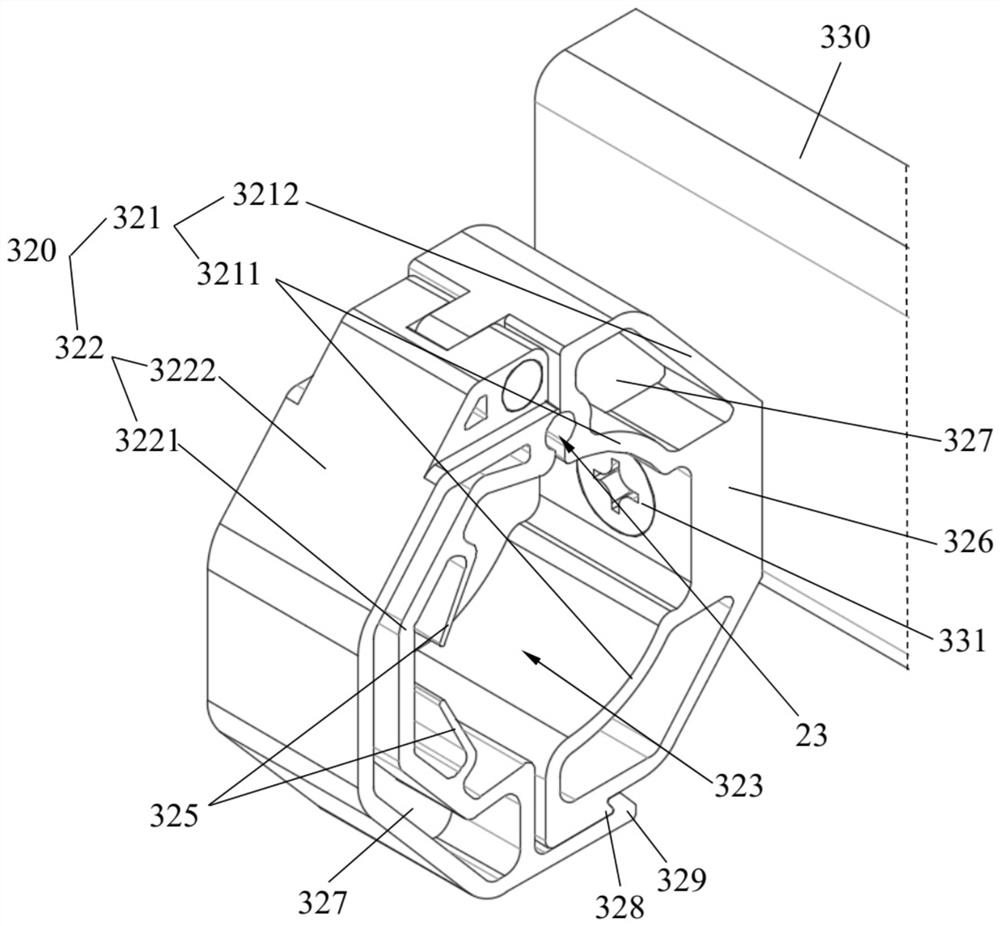

[0050] like figure 1 , Image 6 as well as Figure 8 As shown, the present invention provides a leaky cable clamp mechanism 300 including a support bracket 330, a main clamp 310 and at least two auxiliary clamps 320. The support bracket 330 is fixed on the installation wall 600 of the leaky cable 100. The fixture 310 and at least two auxiliary fixtures 320 are both fixed on the supporting bracket 330 , and at least two auxiliary fixtures 320 are arranged at intervals on both sides of the main fixture 310 , and the main fixture 310 is provided with a main card slot 3114 , the auxiliary clamp 320 is provided with auxiliary clamp slots 323, at least three parts of the leaky cable 100 are clamped in the main clamp groove 3114 and at least two auxiliary clamp grooves 323, and at least two auxiliary clamps 320 vibrate in the leaky cable 100 In the state where the cable 100 vibrates, elastic deformation can be generated to have the function of shock absorption and buffering.

[00...

Embodiment approach 2

[0068] The present invention also provides a leaky cable carrying system for carrying at least one leaky cable 100. The leaky cable carrying system includes a plurality of leaky cable clamping mechanisms 300 and at least one load-bearing cable 200. The plurality of leaky cable clamping mechanisms 300 are along the The leaky cables 100 are arranged at intervals in the axial direction, the load-bearing cables 200 are arranged in parallel with the leaky cables 100, and the load-bearing cables 200 are connected with the outer wall of the leaky cables 100, and the two ends of at least one load-bearing cable 200 are installed with The walls 600 are connected. The specific structure, working principle and beneficial effects of the leaky cable clamp mechanism 300 in this embodiment are the same as those of the leaky cable clamp mechanism 300 in the first embodiment, and are not repeated here.

[0069] In the leaky cable bearing system of the present invention, the leaky cable 100 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com