Photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system

A fuel cell and coupling system technology, applied in the field of photocatalysis, can solve the problems of limiting the practical application of PFC, poor battery performance, and low mass transfer rate, and achieve good biocompatibility, simple structure, and short contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

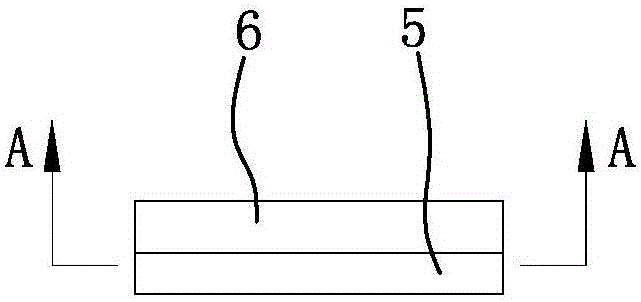

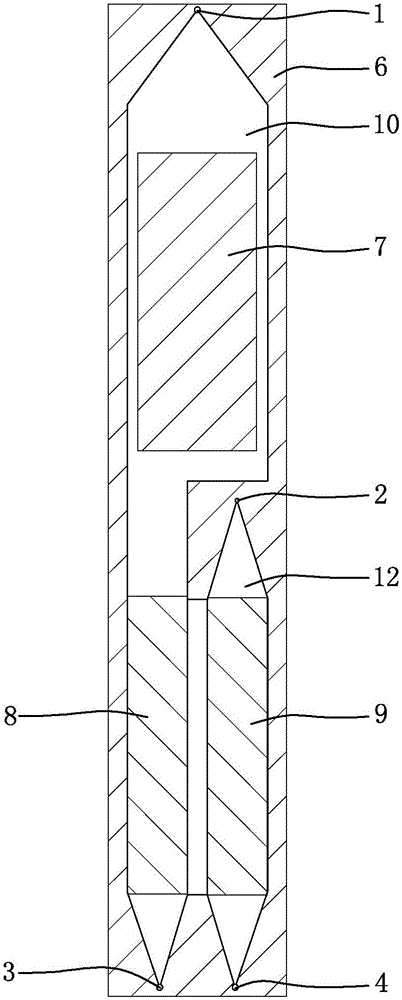

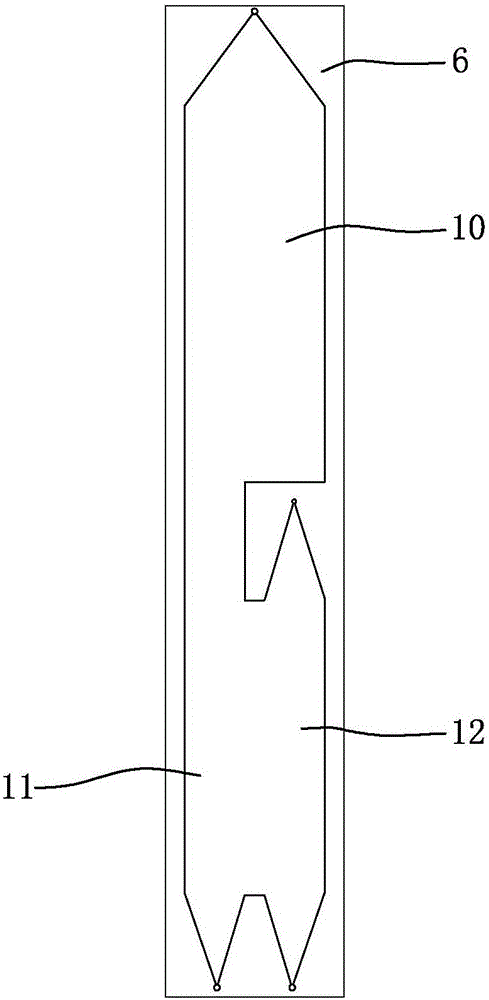

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the reaction chamber 6 is made of non-conductive material, and is preferably cast from PDMS. Of course, as an equivalent replacement, the reaction chamber 6 can also use other polymer materials in the field of microfluidics. A groove-shaped cavity is provided on the reaction chamber 6, and the cavity is sealed by the conductive glass 5 covered on the reaction chamber 6. The conductive glass 5 is preferably FTO conductive glass, and is fixedly connected to the reaction chamber 6. Together. The front part of the cavity of the reaction chamber body 6 is the reaction chamber 10, and the rear part is a cathode chamber 11 and an anode chamber 12 arranged side by side and communicated with each other. The front end of the cathode chamber 11 communicates with the rear end of the reaction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com