Static cracking agent radial expansion pressure test method

A technology of static breaking agent and radial expansion, which is applied in the field of geotechnical engineering, can solve the problems of complex pasting process, error of test results, and great influence of measurement results, etc., and achieve the advantages of simple pasting method, accurate expansion pressure and reduced error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with drawings and embodiments.

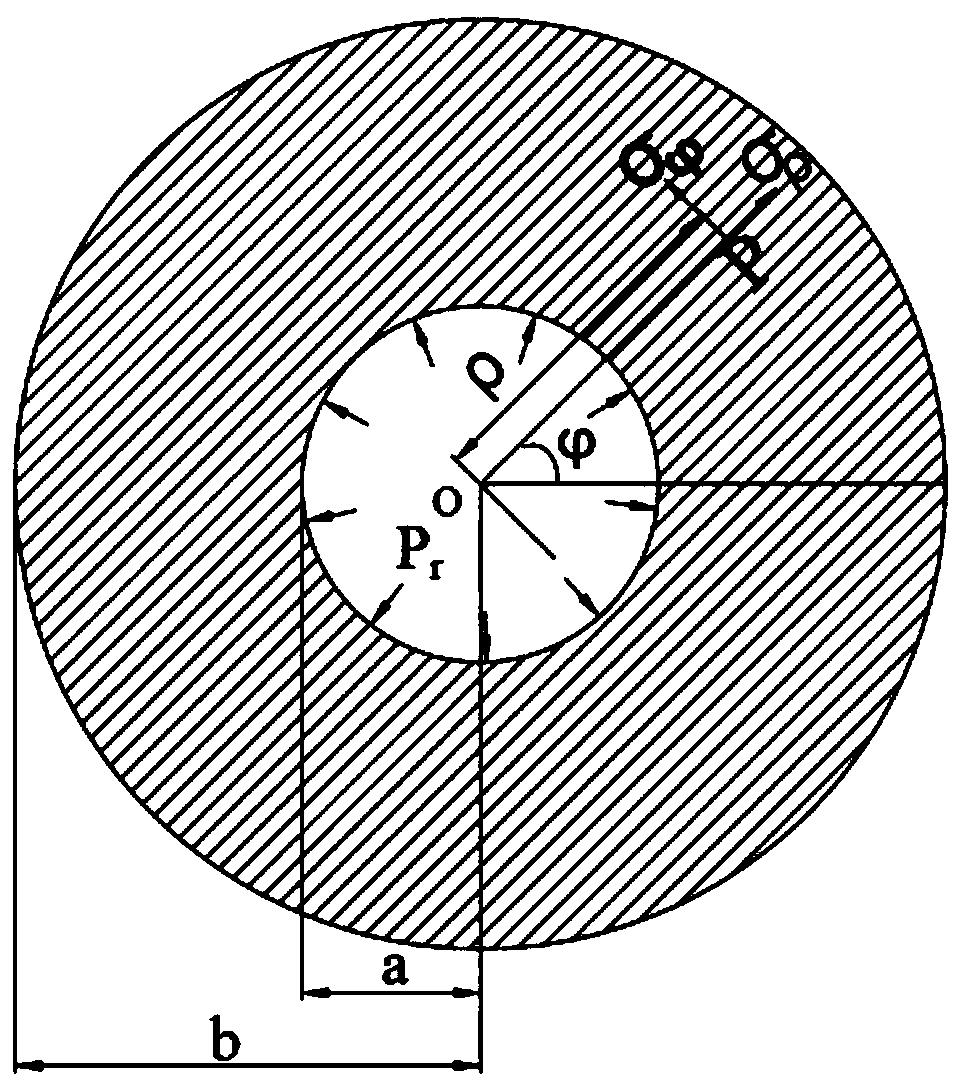

[0060] The present embodiment is to measure the radial expansion pressure of the slurry static breaker with a water content of 32% by the method of the present invention, and its specific steps are as follows:

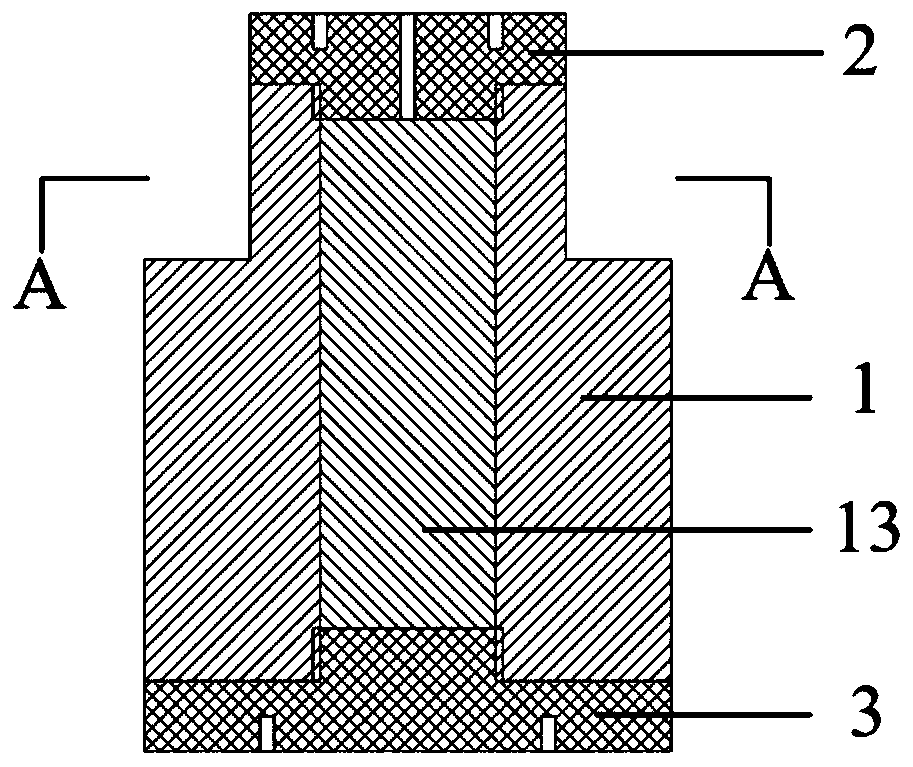

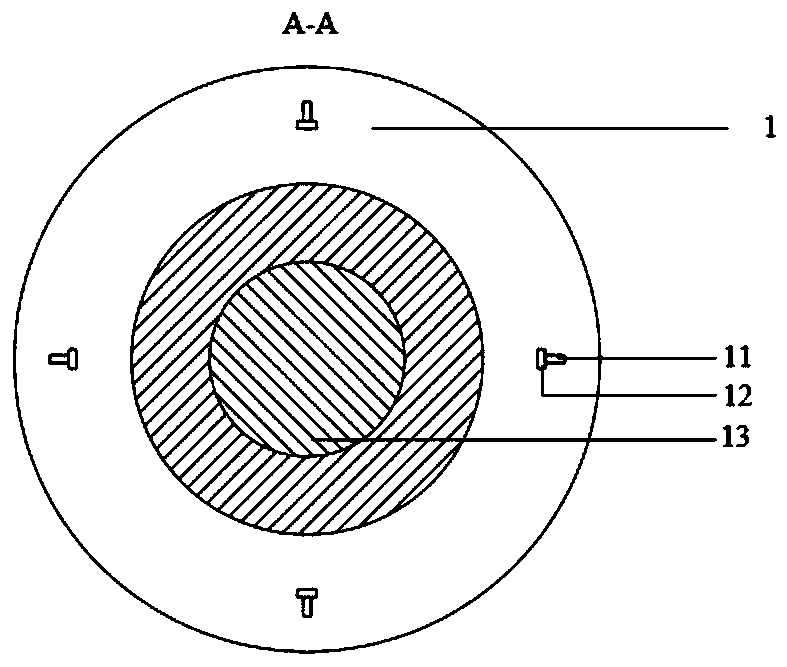

[0061] Step 1, prepare the metal cylinder 1 for testing and the upper end cap 2 and the lower end cap 3 of the closed metal cylinder

[0062] combine figure 2 , image 3 and Figure 4 1. The metal cylinder 1 is processed with 7075-T7365 aluminum alloy material. The elastic modulus of the material is E=38Gpa, and Poisson’s ratio μ=0.25. It is precisely processed into a cylindrical shape with a central through hole by using a numerical control machine tool. The outer surface of the metal cylinder is Radius b = 77.5mm, inner radius a = 21.5mm, total height of the metal cylinder H = 170mm, a convex step is processed on the upper end of the metal cylinder, the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com