Process for bonding metal circular tube rubber lining

A round tube and metal technology, which is applied in the field of metal round tube rubber lining bonding technology, can solve the problems that rubber sheets cannot be evenly bonded, and cannot be knocked, and achieve the effect of improving bonding quality and labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

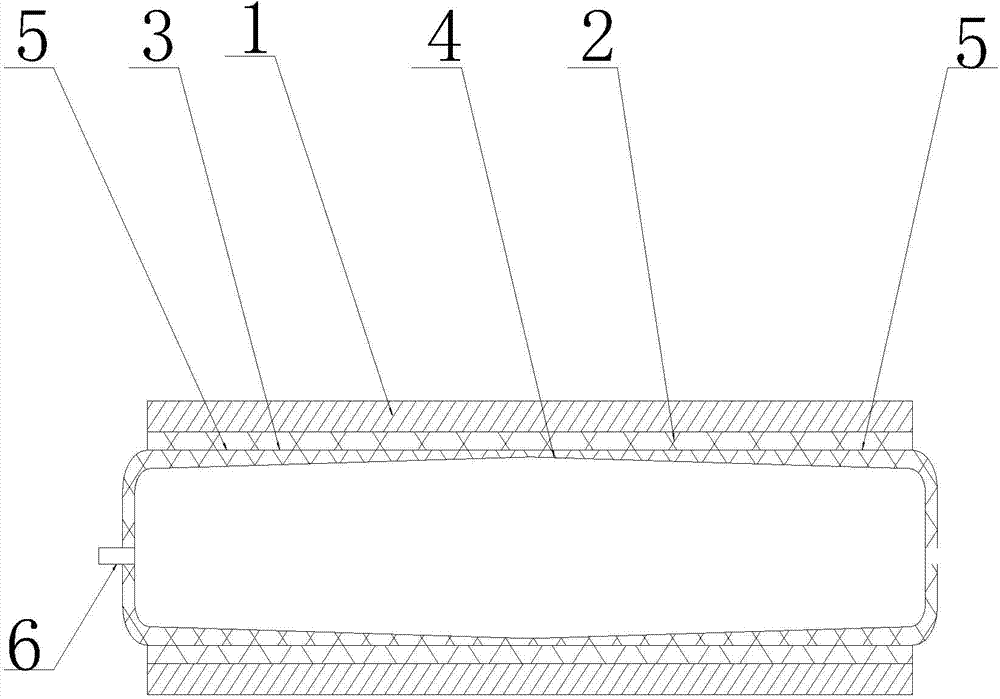

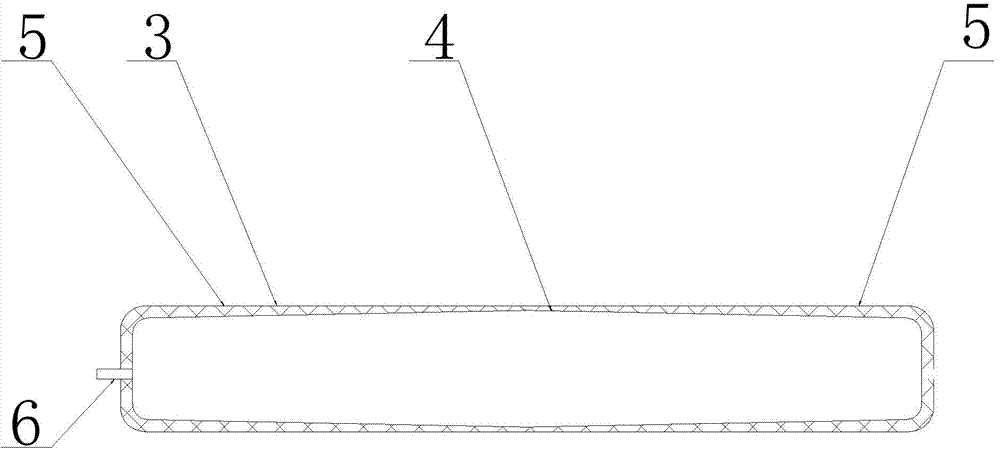

[0022] Such as figure 1 Shown, a metal circular tube rubber lining bonding process, comprising the following steps:

[0023] Step (1): Sandblasting the inner wall of the metal circular tube 1, and cleaning the surface of the inner wall;

[0024] Step (2): brush the primer on the inner wall of the metal round tube 1 after the treatment in step (1), wait for the primer to dry, and then brush the adhesive;

[0025] Step (3): Put the prefabricated cylindrical rubber plate 2 into the metal circular tube 1;

[0026] Step (4): Put the cylindrical airbag 3 with both ends closed into the cylindrical rubber plate 2, the wall thickness of the cylindrical airbag 3 gradually increases from the middle thin-walled part 4 to the two ends, and one end A valve is connected; the thin-walled part 3 is located in the middle of the metal tube 1 ; that is, the two sides of the middle thin-walled part are thick-walled parts 5 .

[0027] Step (5): Inflate the airbag 3 through the air valve 6, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com