Latexing machine for edgefolds of leather shoe upper

A technology for shoe uppers and leather shoes, which is applied to the field of leather shoe upper folding and gluing machines, can solve the problems of troublesome manual operation, waste of time, waste of materials, etc., and achieve the effects of reducing labor intensity, preventing volatilization, and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

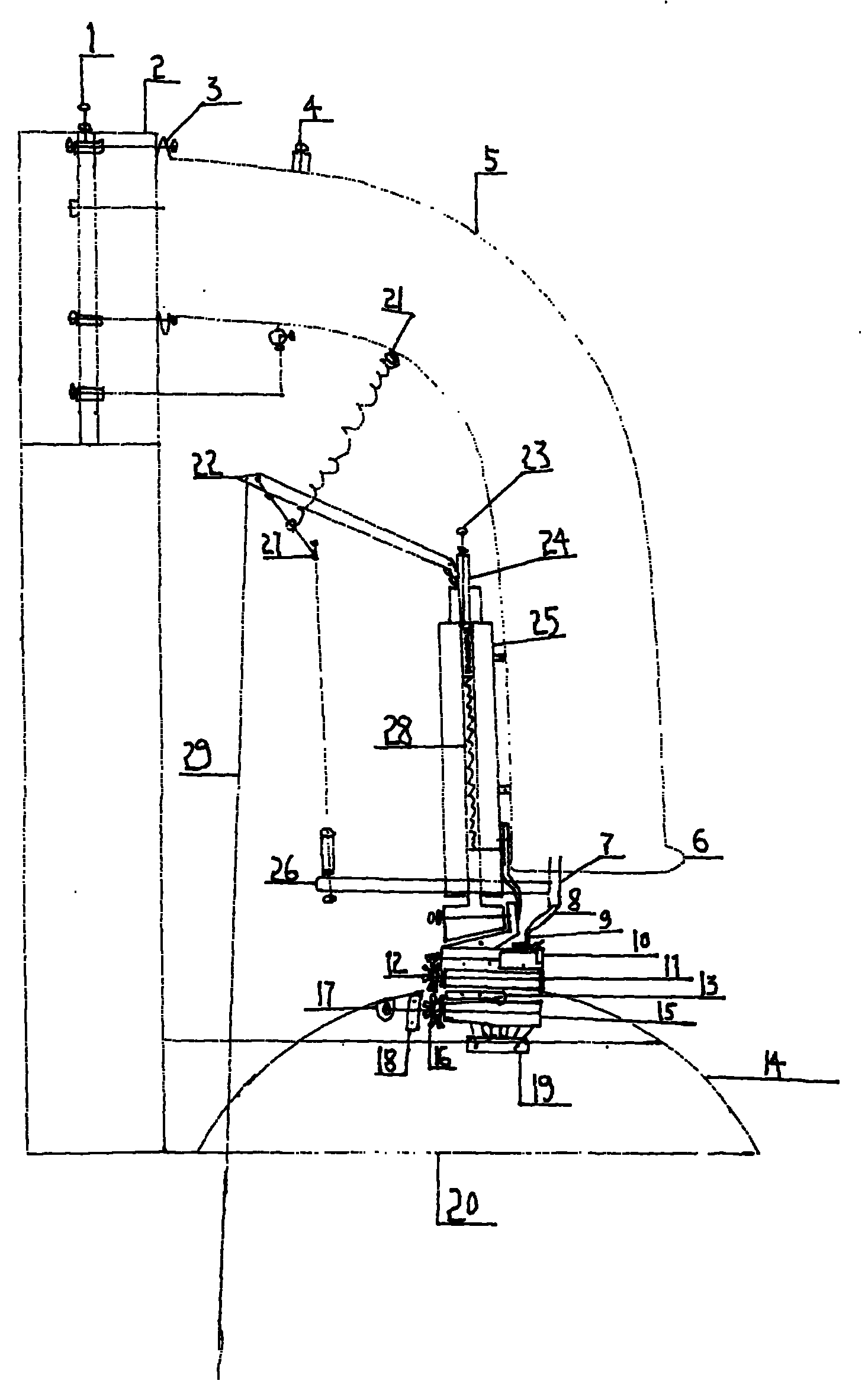

[0014] It includes the glue flow rate mechanism, the glue flow mechanism, the glue transmission mechanism, and the bottom plate is installed on the frame with the speed regulating motor and the reducer.

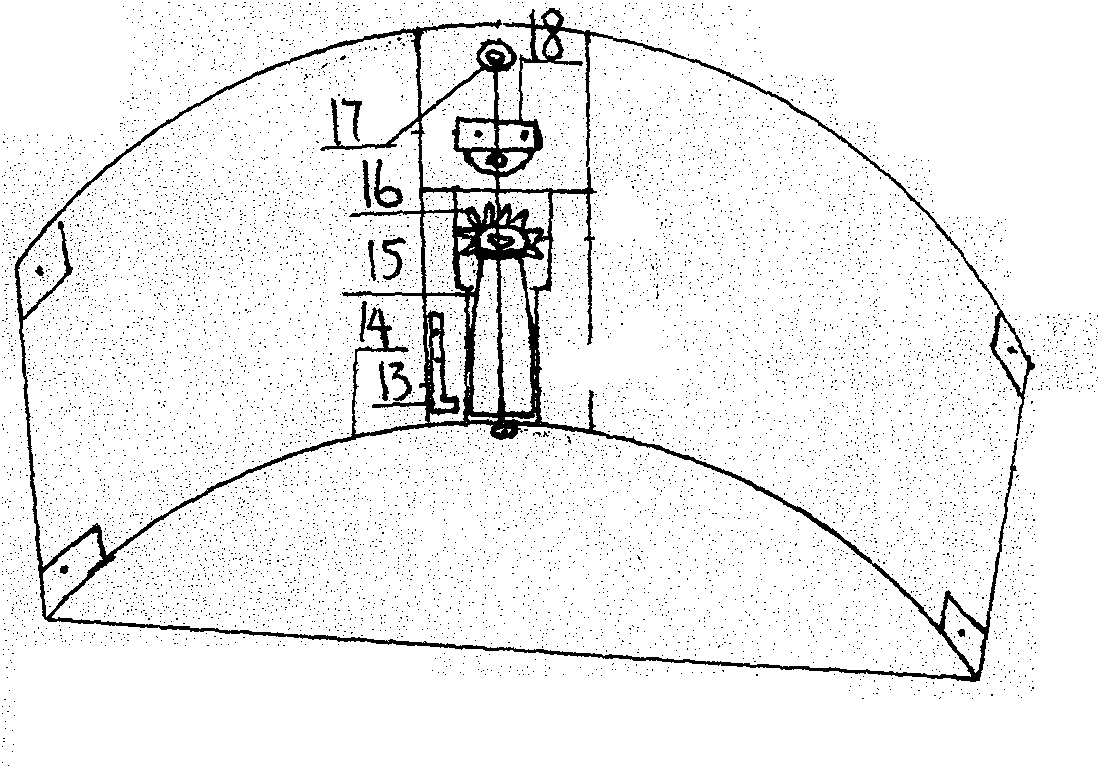

[0015] The main structure of the whole machine is: it includes flow rate mechanism, flow mechanism, transmission mechanism; flow rate mechanism includes: adjusting screw 1, vertical plate 2, upper tube cover 3, glue inlet 4, rubber tube 5, lower tube cover 6, large Valve 7, rubber hose 8; flow mechanism includes: small valve 9, plastic storage box 10, spring 21, upper handle 22, adjustment screw 23, lifting rod 24, hole column 25, lower handle 26, pull rod 27, lifting rod 28. Step on the line 29; the transmission mechanism includes: small roller 11, pinion gear 12, blocking plate 13, material passing shell 14, large roller 15, large gear 16, belt pulley 17, bearing 18, brushes 19 installed on both sides of the roller, Bottom plate 20.

[0016] The specific structural relatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com