Screw-extrusion attaching device for strain gauge patching

A technology of screw extrusion and strain gauges, applied in the field of sensing and detection, can solve the problems of not easy to drive away air bubbles and impurities, inability to ensure the accuracy of strain gauges, uneven patching by hand, etc. Efficient, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

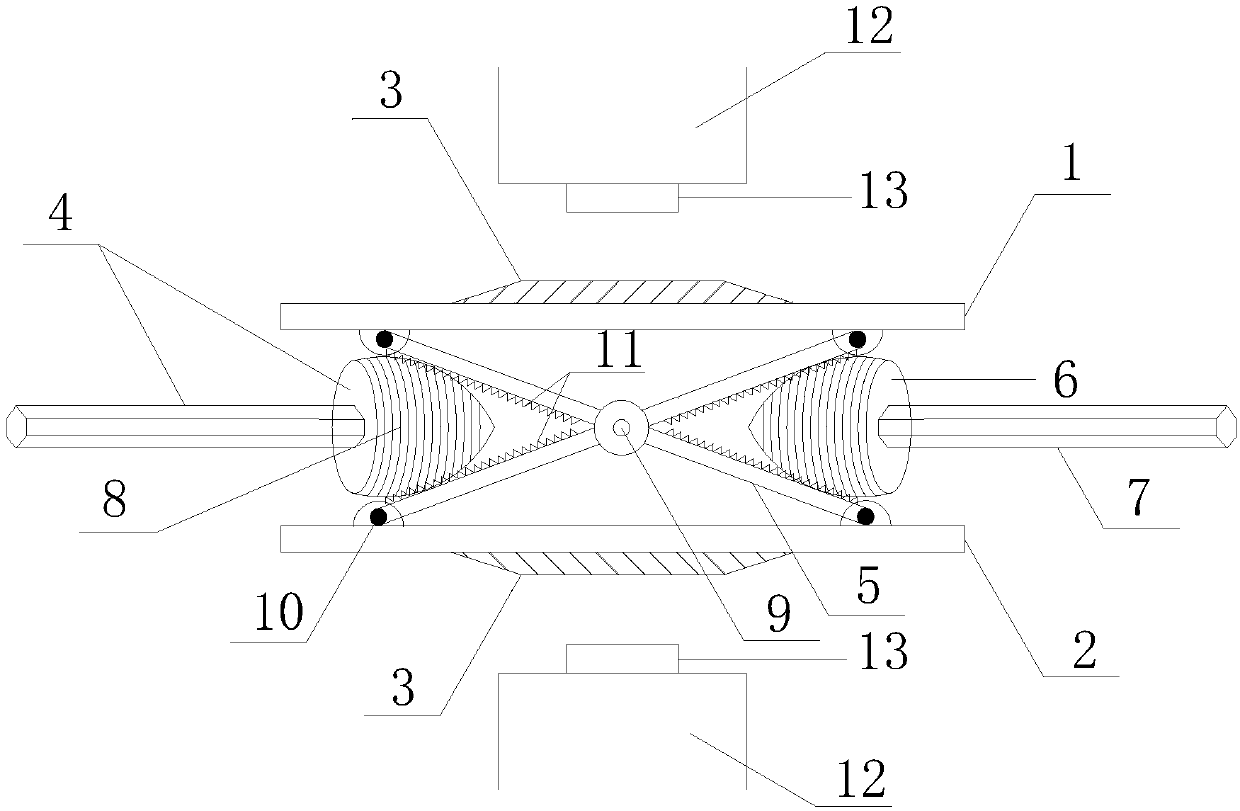

[0011] figure 1 Shown is a spiral extrusion attachment device for strain gauge patches, which consists of an upper plate 1, a lower plate 2, a platform 3, a threaded push rod 4, and a support rod 5.

[0012] The upper plate 1 and the lower plate 2 are interlacedly connected by two support rods 5, and as the angle between the two support rods 5 is changed, the relative movement of the upper plate 1 and the lower plate 2 can be realized; the platform 3 is set as a trapezoid, respectively Welded on the outer surfaces of the upper plate 1 and the lower plate 2, the surface is flat and smooth, and is used to compress the strain gauge 13; the threaded push rod 6 includes a hexagonal rod 7 and a threaded cone 8; the hexagonal rod 7 is a hexagonal prism, It is convenient to clamp the wrench; the threaded cone 6 and the hexagonal rod 7 are welded together, and the surface of the threaded cone 6 is provided with an external thread 8; the support rod 5 is two, the middle is connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com