Keyboard adhesive product automatic assembly equipment and assembly process adopting same

An automatic assembly and product technology, applied in the direction of manufacturing tools, manipulators, electrical components, etc., can solve the problems of low product yield and production efficiency, cannot meet market demand, and consume a lot of manpower, so as to achieve high assembly accuracy and shorten the product process cycle, saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

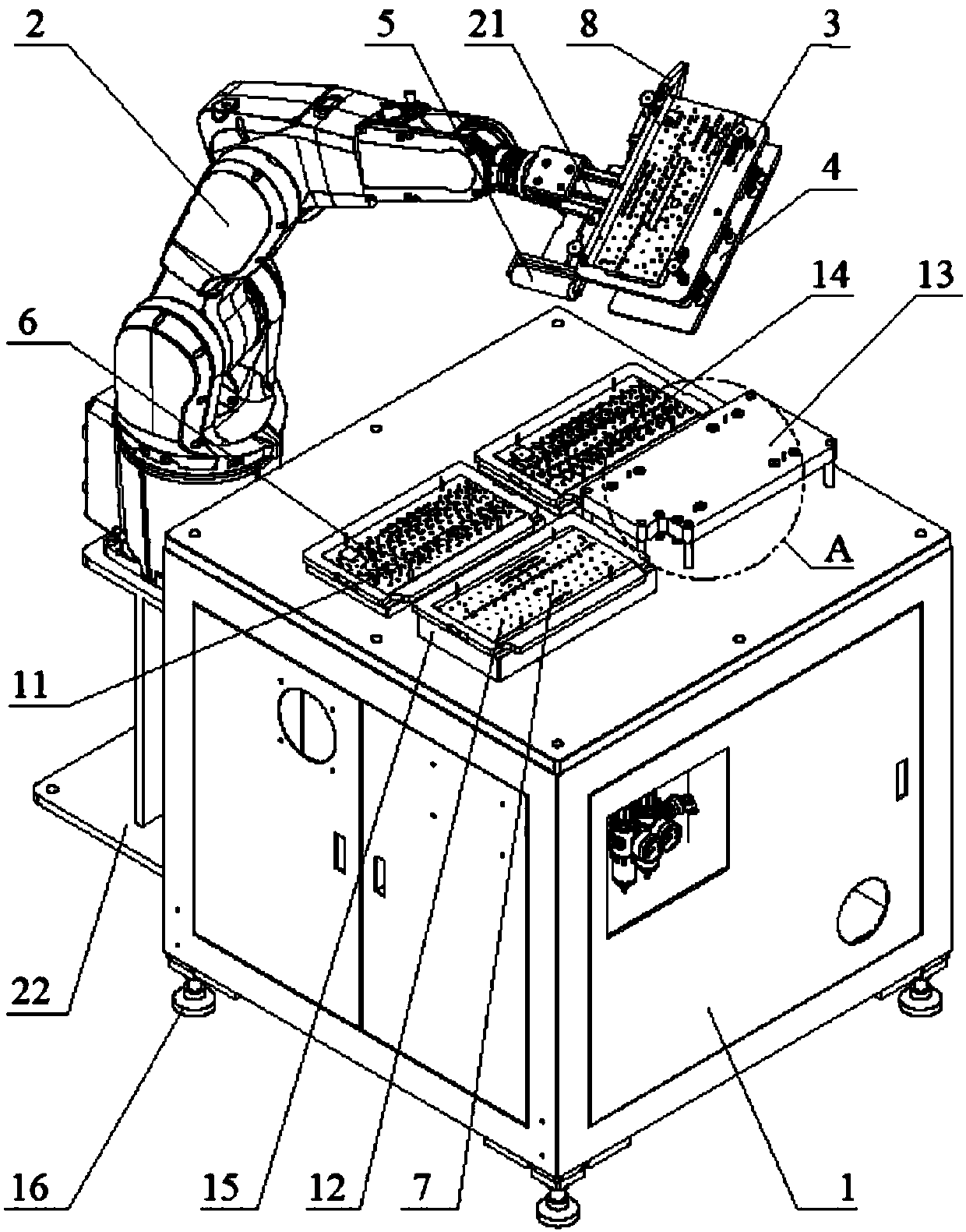

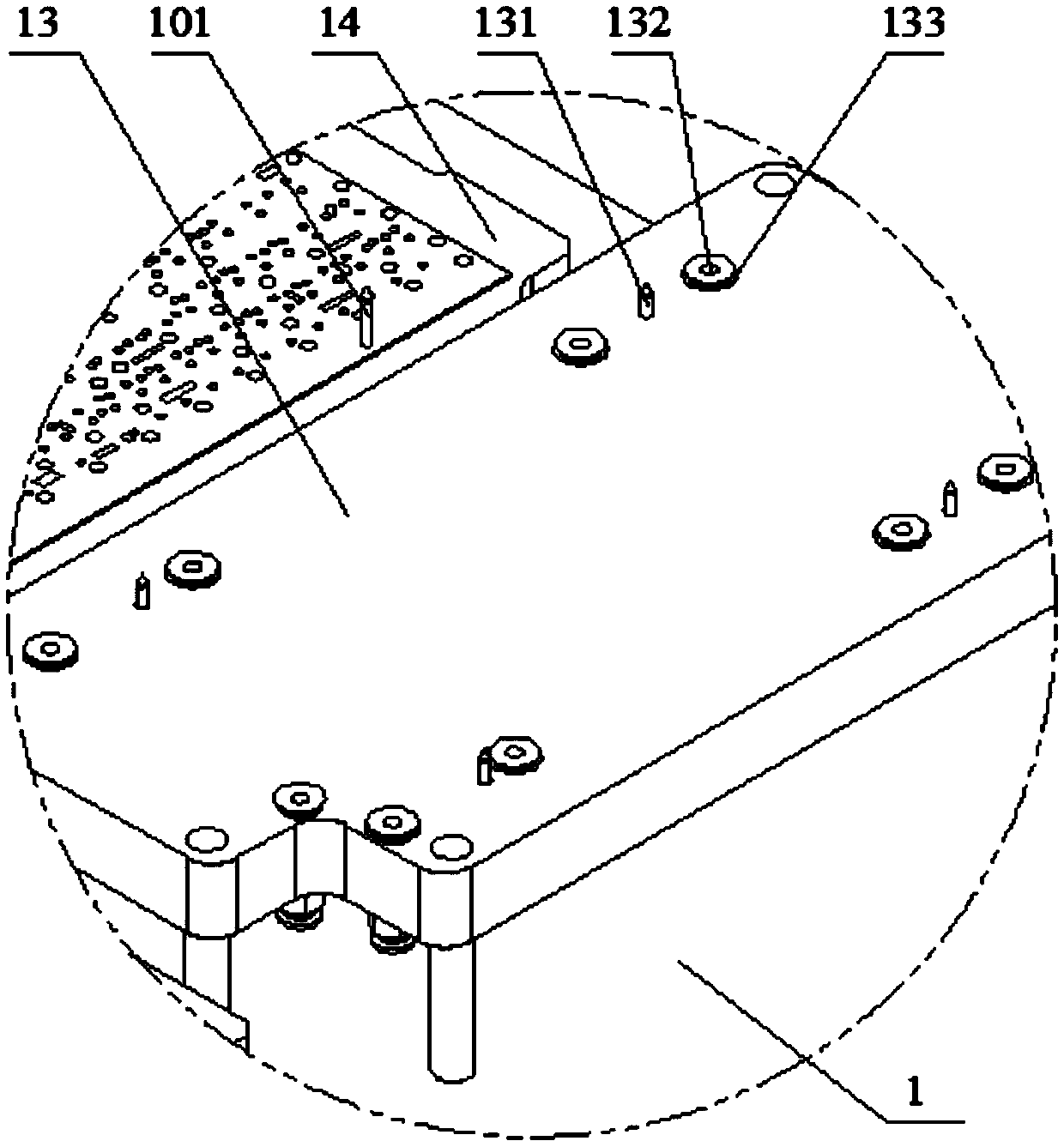

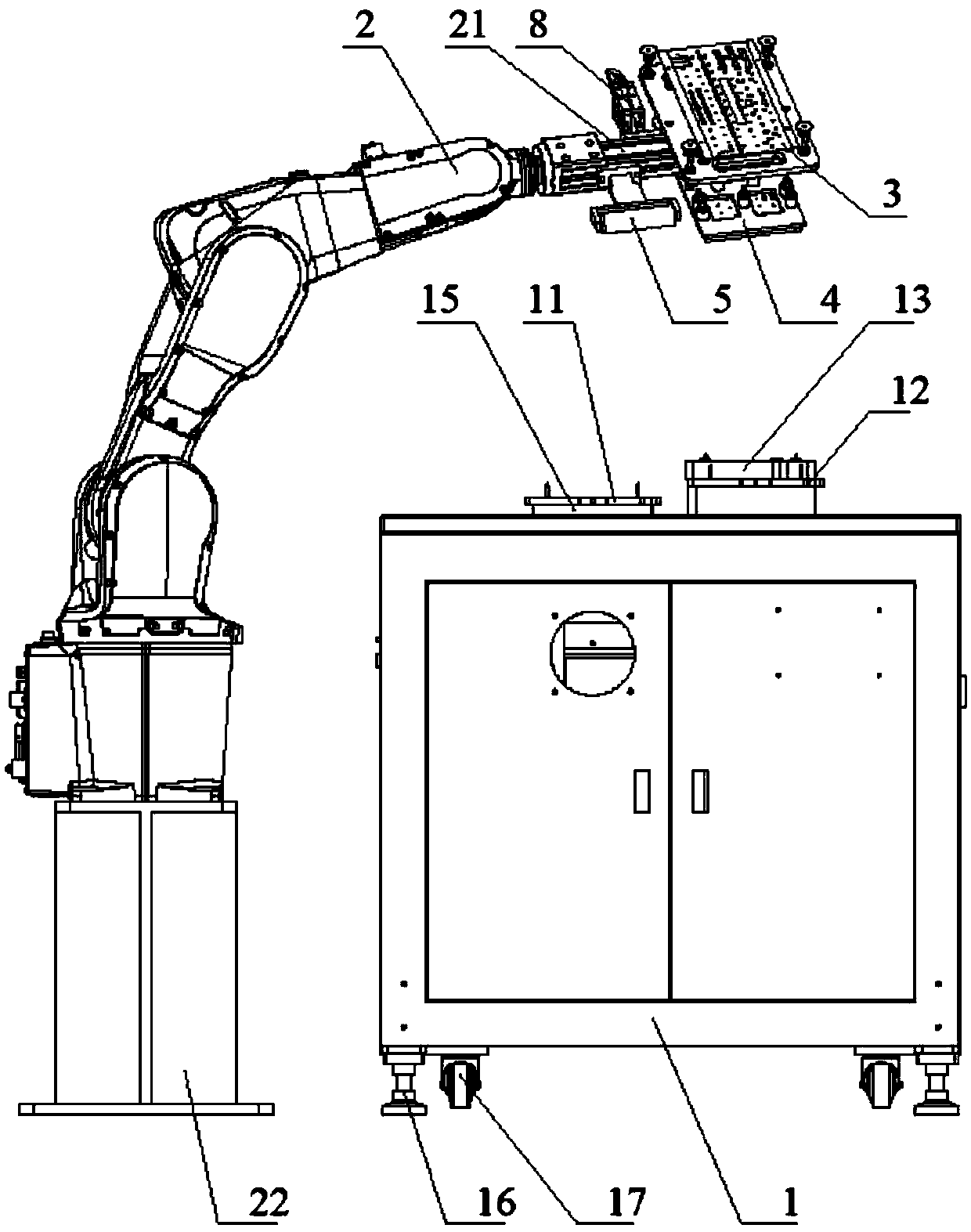

[0038] A kind of keyboard glue product automatic assembly equipment, such as Figure 1~6 As shown, the machine 1 is included, the electric control system and the gas circuit system are arranged in the machine 1, the table of the machine 1 is provided with a first jig 11 for placing the first film material 6, for placing the second film material 7, the second jig 12, the laminating assembly table 13 and the blanking jig 14, the table surface of the laminating assembly table 13 is provided with some first positioning pins 131 and some first vacuum suction cups 132, the first positioning pins 131 and The quantity and distribution of the first vacuum suction cups 132 are determined according to the size specifications of the laminated and assembled film materials. The first film material 6 is usually a semi-finished product after aluminum foil, double-sided adhesive film and screen film are assembled and bonded. The second film material 7 It is usually a PET film, and usually the ...

Embodiment 2

[0050] A kind of assembly process that applies above-mentioned assembly equipment to carry out keyboard glue product, comprises the following steps:

[0051] Step 1, the first film material and the second film material are laminated on the first jig and the second jig respectively;

[0052] Step 2, the manipulator grabs the first film material through the second vacuum suction cup of the first material retrieving device, and then the manipulator turns the mounting frame 180°, and grabs the second film material through the fourth vacuum suction cup of the second material reclaiming device;

[0053] Step 3: The manipulator transfers the second film material to the laminating assembly table through the second material picking device. When the second film material is 2 to 4 mm away from the table surface of the laminating assembly table, the fourth vacuum suction cup breaks the vacuum to make the second film The material falls freely and is positioned and placed by the first posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com