Patents

Literature

34results about How to "Improve shipment quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

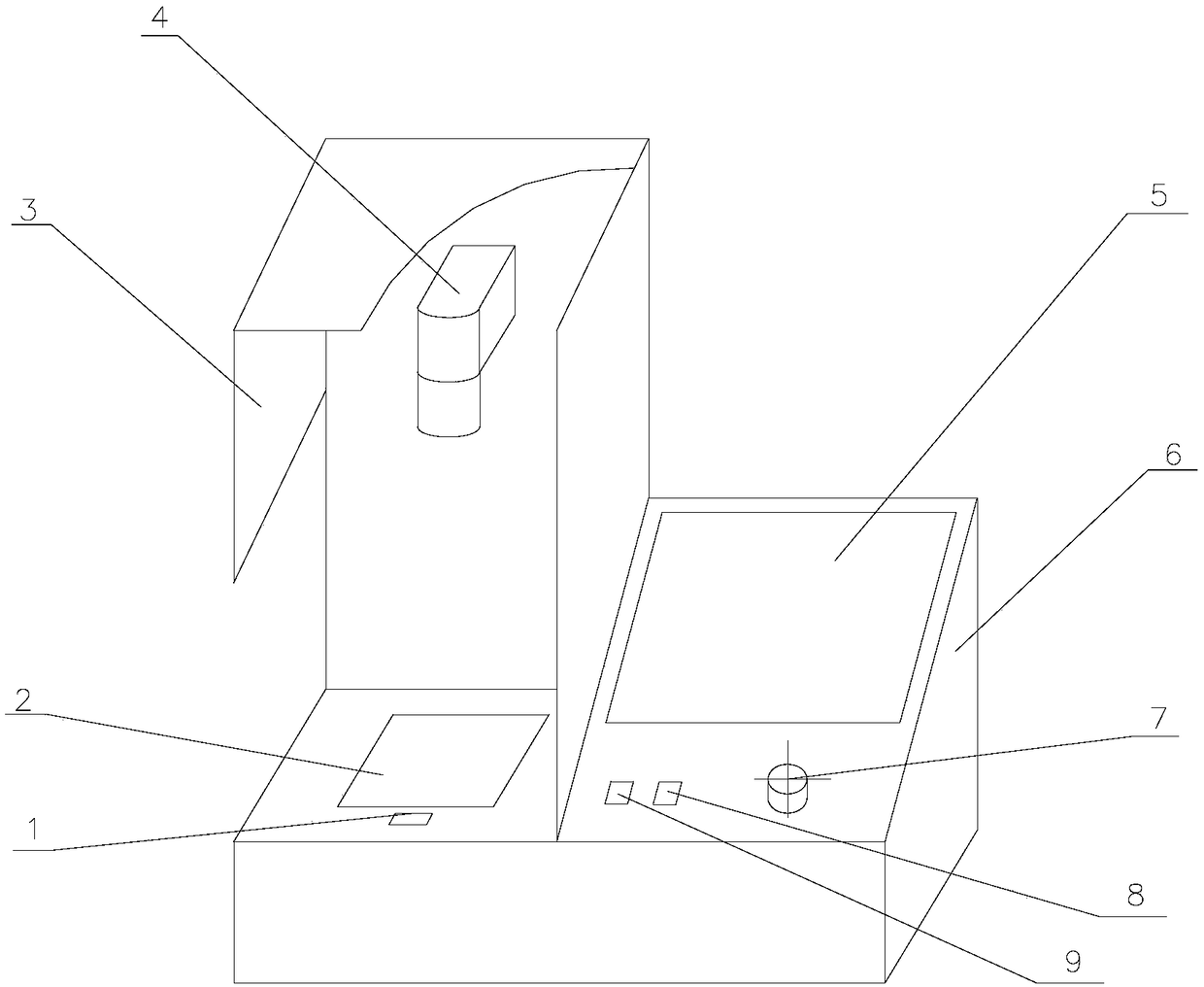

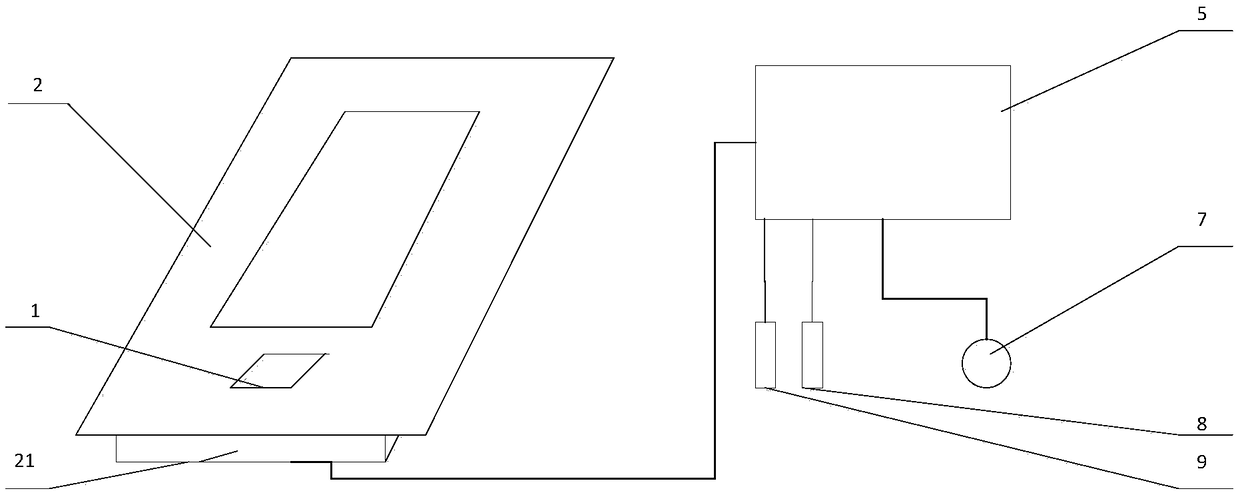

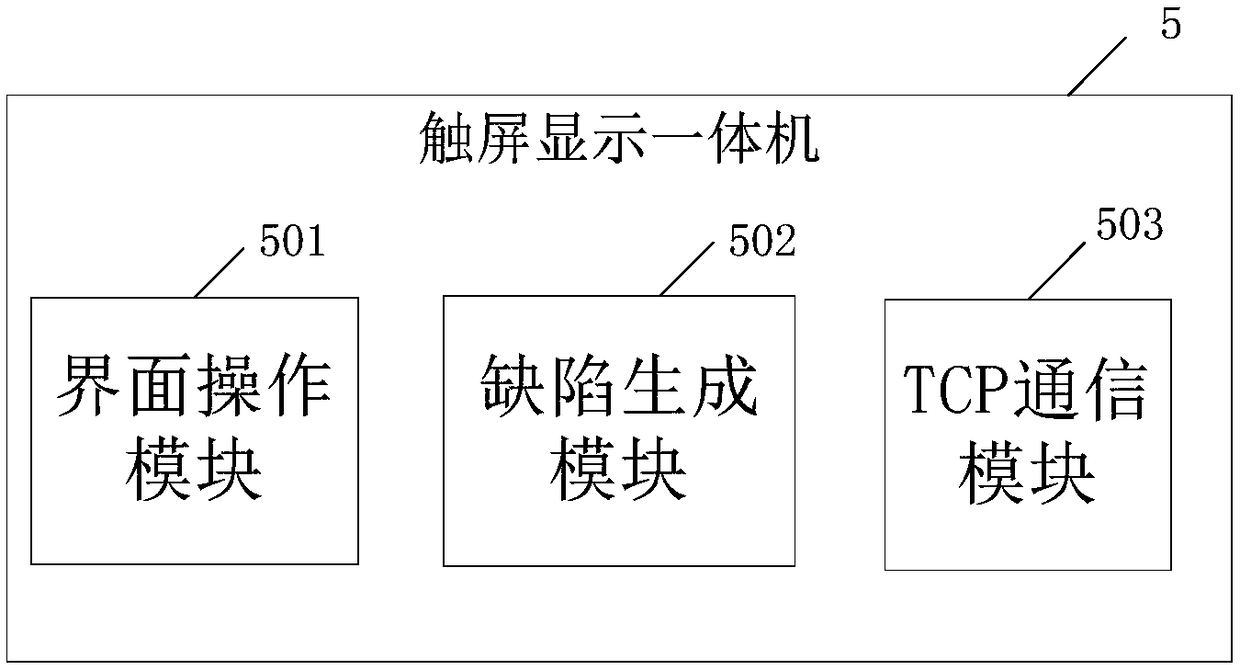

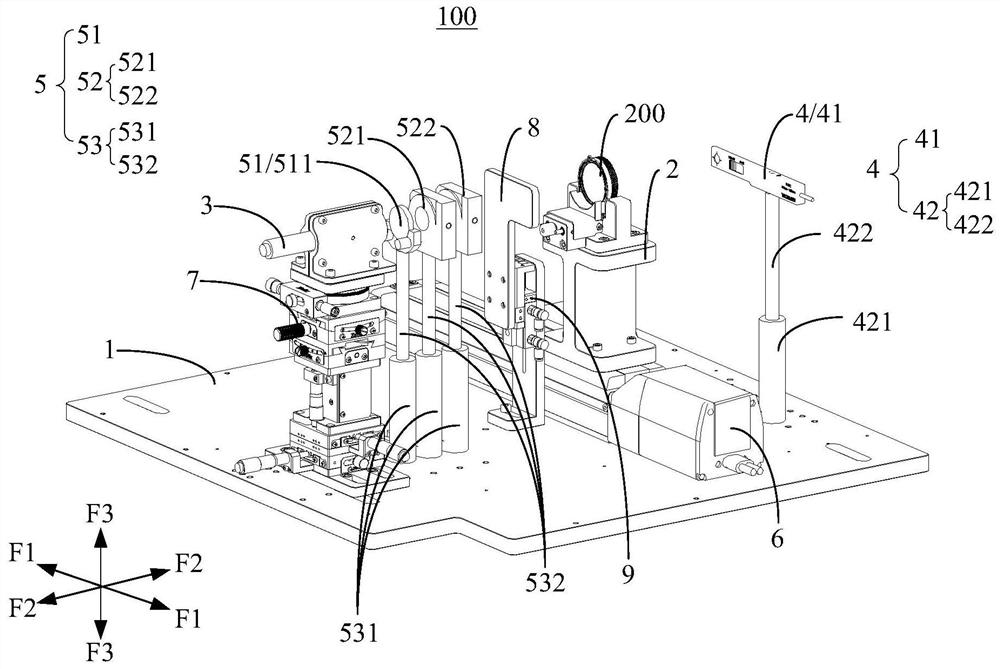

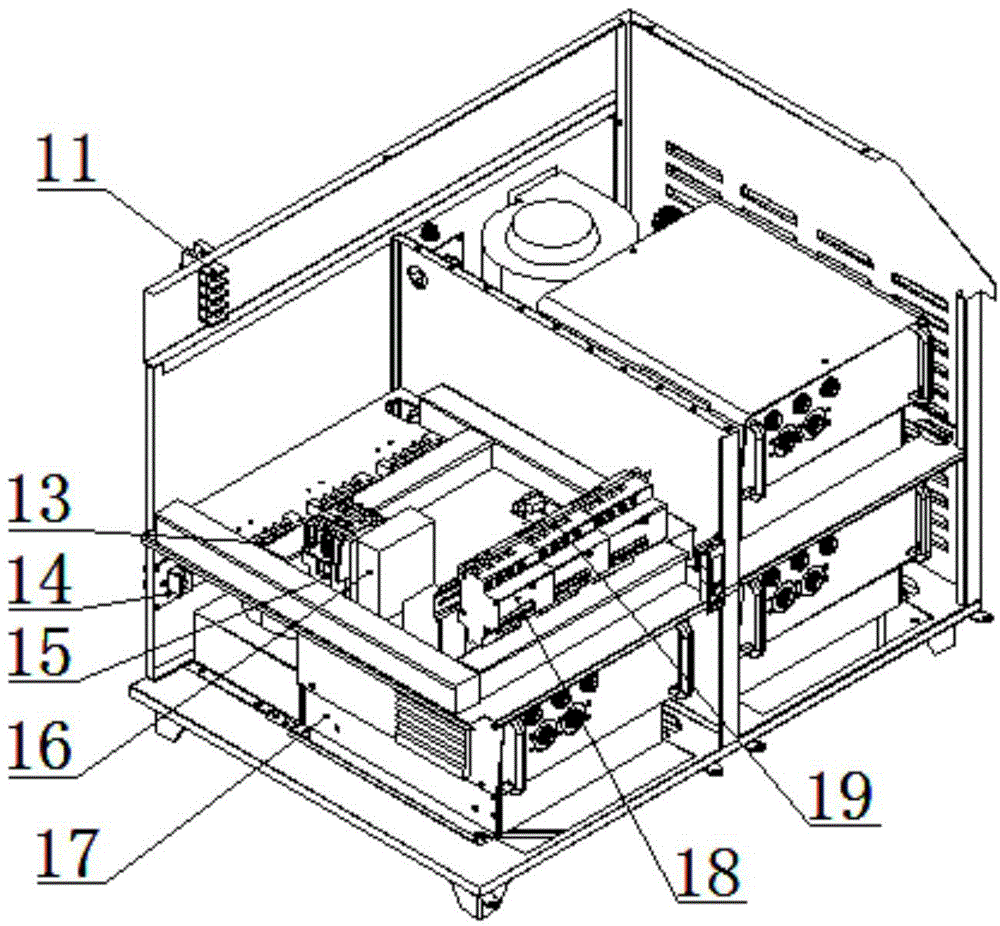

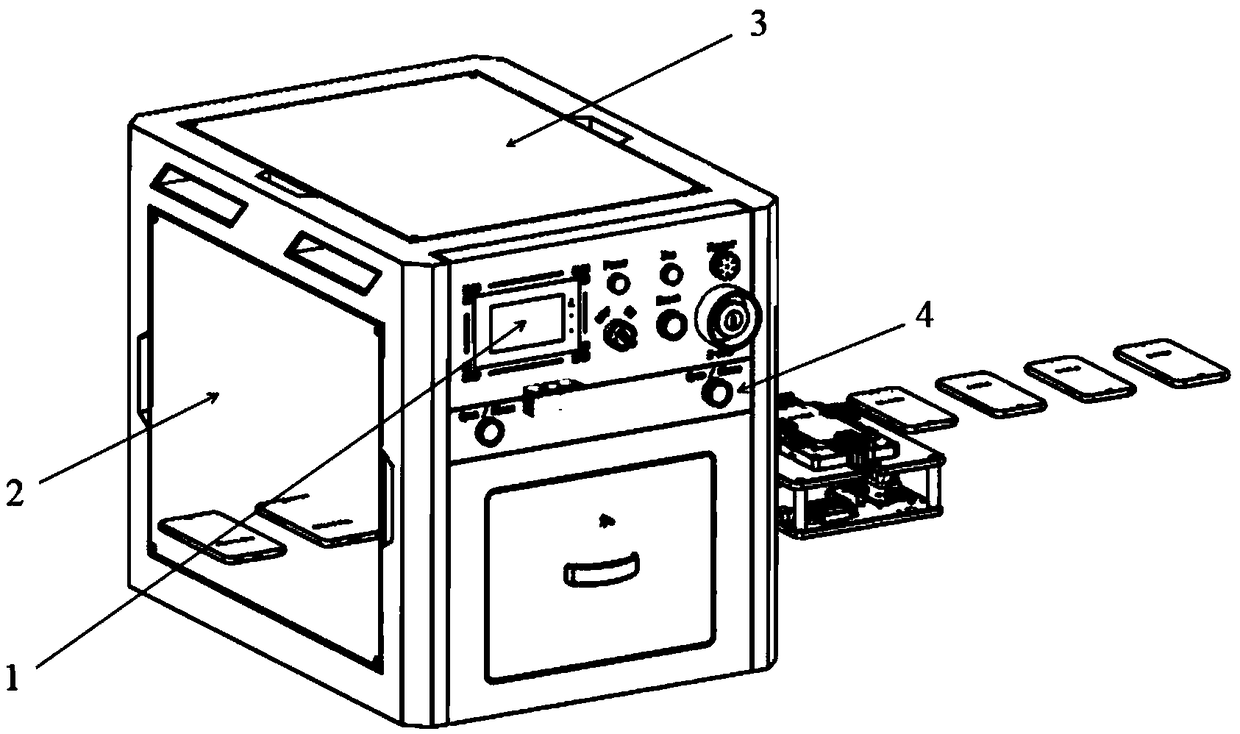

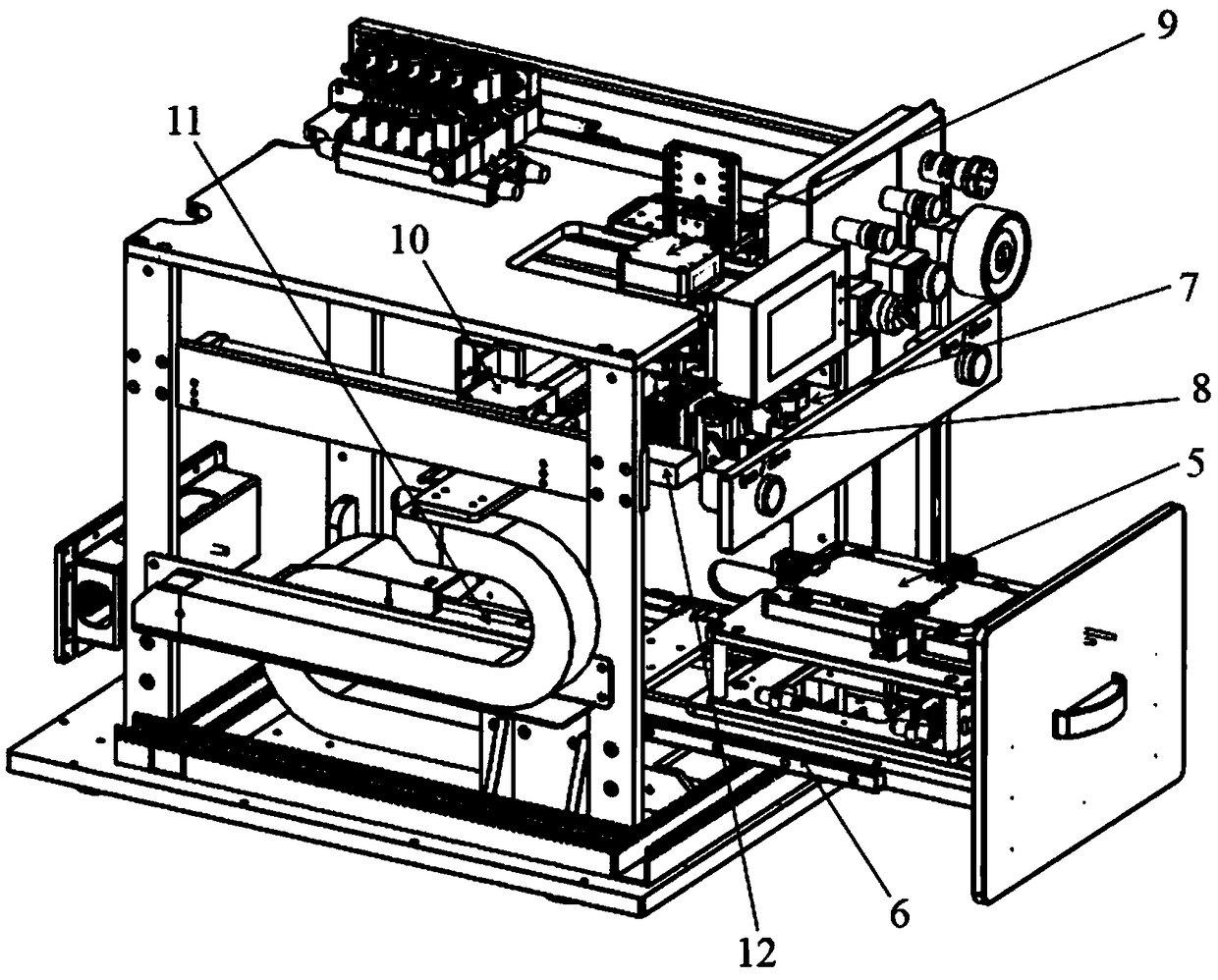

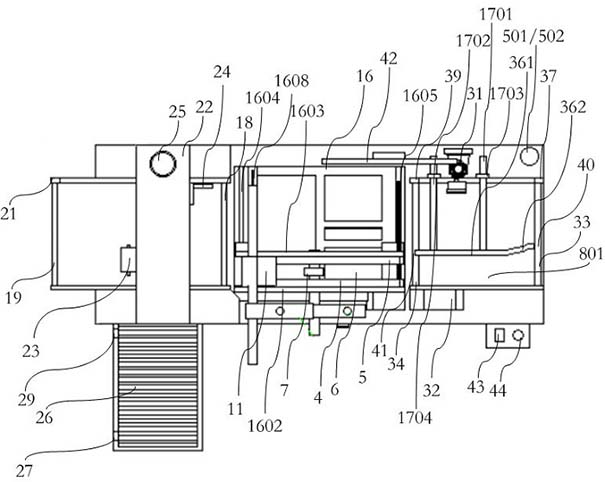

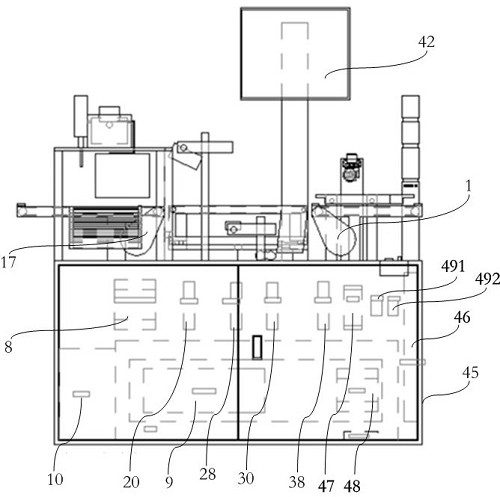

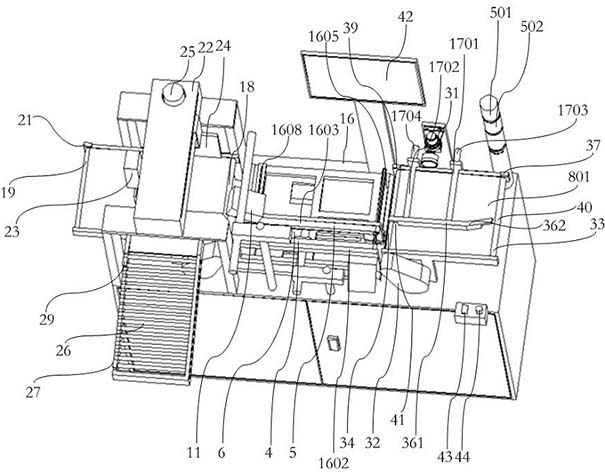

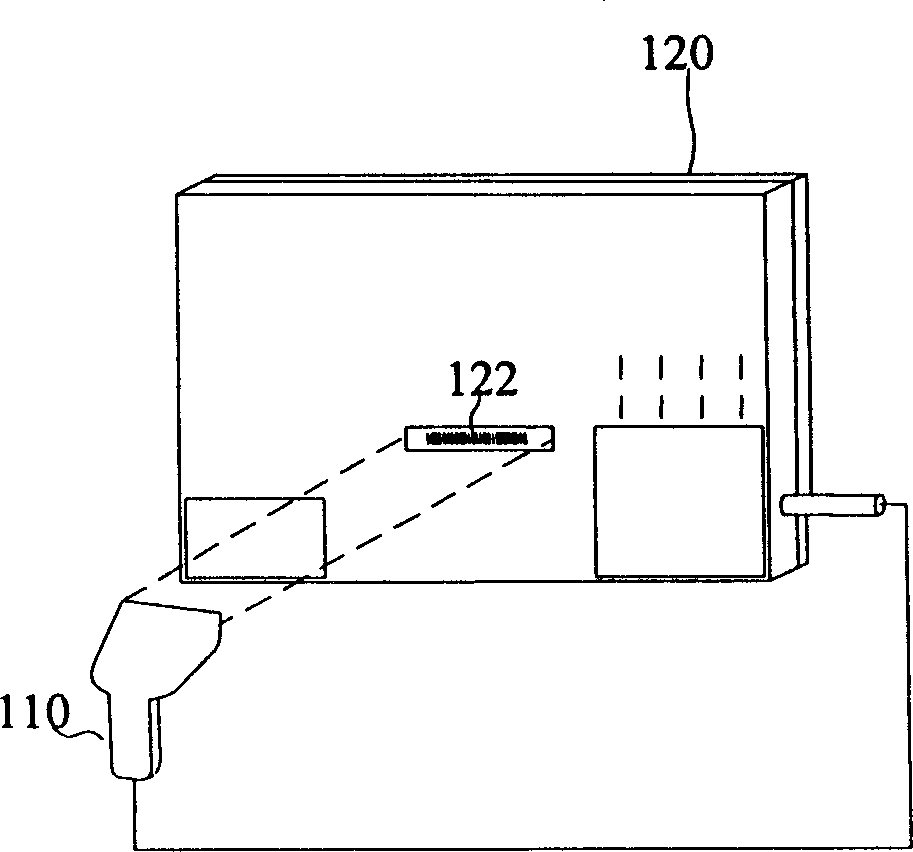

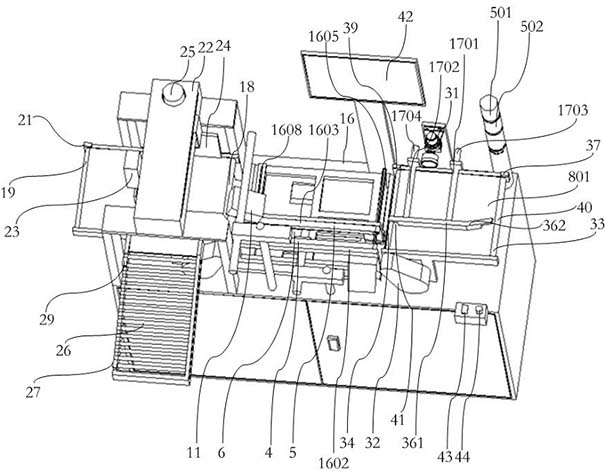

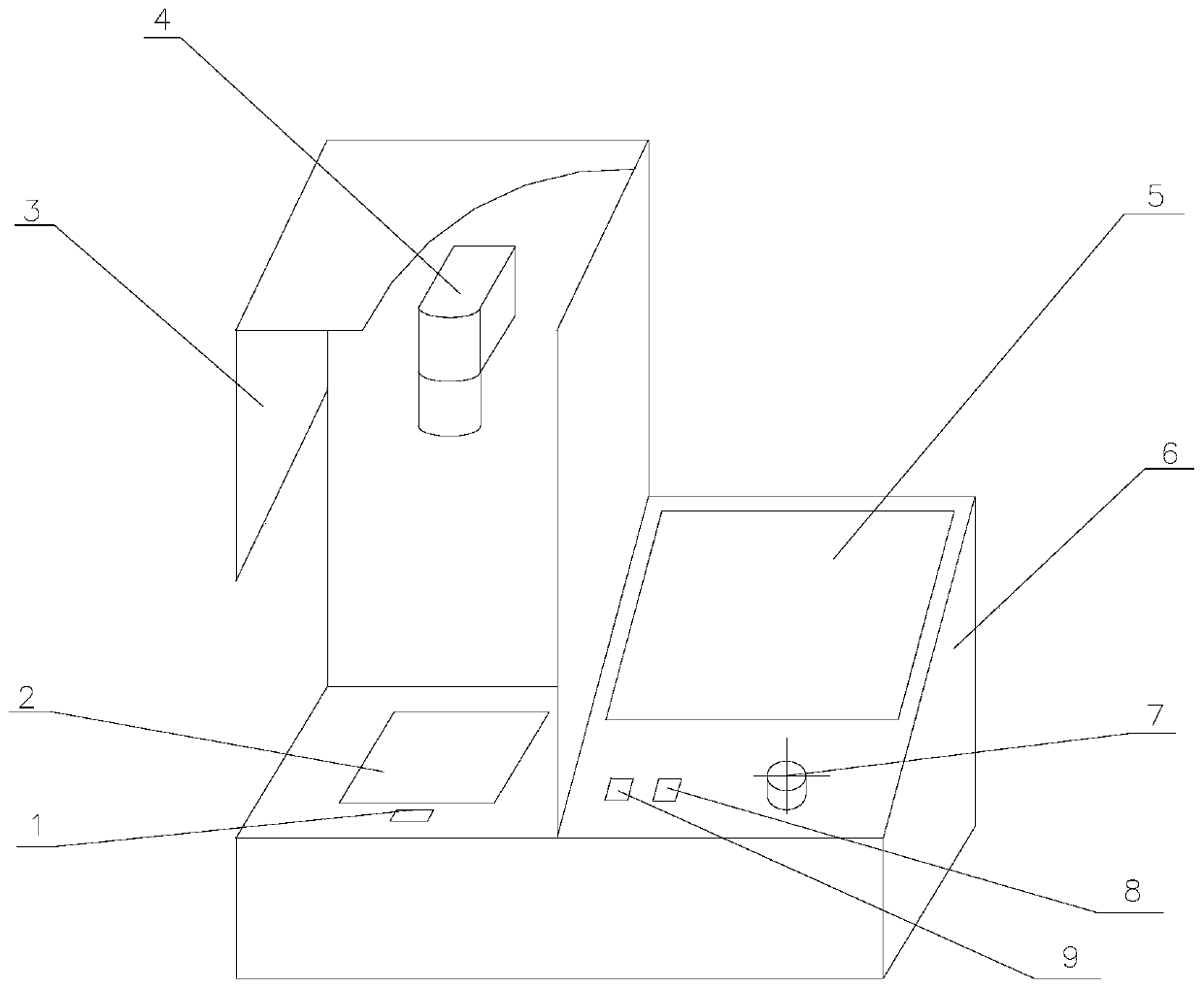

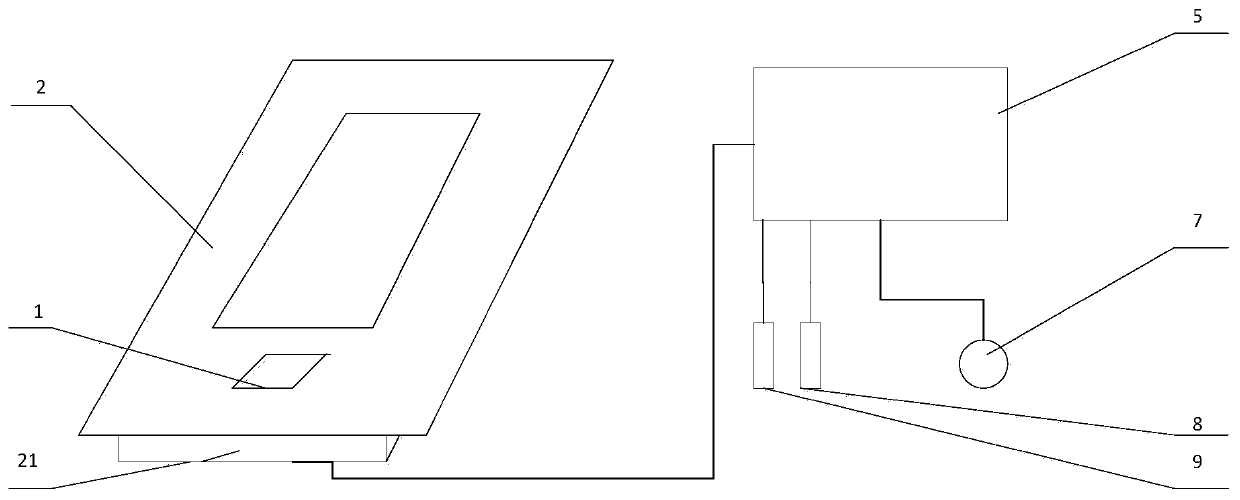

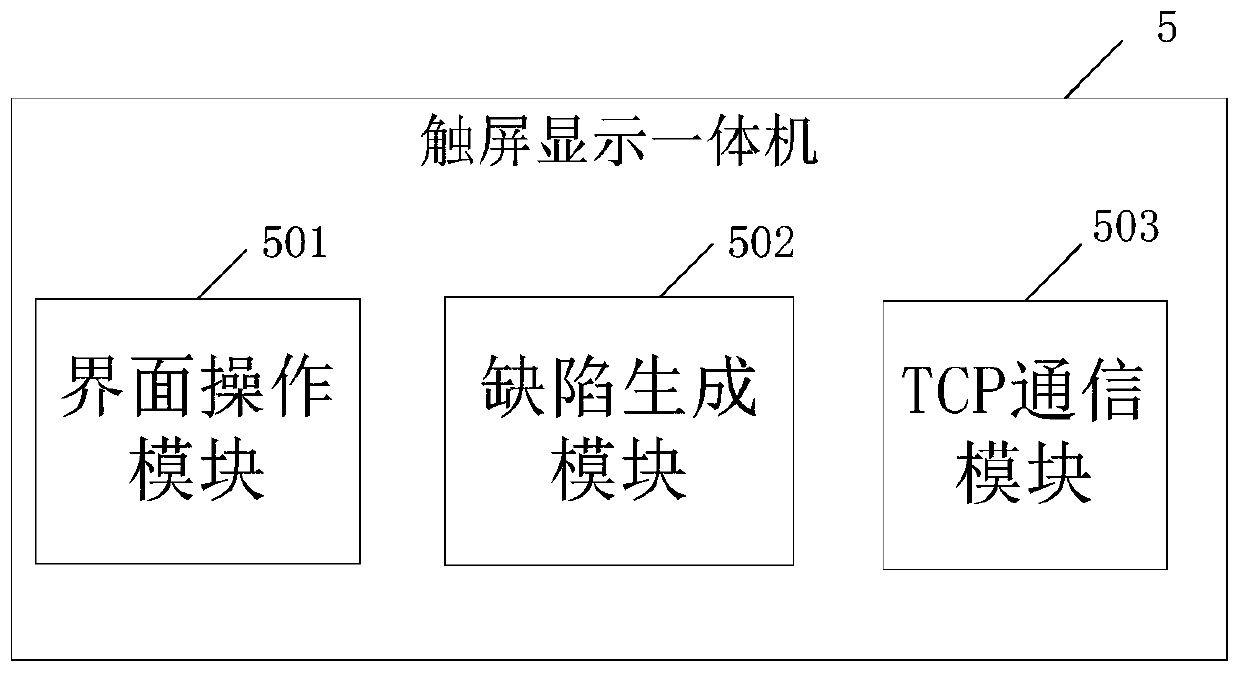

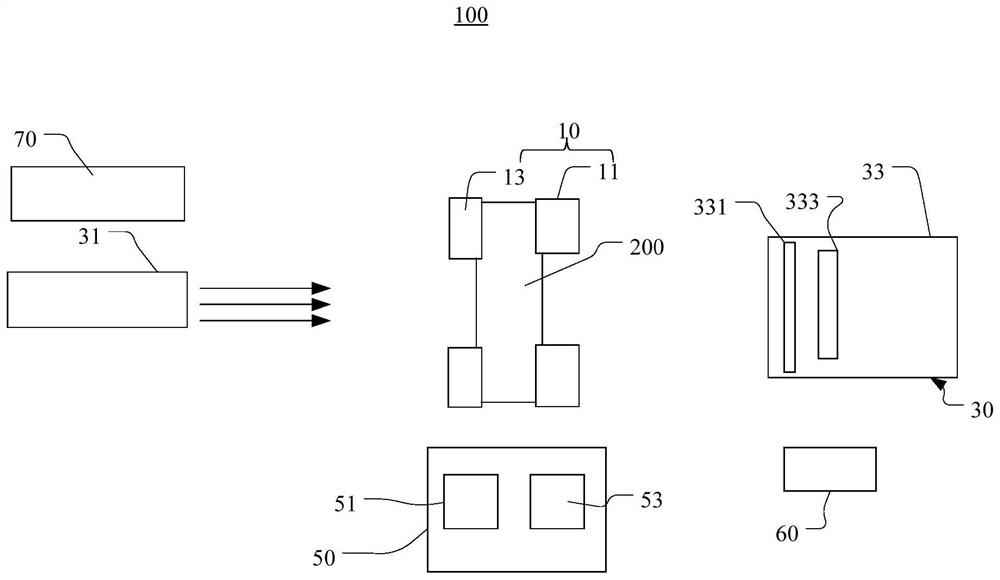

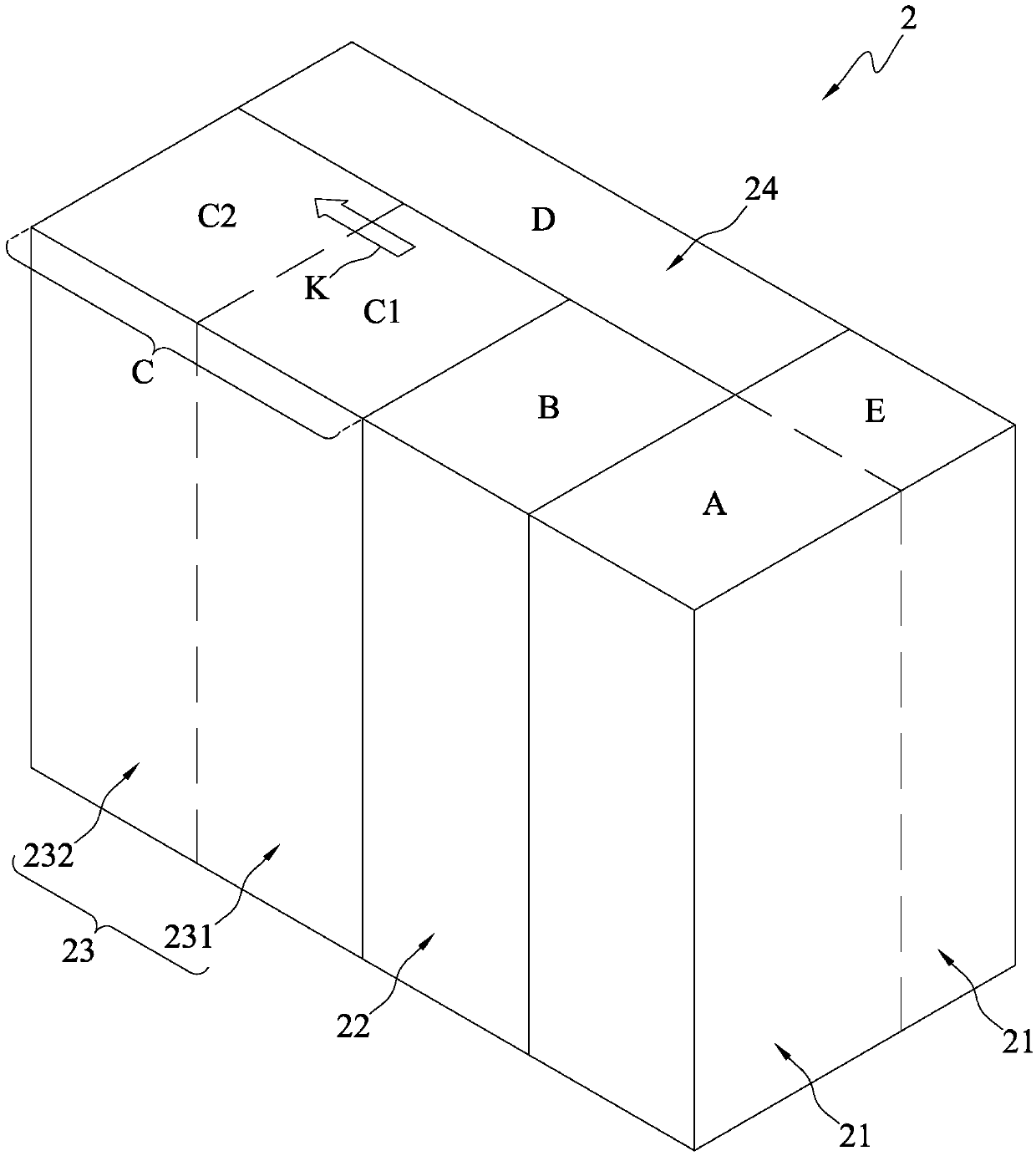

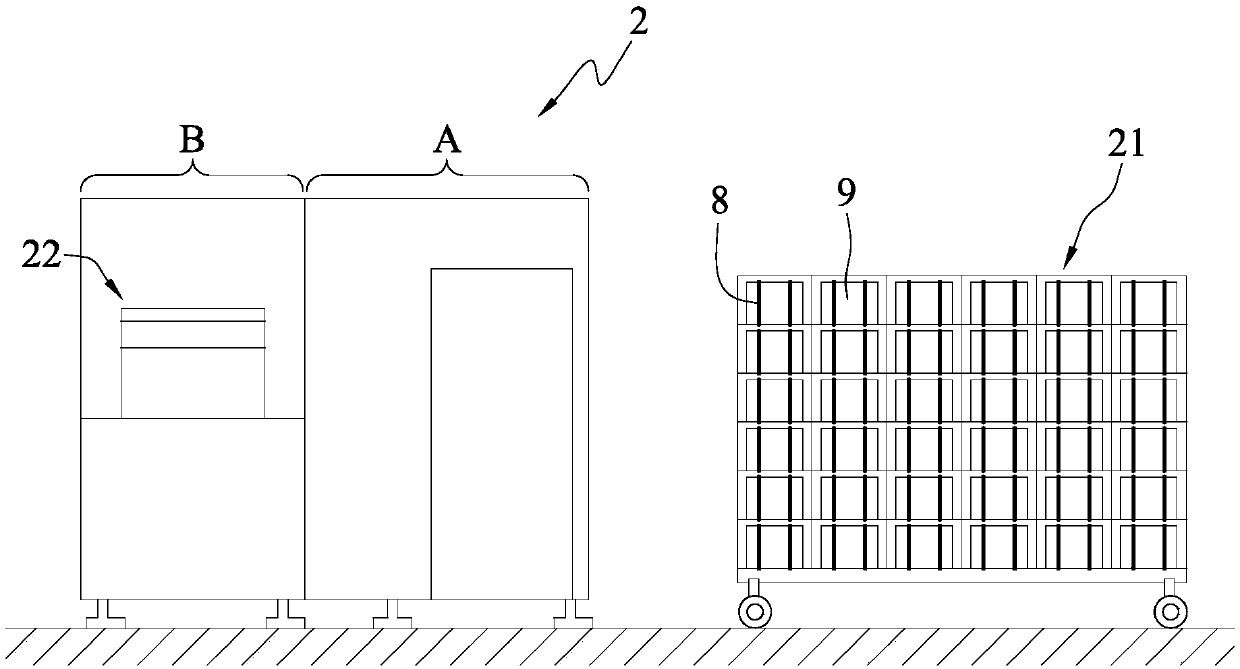

A manufacture apparatus for electronic limits of a display screen defect

ActiveCN109167995AImprove shipment qualityImprove quality inspection efficiencyTelevision systemsManufactured apparatusLight stage

The invention discloses a manufacture apparatus for electronic limits of a display screen defect, comprising an equipment table. A screen lighting stage and a touch screen display integrated machine are respectively arranged on both sides above the equipment table, and a display screen wire arrangement interface is arranged on one side of the screen lighting stage. An industrial camera is fixed onthe side wall of the light-shielding plate, and a light-shielding plate is coated on the upper surface of the screen lighting stage. The industrial camera is located directly above the screen lighting stage. A display screen control board is arranged below the display screen wire arrangement interface. An operation knob, a start control button and a screen lighting control button are arranged atone end of the touch screen display integrated machine. The invention provides the manufacture apparatus for the electronic limits of the display screen defect, which can improve the quality inspection efficiency and improve the delivery quality of the display screen by adjusting the defect degree and the defect position on line, observing and maintaining the electronic limit document on line by human eyes instead of the original manual screening and determining the reference process, and can improve the quality inspection efficiency and improve the delivery quality of the display screen.

Owner:BEIJING LUSTER LIGHTTECH

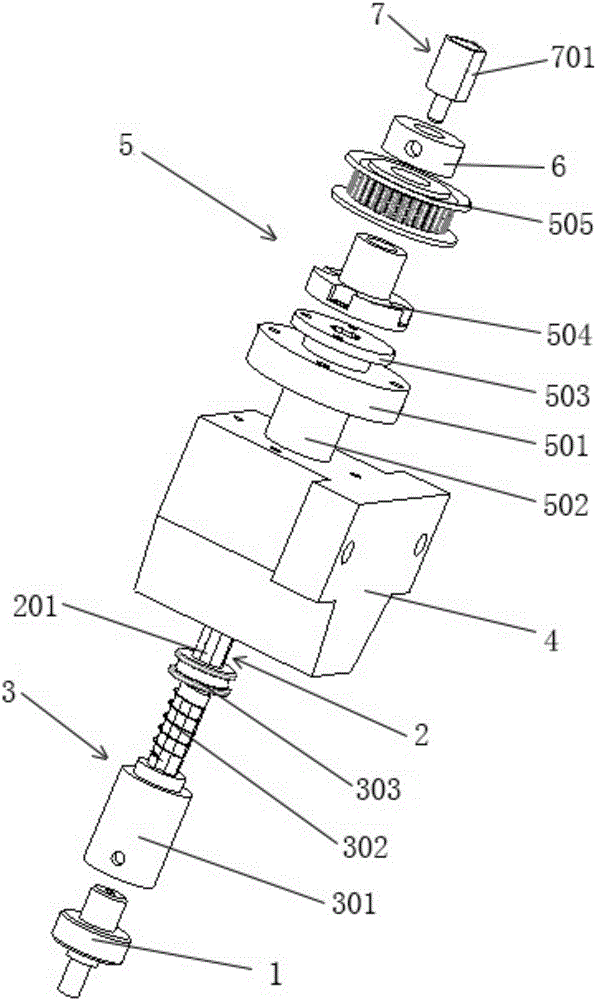

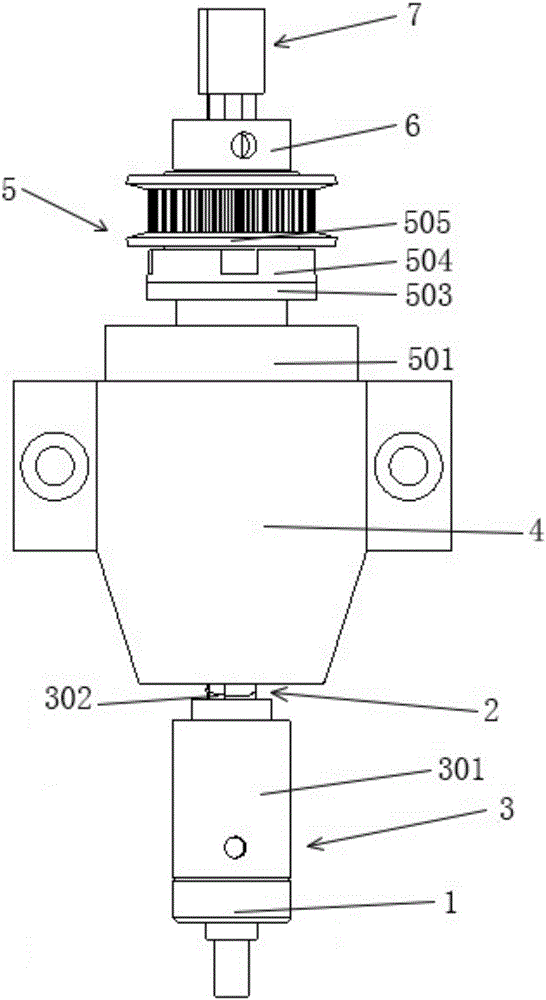

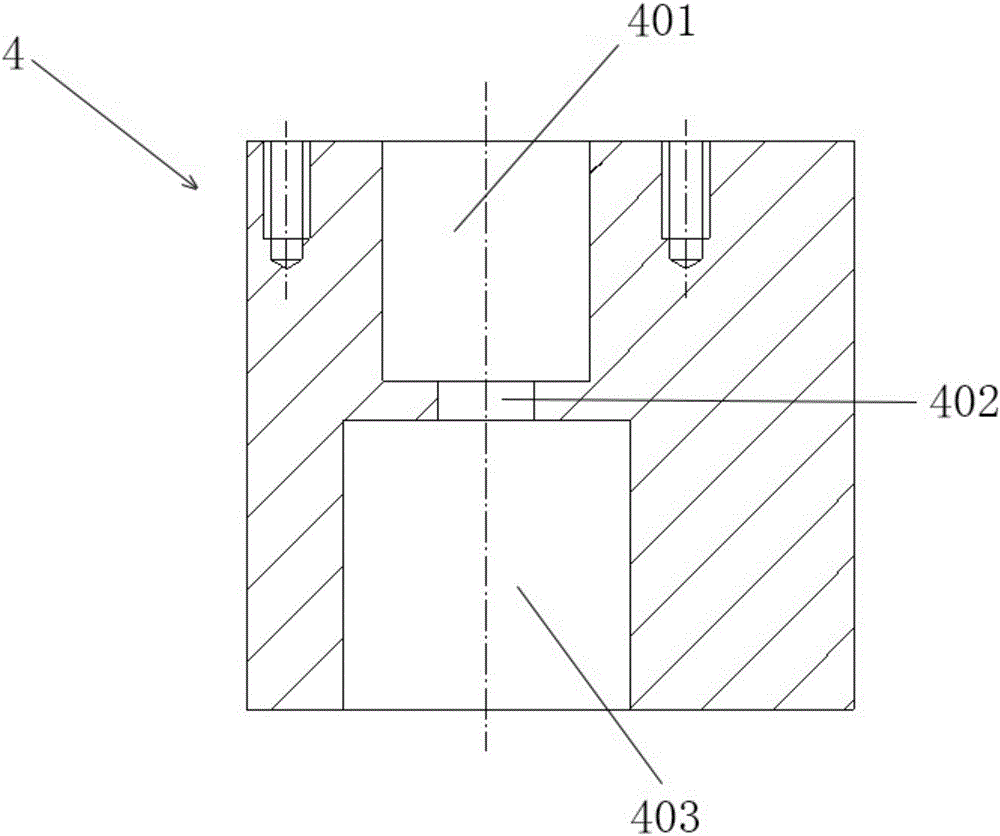

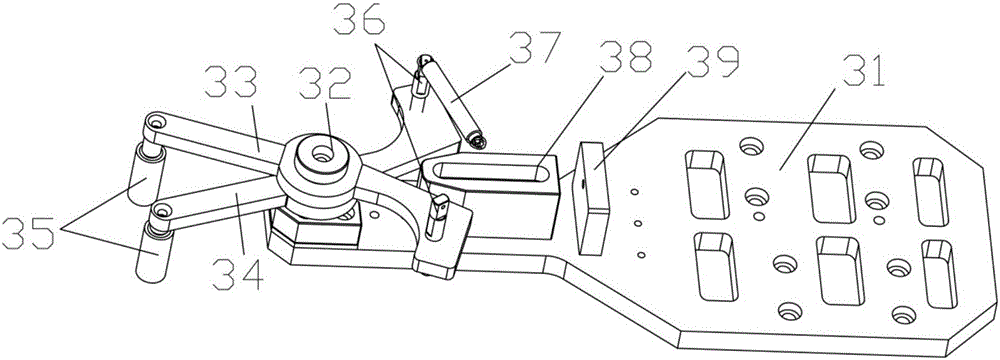

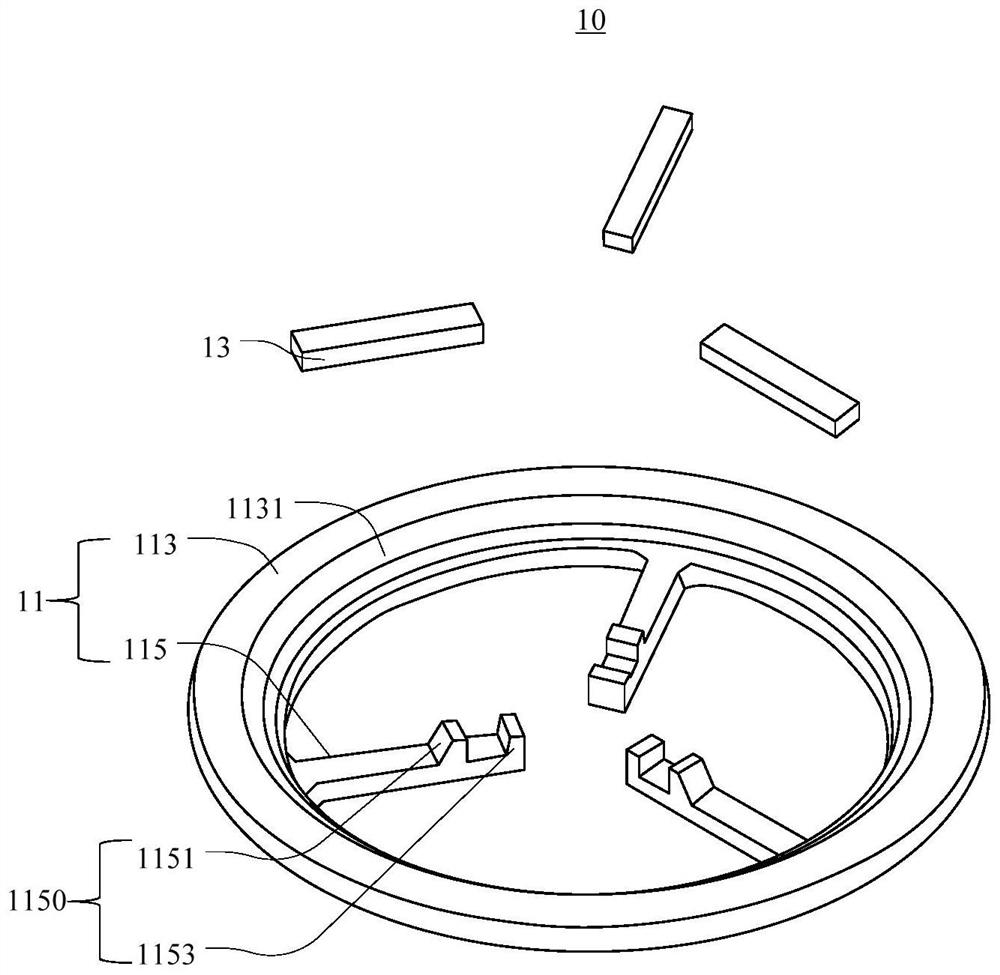

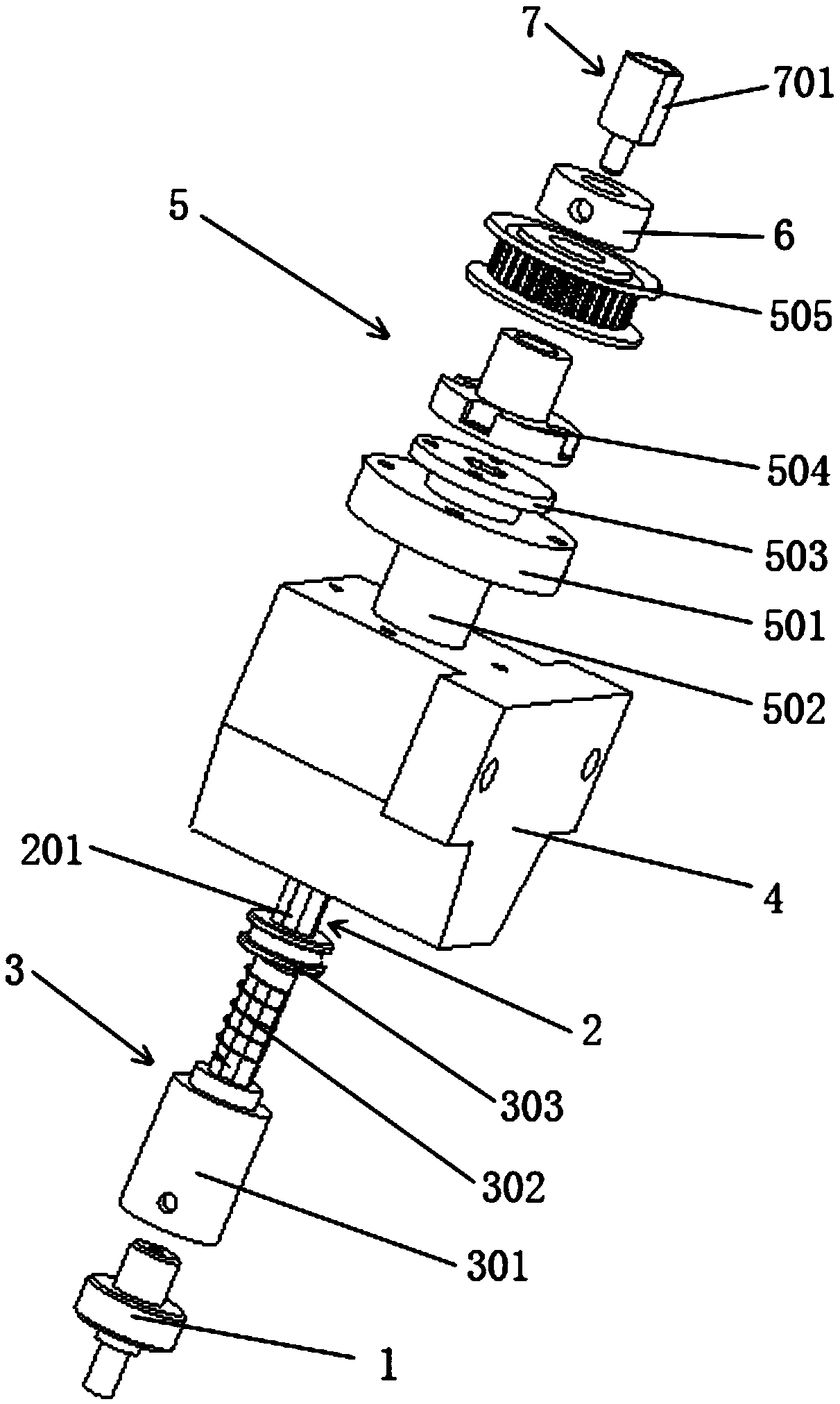

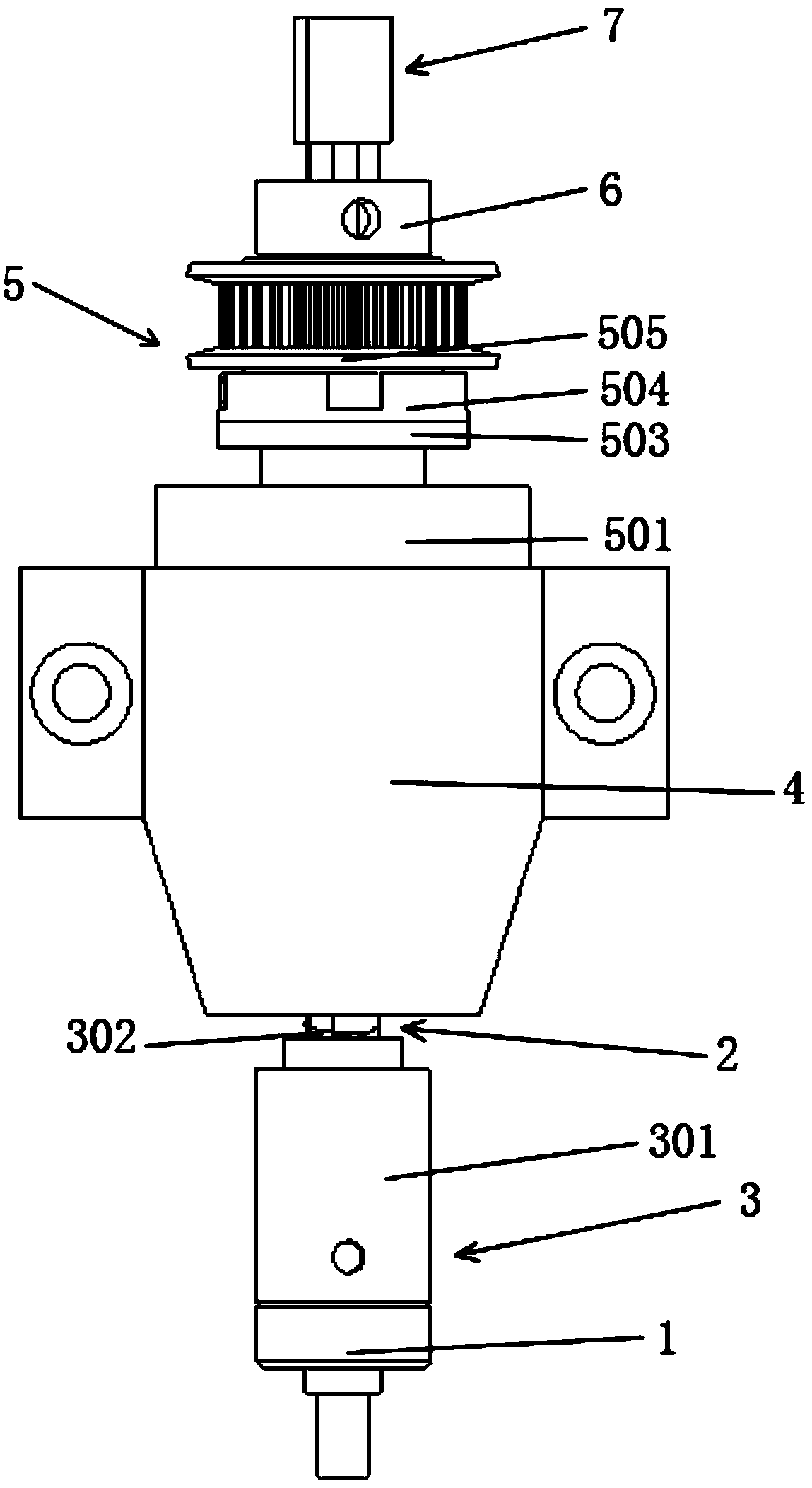

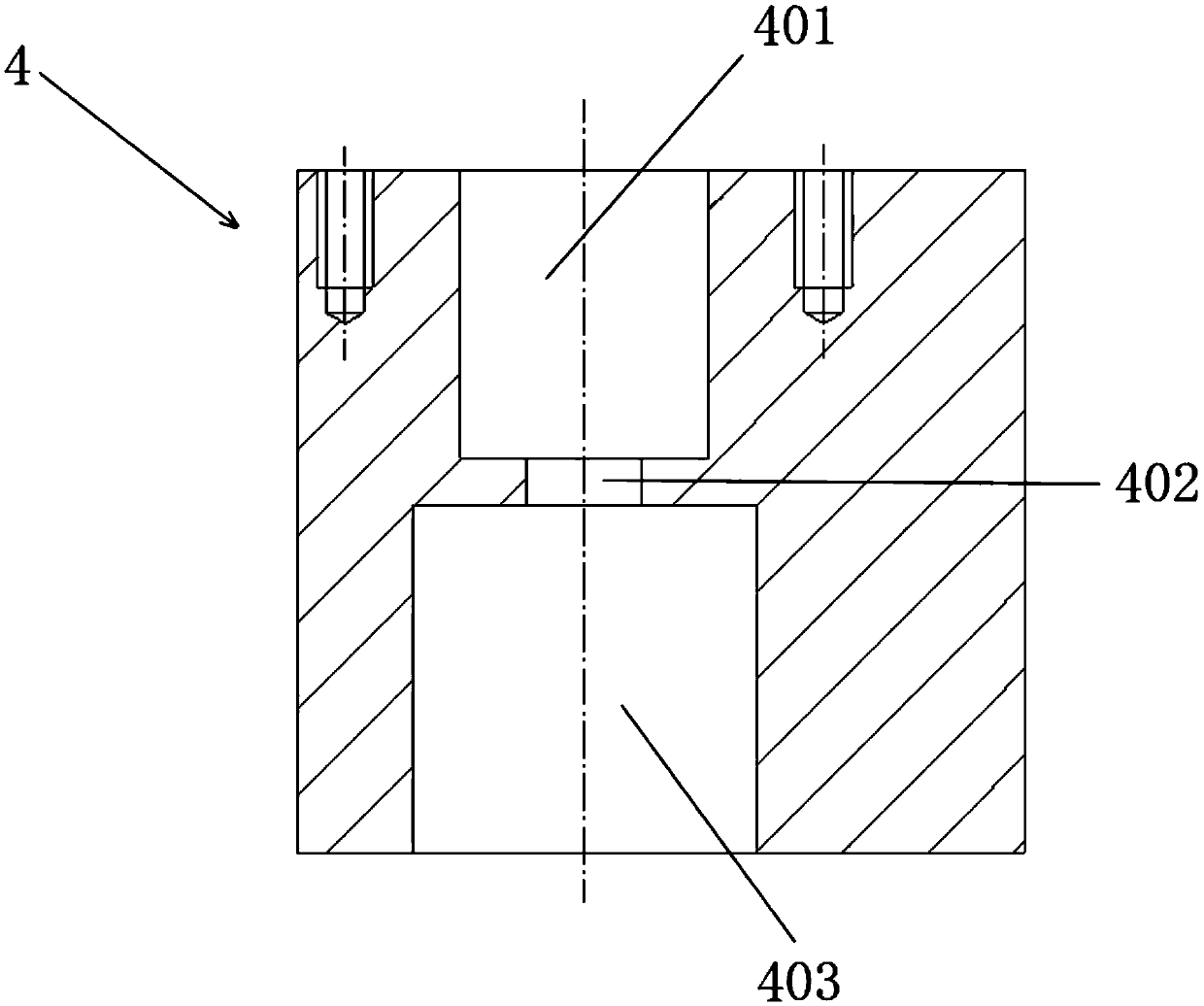

Suction and holding device

ActiveCN106346506AAvoid damageLimit displacement distanceGripping headsAxial displacementContact pressure

The invention discloses a suction and holding device. The suction and holding device comprises a suction nozzle, a center shaft, a suction buffer mechanism, a mounting base, a rotary driving mechanism and a limiting block. The suction and holding device has the advantages that the axial position of the center shaft is adjusted when a lens is sucked, so that the contact pressure between the device and the lens is effectively reduced; by rotating the center shaft, the angle of the sucked lens is adjusted; by adjusting the position of the limiting block on the center shaft, the axial displacement distance of the center shaft is limited, and the telescopic quantity of the center shaft is indirectly changed.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

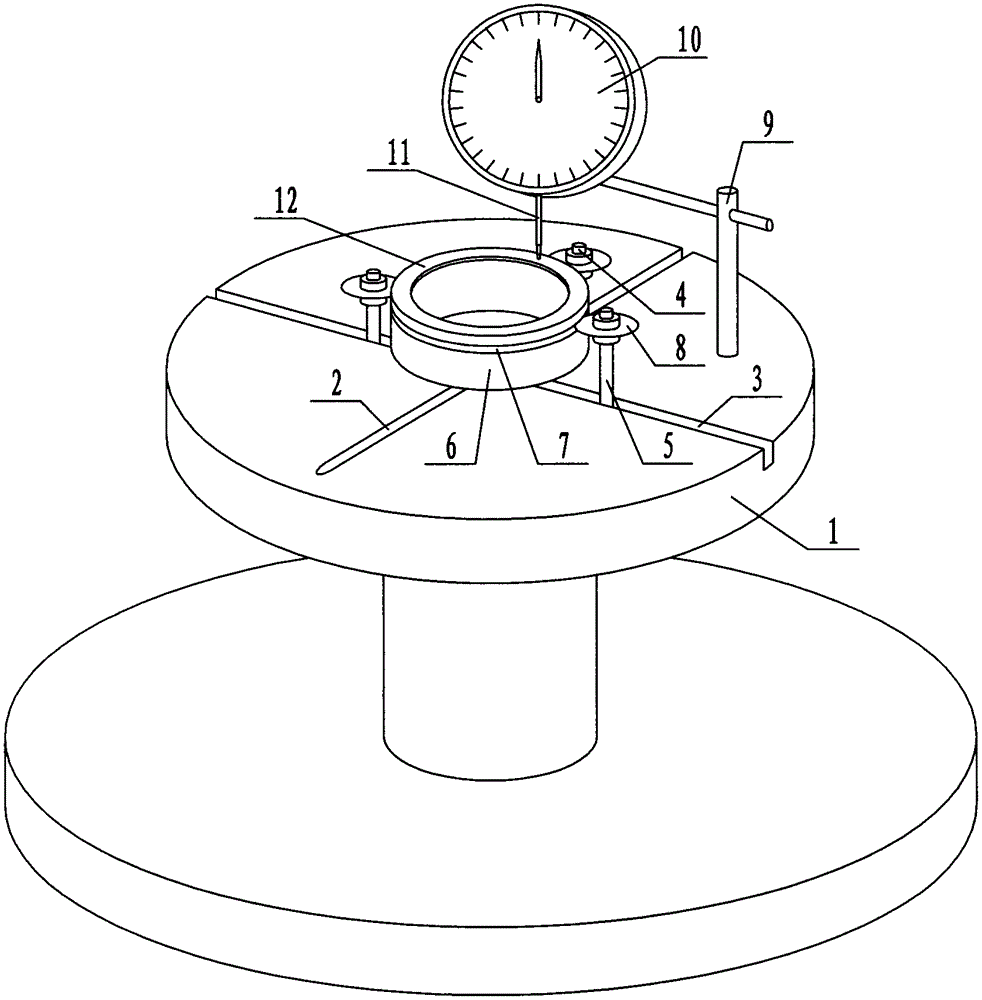

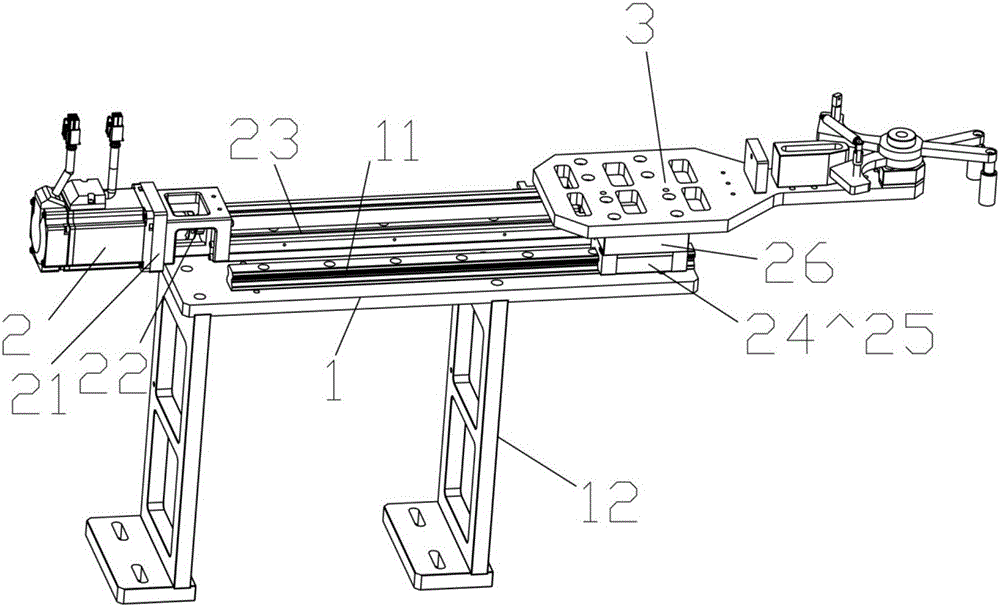

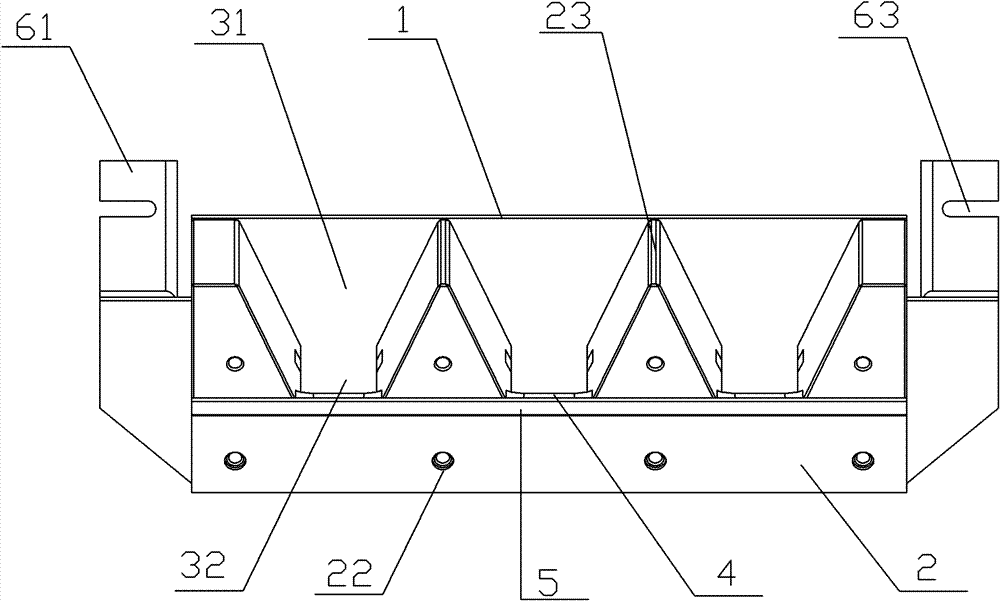

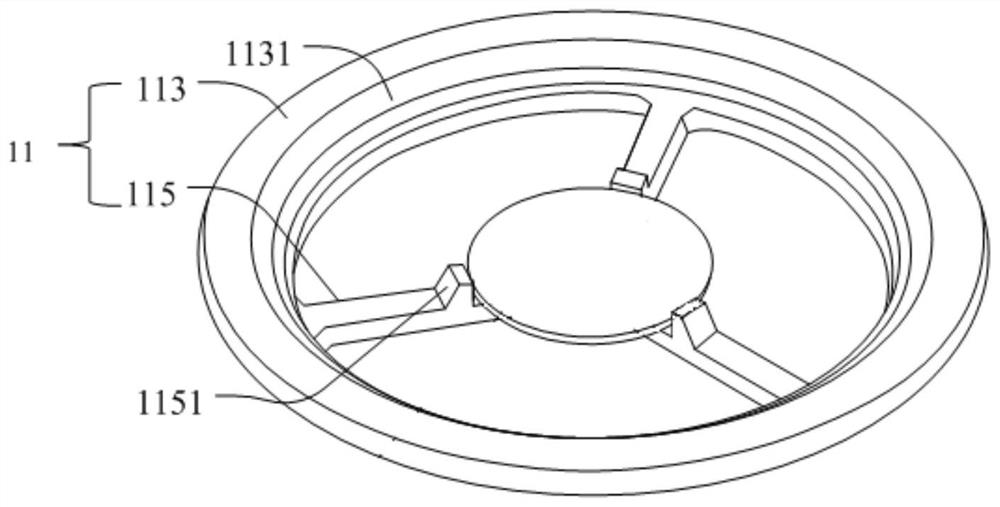

Measuring device of bearing outer ring

InactiveCN105300240AEasy to measureEasy to operateMechanical diameter measurementsEngineeringChassis

The invention discloses a measuring device of a bearing outer ring. The measuring device comprises a chassis. A first installation groove and a second installation groove are arranged in the chassis in an interlaced manner. A first support column is arranged in one end of the first installation groove. Second support columns cooperating with the first support column are respectively arranged in two ends of the second installation groove. Support rotation discs cooperating with tooth moving grooves in the bearing outer ring are rotatably arranged in the first support column and the second support column. A dial indicator is arranged on the chassis via a support. The watch hand of the dial indicator is abutted against the upper end face of the bearing outer ring. The measuring device is advantageous in that the tooth moving grooves arranged in the bearing outer ring rotate on the support rotation discs, so distance from the tooth moving grooves to the bearing outer ring can be quickly measured, thereby acquiring range of parallelism. The measuring method is simple to operate and high in measuring precision; measurement can be easily performed; yield can be effectively ensured; and post-installation quality and product producing quality are improved.

Owner:YANCHENG SANCHUAN BEARING MFG

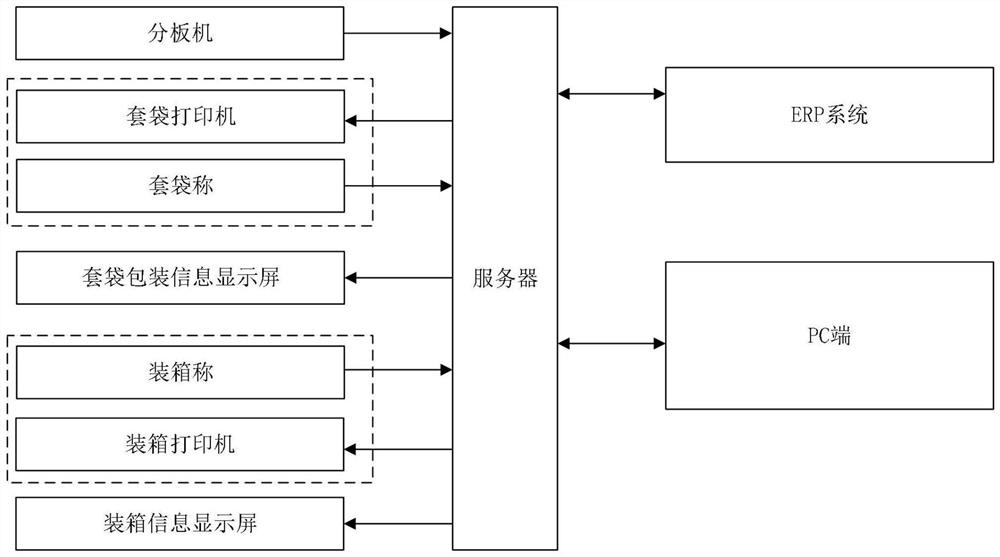

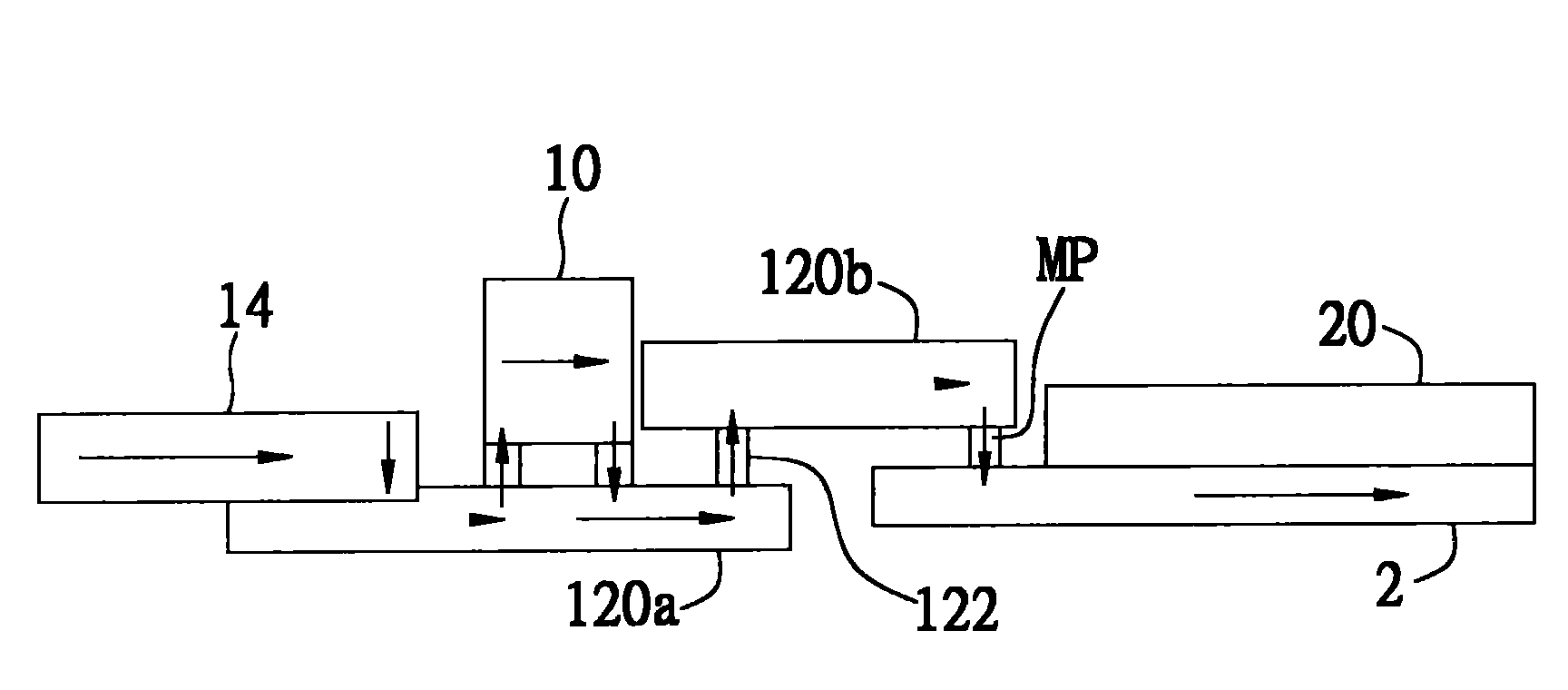

MES interaction system for PCB distribution and packaging

PendingCN112896660AReduce manual involvementReduce labor costsPackaging automatic controlLabelling machinesInformation transferIndustrial engineering

The invention relates to the technical field of PCB packaging, and particularly relates to an MES interaction system for PCB distribution and packaging. The MES interaction system comprises a board distribution machine used for selecting and distributing PCBs, a bagging scale used for weighing, a display screen used for displaying bagged packaging information, a boxing scale used for weighing and boxing, a display screen used for displaying boxing information, a server used for acquiring storage information, an RRP system connected with the server and a PC terminal in bidirectional connection with the server; the board distribution machine transmits board distribution information to the server for storage; the bagging scale and the boxing scale are both connected with the input end of the server and transmit weighing information to the server for storage; the bagged packaging information display screen and the boxing information display screen are both connected with the output end of the server, and are respectively used for displaying weight information of bagging and boxing; and the server carries out terminal information query processing through the PC terminal. According to the system disclosed by the invention, manual participation is reduced, the labor cost and the error rate are reduced, and the shipment quality is improved.

Owner:深圳市冠运智控科技有限公司

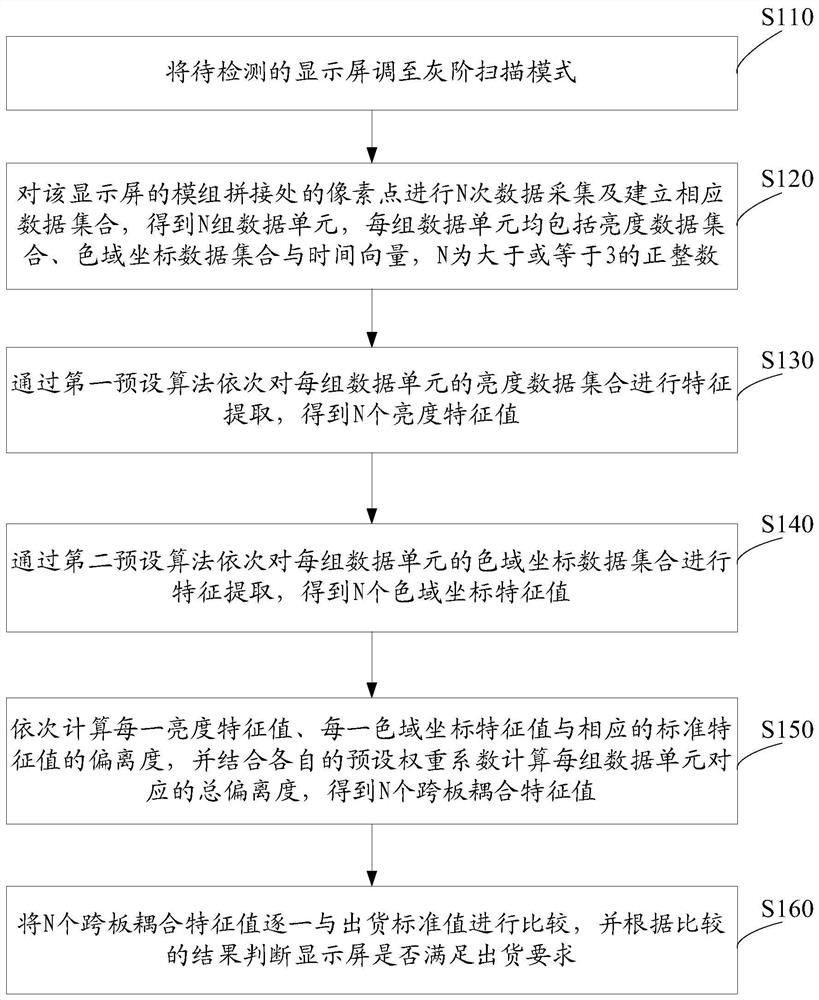

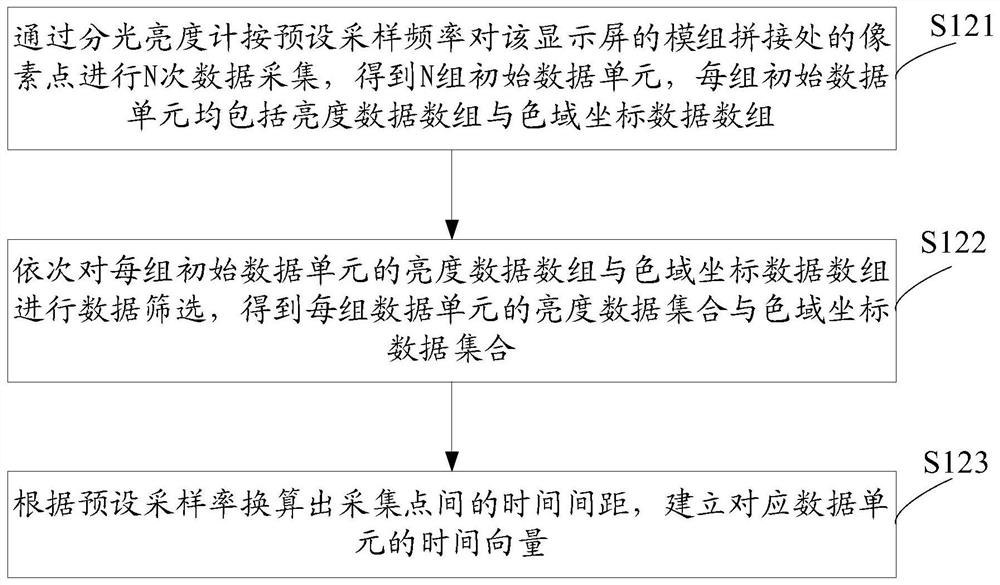

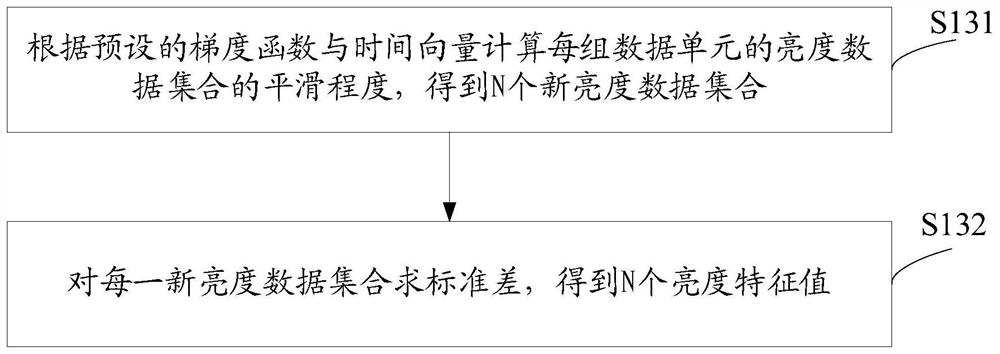

Display screen quality detection method, terminal and storage medium

PendingCN113281017AImprove shipment qualityTroubleshoot technical issuesTesting optical propertiesGamutFeature extraction

The invention discloses a display screen quality detection method, a terminal and a storage medium. The method comprises steps of carrying out the N times of data collection of pixel points at a module splicing part of a display screen in a gray scale scanning mode, building a corresponding data set, and obtaining N groups of data units comprising time vectors; performing feature extraction on each group of data units in sequence to obtain N brightness feature values and N color gamut coordinate feature values; sequentially calculating deviation degrees between each brightness characteristic value and each color gamut coordinate characteristic value and a corresponding standard characteristic value, and calculating to obtain a total deviation degree corresponding to each group of data units by combining respective preset weight coefficients so as to obtain N cross-board coupling characteristic values; and comparing the N cross-board coupling characteristic values with a shipment standard value one by one, and judging whether the display screen meets the shipment requirement or not according to a comparison result. The method is advantaged in that a technical problem that in the prior art, an effective objective shipment standard cannot be formed by detecting shipment of the display screen through subjective watching experience of quality inspectors can be solved.

Owner:UNILUMIN GRP

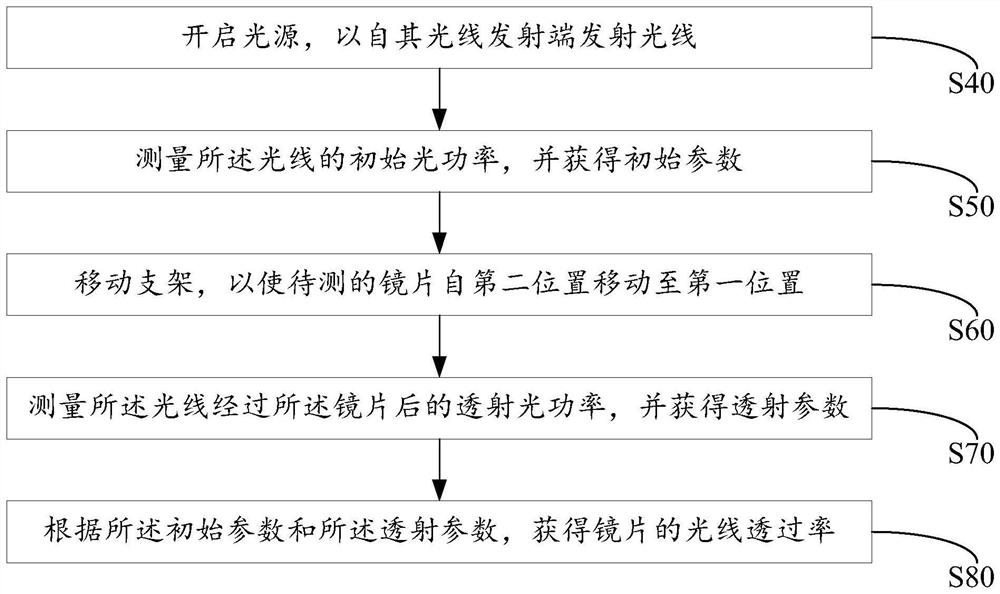

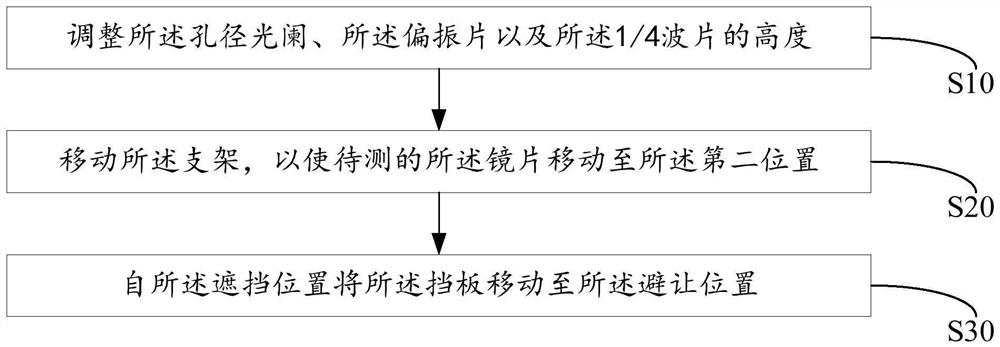

Lens transmittance detection device and detection method thereof

PendingCN114544151ASolve the divergence problemSmall sizeTesting optical propertiesTransmittanceEngineering

The invention discloses a lens transmittance detection device and a detection method thereof. The lens transmittance detection device comprises a base, a bracket, a light source and a detection assembly, the base has a detection area; a lens is arranged on the bracket, the bracket is movably arranged on the base, and a first position and a second position are arranged on the movement stroke; the light source is arranged in the detection area and located on one side of the support, when the support is located at the first position, the light emitting end of the light source is opposite to the light incident side of the lens, and the light propagation path of the light source passes through the central axis of the lens; the detection assembly comprises an optical power meter, the optical power meter is arranged in the detection area and located on the other side of the support, and when the support is located at the first position, the light receiving end of the optical power meter is opposite to the light emitting end of the light source; namely, the transmissivity of the lens is detected through the lens transmissivity detection device, defective products are effectively recognized and intercepted, the qualified rate of the lens is improved, the repair rate of a rear station is reduced, and the product delivery quality is improved.

Owner:GOERTEK INC

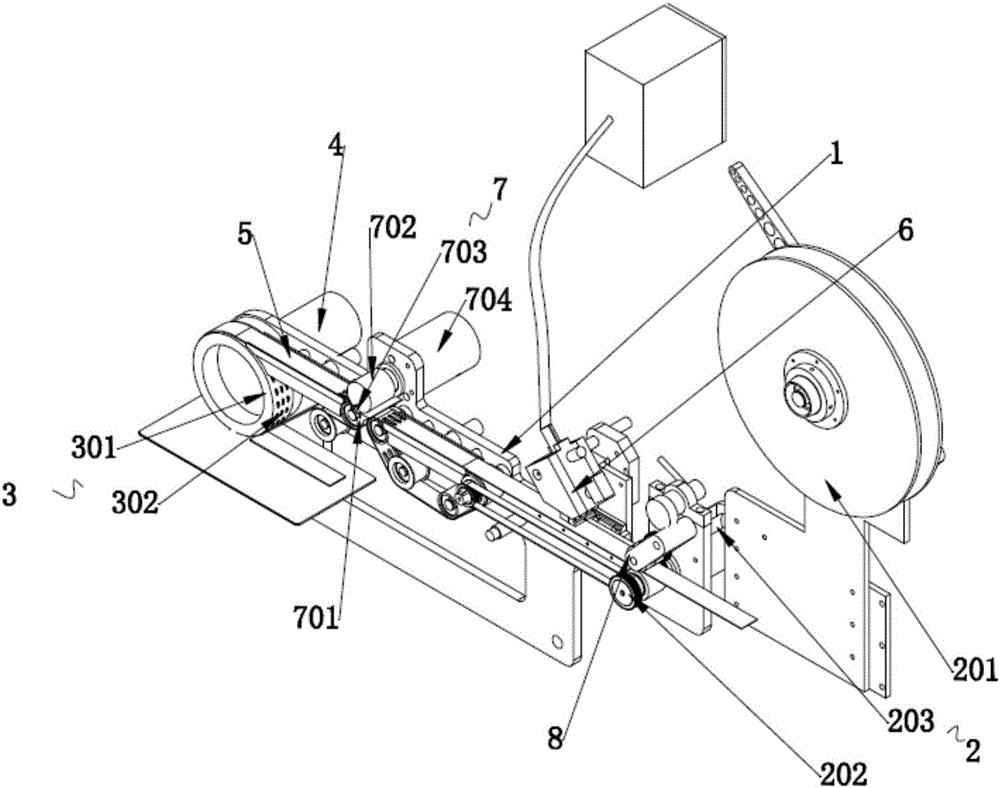

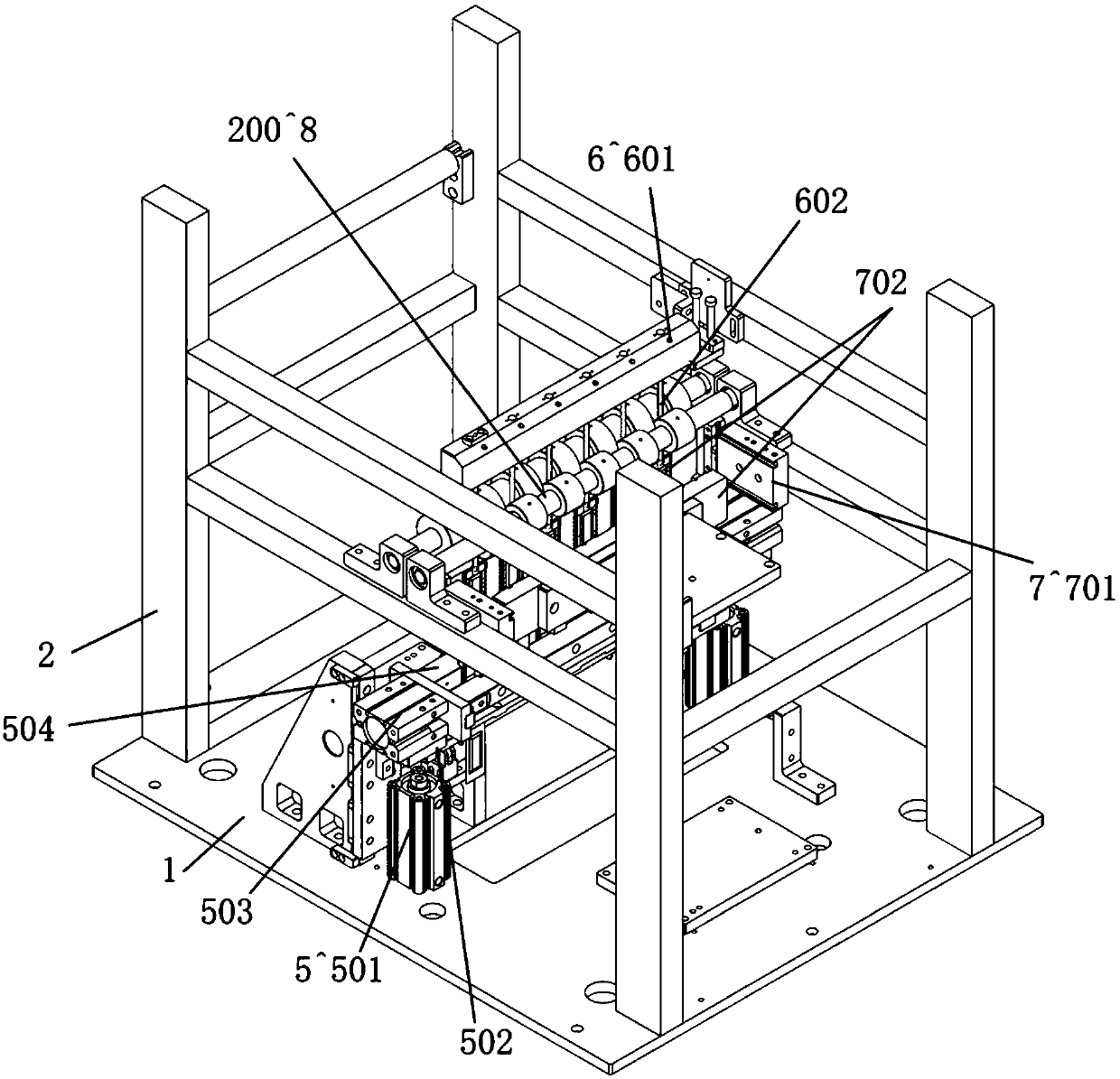

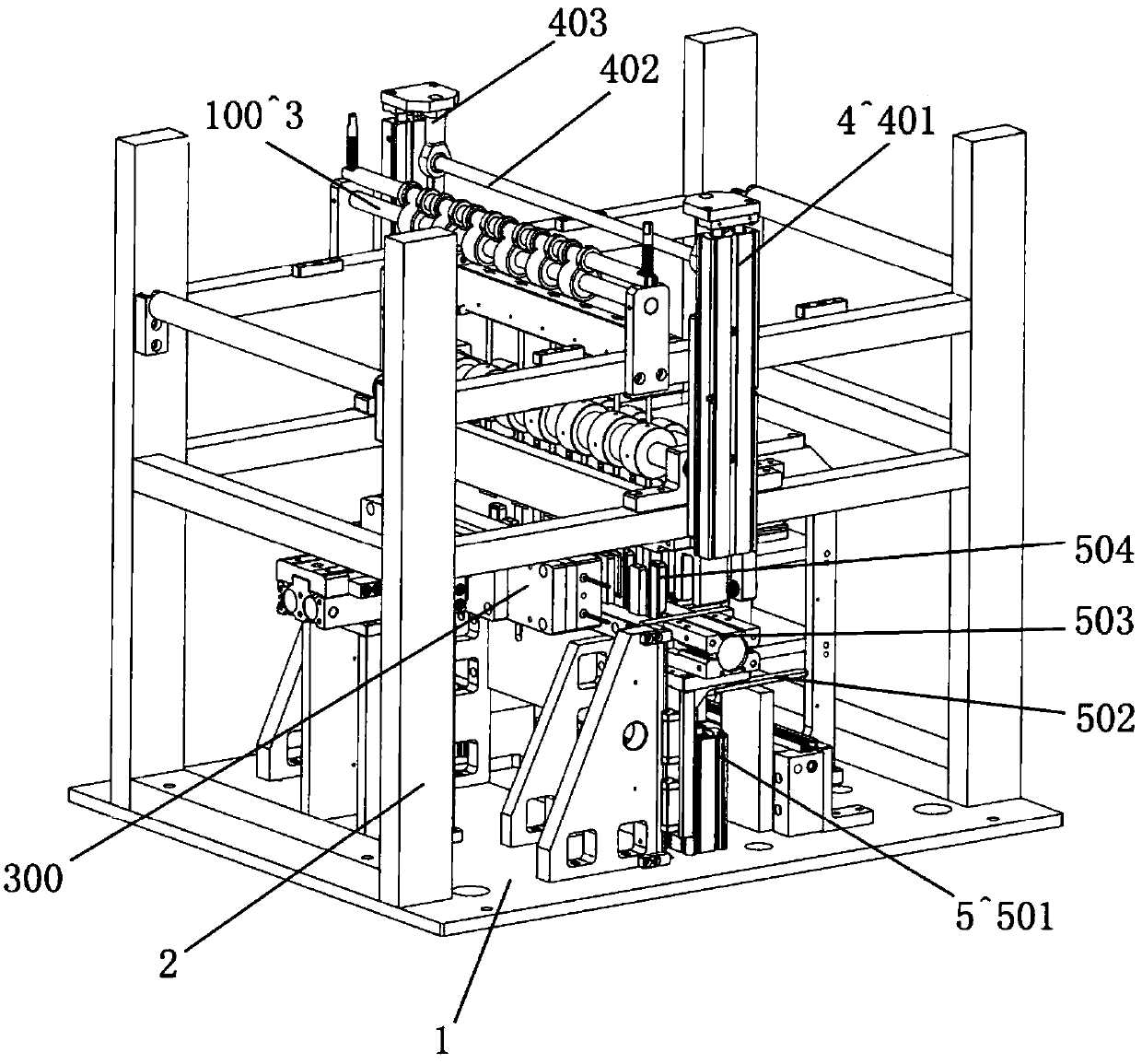

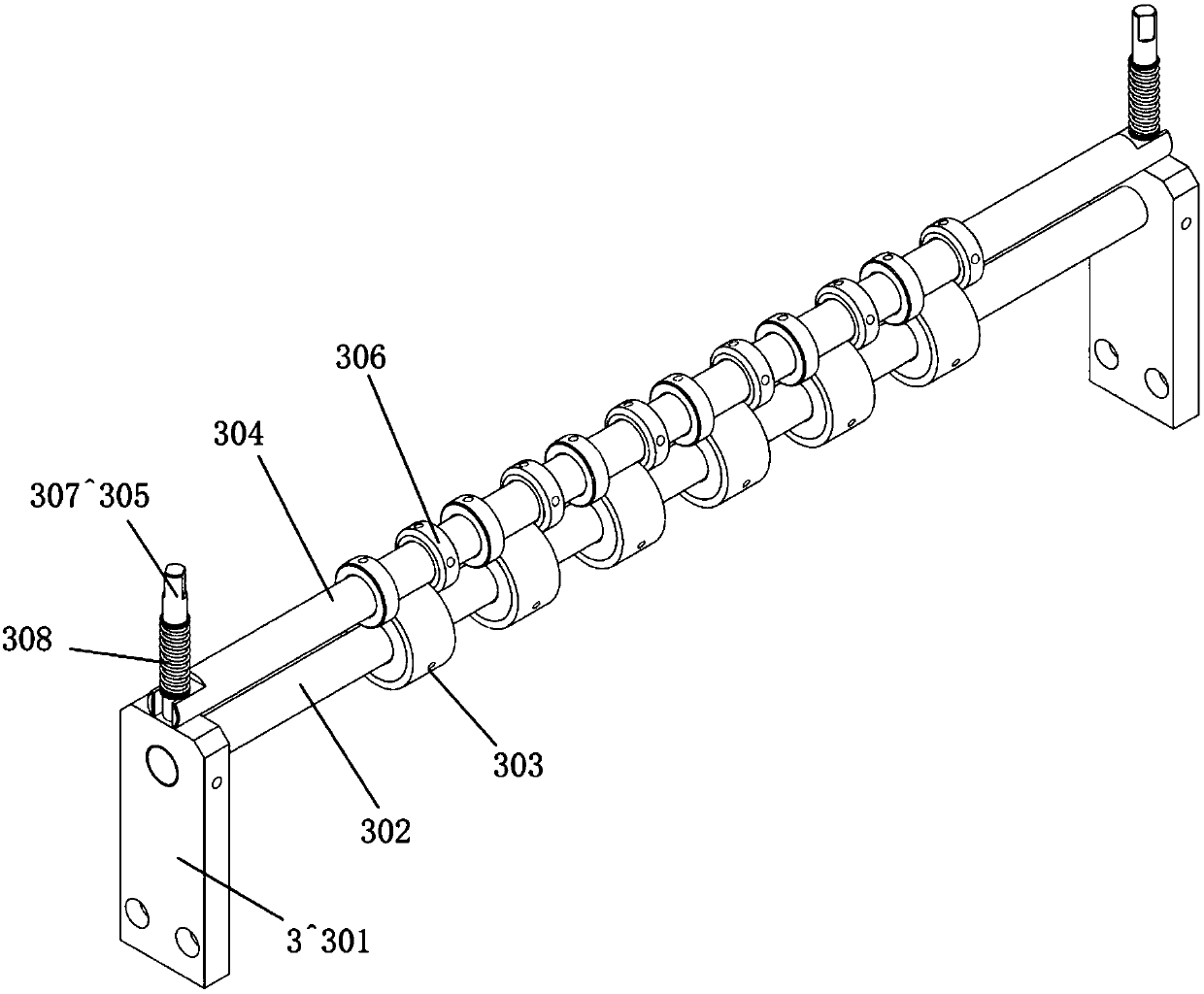

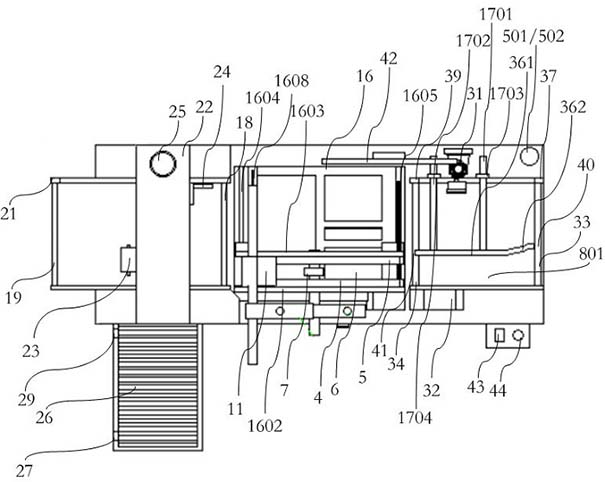

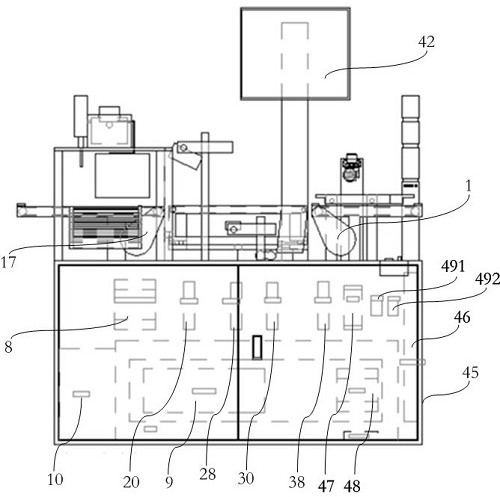

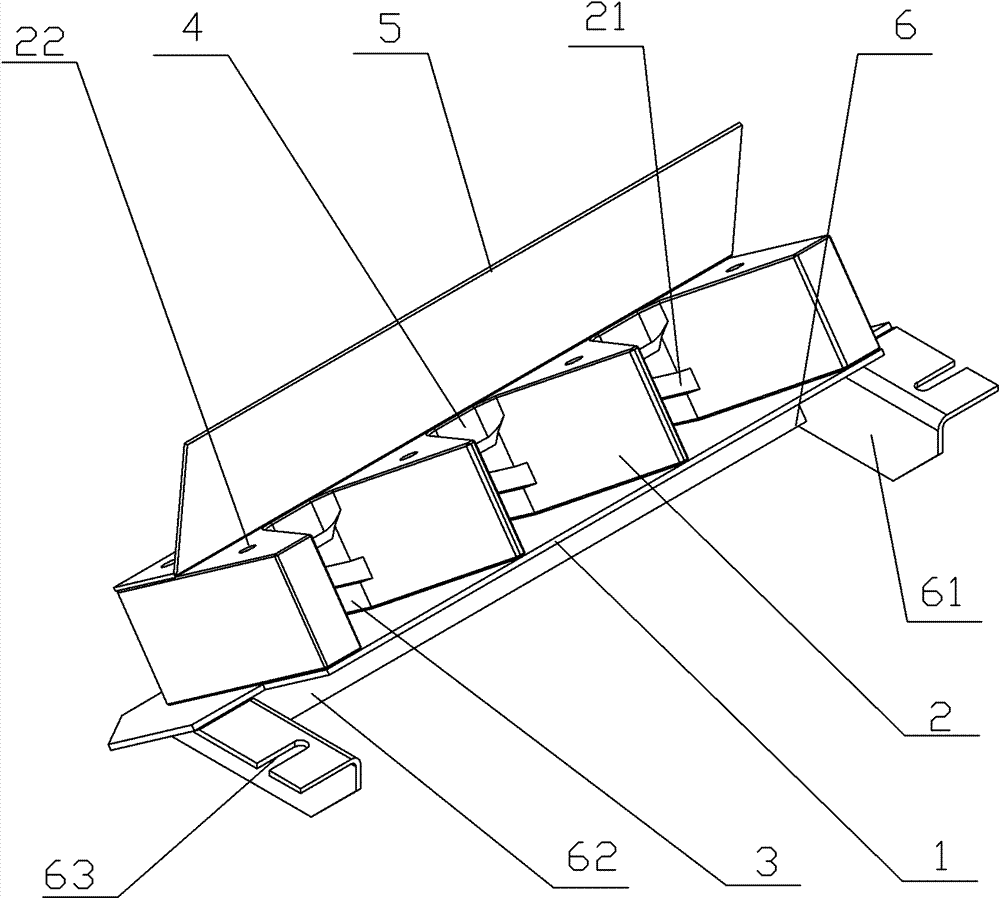

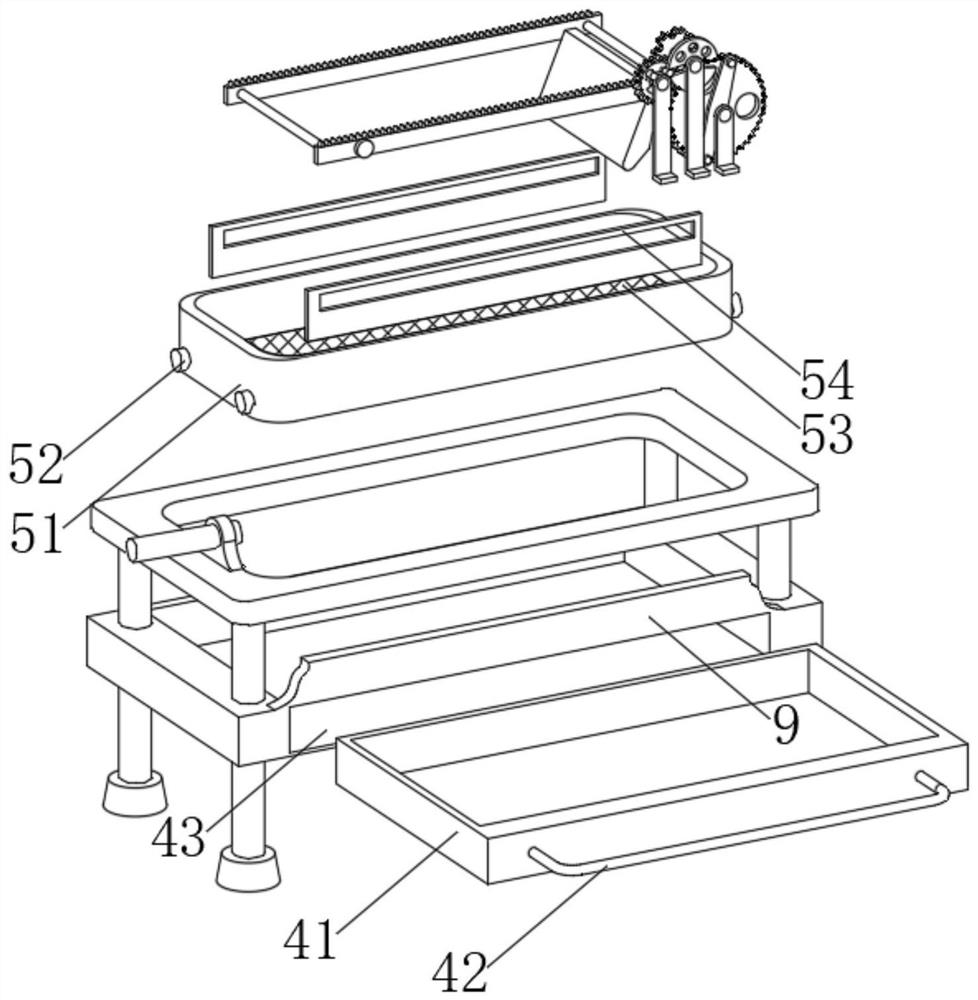

Box pasting machine capable of achieving automatic gluing and adhesive sticker sticking

InactiveCN106476324AIncrease productivityImprove shipment qualityBox making operationsPaper-makingPaperboard

The invention discloses a box pasting machine capable of achieving automatic gluing and adhesive sticker sticking. The box pasting machine capable of achieving automatic gluing and adhesive sticker sticking comprises a paperboard conveying mechanism and a supporting frame plate arranged above the paperboard conveying mechanism. The supporting frame plate is provided with an adhesive sticker feeding mechanism and an air-sucking type sticker disc, the air-sucking type sticker disc is connected with a disc servo motor and arranged above the paperboard conveying mechanism, and the interval between the air-sucking type sticker disc and the paperboard conveying mechanism is smaller than or equal to the thickness of a single paperboard. The adhesive sticker feeding mechanism and the air-sucking type sticker disc are located on the same horizontal plane, and an adhesive sticker conveying mechanism is arranged between the adhesive sticker feeding mechanism and the air-sucking type sticker disc. A glue spraying mechanism is arranged above the adhesive sticker conveying mechanism. According to the box pasting machine capable of achieving automatic gluing and adhesive sticker sticking, an adhesive sticker is accurately stuck to a moving paperboard, so that production efficiency is improved, and the production cost is lowered. Gluing is conducted in a glue spraying mode instead of a glue scraping mode, influences caused by technical factors of glue scraping are avoided, and the product output quality is greatly improved.

Owner:HUIZHOU SHENGSHENG PACKAGING EQUIP

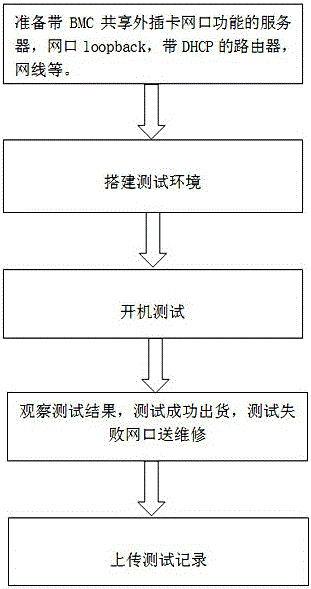

Method of batch-testing network cards with NCSI function

InactiveCN105791052AEasy to testReduce testing costsData switching networksLoopbackNetwork interface controller

The invention discloses a method of batch-testing network cards with an NCSI function. The method comprises the steps of using a router with a DHCP function to build a network test environment, making a network port loopback, preparing a server host with a BMC external network port sharing function, inserting a network card with an NCSI function into a PCIE slot of a server, starting the server, carrying out network card NCSI and network port network performance test through use of software. According to the invention, a cheap router with a DHCP function is used to build a network test environment, a network card with an NCSI function can be tested easily, the test cost is saved greatly, and the test coverage and the output quality of products are improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

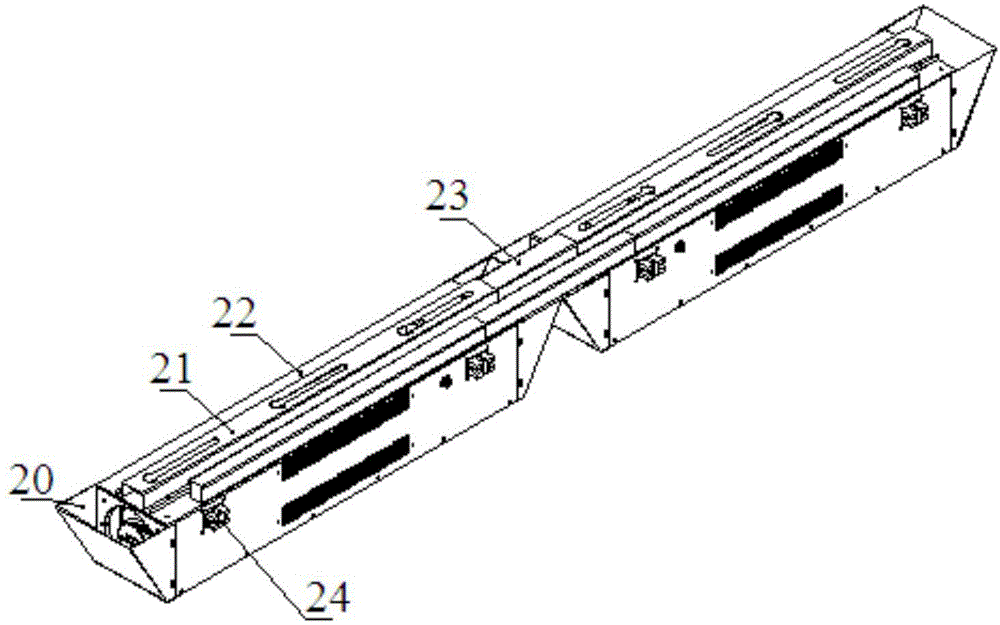

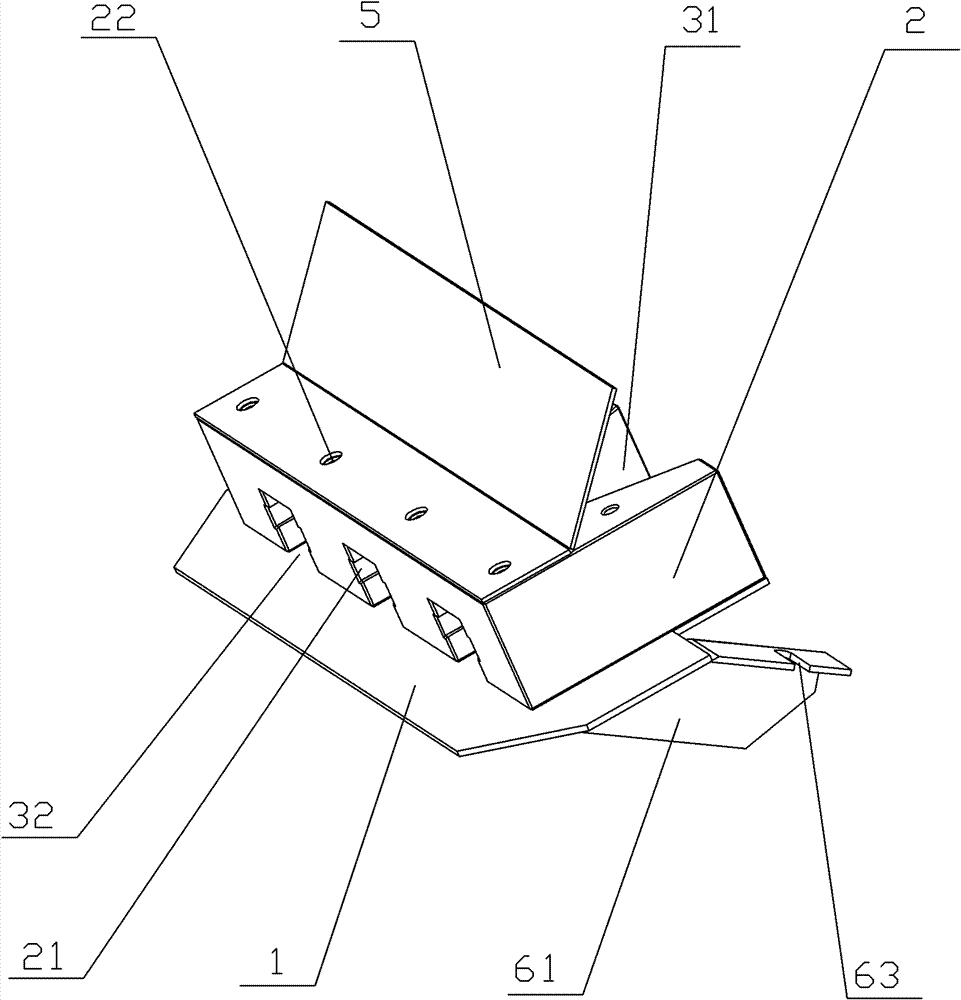

Label rolling mechanism

The invention provides a label rolling mechanism. The label rolling mechanism comprises a driving assembly and a label rolling assembly connected to the driving assembly. The label rolling assembly comprises a base plate, a rotary shaft, a left driving rod, a right driving rod, label rolling wheels, restoration struts and an elastic restoration piece, wherein the initial end of the base plate is connected to the driving assembly; the rotary shaft is arranged at the tail end of the base plate; the middle portion of the left driving rod and the middle portion of the right driving rod are arranged on the rotary shaft in a crossed mode, and the left driving rod and the right driving rod are used in cooperation; the label rolling wheels are arranged at the tail end of the left driving rod and the tail end of the right driving rod correspondingly; the restoration struts are arranged at the initial end of the left driving rod and the initial end of the right driving rod correspondingly; and the two ends of the elastic restoration piece are connected to the restoration struts arranged at the initial end of the left driving rod and the initial end of the right driving rod correspondingly. According to the label rolling mechanism, a label attached to the surface of an arc-surface product can be rolled, and bubbles are eliminated after the label is attached to an arc surface, so that the label is attached more smoothly, and accordingly the outgoing quality of the product is improved.

Owner:BOZHON PRECISION IND TECH CO LTD

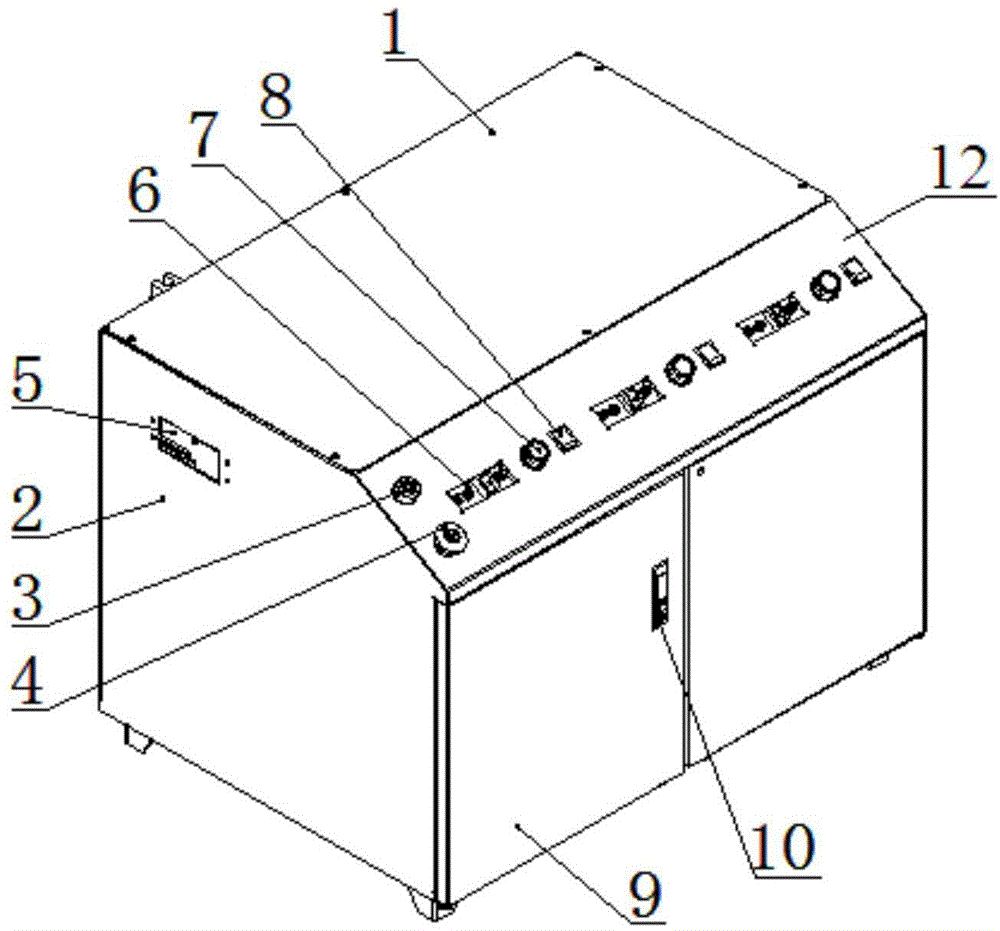

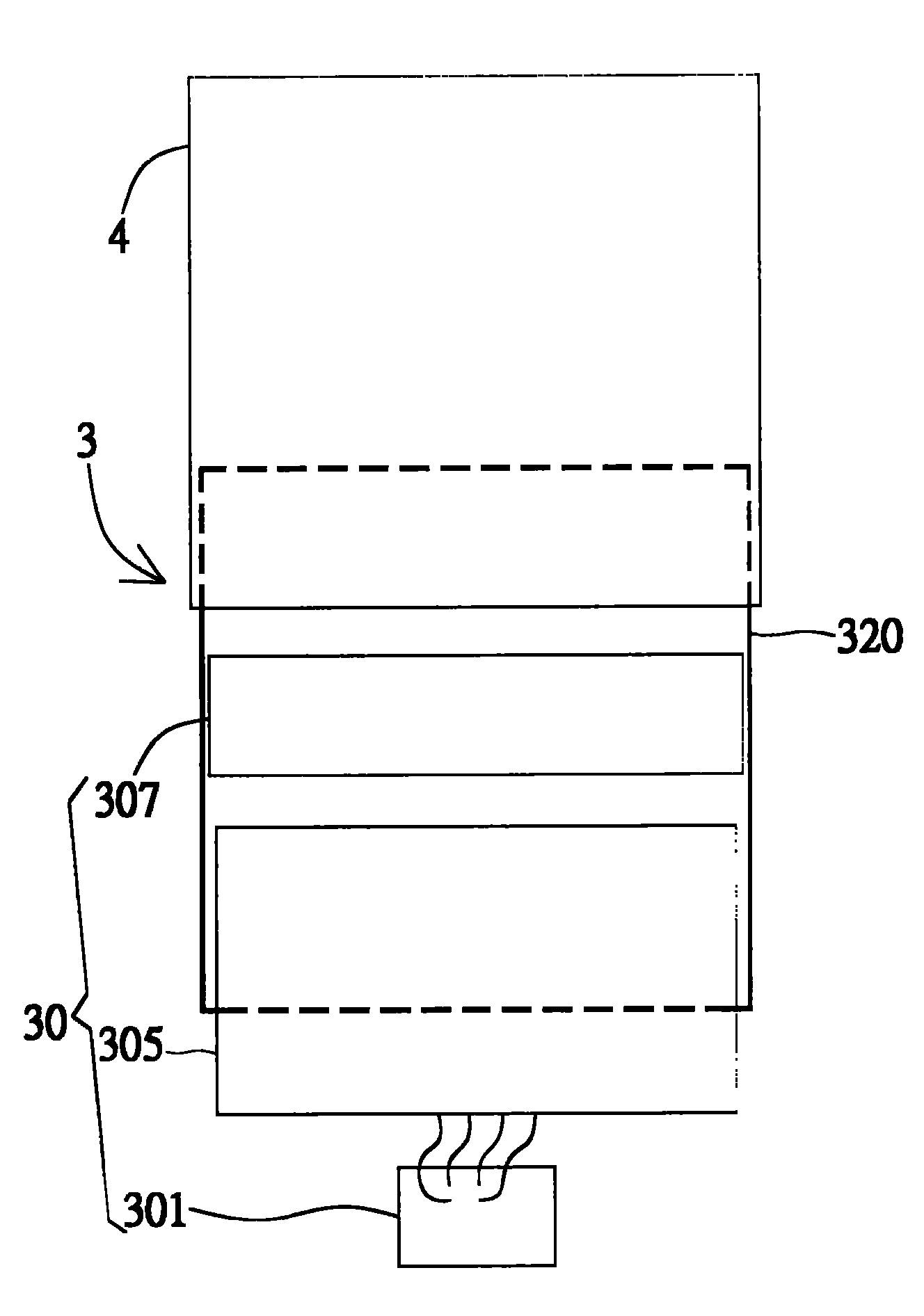

Metal can coating electromagnetic induction automatic drying heating device

InactiveCN104815787AImprove heating efficiencyImprove energy savingPretreated surfacesCoatingsElectrical connectionEngineering

The invention discloses a metal can coating electromagnetic induction automatic drying heating device comprising a control cabinet and a heater. The control cabinet comprises a cabinet body, a power supply input terminal, a first aerial socket, a control panel, a main electromagnetic heating machine, a circuit breaker, an alternating current contactor, a switching power supply, an alarm signal board and a terminal bus. The heater comprises a housing, an electromagnetic induction coil, a micro-crystalline board and a second aerial socket. The control cabinet provides an alternating current to the heater through an electrical connection wire bundle. The metal can coating electromagnetic induction automatic drying heating device heats the metal can coating by means of electromagnetic induction heating, so as to dry the coating quickly. The metal can coating electromagnetic induction automatic drying heating device has the advantages of being safe in use, being environment-friendly, being energy-saving and being time-saving.

Owner:HEFEI SHUNCHANG ELECTROMAGNETIC INDUCTION TECH

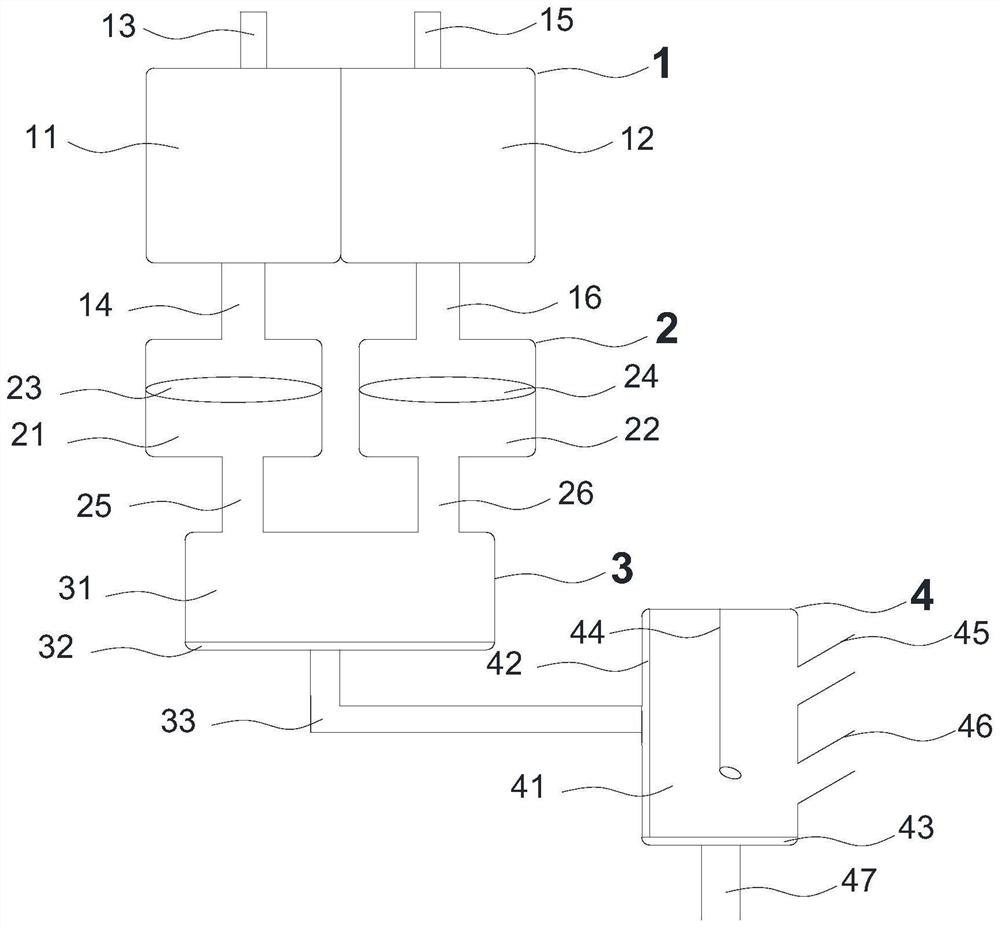

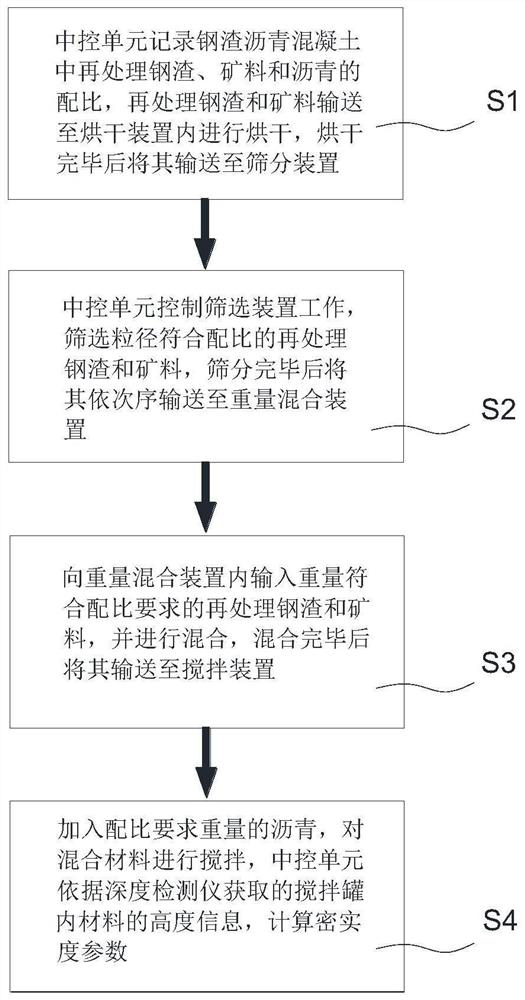

Asphalt concrete preparation method based on retreated steel slag

ActiveCN114180882AImprove compactnessImprove production efficiencySolid waste managementSlagStructural engineering

The invention relates to the technical field of preparation of asphalt concrete based on retreated steel slag, in particular to a preparation method of asphalt concrete based on retreated steel slag, which comprises the steps of drying, screening, weighing and mixing, stirring, discharging and the like. The central control unit automatically calculates the weights of the retreated steel slag, the mineral aggregate and the asphalt according to the proportion, controls the screening unit to screen out the retreated steel slag and the mineral aggregate with the required particle size, and mixes the retreated steel slag and the mineral aggregate meeting the weight requirement of the proportion and then enters the stirring device; the depth detection sensor arranged in the stirring device detects the height of a material in the stirring tank in real time and feeds back the height to the central control unit, and the central control unit judges whether the compactness meets the standard by calculating the height ratio and adjusts the compactness by selecting a mode of adjusting the rotating speed of the stirring rod, the stirring time or adding other materials. The preparation efficiency of the steel slag asphalt concrete and the shipment quality of the steel slag asphalt concrete are improved.

Owner:包头市鹿城路桥工程有限公司

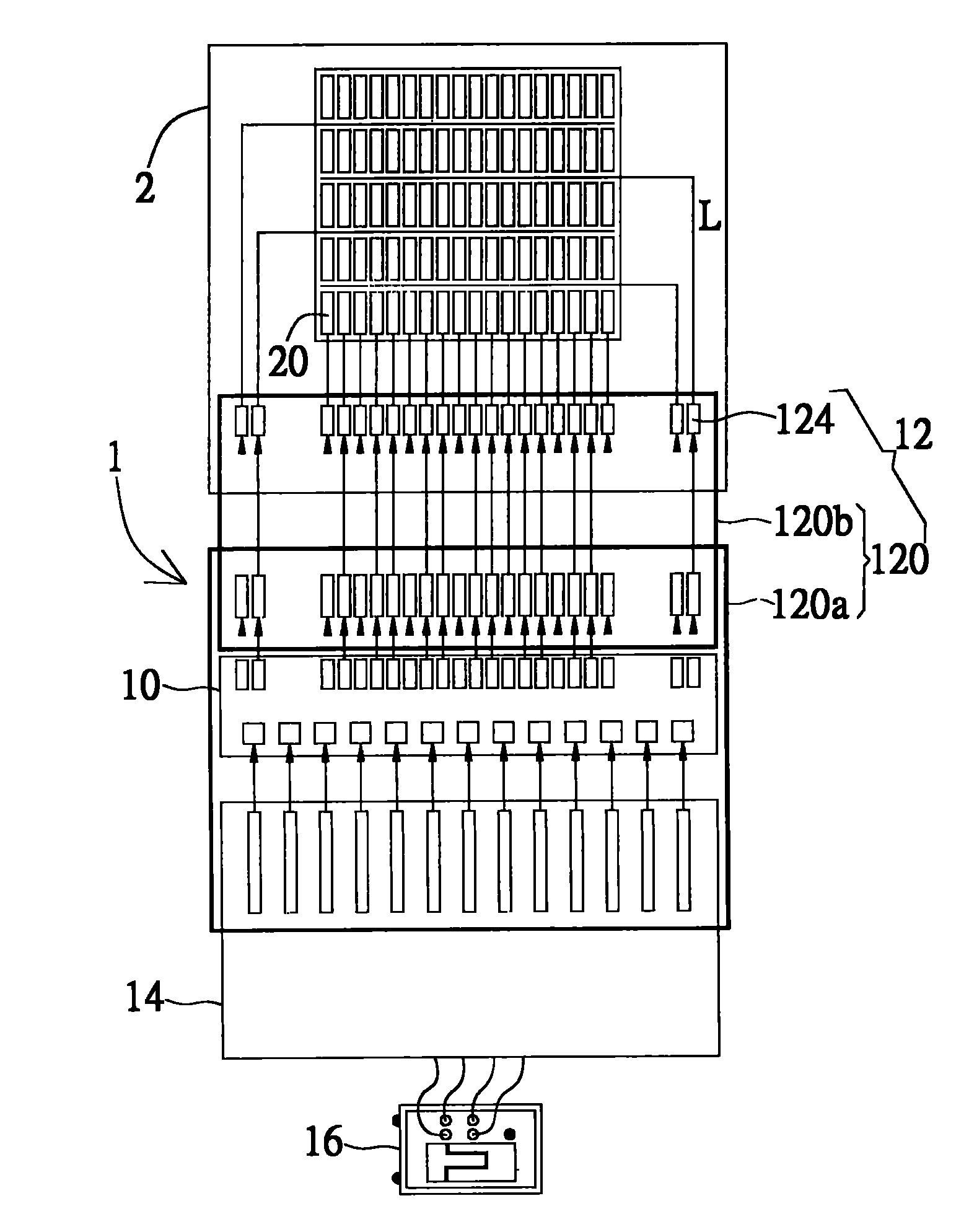

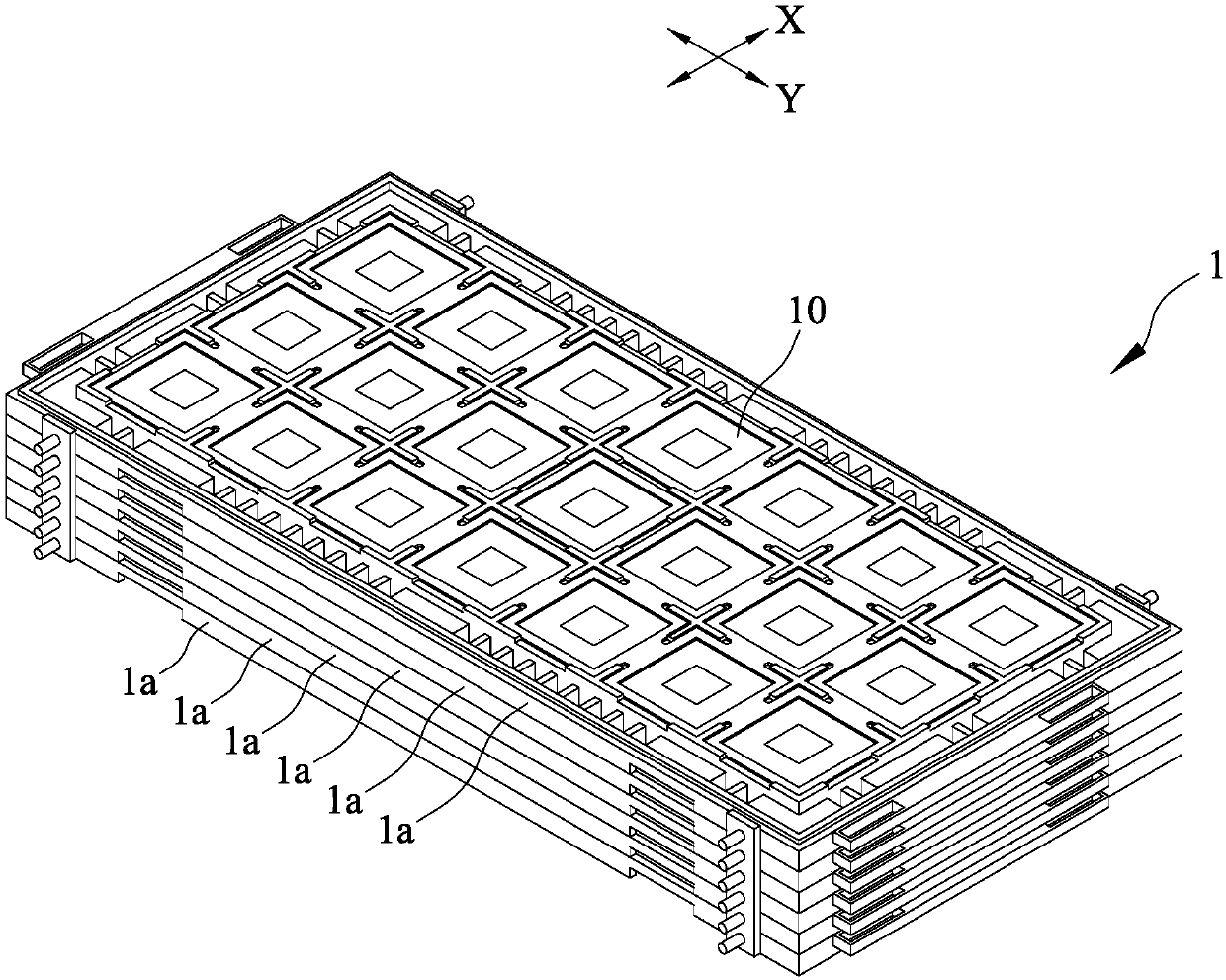

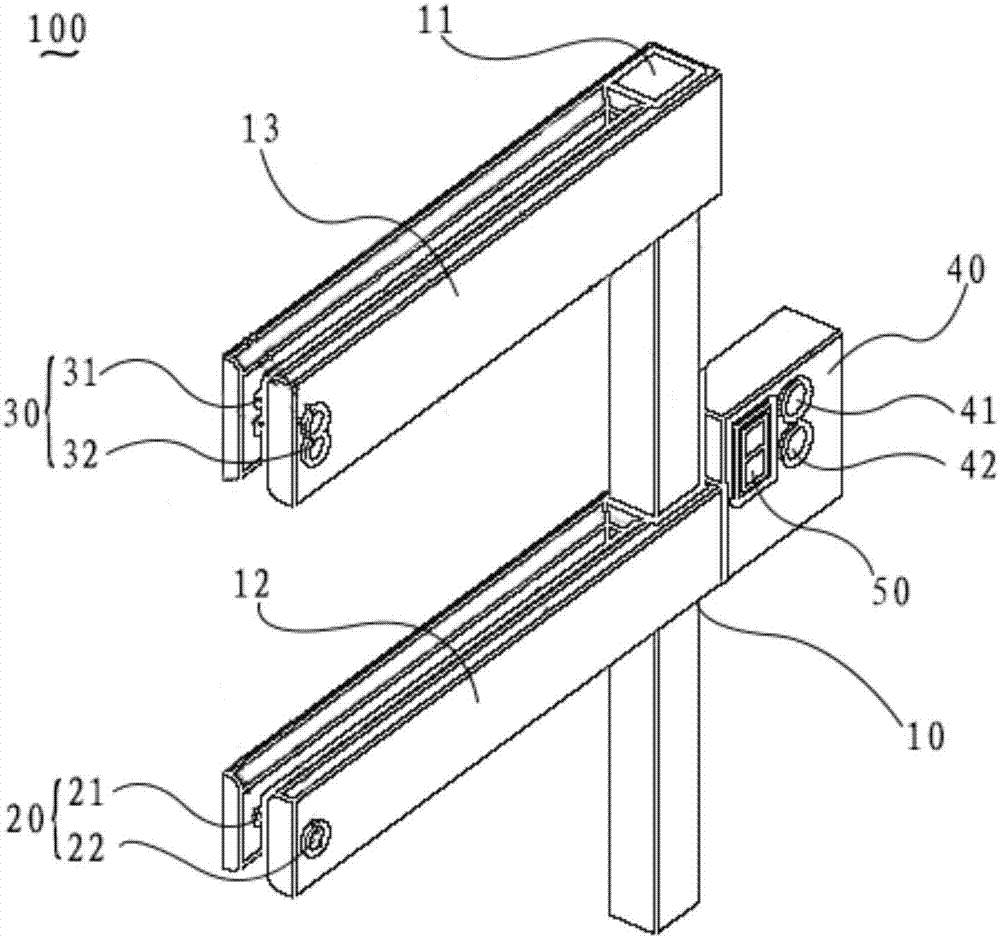

Display panel testing system and microprobe device thereof

ActiveCN102062790AAvoid the phenomenon of increased impedanceReduce manufacturing costElectrical measurement instrument detailsElectrical testingIntegrated circuitMicroprobe

The invention discloses a display panel testing system comprising a testing device and a microprobe device which are used for testing a display panel to be tested. The testing device is used for generating testing signals; the microprobe device comprises a substrate and a microprobe; the substrate is coupled with the testing device and provided with testing integrated circuits arranged symmetrically; and the microprobe is arranged on the substrate and coupled with the display panel to be tested. When being inputted into the substrate of the microprobe device and transmitted to the testing integrated circuits along a specific path, the testing signals are reversed by the testing integrated circuits and transmitted to the substrate of the microprobe device, and then the testing signals are outputted to the display panel to be tested through the microprobe.

Owner:AU OPTRONICS CORP

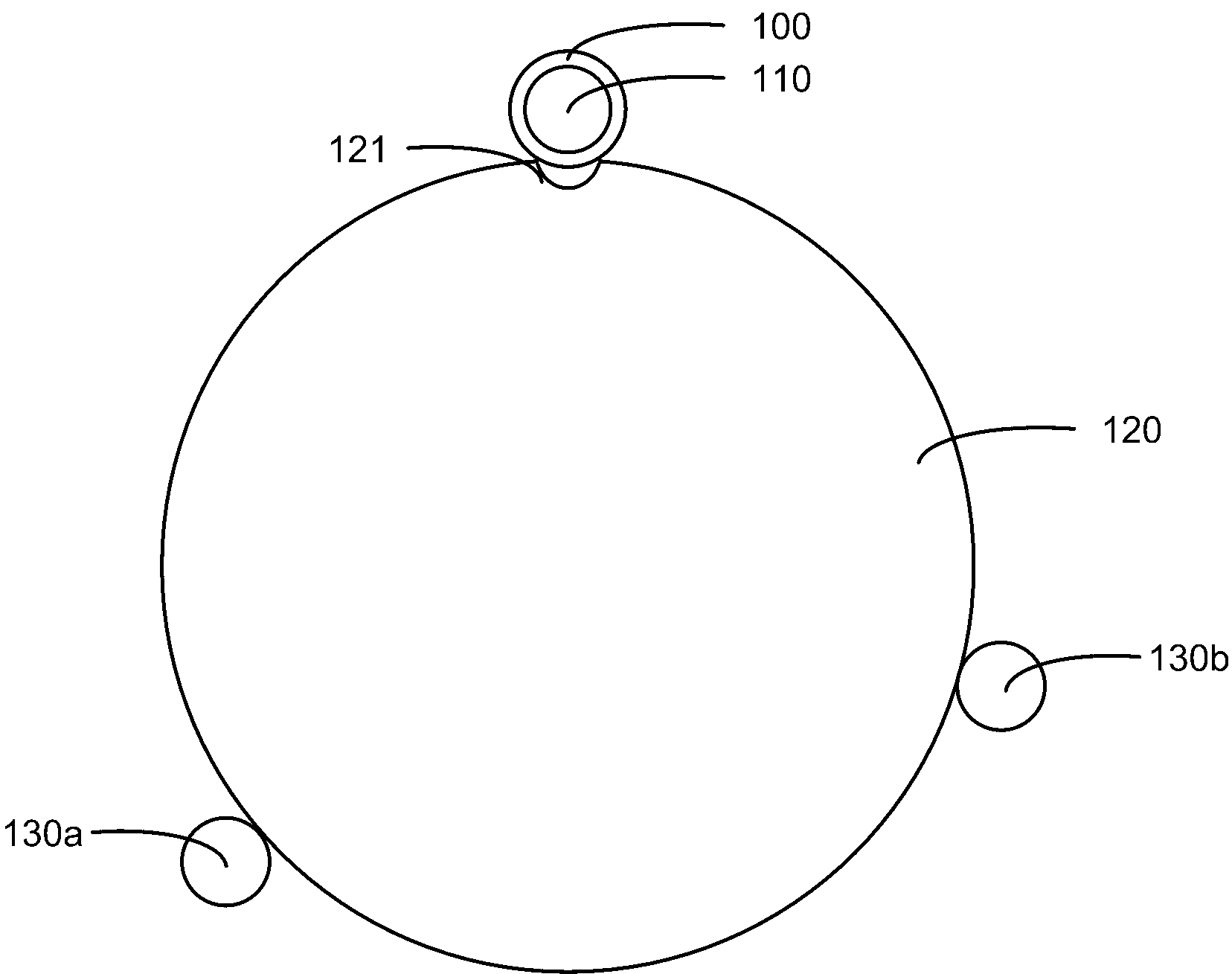

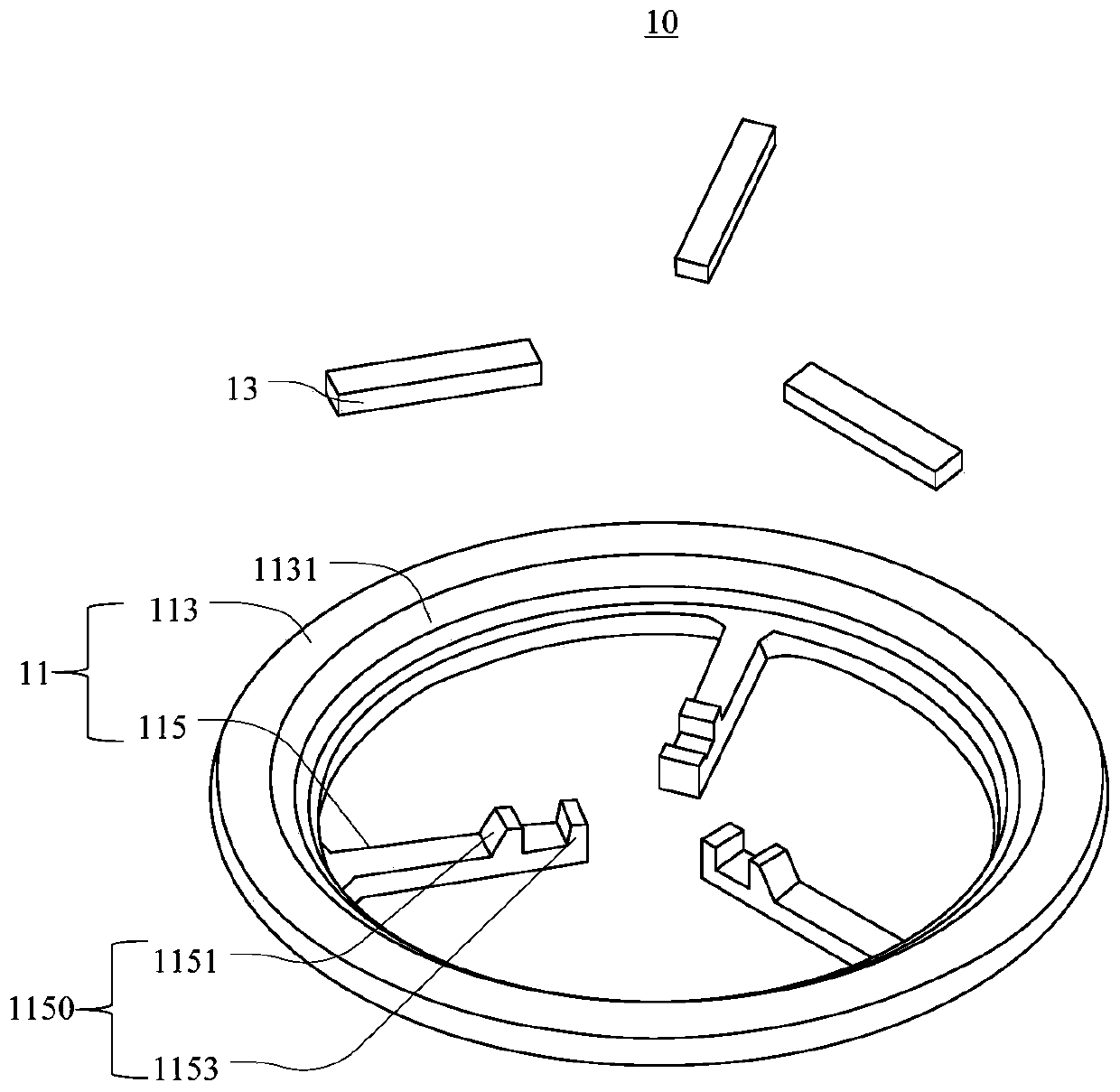

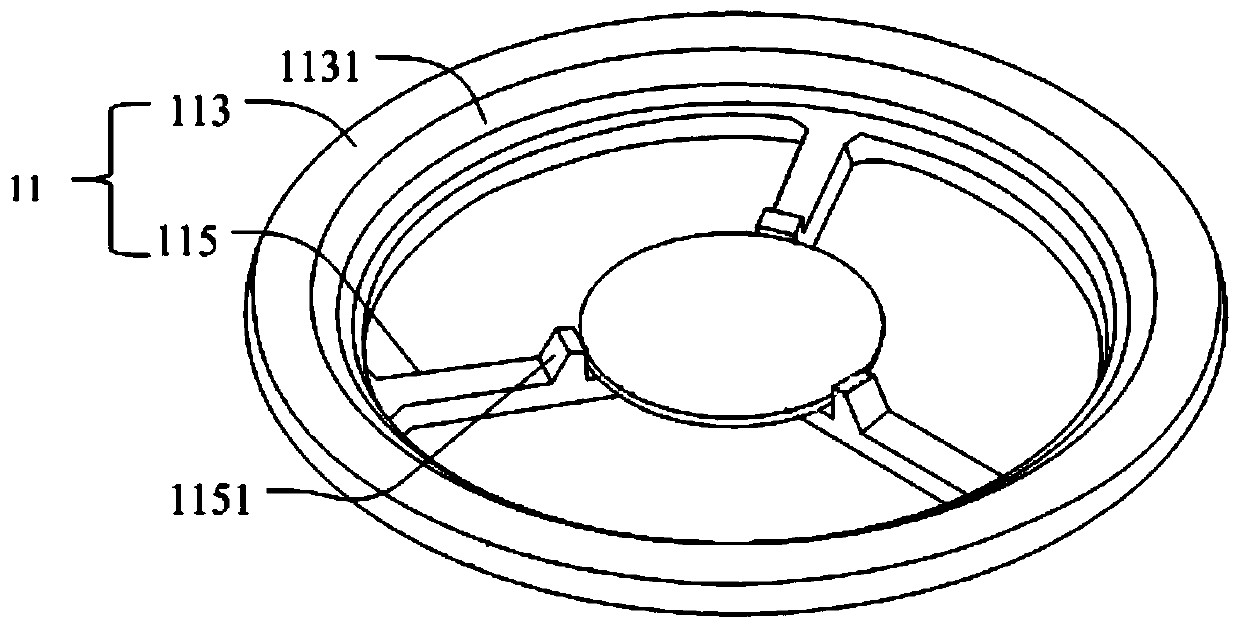

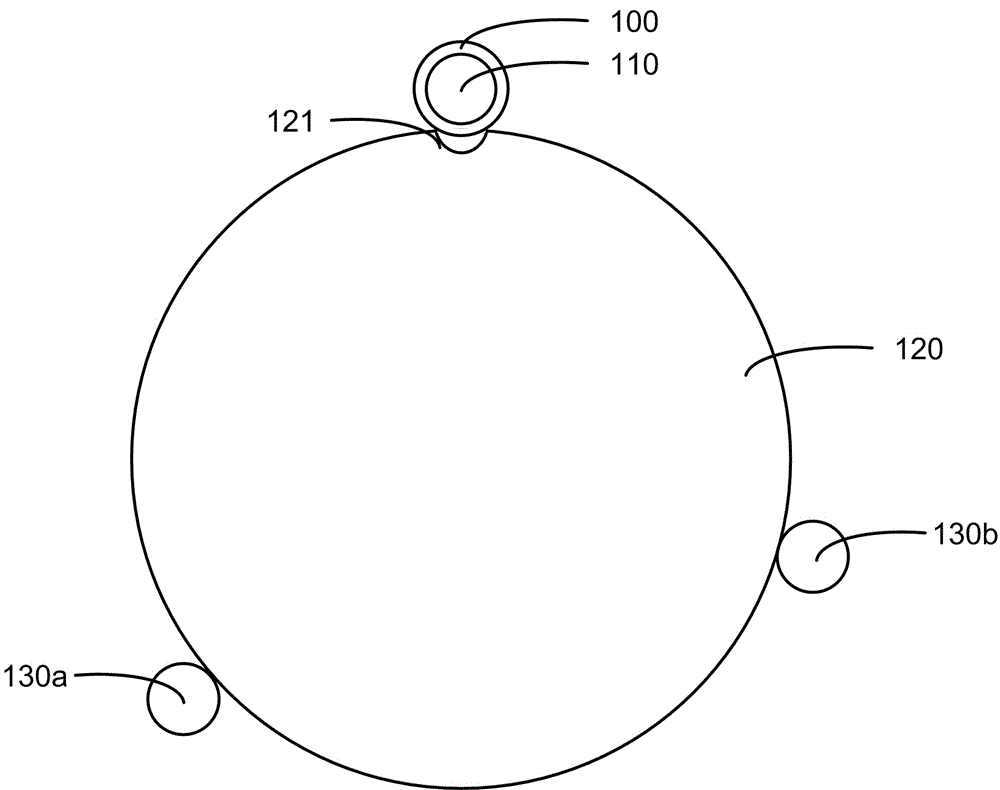

Vacuum casing for critical dimension scanning electron microscopy (CD-SEM)

ActiveCN103035465AEasy to installSimple structureElectric discharge tubesHardnessElectron microscope

The invention discloses a vacuum casing for a CD-SEM. The vacuum casing is in a ring structure, the inner diameter of the vacuum casing is matched with a pin arranged on a stage of the CD-SEM, and the hardness of the vacuum casing is smaller than that of a wafer to be tested. A notch at the edge of the wafer to the tested can be protected from being damaged through installing the vacuum casing on the notch pin of the CD-SEM, therefore the delivery quality of the wafer is improved, and the production cost is reduced. Additionally, the vacuum casing has the advantages of being simple in structure, convenient to install, easy to process and the like.

Owner:CSMC TECH FAB2 CO LTD

MMI function test system

InactiveCN109391722AReduce in quantityImprove test efficiencySubstation equipmentTest efficiencyManual testing

The invention discloses an MMI function test system comprising a rack. The front side of the rack is equipped with a display screen and a two-hand start button. The left and right sides of the rack are provided with side plates, the upper end of the rack is provided with a cover plate, the inner bottom of the rack is provided with a product fixture module for fixing a mobile phone, the inside of the rack is provided with a simulated human hand button device which is located above the product fixture module, and the inner top wall of the rack is provided with a working platform for detecting the mobile phone. Compared with a current pure manual test, the invention has the advantages that the test efficiency can be greatly improved, a test process can be recorded and a test result record canbe recorded, the test data in an Excel format can be exported, the production data can be conveniently analyzed by a factory so as to transform a production process and control bad items, the overallquality level is improved, the phenomena of misjudgment and missed detection that are easy to occur in a manual testing process can be reduced, and the quality of product shipments is improved.

Owner:SHENZHEN BOHUITE TECH CO LTD

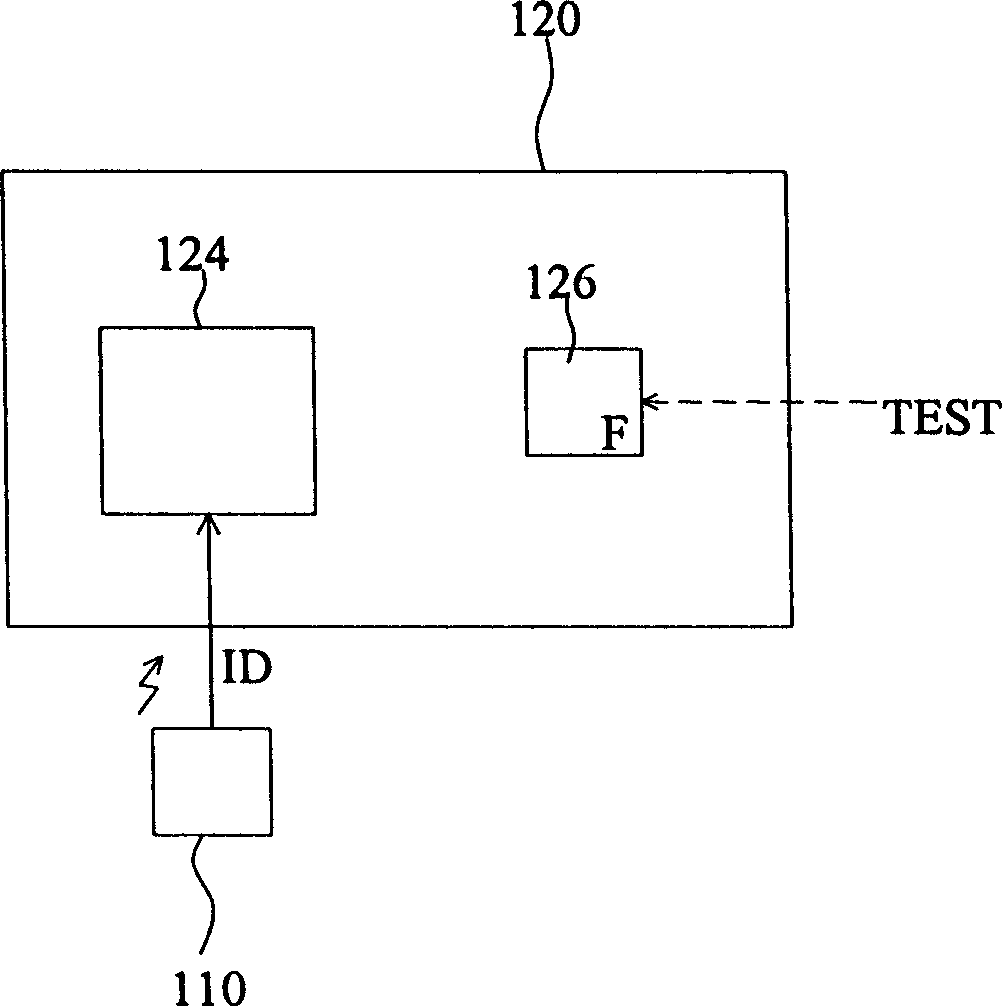

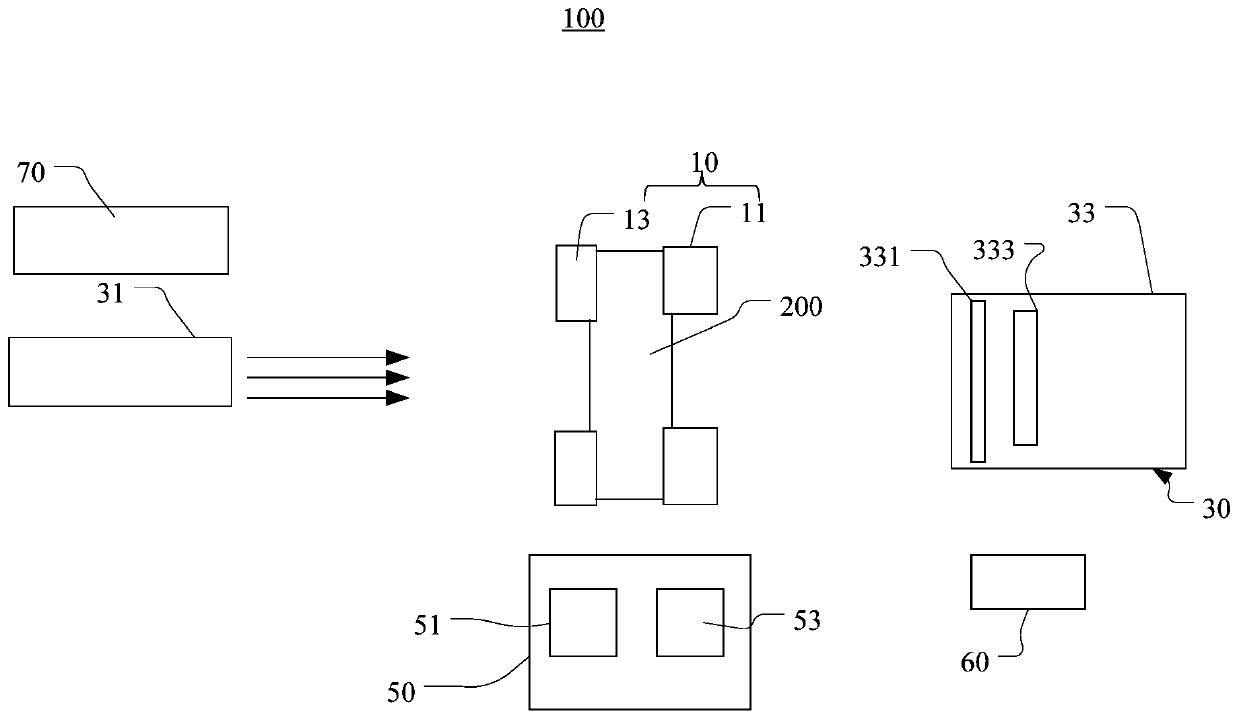

Production line information transmission processing method, automatic detection system and equipment

ActiveCN114079831BImprove shipment qualityImprove yield rateTelemetry/telecontrol selection arrangementsTransmissionProduction lineInformation transmission

The invention discloses a method for transmission and processing of production line information, an automatic detection system and equipment, wherein the automatic detection system includes a server for configuring detection parameter information according to external input information, receiving and processing the production line information sent by the automatic detection equipment , and generate return information according to the processing results; automatic detection equipment is used to detect online products to obtain production line information; the production line information includes current detection parameters of online products and online product ID codes of current products; transmission network, It is used to transmit the production line information acquired by the automatic detection equipment to the server and transmit the return information generated by the server according to the processing results to the automatic detection equipment. The invention can standardize the detection standards of each detection terminal by configuring server-side parameters, perform remote quality control on online products, solve the problem of single-machine detection, and effectively improve the quality of shipments and the yield of good products.

Owner:LONGCHEER ELECTRONICS HUIZHOU

Feed method

ActiveCN105752375BGuaranteed smoothnessMaintain feed length stabilityWrapping material feeding apparatusWrappingDental flossingEngineering

Owner:YUANTAI AUTOMATION TECH SUZHOU

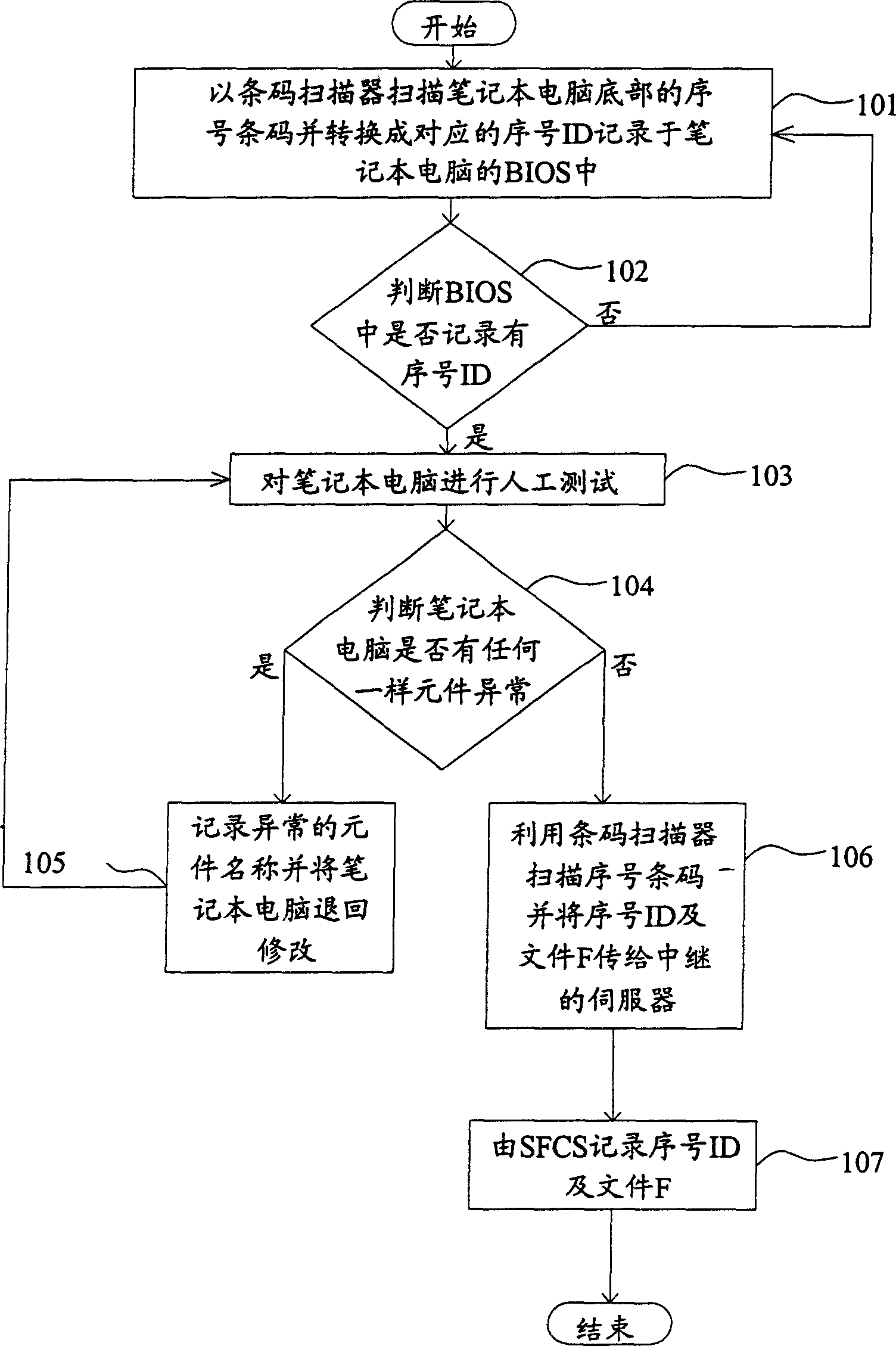

Machine table detection card method

InactiveCN1549122APrevent improper operation processImprove shipment qualityDetecting faulty computer hardwareSensing by electromagnetic radiationComputer hardwareCharge couple device

The machine test checking on method is to create one group of cipher in the machine to be tested, to test the elements in the machine to find the abnormal function of elements, to repair the machine if some abnormal element is found, to repeat the element test until all the elements are shown to be normal and the electronic bar code corresponding to the cipher is shown in the screen, and to read the electronic bar code with CCD type bar code scanner and compare the cipher as the test checking on action.

Owner:WISTRON CORP

Transmission processing method of production line information, automatic detection system and equipment

ActiveCN114079831AImprove shipment qualityImprove yield rateTelemetry/telecontrol selection arrangementsTransmissionProduction lineQuality control

The invention discloses a transmission processing method of production line information, an automatic detection system and automatic detection equipment. The automatic detection system comprises: a server which is used for configuring detection parameter information according to external input information, receiving and processing the production line information sent by the automatic detection equipment, and generating return information according to a processing result; the automatic detection equipment used for detecting online products so as to obtain production line information, wherein the production line information comprises current detection parameters of the online products and an online product ID code of a current product; and a transmission network which is used for transmitting the production line information acquired by the automatic detection equipment to the server and transmitting return information generated by the server according to a processing result to the automatic detection equipment. According to the transmission processing method, the detection standard of each detection terminal can be standardized by configuring the parameters of the server side, remote quality control is carried out on online products, the problem of single-machine detection is solved, and the shipment quality and the shipment yield are effectively improved.

Owner:LONGCHEER ELECTRONICS HUIZHOU

Bottle cap detection device

InactiveCN102221318BImprove shipment qualityWon't be squeezedMechanical measuring arrangementsEngineeringBottle cap

The invention discloses a bottle cap detection device which comprises a detection substrate and a detection body, wherein the detection body is movably fixed on the detection substrate; at least one channel is formed on the detection body, and comprises a leading channel and a detection channel; a barrier which prevents an abnormal bottle cap from being extruded by a subsequent falling bottle capand passing through the detection channel; and an inclined surface which prevents the bottle cap behind the abnormal bottle cap from entering the detection channel. The device has a simple structure and is convenient for assembling, the bottle cap passes through the detection channel by utilizing the gravity of the bottle cap, and the barrier blocks the falling bottle cap behind the abnormal bottle cap in the detection channel, so that the abnormal bottle cap is prevented from being extruded by the subsequent falling bottle cap and passing through the detection channel, so that the device hassmall detection errors and can perform line production, the bottle cap delivery quality is increased, and the working efficiency is increased.

Owner:SINO ASIA PLASTIC PACKAGE ZHONGSHAN

A display device for defect electronic limit preparation

ActiveCN109167995BImprove shipment qualityImprove quality inspection efficiencyTelevision systemsComputer hardwareEngineering

The invention discloses a manufacture apparatus for electronic limits of a display screen defect, comprising an equipment table. A screen lighting stage and a touch screen display integrated machine are respectively arranged on both sides above the equipment table, and a display screen wire arrangement interface is arranged on one side of the screen lighting stage. An industrial camera is fixed onthe side wall of the light-shielding plate, and a light-shielding plate is coated on the upper surface of the screen lighting stage. The industrial camera is located directly above the screen lighting stage. A display screen control board is arranged below the display screen wire arrangement interface. An operation knob, a start control button and a screen lighting control button are arranged atone end of the touch screen display integrated machine. The invention provides the manufacture apparatus for the electronic limits of the display screen defect, which can improve the quality inspection efficiency and improve the delivery quality of the display screen by adjusting the defect degree and the defect position on line, observing and maintaining the electronic limit document on line by human eyes instead of the original manual screening and determining the reference process, and can improve the quality inspection efficiency and improve the delivery quality of the display screen.

Owner:BEIJING LUSTER LIGHTTECH

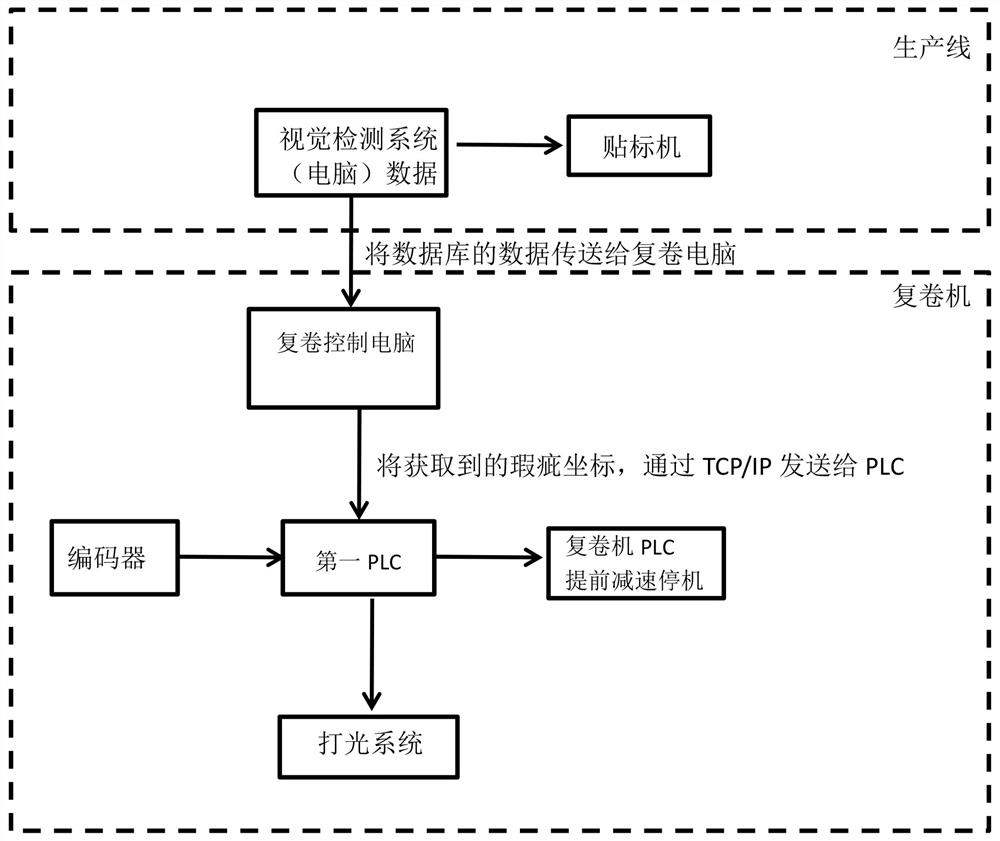

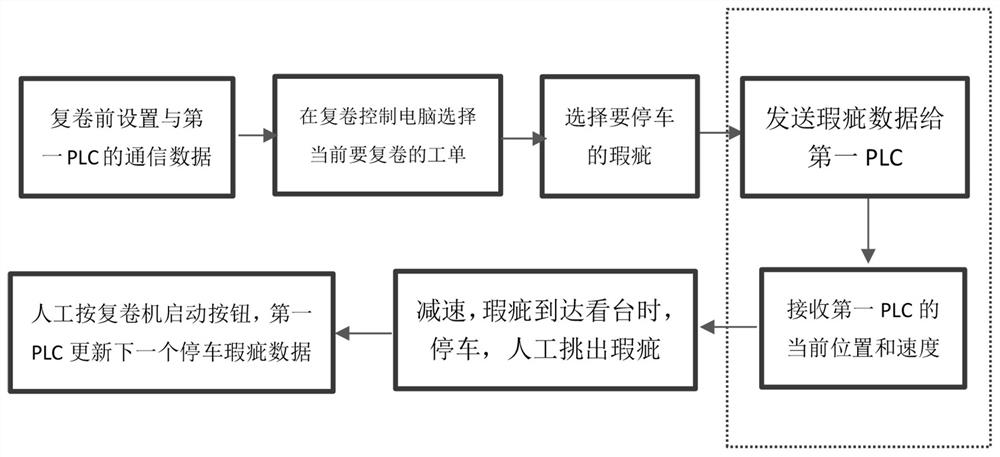

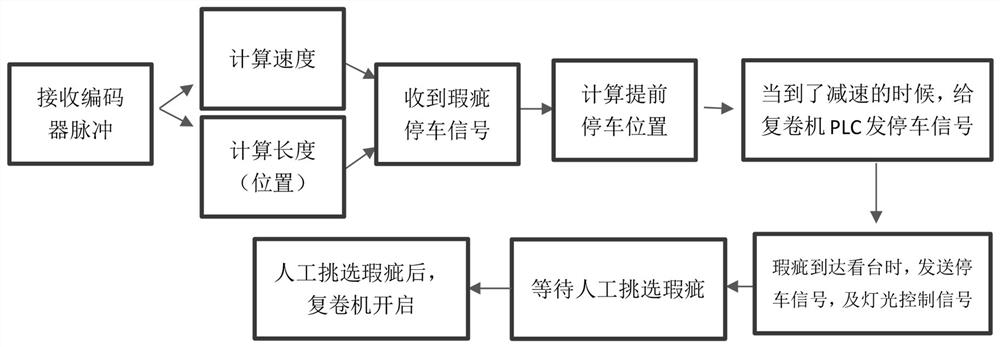

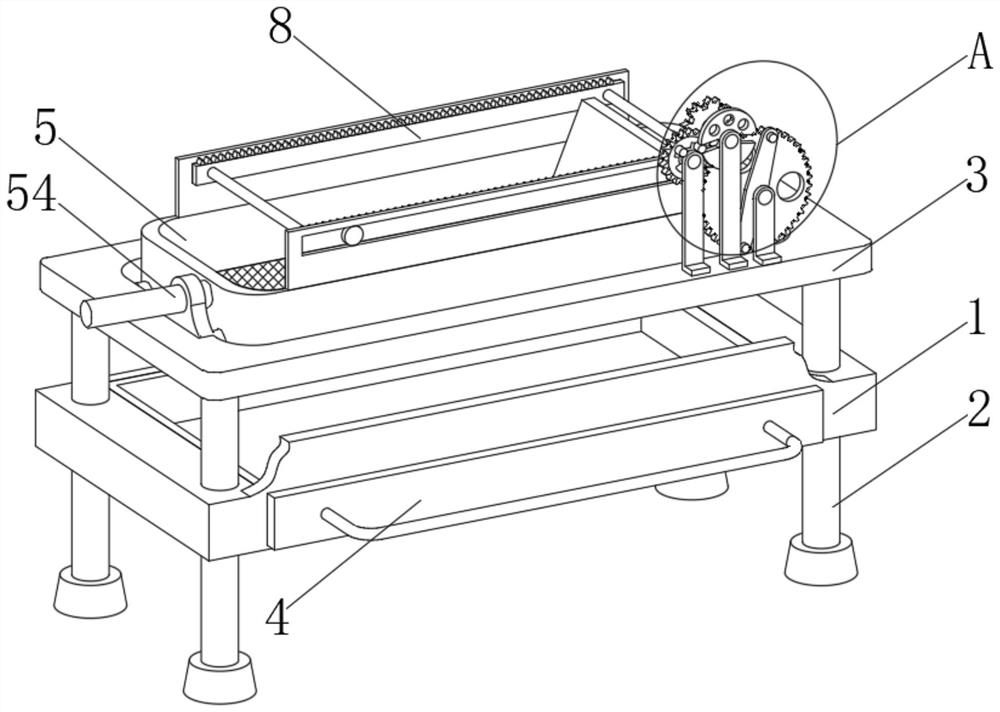

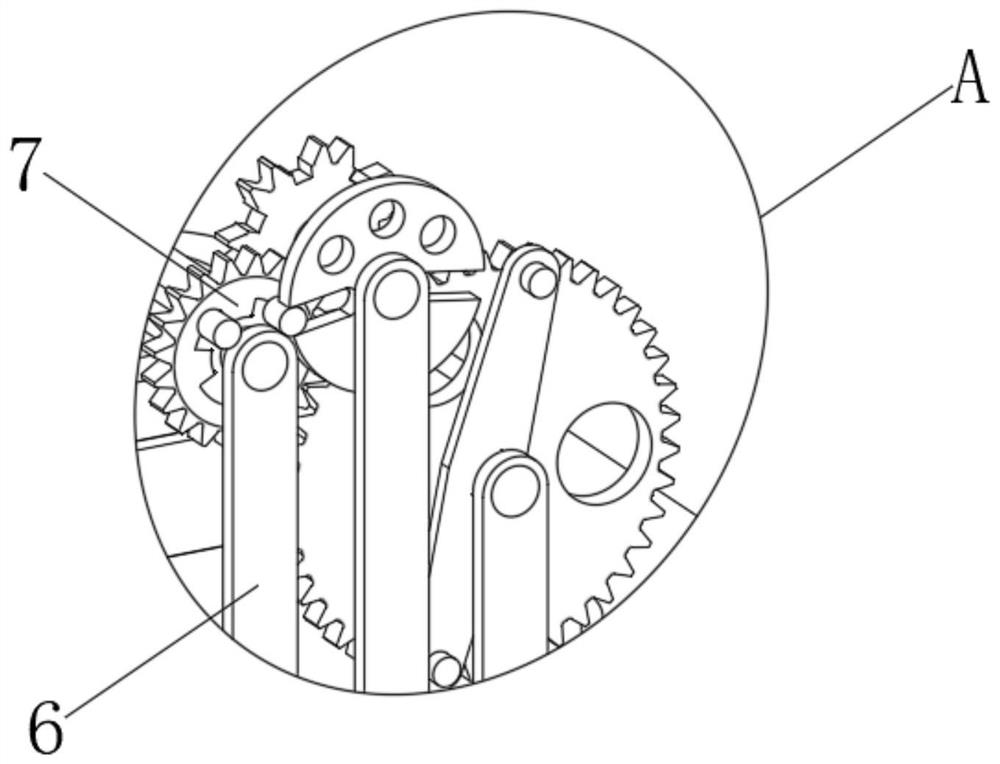

Machine vision-based coiled material off-line automatic parking rewinding method

InactiveCN114751242AEasy to operateImprove efficiencyFunction indicatorsOptically investigating flaws/contaminationMachine visionProgrammable logic controller

The invention provides a machine vision-based coiled material off-line automatic parking rewinding method, which comprises the following steps that: a rewinding control computer is used for receiving flaw data of a visual detection system on a target coiled material, and during rewinding operation, the rewinding control computer is used for sending position data of flaws closest to a stand in the longitudinal direction to a first PLC (Programmable Logic Controller) one by one; the first PLC sends a speed reduction signal to the rewinding machine PLC in advance corresponding to the longitudinal position data of the current flaw, and then sends a stop signal, so that the rewinding machine PLC controls the rewinding machine to stop under the condition that the speed is reduced aiming at the flaw which is about to arrive at the stand, and the flaw is stopped at the detection position on the stand. The rewinding efficiency and accuracy are improved, and meanwhile the working intensity of operators is reduced.

Owner:杭州百子尖科技股份有限公司

Ocean caught marine product sorting device

InactiveCN113170814AAvoid blockingImprove shipment qualityShellfish/bivalves grading/classificationMarine engineeringMechanical engineering

Owner:北海海洋渔民专业合作社

Optical wavefront measuring system and optical wavefront measuring method

ActiveCN110231149AHigh measurement accuracyImprove reliabilityDetection of fluid at leakage pointTesting optical propertiesWavefrontPhysics

The present application provides an optical wavefront measuring system and method for application in the field of optical wavefront detection. The optical wavefront measuring system comprises a carrying device, a wavefront measuring device and a temperature and humidity device. The carrying device is used for positioning a to-be-measured liquid optical element. The wavefront measuring device is used for detecting wavefront information passing through the liquid optical element. The temperature and humidity device is used for adjusting a temperature of an environment of the liquid optical element to a preset temperature and adjusting a humidity of the environment of the liquid optical element to a preset humidity. When a processor determines that the temperature of the environment of the liquid optical element is the preset temperature and the humidity is the preset humidity, the processor controls the wavefront measuring device to detect the wavefront information passing through the liquid optical element so that the wavefront measuring device can detect the optical performance of the liquid optical element in a specific environment, thereby improving the measurement accuracy of the wavefront measuring system and benefiting the improvement of the reliability of the liquid optical element.

Owner:HUAWEI TECH CO LTD

Optical wavefront measurement system and optical wavefront measurement method

ActiveCN110231149BHigh measurement accuracyImprove reliabilityDetection of fluid at leakage pointTesting optical propertiesWavefrontLiquid state

Owner:HUAWEI TECH CO LTD

Tape punching apparatus and tape punching method

ActiveCN110271701APrevent emergenciesPrevent mutual separationBinding material applicationBundling machine detailsPunchingSemiconductor package

The present invention provides a tape punching apparatus and a tape punching method. A removal device automatically removes a magic tape that fastens a plurality of trays, to replace the conventional mechanism that the magic tape is removed by labors and prevent the trays from being separated one another. Therefore, the semiconductor packages received on the trays are prevented from falling to the ground and damaged.

Owner:SILICONWARE PRECISION IND CO LTD

Collar sleeve length monitoring method and device

ActiveCN107881750AAffect delivery efficiencyEnable continuous monitoringInspecting textilesNormal deliveryMonitoring methods

The invention relates to a collar sleeve length monitoring method and device. The method comprises steps that a plurality of collar sleeves are orderly delivered at equal intervals and orderly pass through a reference position and a detection position; a distance between the reference position and the detection position is equal to a sum of a distance between two adjacent collar sleeves and a preset collar sleeve length; a time of period of the current collar sleeve reaching the detection position and a time of period of a next collar sleeve reaching the reference position are detected and then a comparison is made therebetween; and whether the linear length of the current collar sleeve is equal to the preset collar sleeve length according to a comparison result. The monitoring method canavoid collar sleeve delivery efficiency reduction due to multi-time measurement by workers, so continuous monitoring for the collar sleeve during a normal delivery process can be realized and production process continuity can be improved; production efficiency can be greatly improved and labor intensity can be lowered; detection miss can be avoided; production quality can be enhanced; and clothesscrap can be reduced, so production cost can be lowered.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Suction device

ActiveCN106346506BRealize integrationImprove versatilityGripping headsAxial displacementContact pressure

The invention discloses a suction and holding device. The suction and holding device comprises a suction nozzle, a center shaft, a suction buffer mechanism, a mounting base, a rotary driving mechanism and a limiting block. The suction and holding device has the advantages that the axial position of the center shaft is adjusted when a lens is sucked, so that the contact pressure between the device and the lens is effectively reduced; by rotating the center shaft, the angle of the sucked lens is adjusted; by adjusting the position of the limiting block on the center shaft, the axial displacement distance of the center shaft is limited, and the telescopic quantity of the center shaft is indirectly changed.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

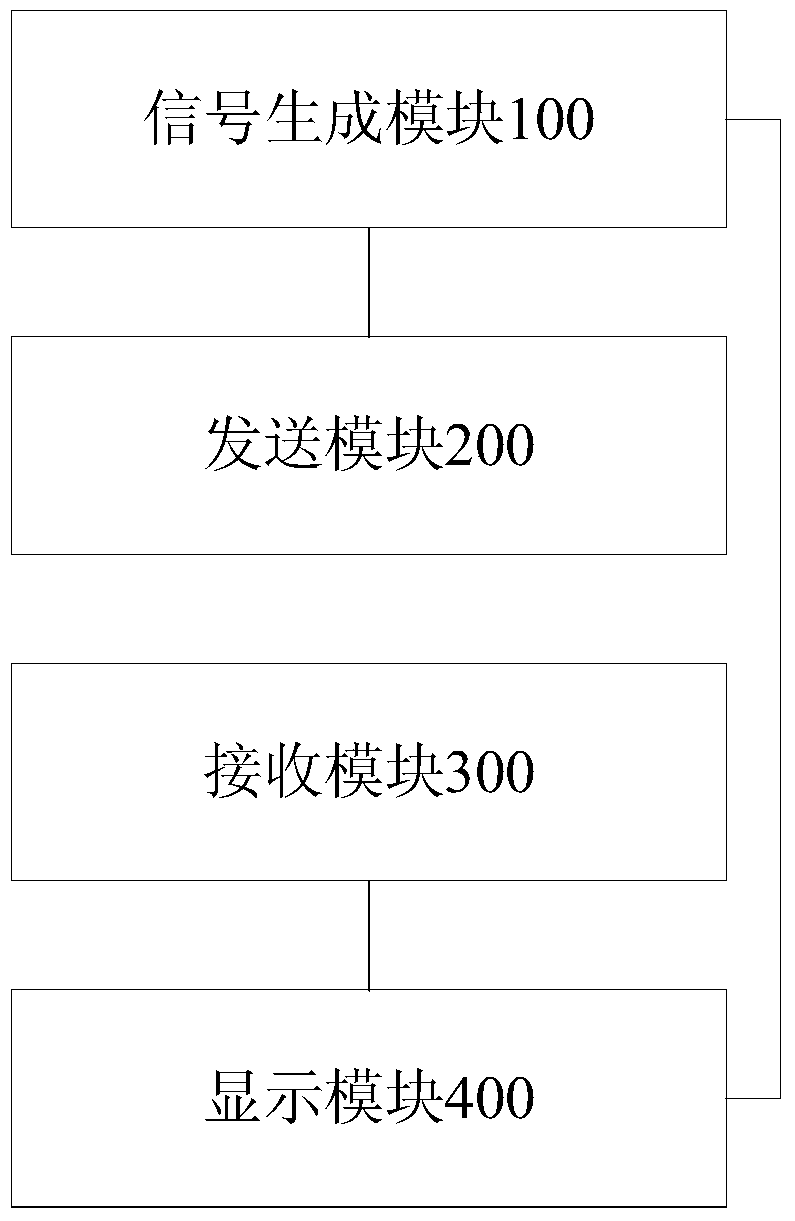

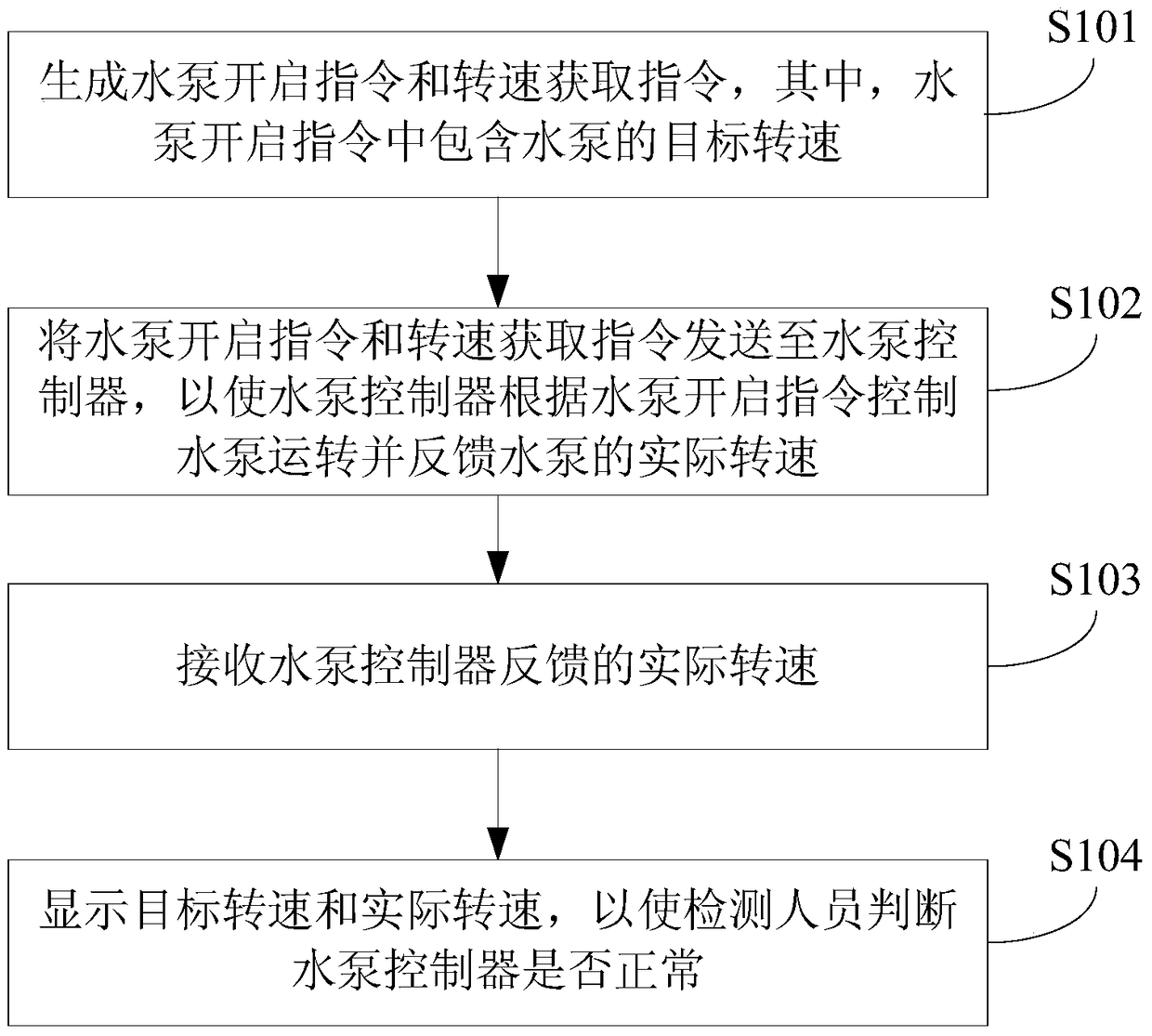

Testing equipment and testing method for vehicle water pump controller

The invention discloses a vehicle water pump controller detection device and detection method. The detection device comprises a signal generation module which is used for generating a water pump starting instruction and a rotating speed obtaining instruction, wherein the water pump starting instruction includes target rotating speed of a water pump; a transmitting module which is used for transmitting the water pump starting instruction and the rotating speed obtaining instruction to a water pump controller so that the water pump controller is enabled to control the water pump to operate according to the water pump starting instruction and feed back actual rotating speed of the water pump; a receiving module which is used for receiving actual rotating speed fed back by the water pump controller; and a display module which is used for displaying target rotating speed and actual rotating speed so that detection personnel are enabled to judge normality of the water pump controller. According to the vehicle water pump controller detection device, the detection personnel are enabled to judge normality of the water pump controller via the displayed target rotating speed and actual rotating speed of the water pump so that shipping quality of the water pump controller product can be greatly enhanced.

Owner:BYD CO LTD

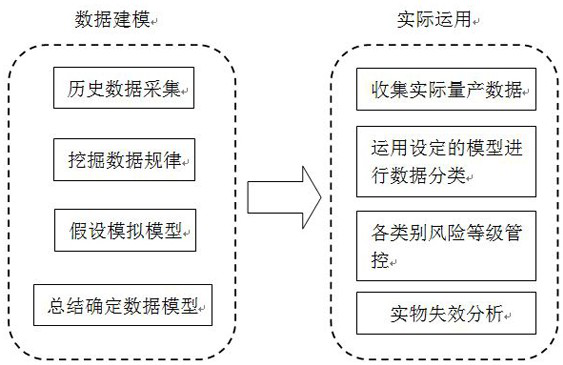

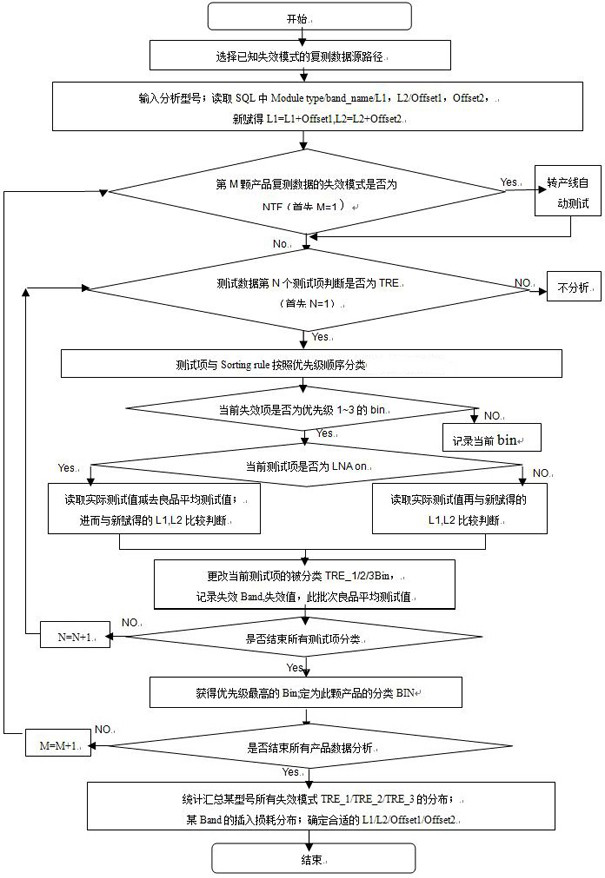

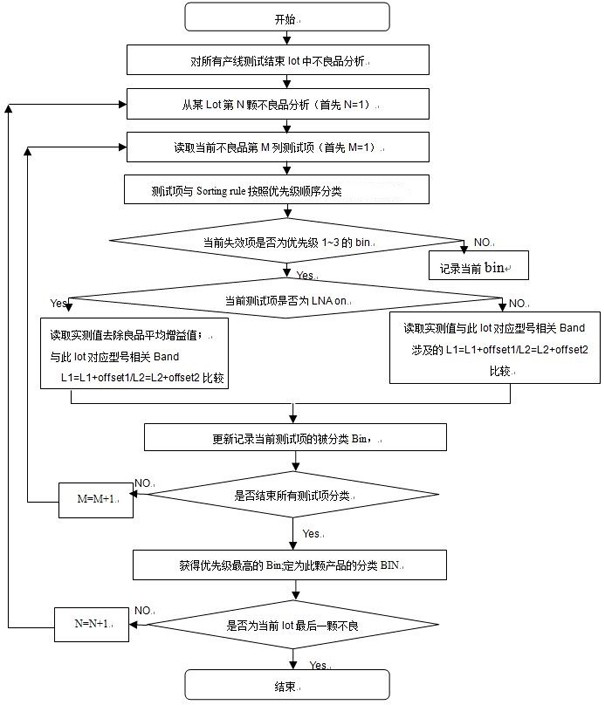

Method and system for classifying defective radio frequency front-end module chips in mass production

PendingCN112836761AImprove work efficiencyRealize management and control analysisCharacter and pattern recognitionDesign optimisation/simulationRisk levelRadio frequency

The invention provides a method and system for classifying defective radio frequency front-end module chips in mass production, which can perform classification according to test data of defective products, thereby performing management and control analysis on classes of different risk levels, improving the detection rate of risk failure, and further improving the quality of the products.

Owner:RF360 TECH (WUXI) CO LTD

Critical Dimension Scanning Electron Microscope and Its Vacuum Tube

ActiveCN103035465BEasy to installSimple structureElectric discharge tubesScanning electron microscopeElectron microscope

Owner:CSMC TECH FAB2 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com