Method and system for classifying defective radio frequency front-end module chips in mass production

A radio frequency front-end, classification method technology, applied in character and pattern recognition, special data processing applications, instruments, etc., can solve problems such as risk failure sampling, affecting product delivery quality, etc., to optimize work efficiency and improve delivery quality. , the effect of improving the detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

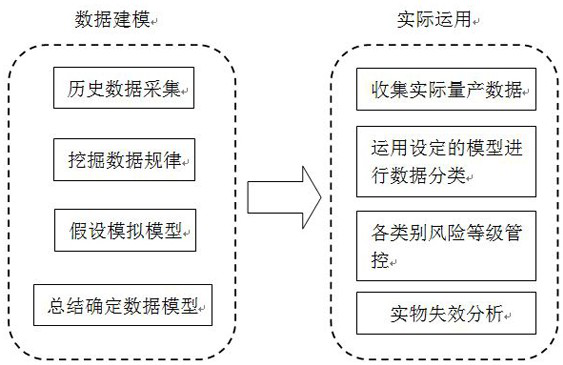

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

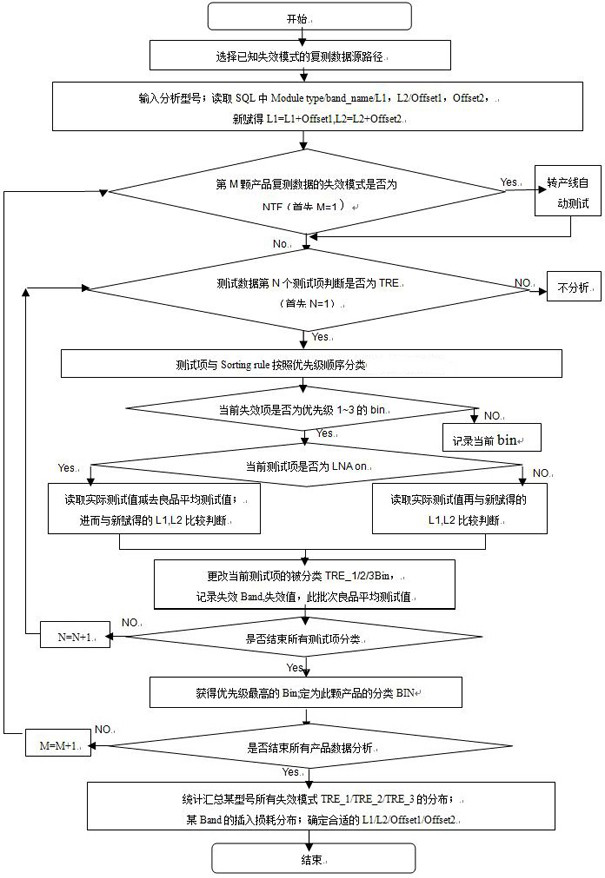

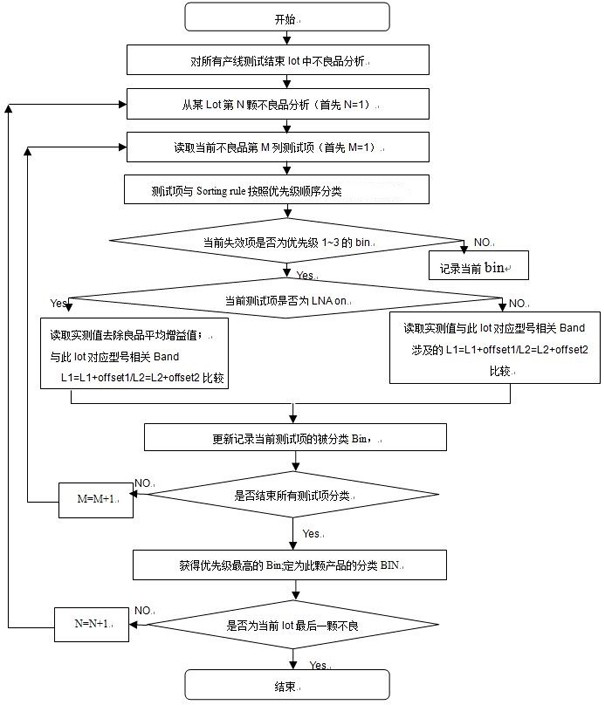

[0032] A method for classifying defective chips produced in mass production of radio frequency front-end modules, comprising:

[0033] Step 1. computer collects the historical test data of defective product; Described historical test data comprises: product model, the frequency band of described product model and the failure mode under each frequency band, the insertion loss corresponding to described failure mode and gain test item, all The test values of the above insertion loss and gain test items;

[0034] Step 2. The computer sets the first basic classification value L1B and the second basic classification value L2B according to the distribution of failure modes and insertion loss and gain test values of the same frequency band B of all product models, so that 100% of the high-risk failure modes correspond to The test value is between L1B and L2B, at least 72% of the test values corresponding to the medium risk failure mode are between L1B and L2B, at least 70% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com