Suction and holding device

A technology of holding devices and mounting seats, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as increased production costs, air leakage, and poor overall air tightness, and achieve reduced damage, small size, and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] According to one embodiment of the present invention, the method for adjusting the lens angle by using the holding device of the present invention is as follows:

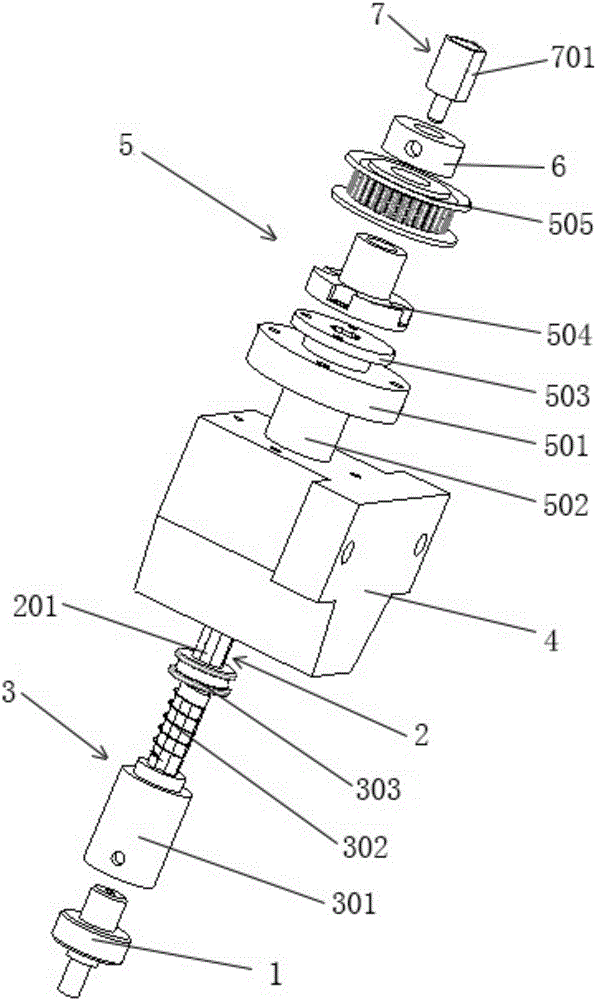

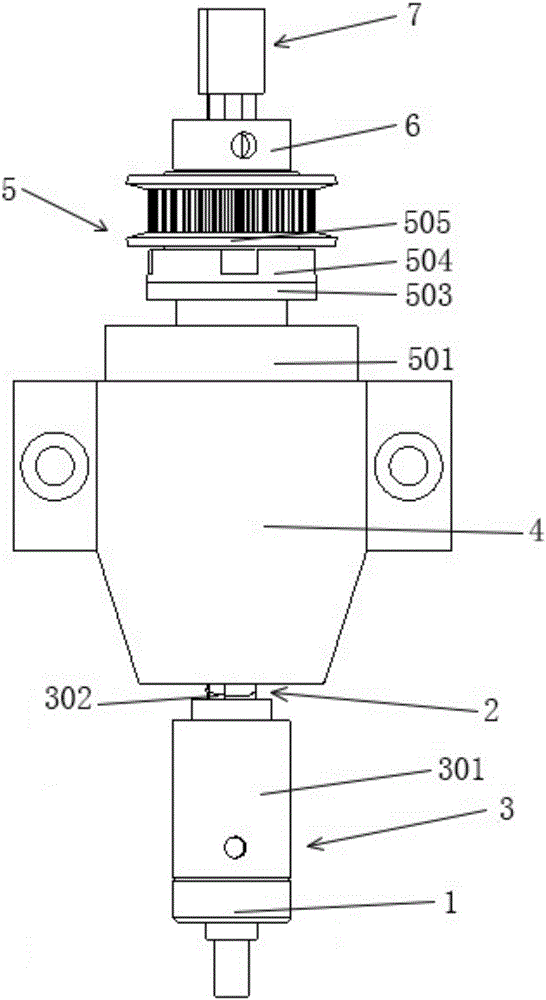

[0051]The pulley 505 in the rotary driving mechanism 5 is connected with a power source, so that the pulley 505 is driven to rotate by the power source. The rotation of the pulley 505 can drive the rotation driving mechanism to rotate. Because the pulley mount 504 is fixedly connected with the pulley 505 with a top screw, the flange 503 and the pulley mount 504 are connected by bolts, and the shaft sleeve 502 and the flange 503 are an interference fit, so when the pulley 505 rotates, the The pulley mounting seat 504, the flange 503 and the shaft sleeve 502 rotate coaxially and in the same direction together with them. The shaft sleeve 502 is keyed to the central shaft 2. When the shaft sleeve 502 is driven by the pulley 505 to rotate synchronously with the same axis, the shaft sleeve 502 and the central shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com