Feed method

A feeding method and feeding technology, applied in the direction of packaging material feeding device, transport packaging, wrapped objects, etc., can solve the problems of variable length of dental floss, occupying human resources, affecting the quality of product shipments, etc., to improve the output The effect of improving the quality of goods and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

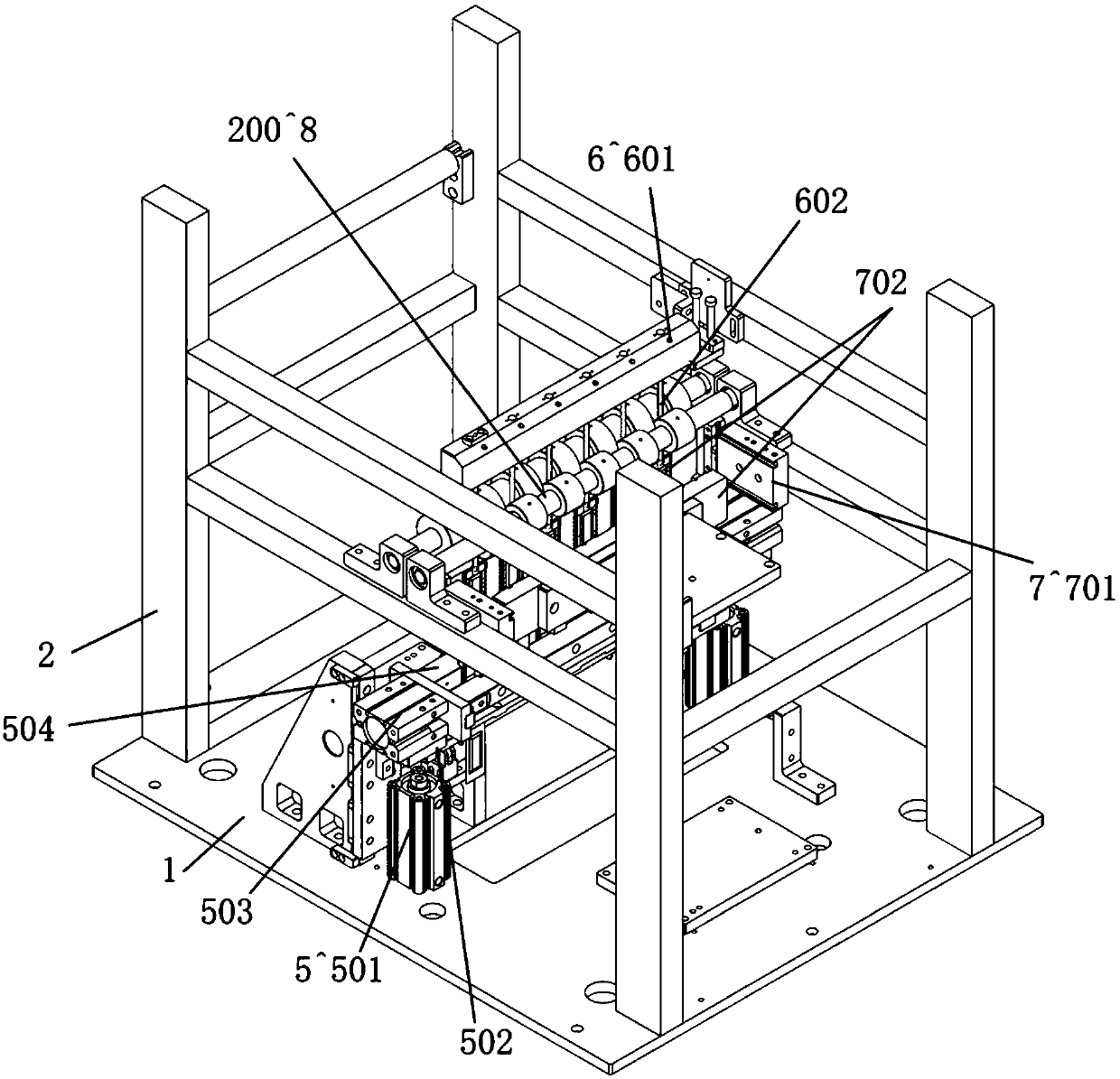

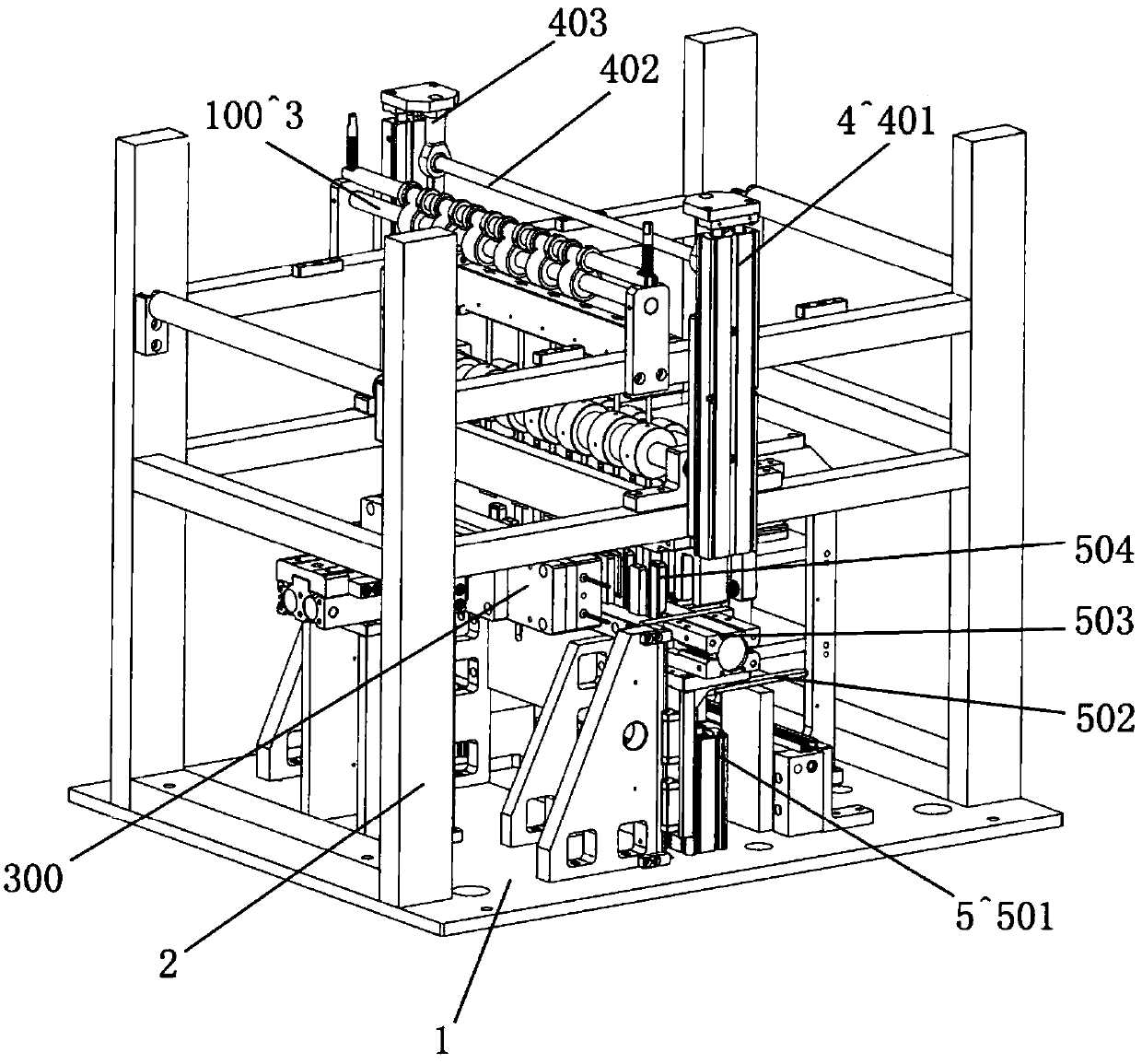

[0040] refer to Figure 1-Figure 5 , the present embodiment provides a dental floss packaging device, including a bottom plate 1, a mounting frame 2 arranged on the bottom plate 1, and a feeding mechanism 100 sequentially arranged on the mounting frame from top to bottom and used in conjunction with, Threading mechanism 200, and packaging mechanism 300 and cutting mechanism (not shown in the figure);

[0041] The feeding mechanism 100 includes a leveling module 3 and an auxiliary traction module 4 that are arranged on the upper end of the mounting frame 2 and are used in conjunction with each other. Feed jaw module 5;

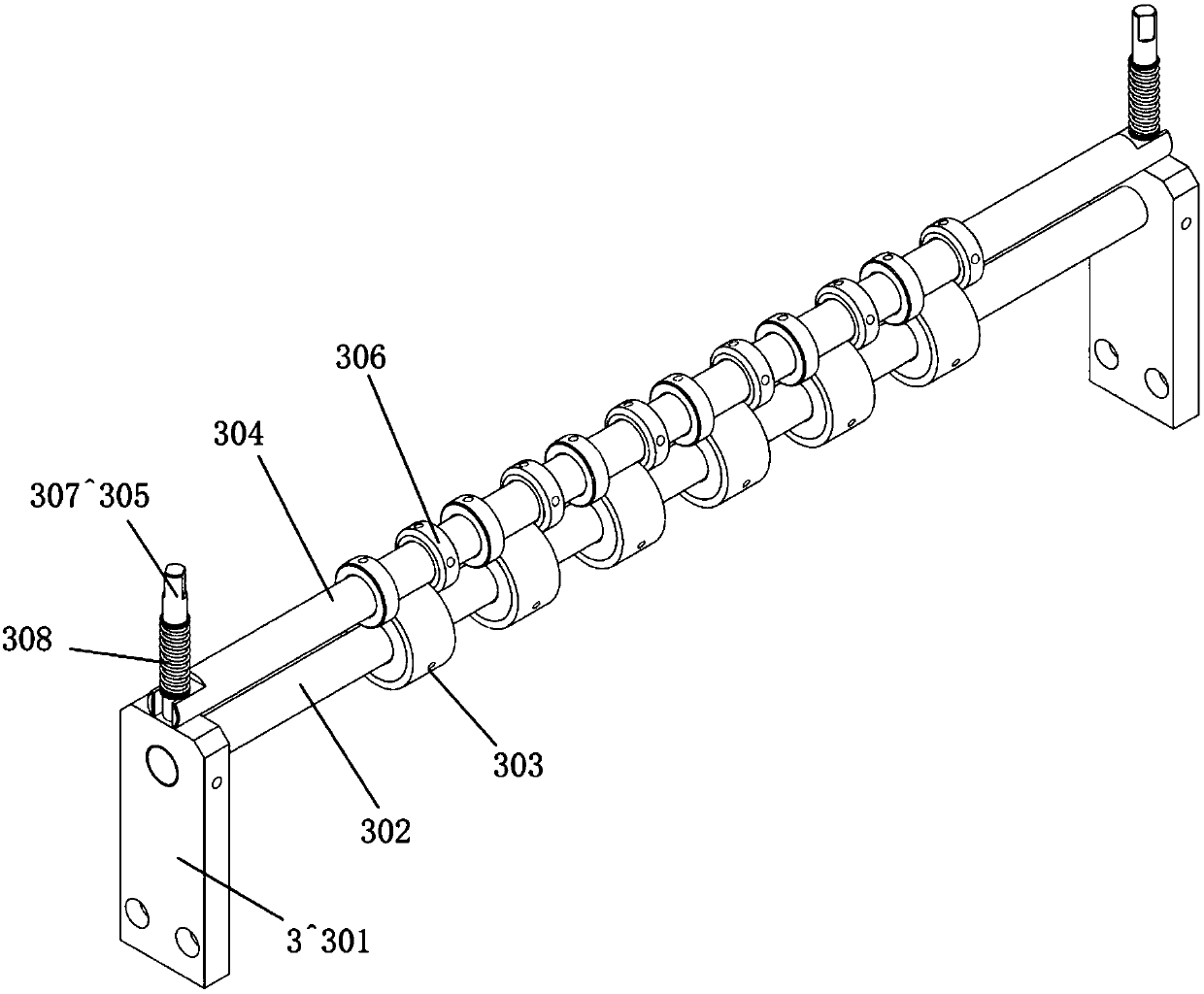

[0042] The leveling module 3 includes a leveling mounting plate 301 fixedly arranged on the mounting frame 2, a leveling shaft 302 on which a leveling roller 303 is arranged on the leveling mounting plate 301, and a leveling shaft 302 provided with an auxiliary flattening elastic member. 305 is arranged on the leveling mounting plate 301 and the flattening sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com