Box pasting machine capable of achieving automatic gluing and adhesive sticker sticking

An automatic gluing and tape technology, which is used in container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc. It can solve the problems affecting product shipment quality, large handling workload, and high work intensity. To avoid the influence of squeegee process factors, reduce production costs, and improve the quality of shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

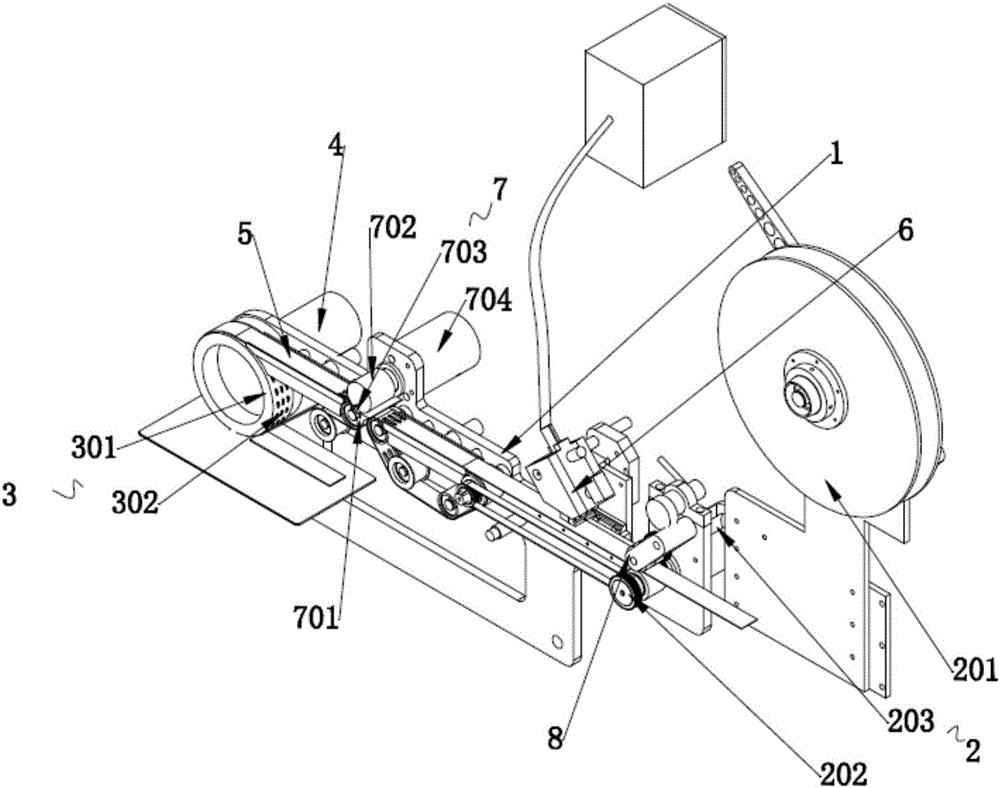

[0016] Such as figure 1 , the present embodiment provides a box gluer for automatic gluing and self-adhesive adhesive tape, including a cardboard conveying mechanism (not shown in the figure) and a support plate 1 arranged above the cardboard conveying mechanism, and the support plate 1 is provided with There is a self-adhesive tape feeding mechanism 2 and an aspirating sticker disc 3, the aspirating sticker disc 3 is connected with a disc servo motor 4, and the aspirating sticker disc 3 is arranged above the cardboard conveying mechanism And the gap between the cardboard conveying mechanism is less than or equal to the thickness of a single piece of cardboard; the self-adhesive tape feeding mechanism 2 and the suction type sticker disc 3 are set on the same horizontal plane and a self-adhesive tape is arranged between the two A conveying mechanism 5, a glue spraying mechanism 6 is arranged above the self-adhesive tape conveying mechanism 5.

[0017] Described self-adhesive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com