Machine vision-based coiled material off-line automatic parking rewinding method

An automatic parking and machine vision technology, applied in the direction of winding strip, thin material processing, optical testing flaws/defects, etc. Improve efficiency and facilitate work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

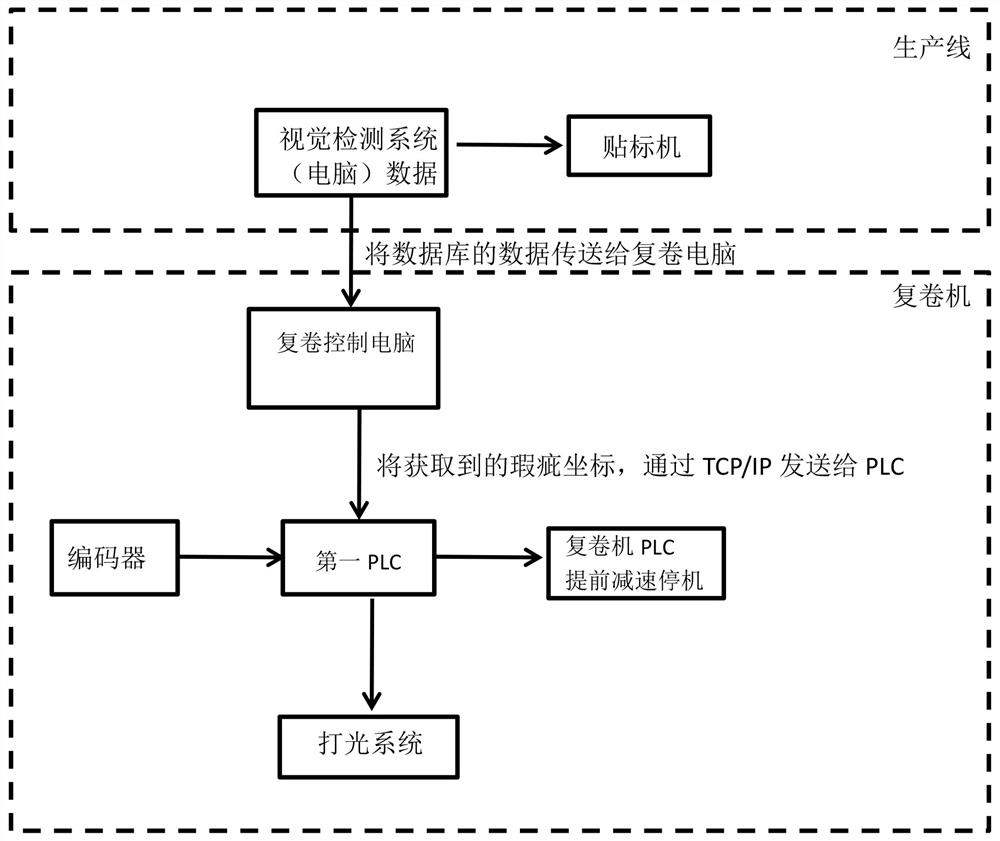

[0038] Refer to attached drawings. The invention provides a machine vision-based off-line automatic parking and rewinding method for coiled materials. The rewinding machine is additionally equipped with a rewinding control computer, and a PLC is the first PLC described below. The first PLC also is configured with an encoder. Among them, the rewinding control computer is connected in communication with the visual inspection system of the coil production line. In the state of networking, the database of the visual inspection system transmits the defect information of the coil to be rewinded to the rewinder through TCP / IP. Control the computer. As an alternative, the defect information of the roll to be rewound can also be copied and transferred through the mobile storage in an offline state.

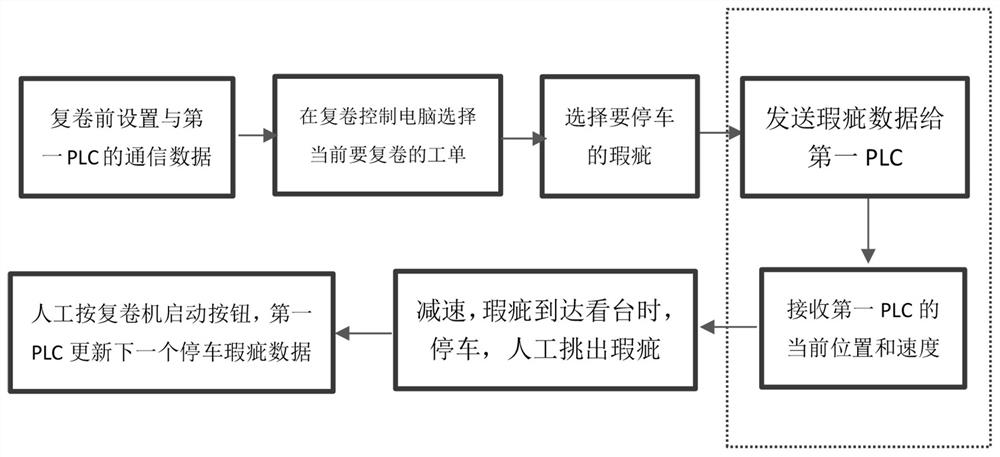

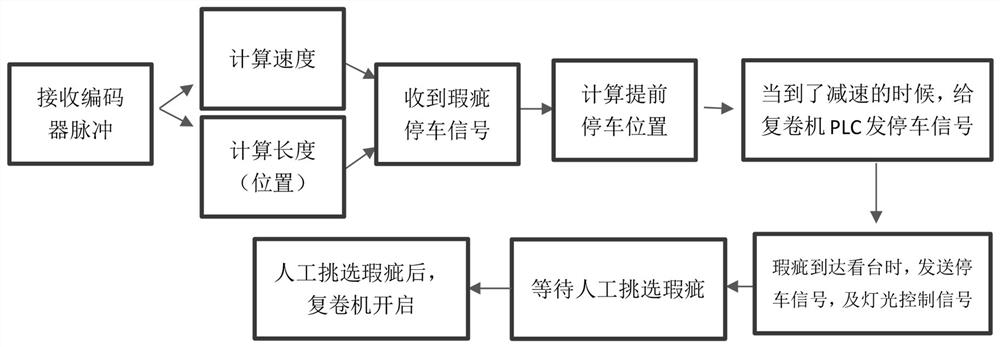

[0039] The machine vision-based off-line automatic parking and rewinding method for coil material comprises the following steps:

[0040] In step S1, a rewinding control computer is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com