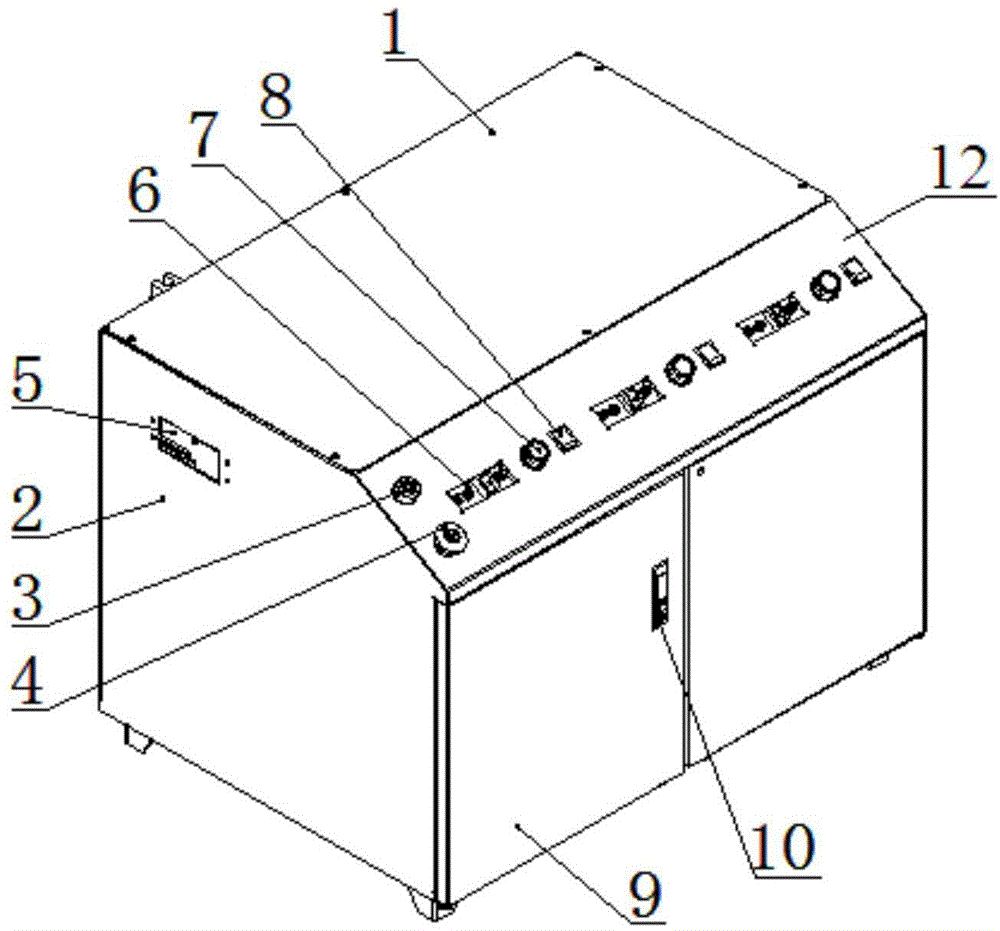

Metal can coating electromagnetic induction automatic drying heating device

An electromagnetic induction, drying and heating technology, applied in coating, device for coating liquid on surface, surface pretreatment, etc., can solve the problems of quality impact, labor intensity of workers, uneven firepower, etc., and achieve delivery quality The effect of improvement, obvious energy saving effect and rapid heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

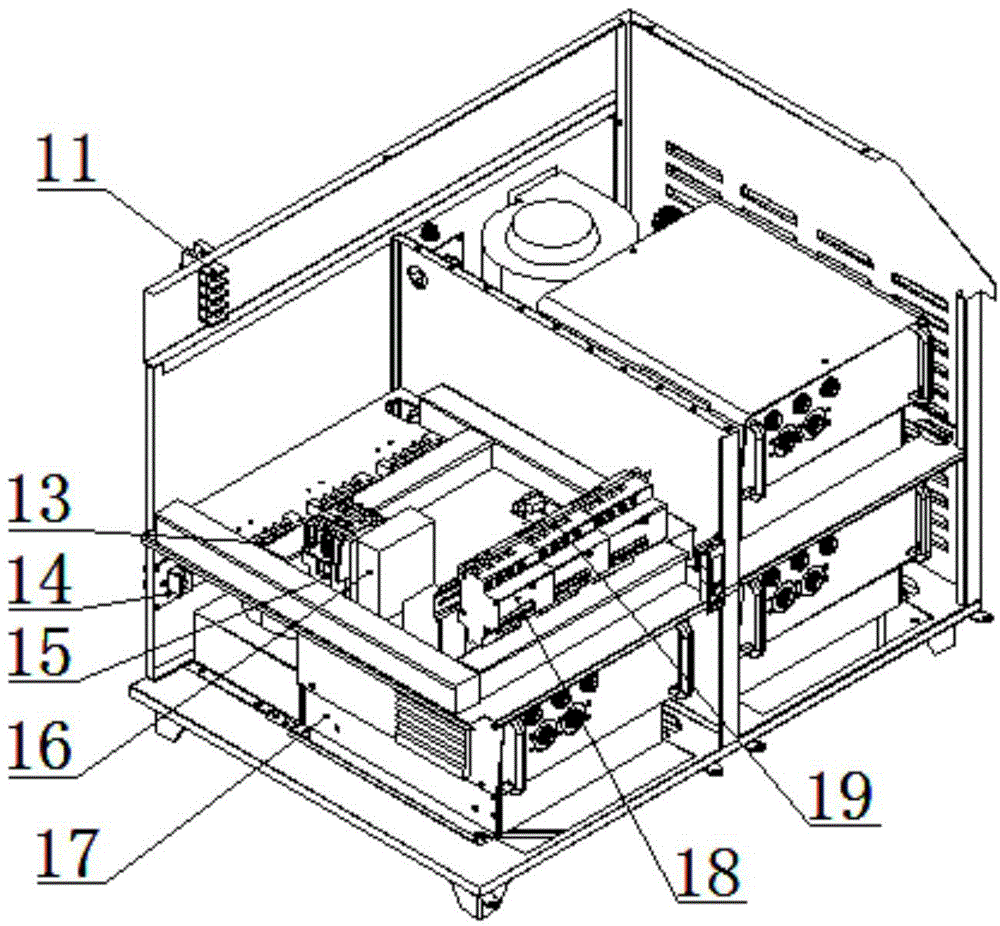

[0031] The installation method of the electromagnetic heating host 17 has the following specific implementations: one implementation is that three electromagnetic heating hosts are installed in the cabinet 2, which can control six heaters; another implementation is that two are installed in the cabinet 2 The electromagnetic heating host can control four heaters; another embodiment is to install an electromagnetic heating host in the cabinet 2 to control two heaters.

[0032] The power input terminal 11 is connected to the leakage protector 5 through a cable, the leakage protector 5 is connected to the main circuit of the AC contactor 15 through a cable, the main circuit of the AC contactor 15 is connected to the circuit breaker 18 through a cable, and the circuit breaker 18 passes through The cable is connected with the terminal block 13; the input of the alarm signal board 19 is connected with the electromagnetic heating host 17 through the wire harness, the output signal of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com