A display device for defect electronic limit preparation

A technology for preparing devices and display screens, which can be applied to TV, electrical components, image communication, etc., can solve the problems of difficulty in obtaining defect benchmarks and inconvenient correction, and achieve the effect of improving the efficiency of quality inspection and the quality of shipments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

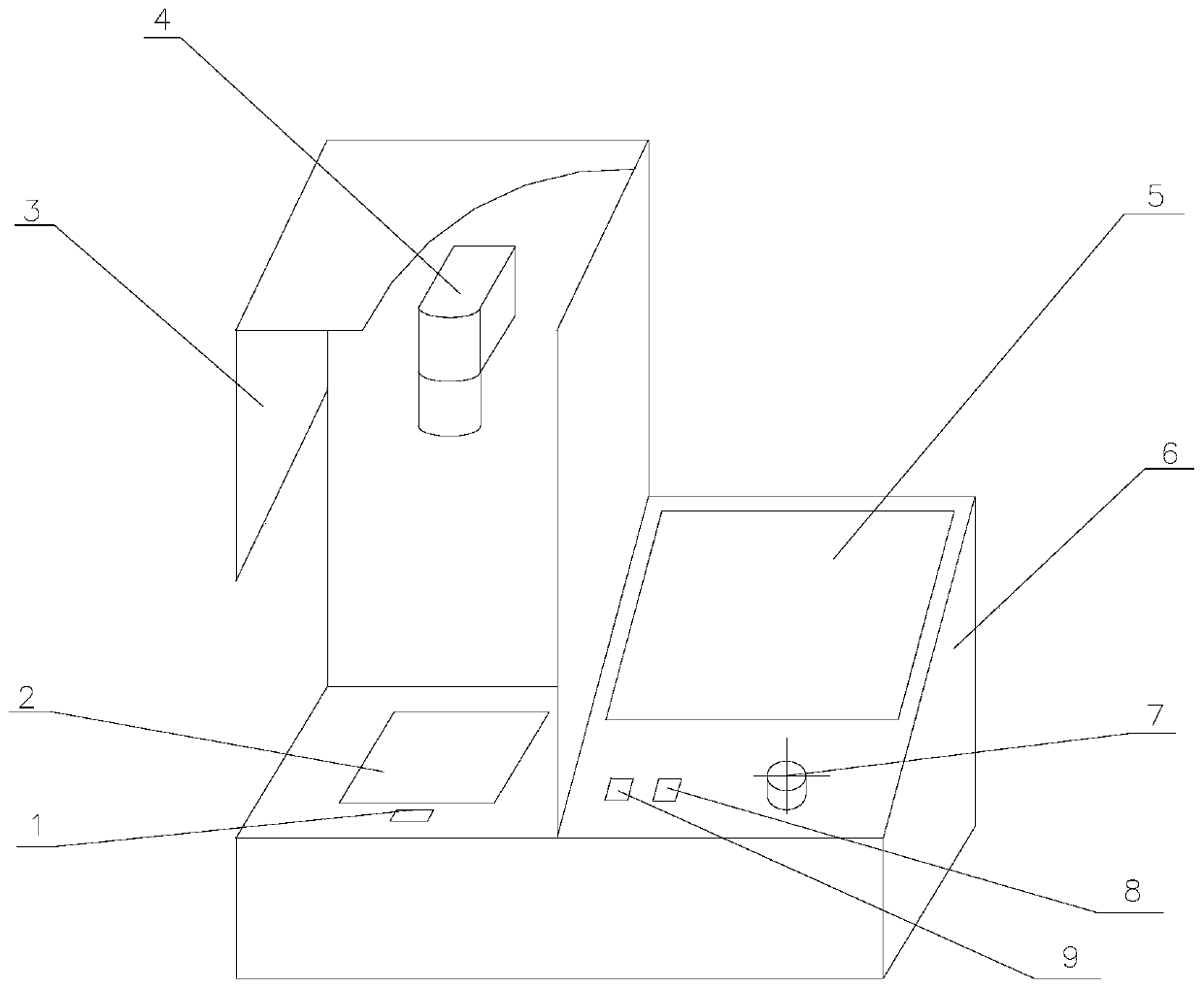

[0025] see figure 1 , which is a structural diagram of a display device for electronically limiting defects of the present application.

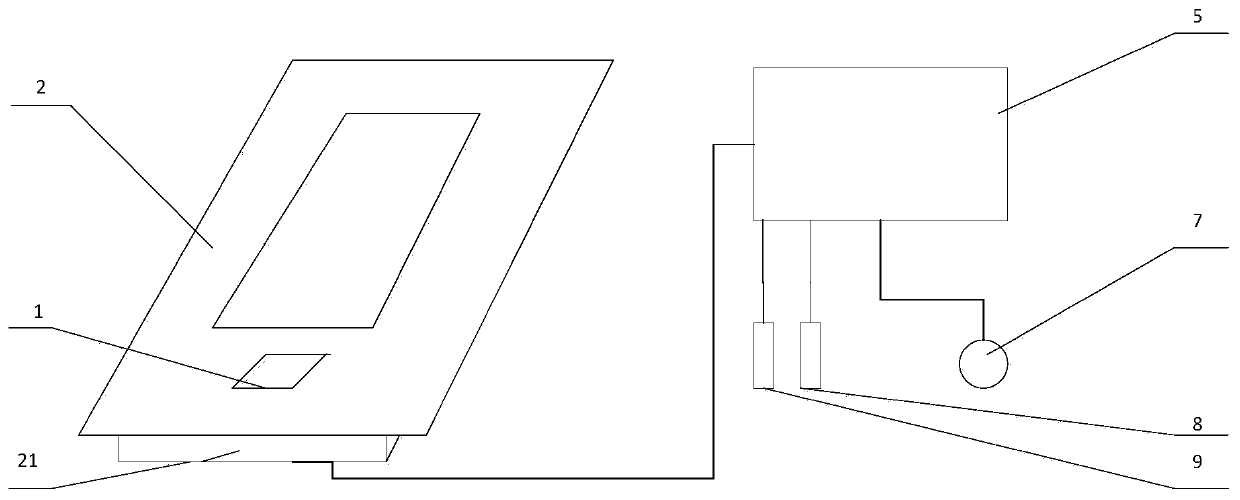

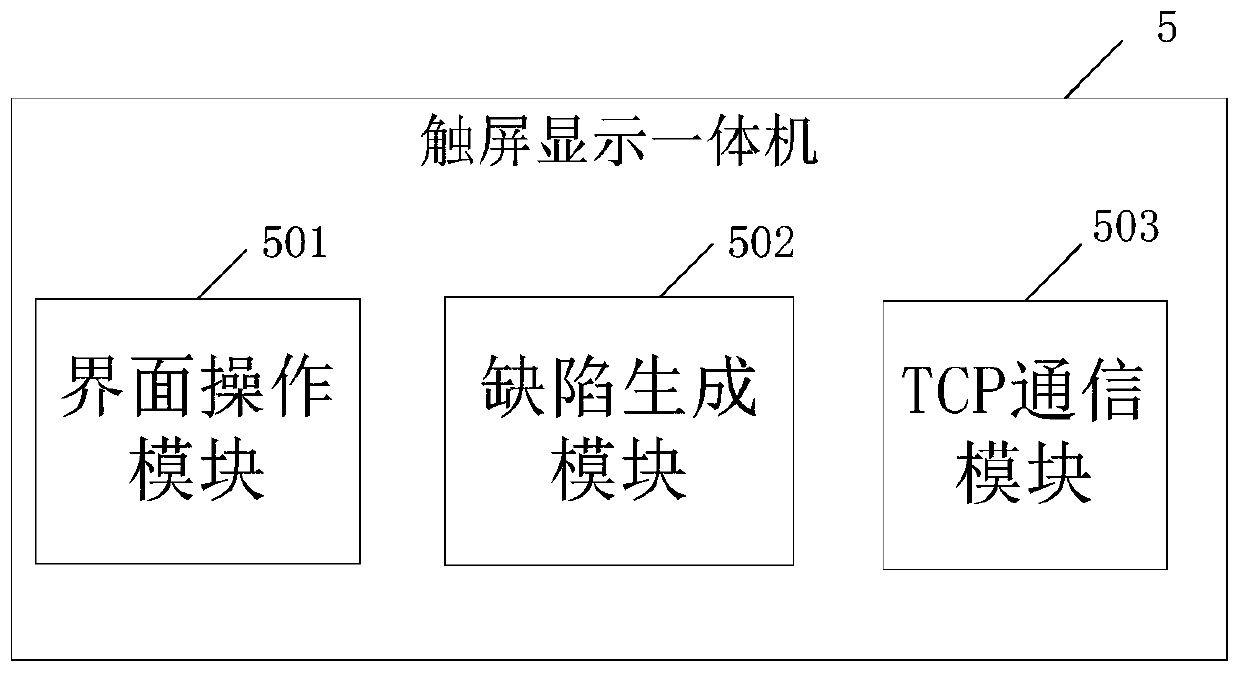

[0026] Depend on figure 1 It can be seen that the embodiment of the present application provides a display screen defect electronic limit preparation device, the device includes an equipment machine 6; the two sides above the equipment machine 6 are respectively equipped with a screen lighting platform 2 and a touch screen display integrated machine 5, of which,

[0027] One side of the screen lighting platform 2 is provided with a display cable interface 1; the upper side of the screen lighting platform 2 is covered with a shading plate 3, and an industrial camera 4 is fixed on the side wall of the shading plate 3; The industrial camera 4 is located directly above the screen lighting platform 2; a display control board 21 is provided below the display cable interface 1;

[0028] One end of the touch screen display all-in-one machine 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com