Novel transparent spiral water suction pipe production process

A production process and suction pipe technology, applied in the field of new transparent spiral suction pipe production process, can solve the problems of long production process, customized personalized products, inability to observe the exact state of fluid or powder conveyed in the pipe, and achieve convenient operation and high efficiency. Effects of Strength and Adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

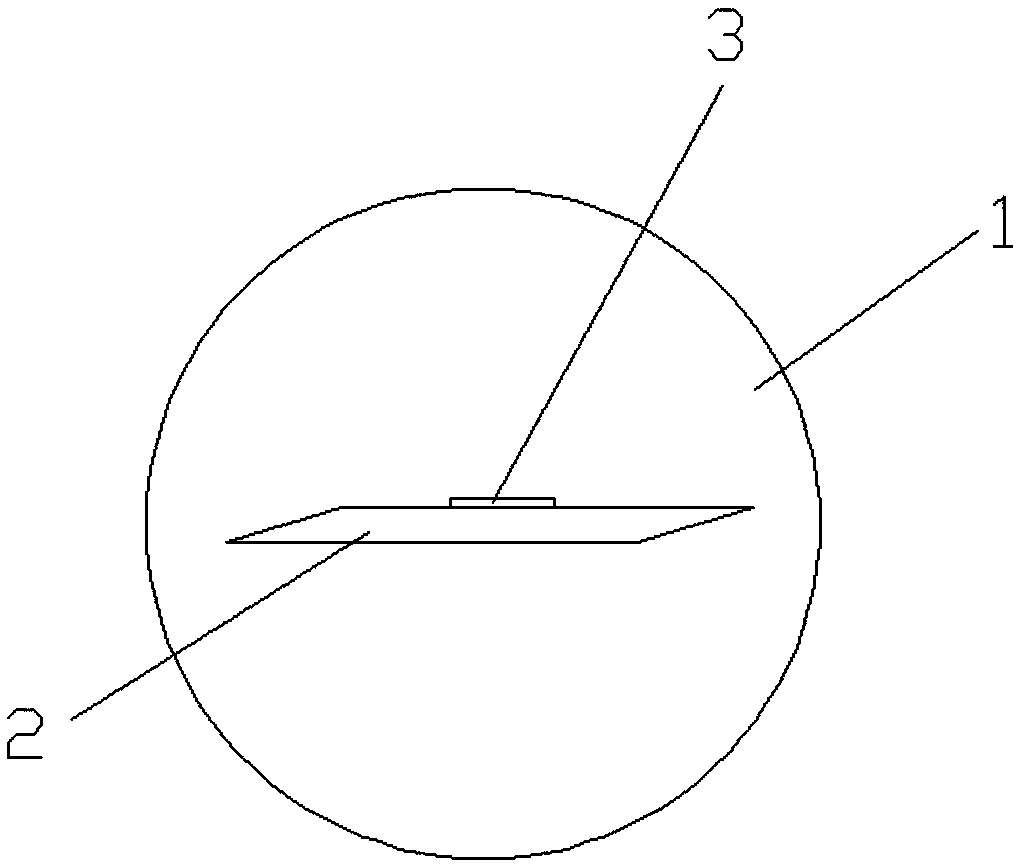

Image

Examples

Embodiment 1

[0025] A new type of transparent spiral suction pipe production process, the specification is 150mm, including the following steps:

[0026] S1) Extrude the inner lining layer: Put PVC resin P-700, epoxy soybean oil, white carbon black, anti-aging agent 264, toughening agent CPE, calcium-zinc composite stabilizer, cleaning agent zeolite powder and cold-resistant plasticizer DOA Put it into a stirring device, stir and mix at 100°C for 30 minutes, put the mixture into a twin-screw extruder, extrude and granulate, plasticize, cool and shape, put the granules into the barrel, and extrude the granules through a single screw The inner lining layer is extruded by the machine die, the die temperature is 135°C, the extrusion speed is 2.6m / min, and the inner lining layer is formed on the mandrel after being wound by the mandrel;

[0027] S2) Extrude the bonding layer: Put PVC resin P-700, anti-aging agent 264, toughening agent CPE and cold-resistant plasticizer DOA into the stirring dev...

Embodiment 2

[0035] A new type of transparent spiral suction pipe production process, the specification is 150mm, including the following steps:

[0036] S1) Extrude the lining layer: PVC resin SG-3, chlorinated paraffin, white carbon black, anti-aging agent 2246, toughening agent CPE, calcium-barium-zinc composite stabilizer, detergent zeolite powder, cold-resistant plasticizer DOA, The flow aid ACR401 is put into the stirring device, stirred and mixed at 105°C for 25 minutes, the mixture is put into the twin-screw extruder, extruded and granulated, plasticized, cooled and shaped, and the granules are put into the barrel. Extrude the inner lining layer through the single-screw extruder die, the die temperature is 160°C, the extrusion speed is 3.1m / min, and the inner lining layer is formed on the mandrel after being wound by the mandrel;

[0037] S2) Extrude the bonding layer: Put PVC resin SG-3, chlorinated paraffin, anti-aging agent 2246, and toughening agent CPE into the stirring device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com