Patents

Literature

54results about How to "No height difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

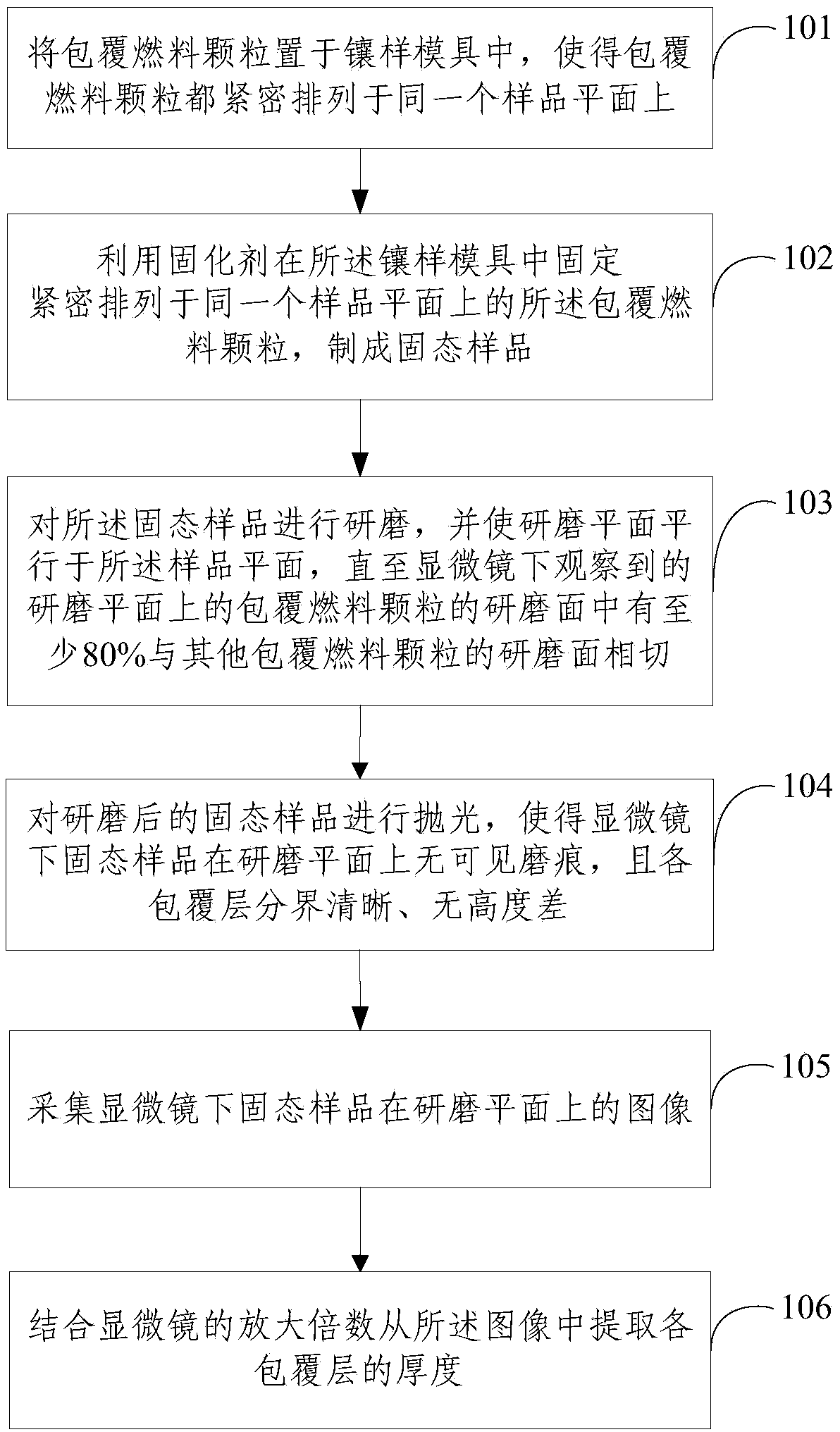

Method for measuring thickness of coating layer of coated fuel particles

ActiveCN103778980ASimple processMeasure thicknessNuclear energy generationNuclear monitoringMicroscopeMetallurgy

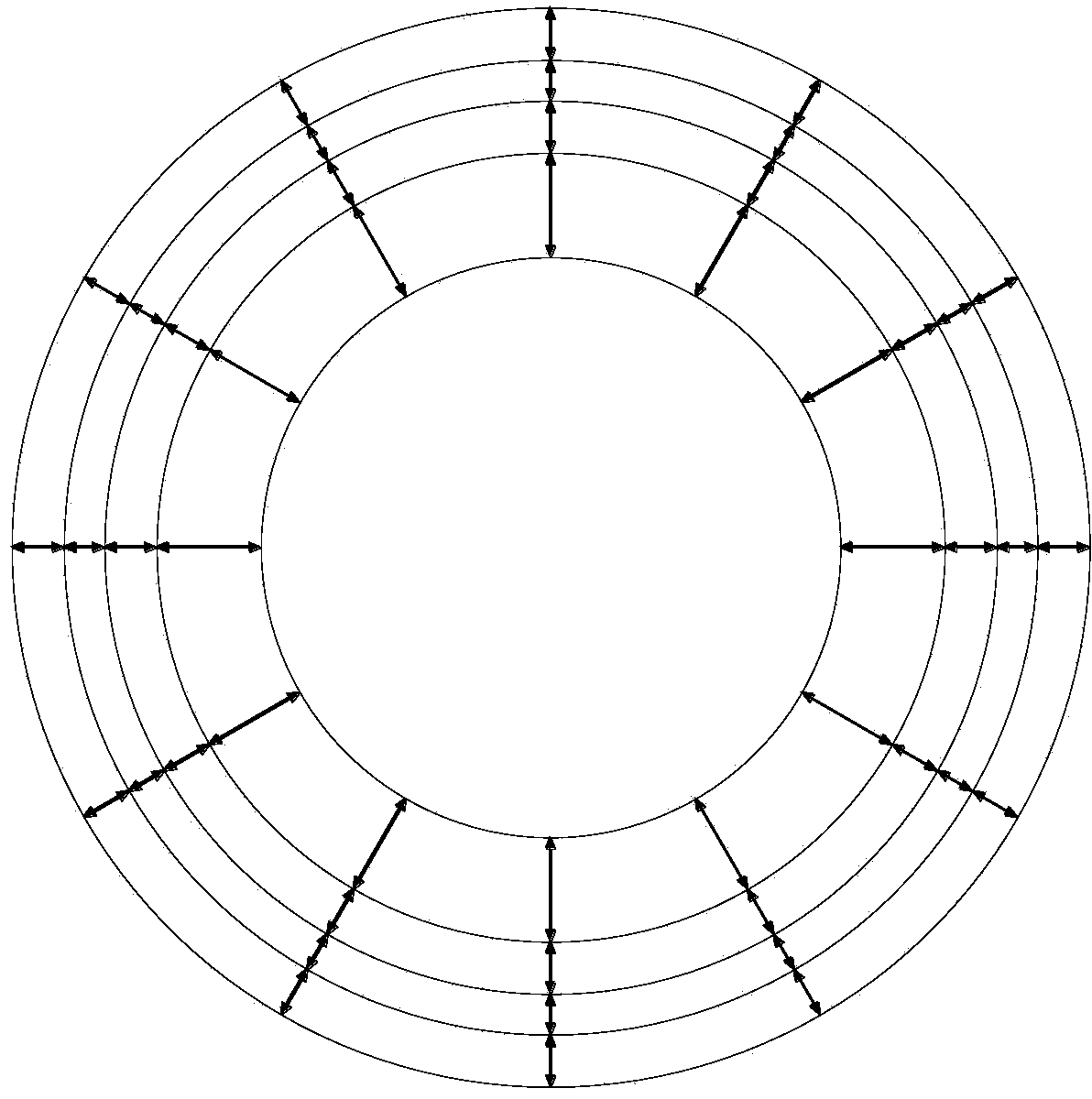

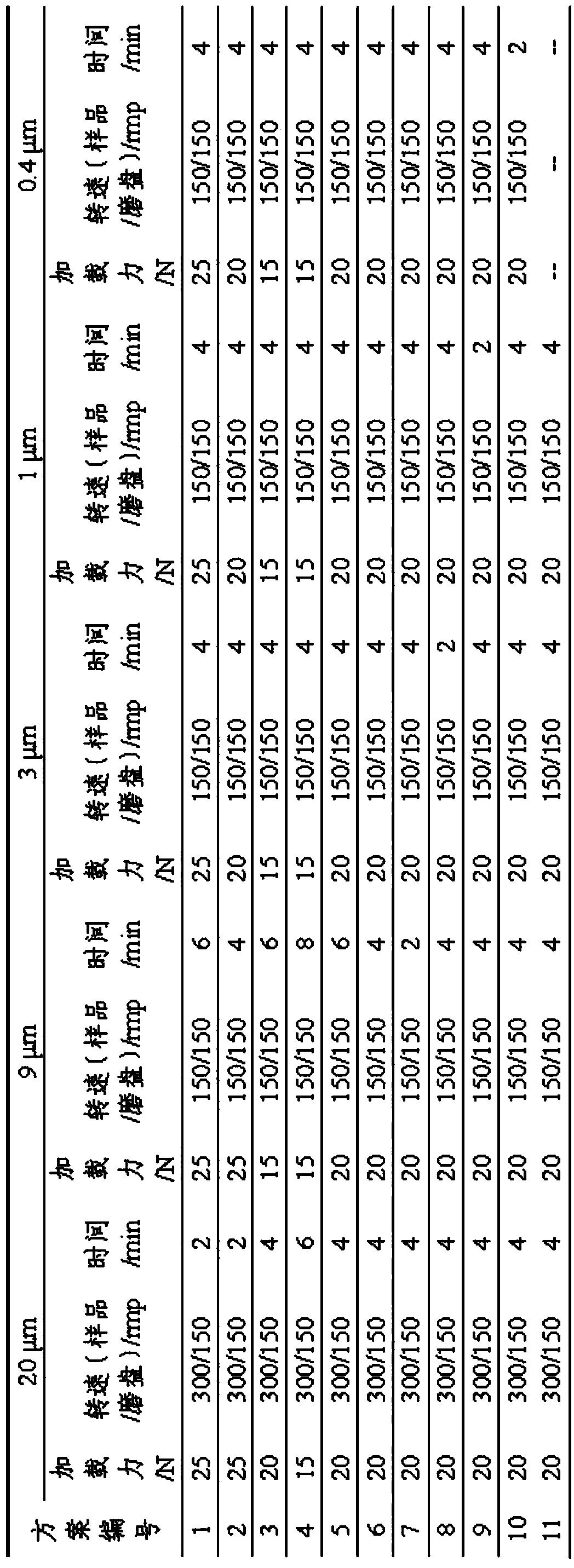

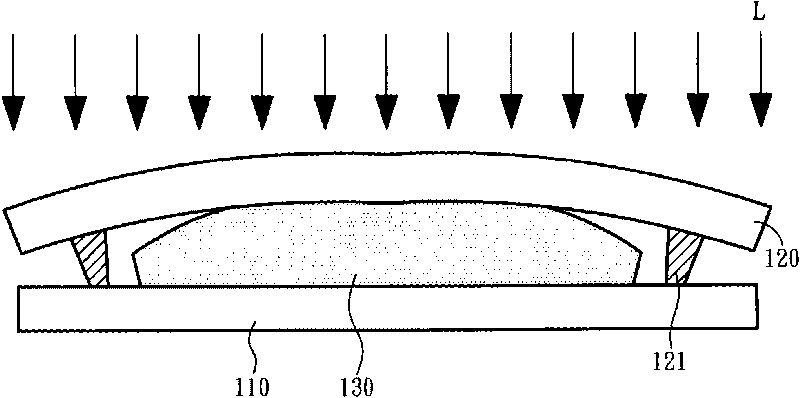

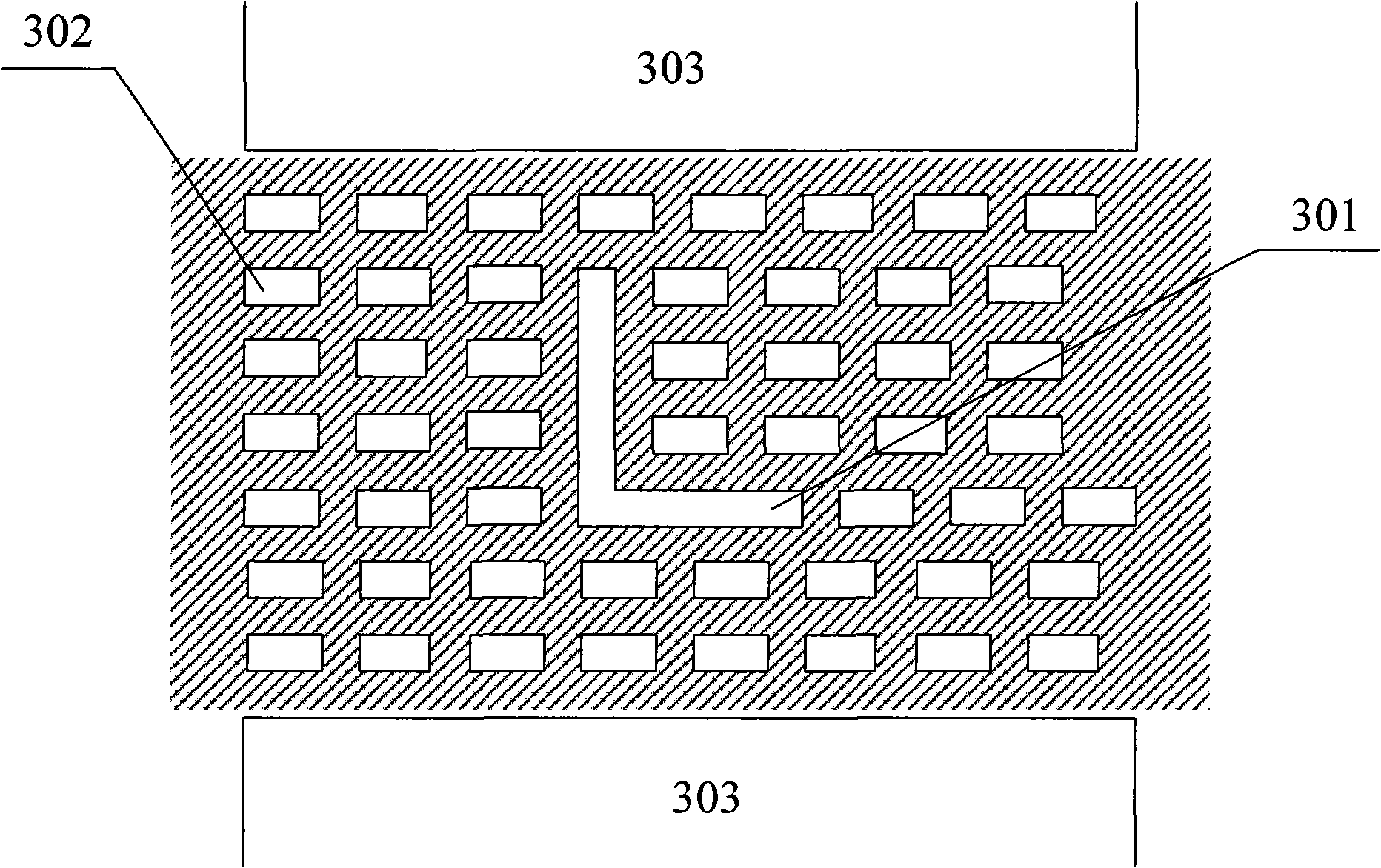

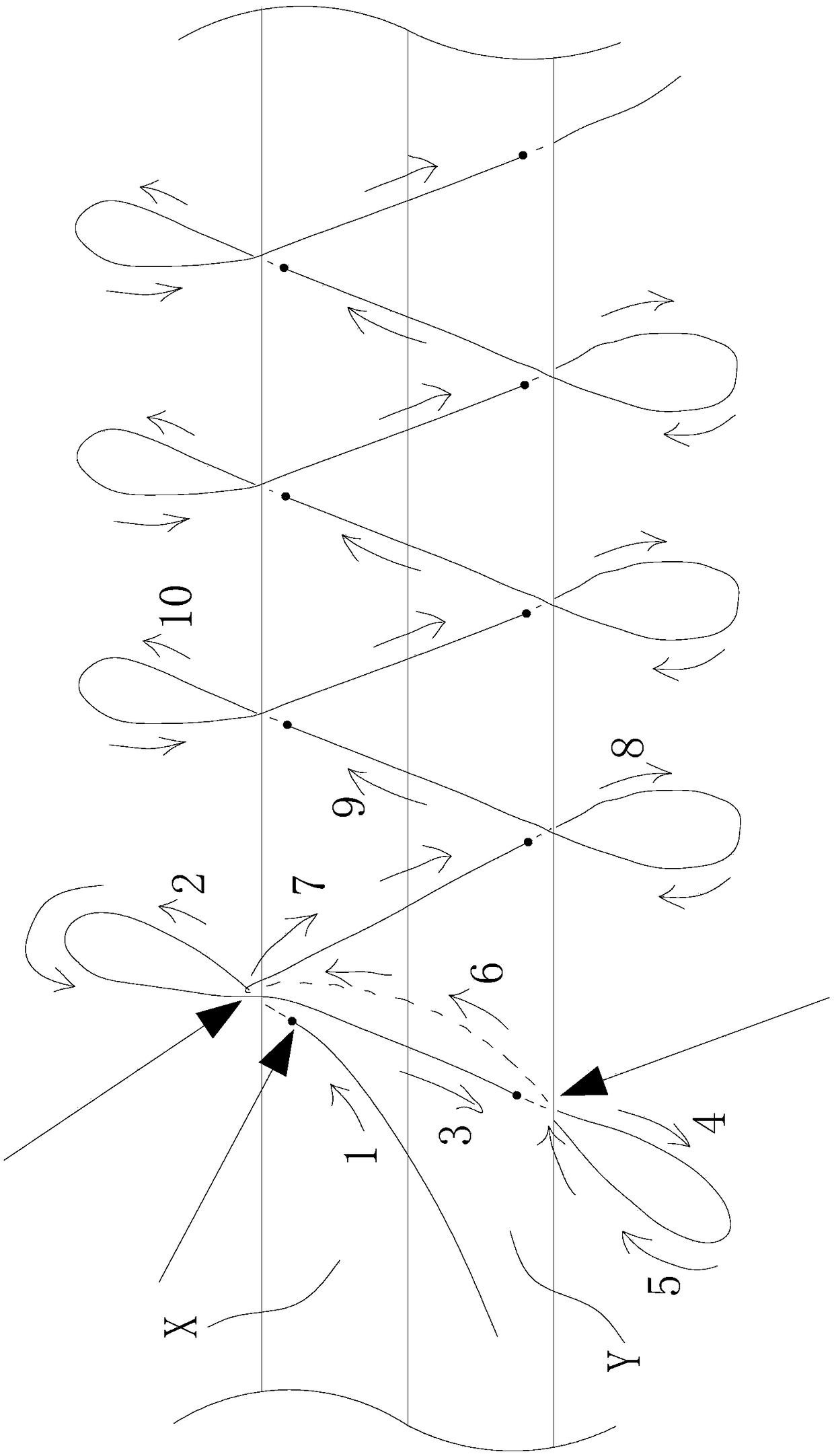

The invention provides a method for measuring the thickness of a coating layer of coated fuel particles. The method comprises the following steps: placing coated fuel particles in a sample-embedding die so that the coated fuel particles are closely arranged on the same sample plane, fixing the coated fuel particles in the sample-embedding die by using a curing agent to prepare a solid sample, grinding the solid sample, and enabling a grinding plane to be parallel to the sample plane until at least 80% of grinding surface of the coated fuel particles on the grinding plane observed under a microscope is tangent to the grinding surface of other coated fuel particles; polishing the ground solid sample so that the solid sample has no visible grinding crack on the grinding plane under the microscope, and the coating layers are clear in dividing line and free from height difference; acquiring an image of the solid sample on the grinding plane under the microscope; and then extracting the thickness of each coating layer from the image in combination of magnification times of the microscope. The method can be used for fast and accurately measuring the thickness of the coating layer of the coated fuel particles.

Owner:TSINGHUA UNIV

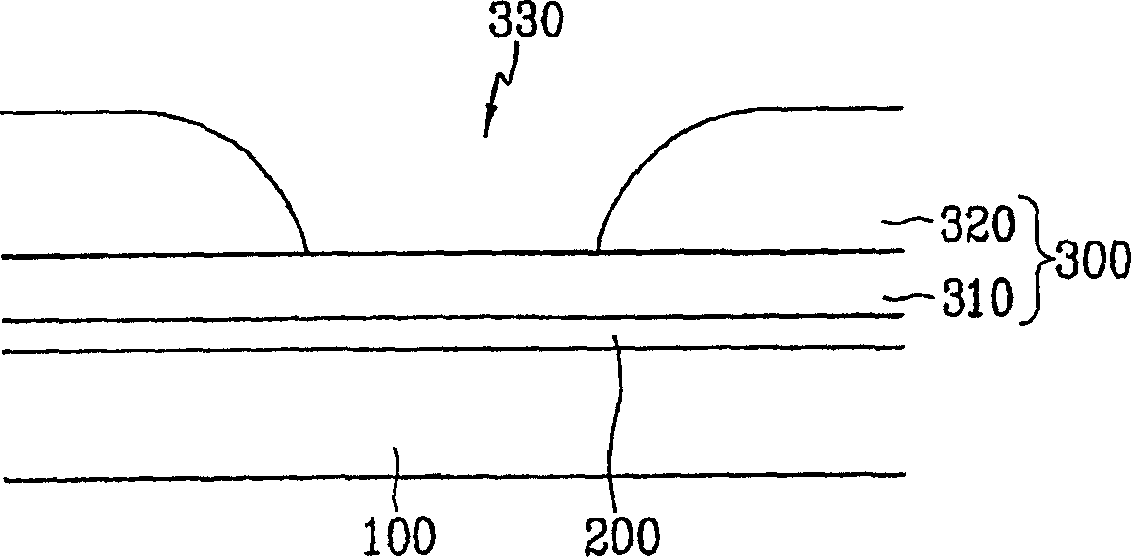

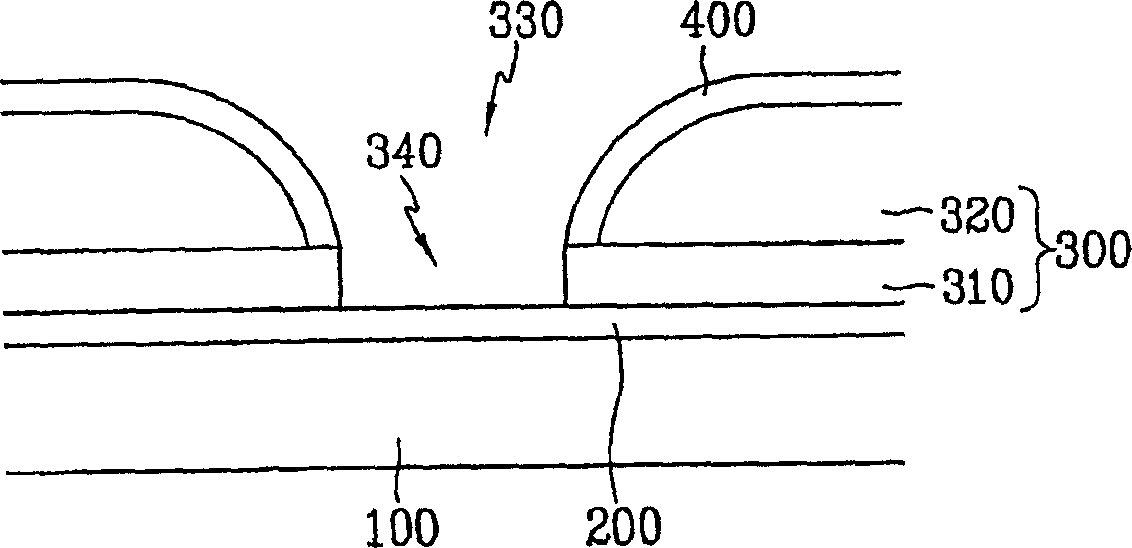

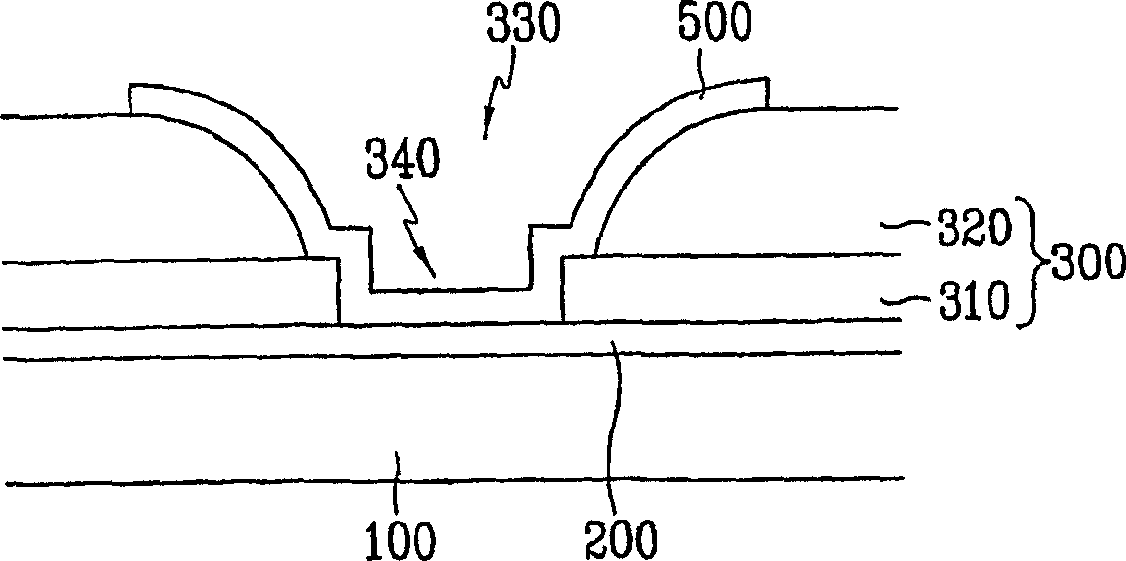

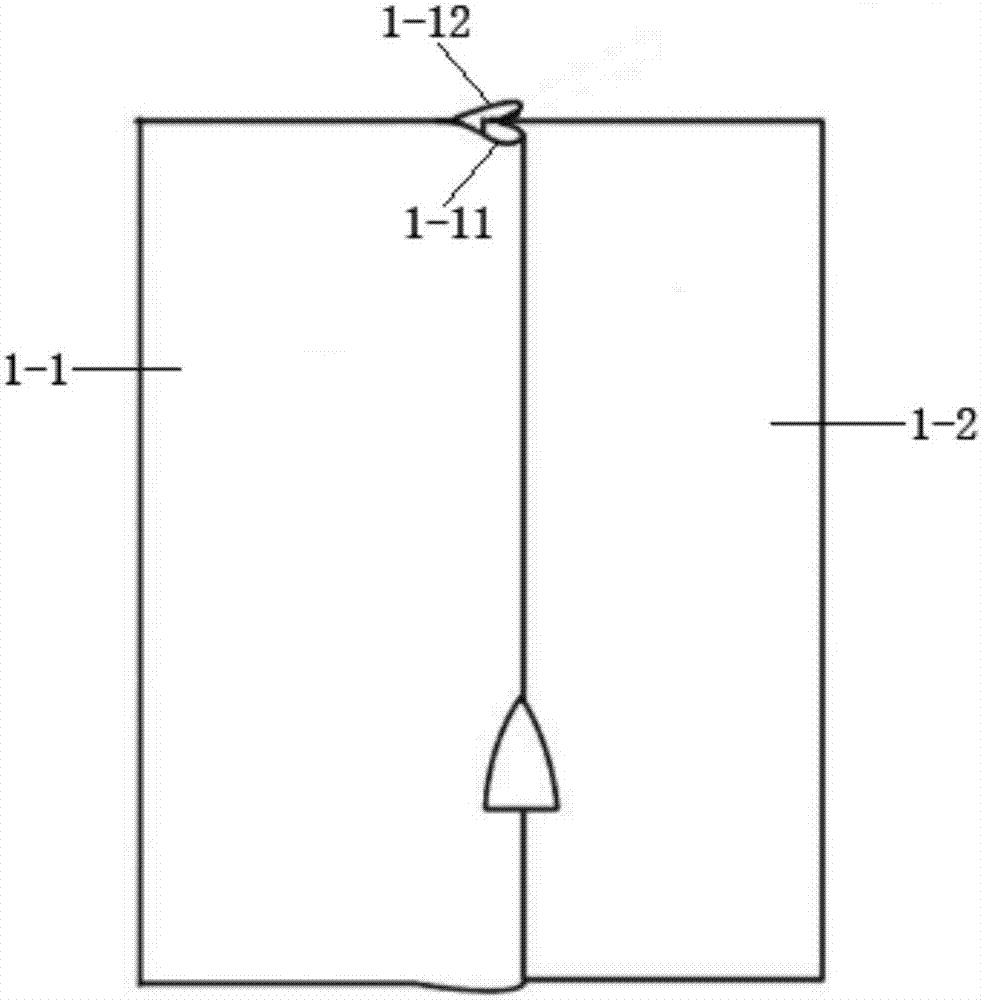

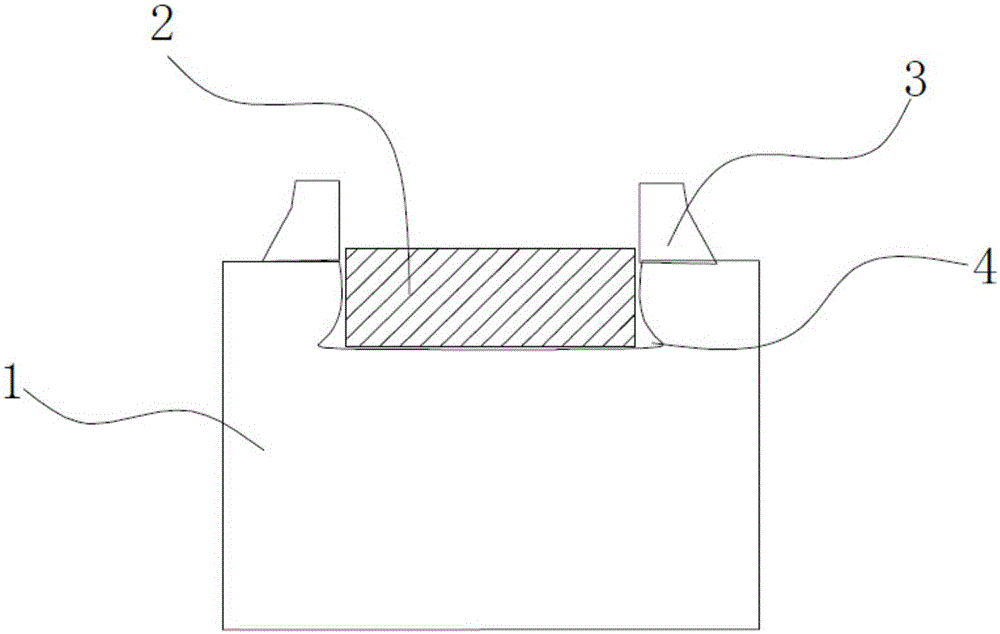

Contact portion of semiconductor device and manufacturing method thereof including thin film transistor array panel for contact portion display device and manufacturing method thereof

InactiveCN1623235AEasy to shapeSimple manufacturing methodTransistorSolid-state devicesResistOhmic contact

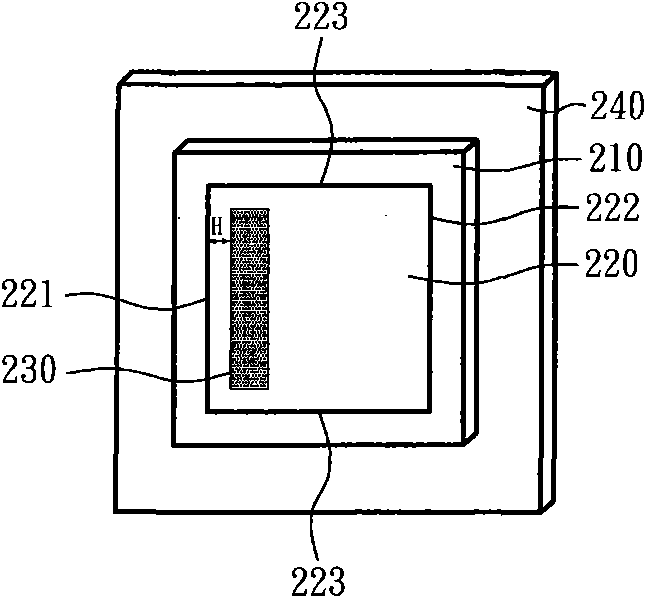

A gate wiring including a gate line, a gate electrode and a gate pad and extending in a lateral direction is formed on the substrate. A gate insulating layer is subsequently formed, and a semiconductor layer and an ohmic contact layer are sequentially formed thereon. A conductive material is deposited and patterned to form data wiring including data lines intersecting the gate lines, source electrodes, drain electrodes, and data pads. A first insulating layer made of silicon nitride is deposited on the substrate, and a second insulating layer made of photosensitive organic insulating material is coated on the first insulating layer. The second insulating layer is patterned to form a convex-concave pattern and a first contact hole opposite to the drain electrode exposing the first insulating layer on a surface thereof. Subsequently, the first insulating layer and the gate insulating layer are patterned together by photolithography using a photoresist pattern to form contact holes exposing the drain electrode, the gate pad, and the data pad, respectively. Next, indium tin oxide (ITO) or indium zinc oxide (IZO) is deposited and patterned to form light-transmitting electrodes, sub-gate pads, and sub-gate pads connected to drain electrodes, gate pads, and data pads, respectively. data pad. Finally, a reflective conductive material is deposited on the light-transmitting electrode and patterned to form a reflective film with corresponding holes in the pixel area.

Owner:SAMSUNG DISPLAY CO LTD

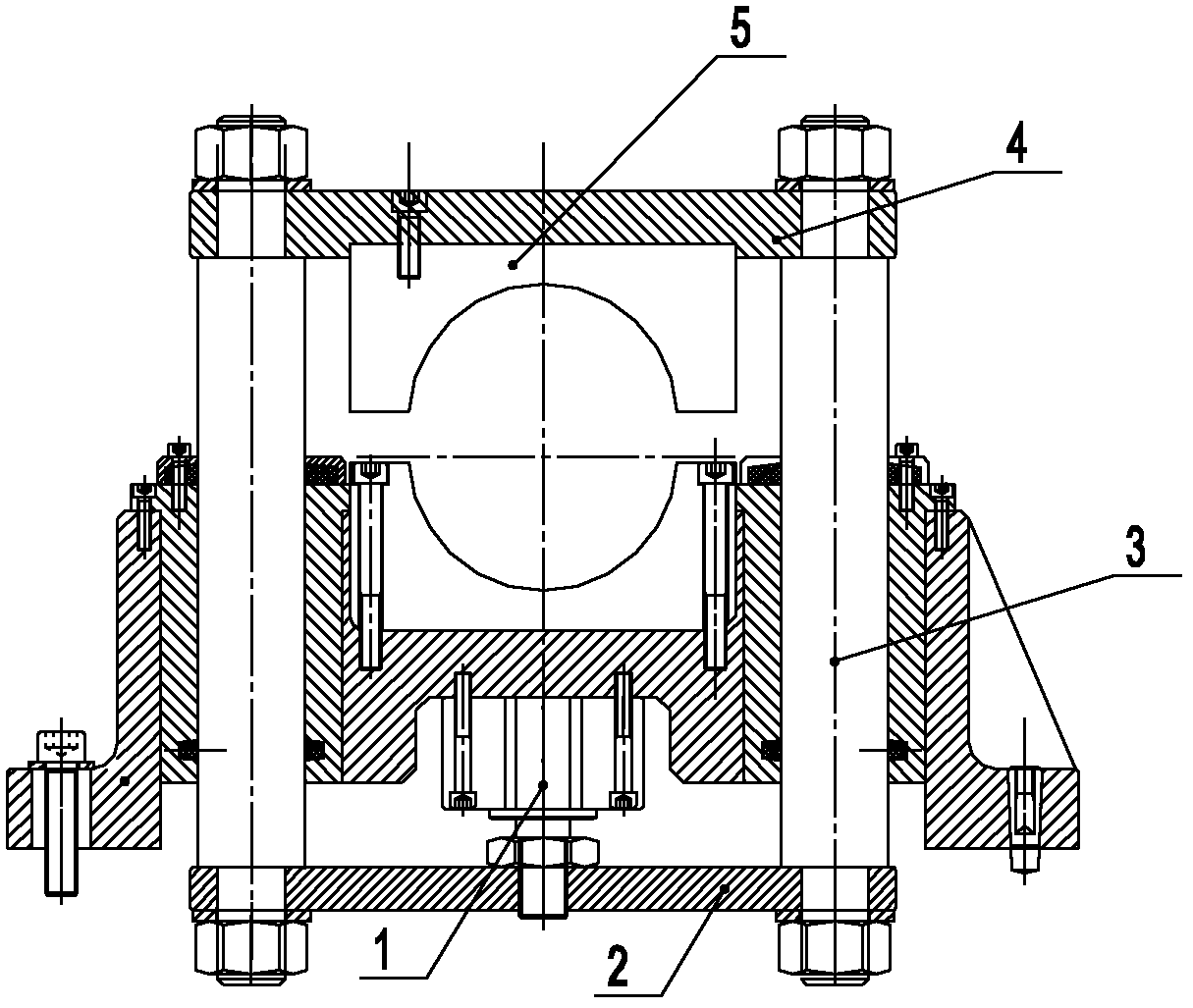

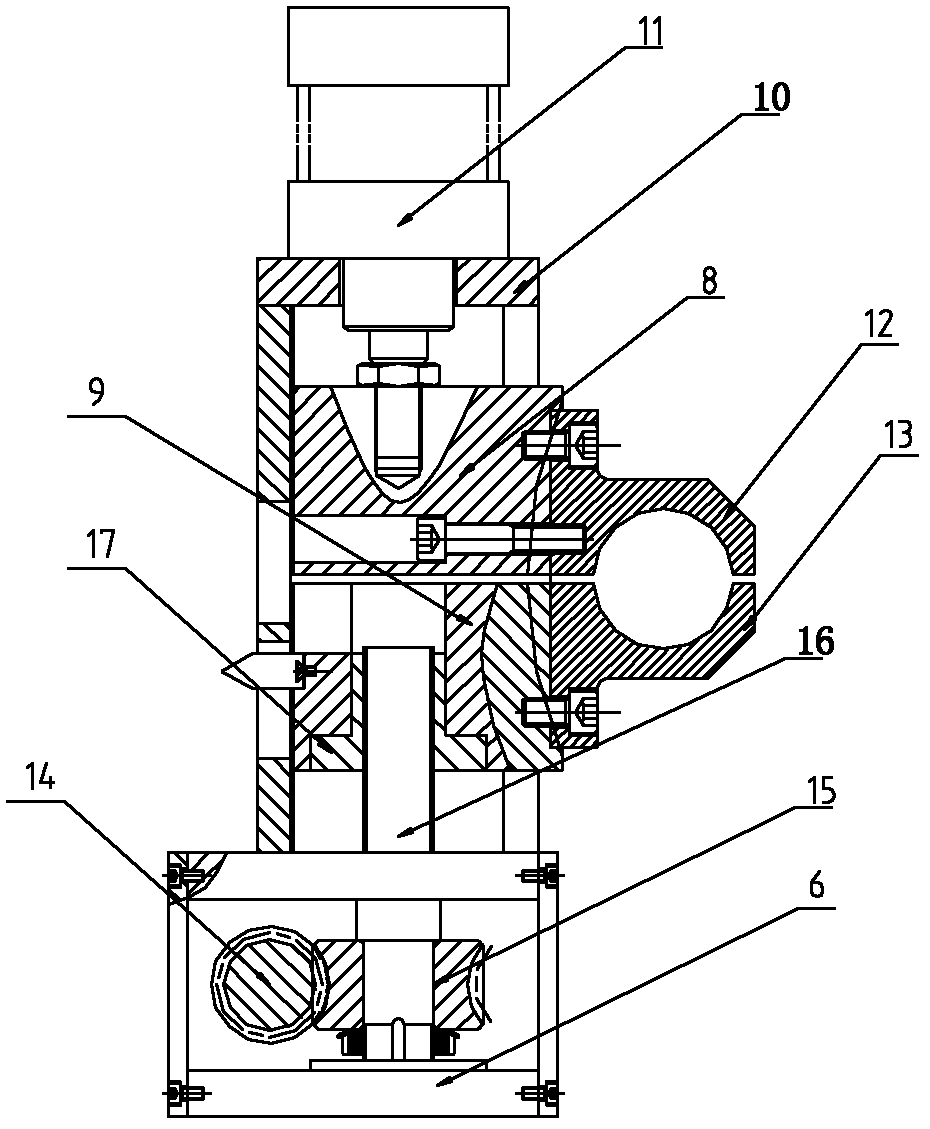

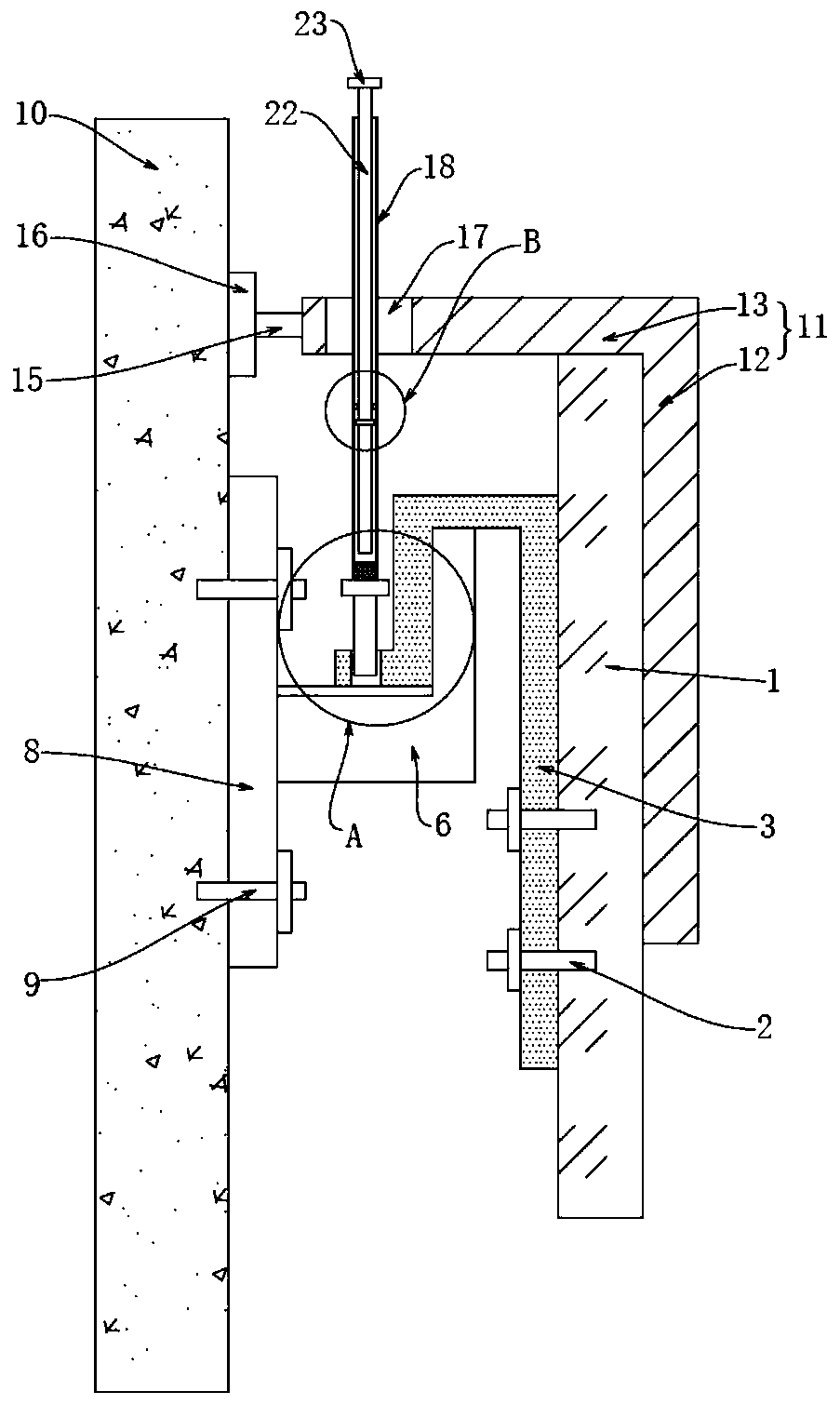

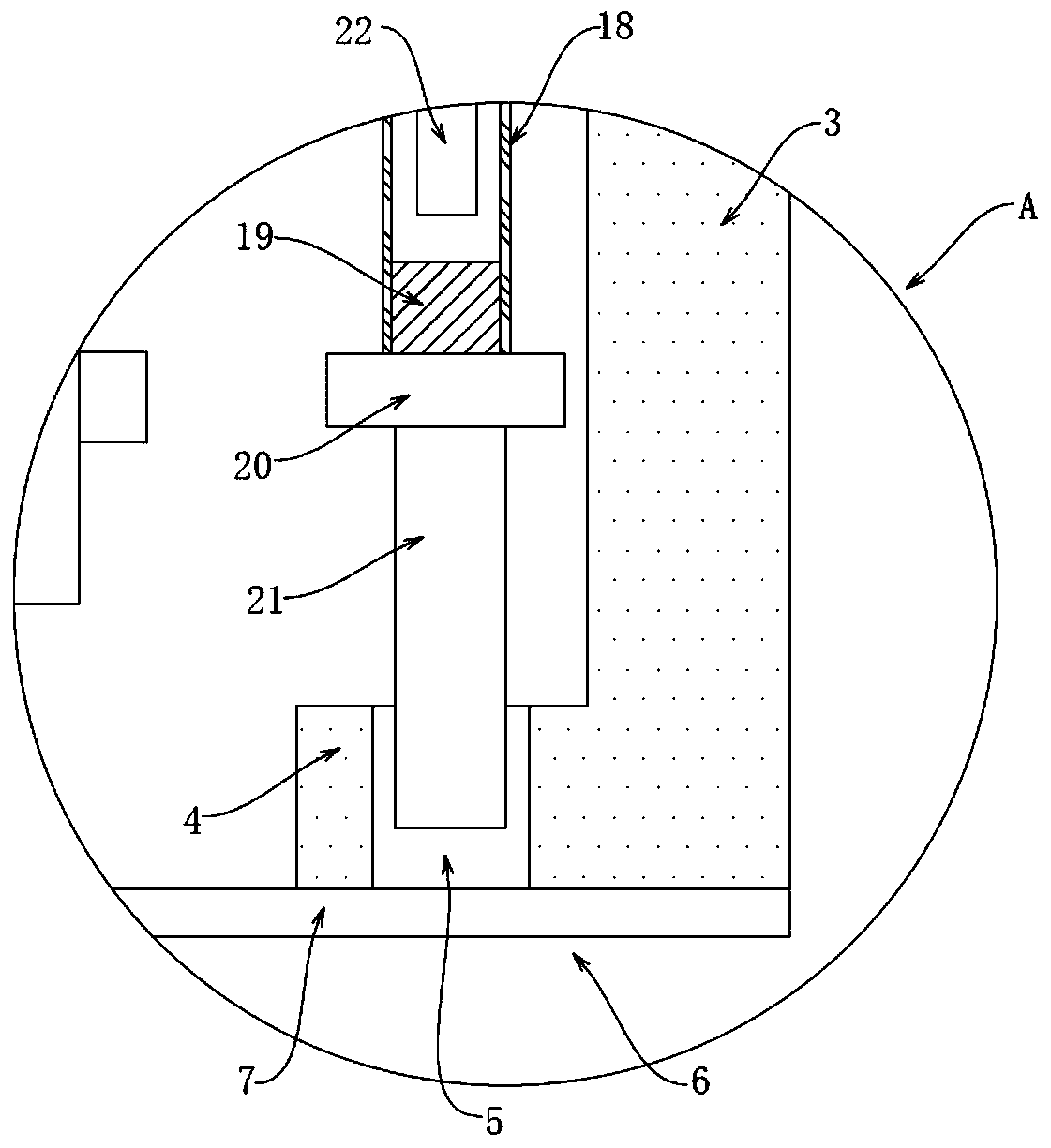

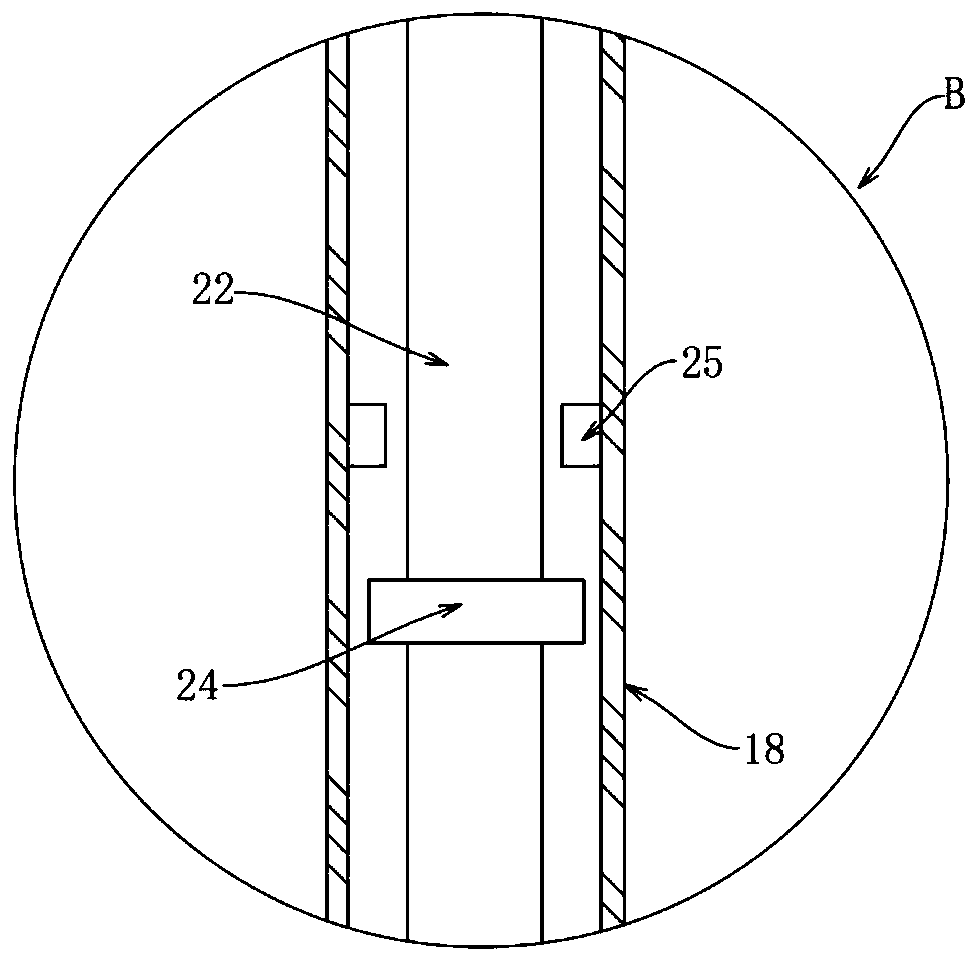

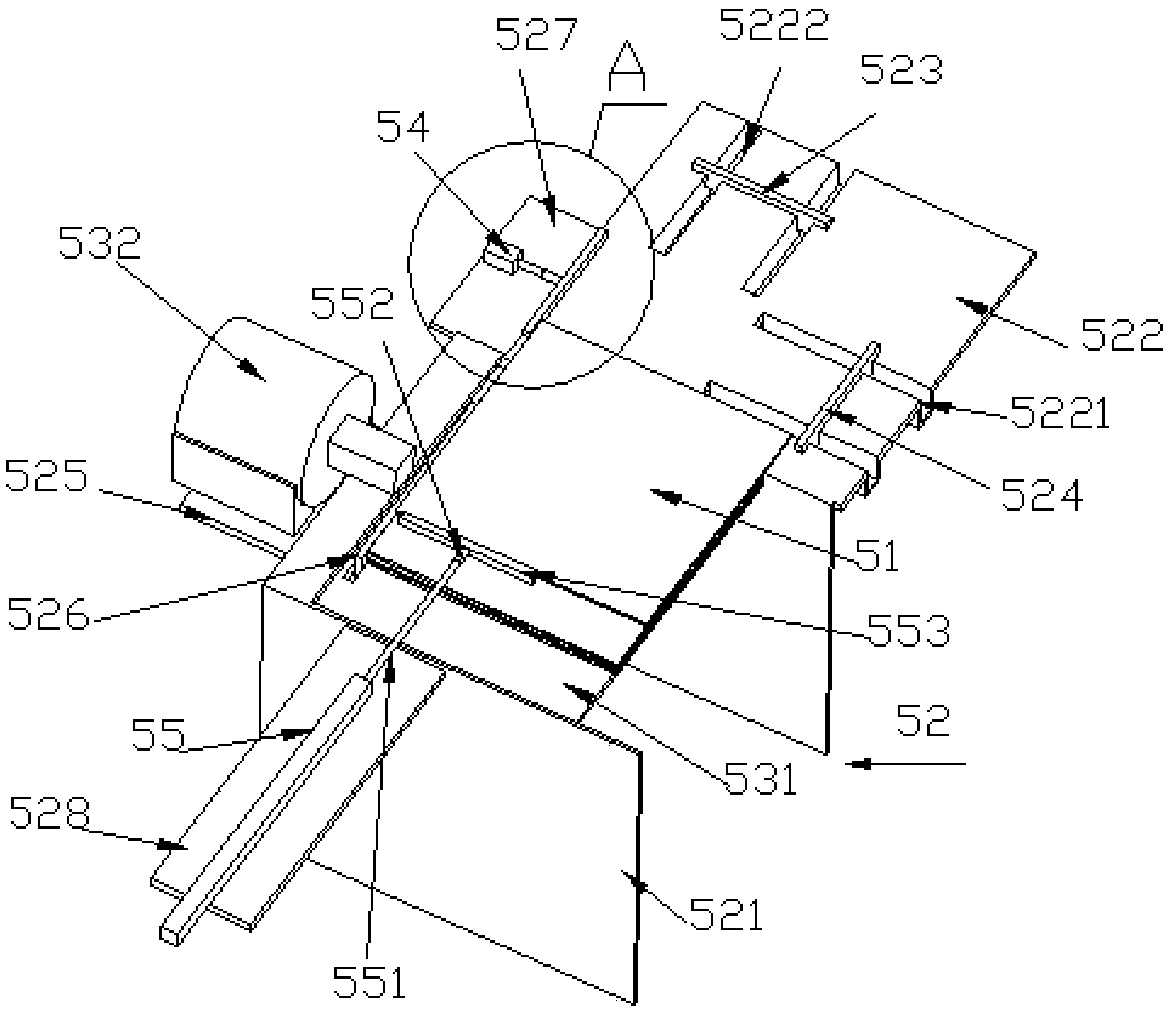

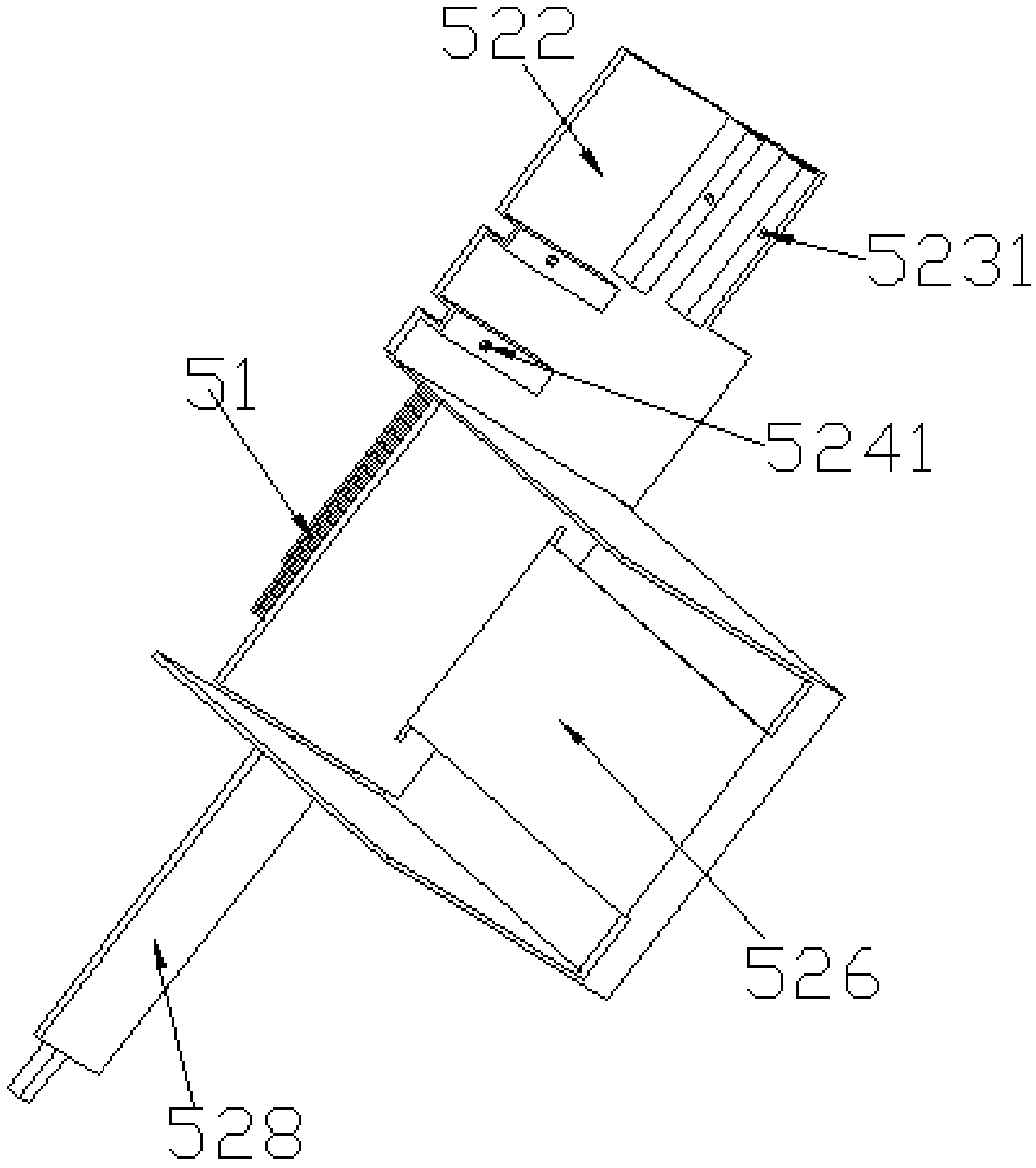

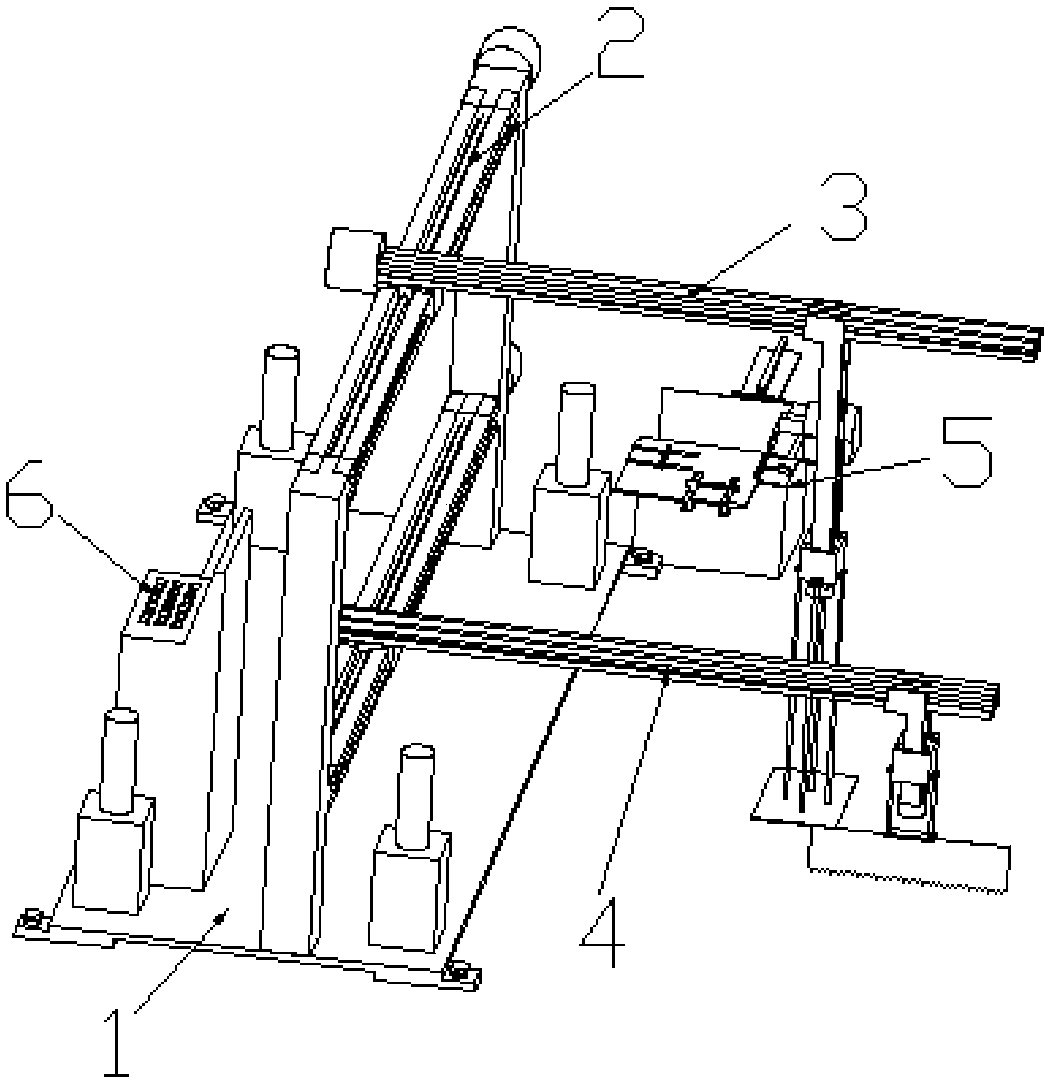

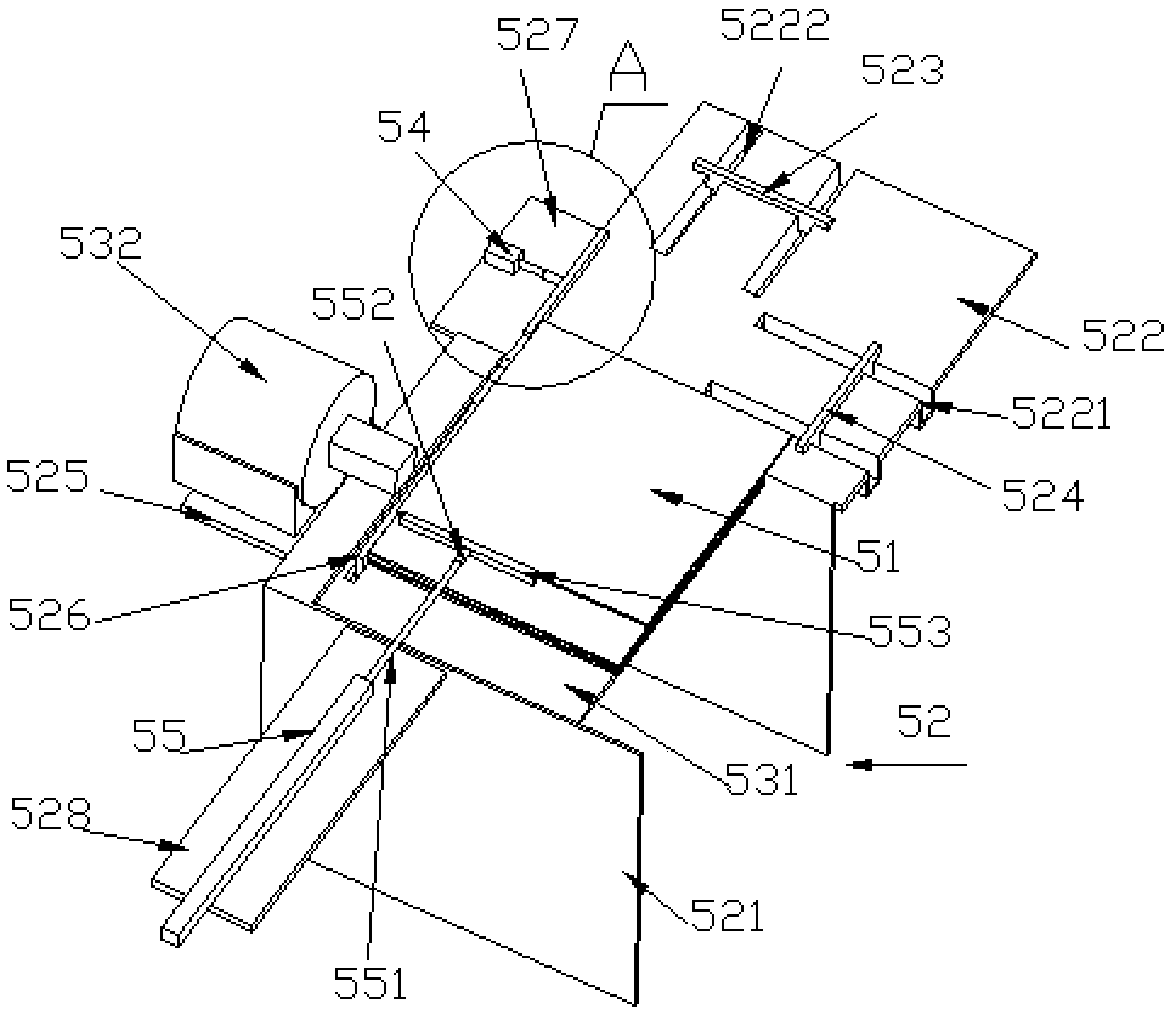

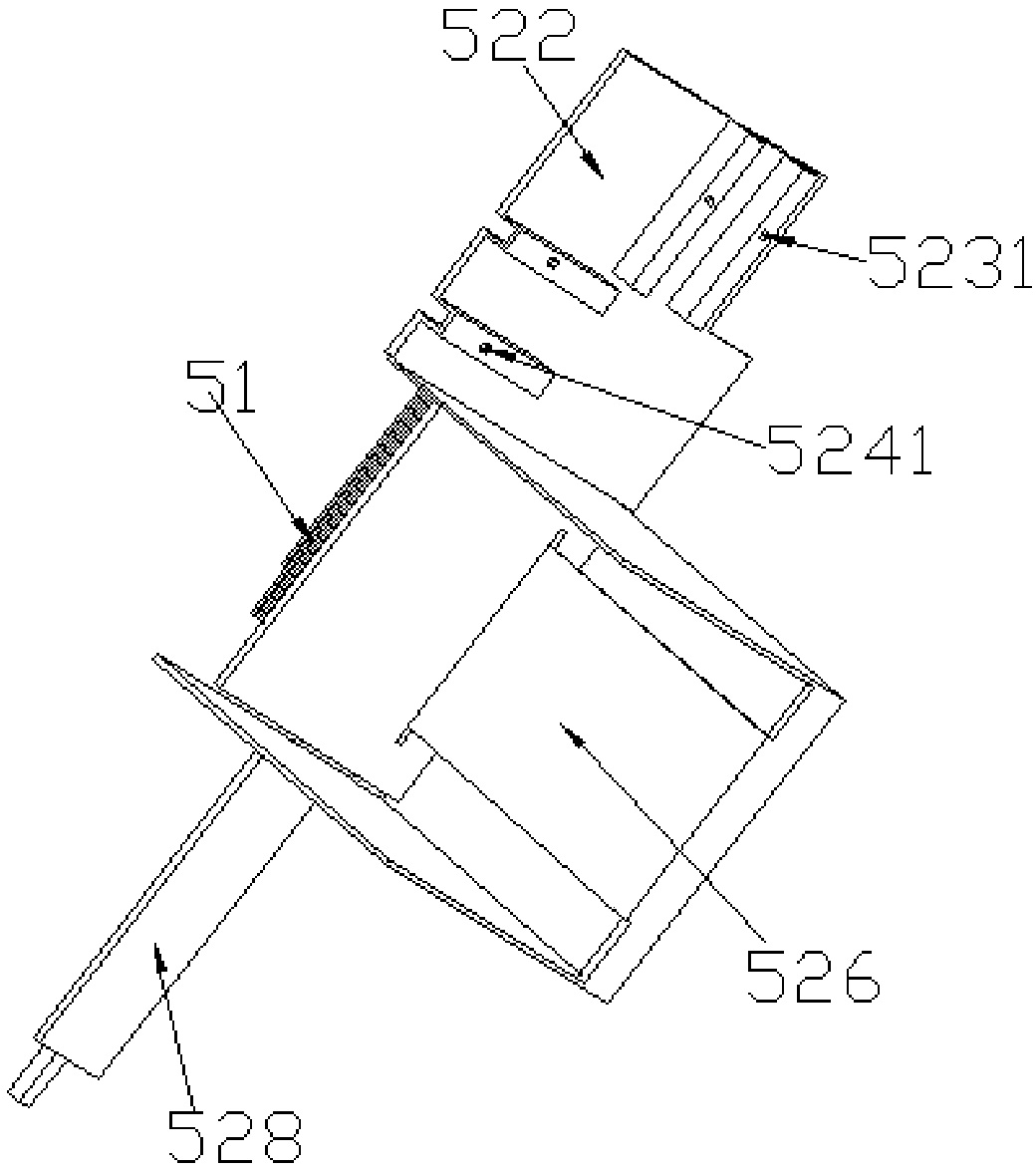

Clamping mechanism of pipe cutting machine

InactiveCN102626874AReduce jitterReduce jumpingMetal sawing devicesPositioning apparatusEngineeringMechanical engineering

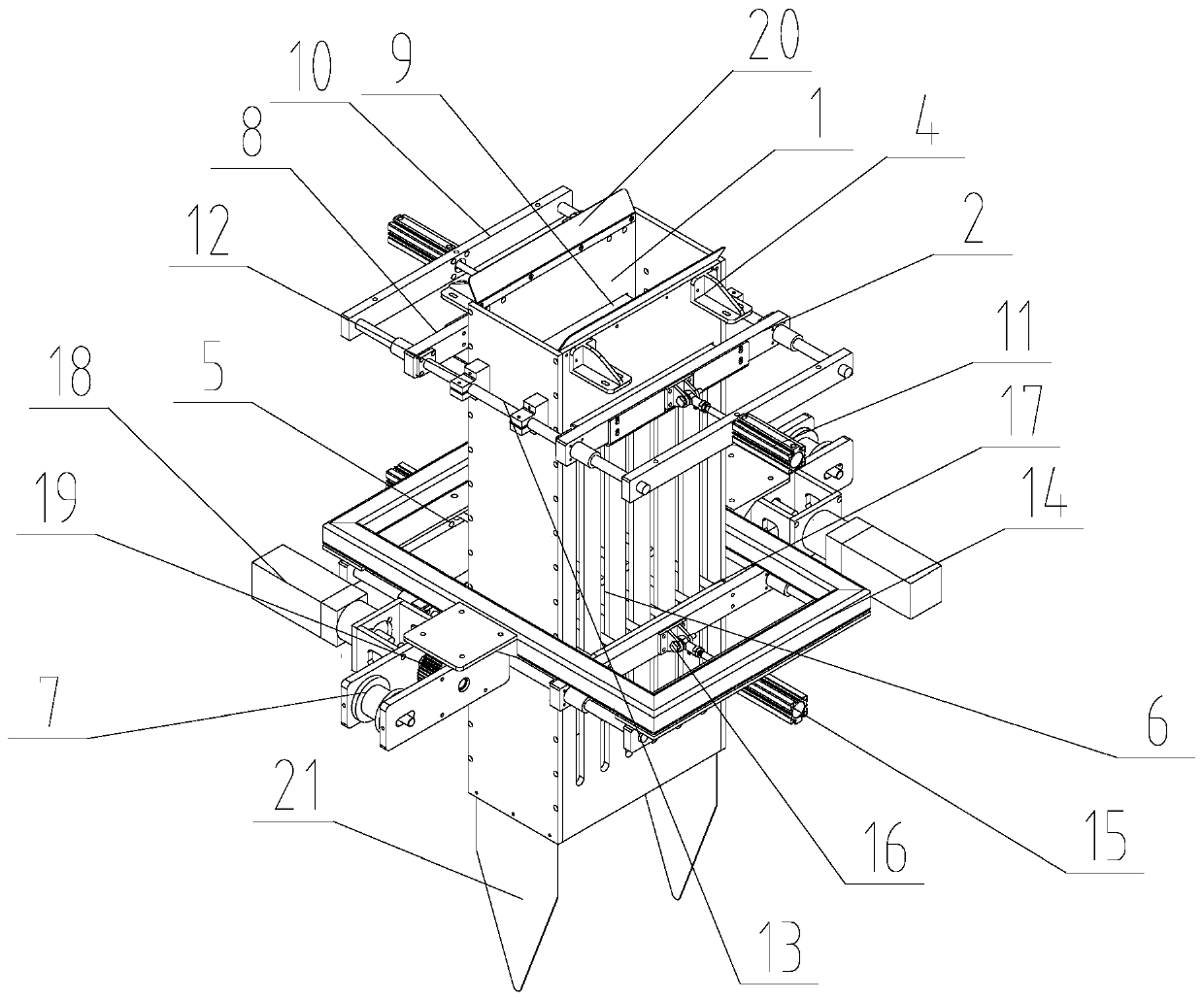

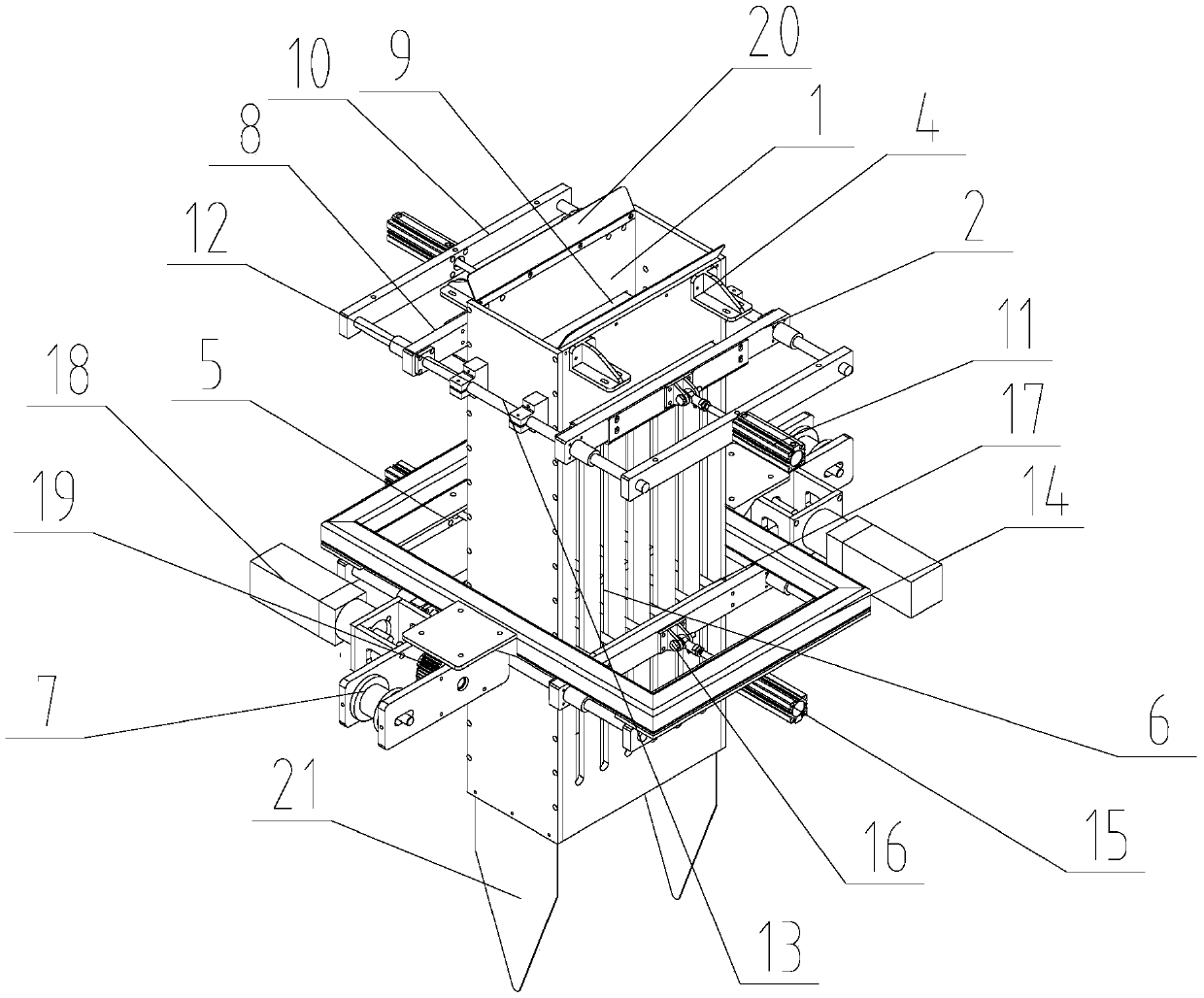

The invention discloses a clamping mechanism of a pipe cutting machine. The clamping mechanism comprises a base, wherein a plurality of side plates are arranged on the base; an upper slide block and a lower slide block are movably arranged in the side plate; an ejector plate is arranged on the side plate; a slide block driving mechanism is arranged on the ejector plate; an upper clamping block is arranged at the side surface of the upper slide block; a lower clamping block is arranged at the side surface of the lower slide block; the upper slide block is connected with the slide block driving mechanism; and an adjusting mechanism used for simultaneously adjusting two sides of the lower slide block is arranged in the base. The invention provides the clamping mechanism of the pipe cutting machine with compact structure, convenience for adjustment, good concentricity of the upper and lower clamping blocks after the adjustment and high saw blade utilization rate during cutting.

Owner:江苏中港冶金设备科技有限公司

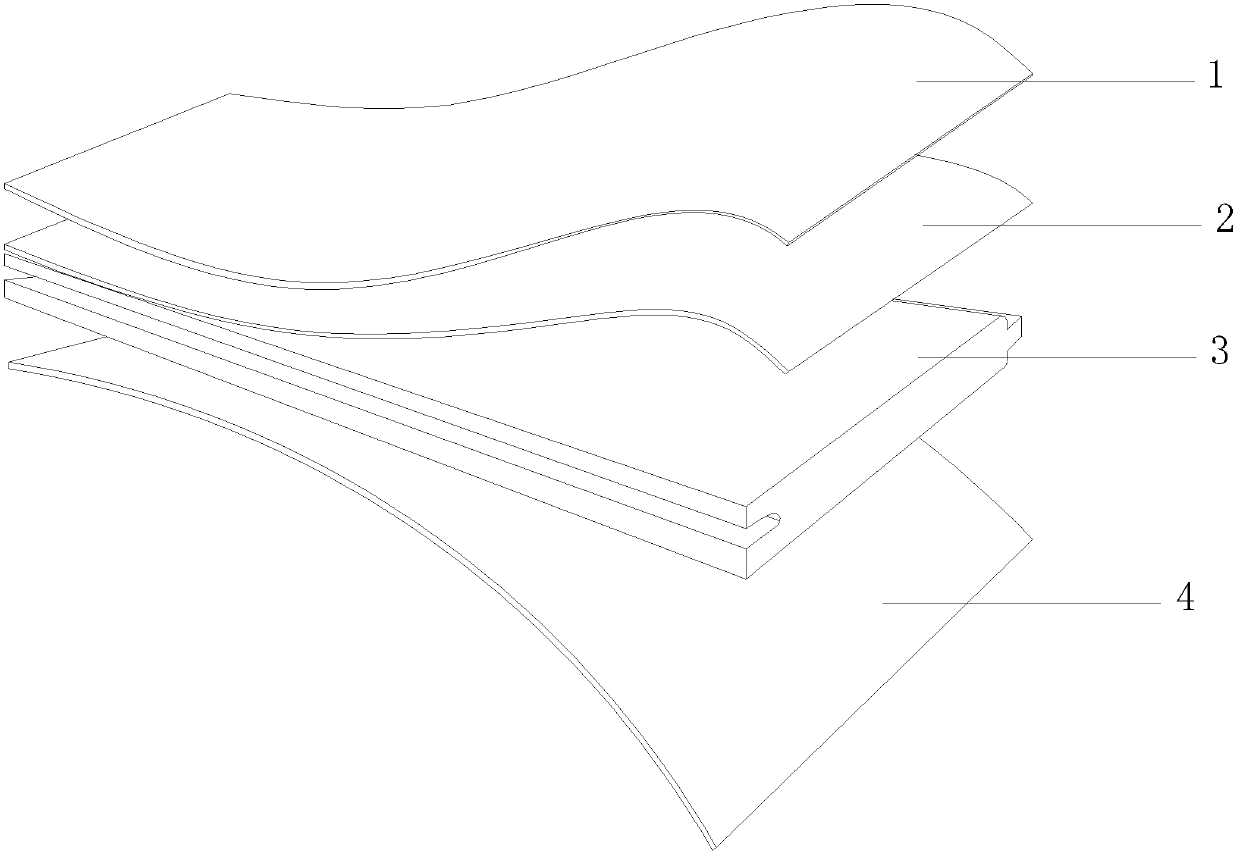

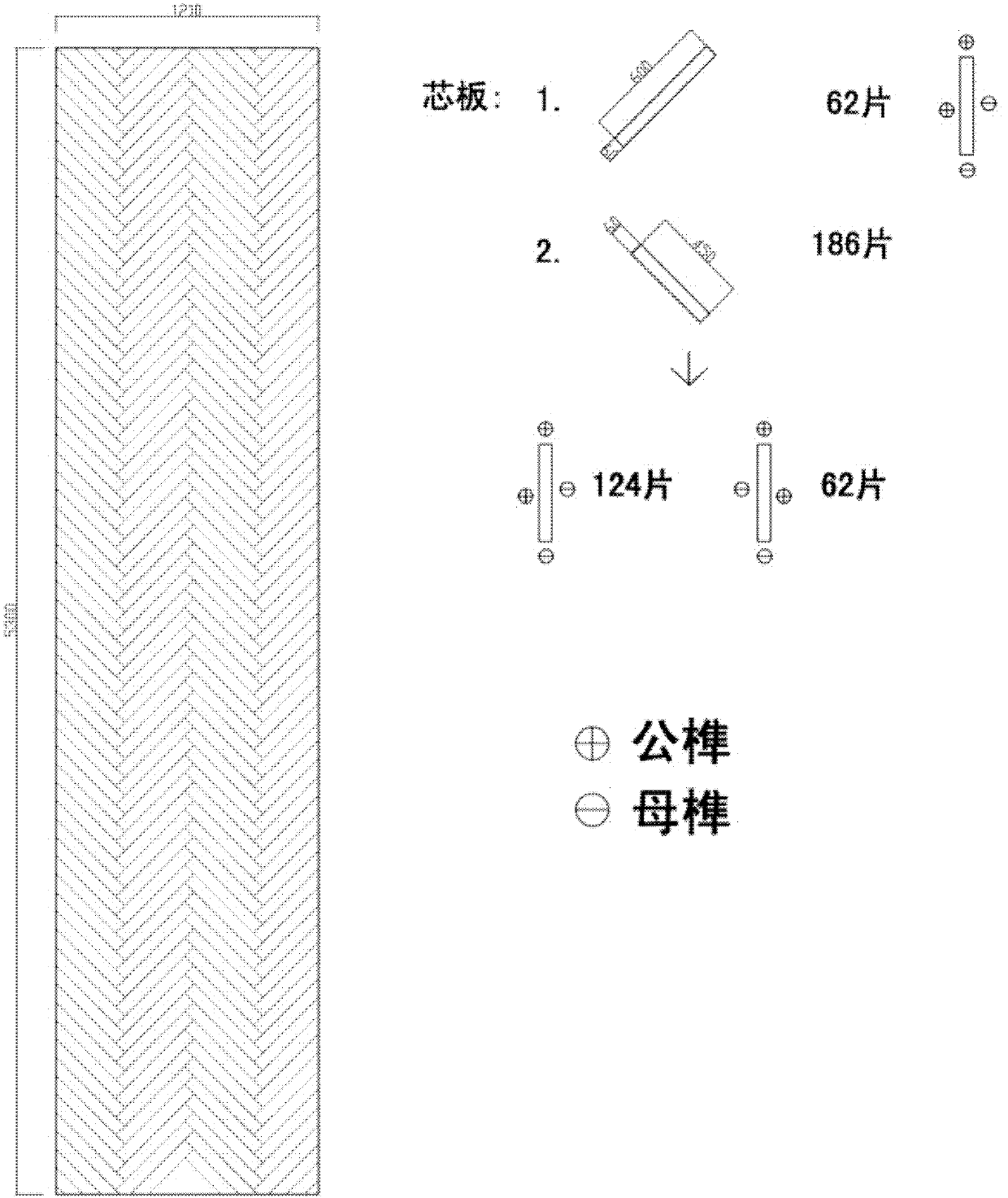

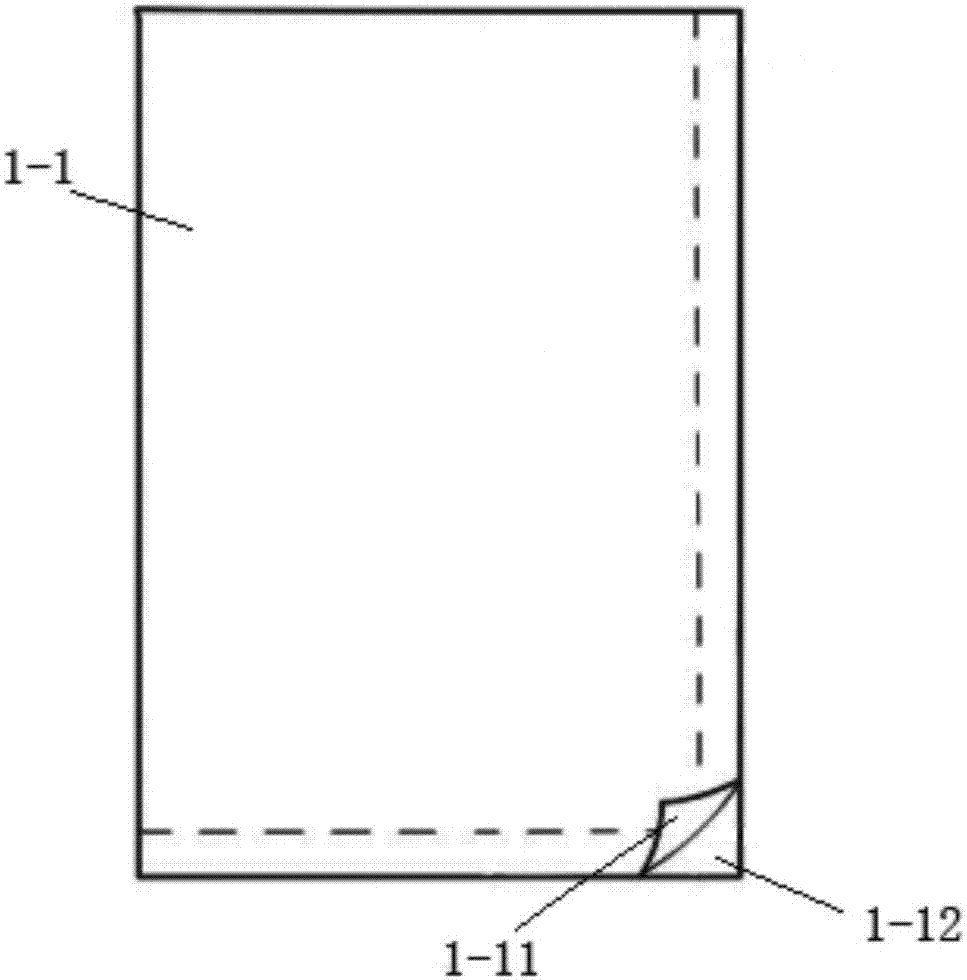

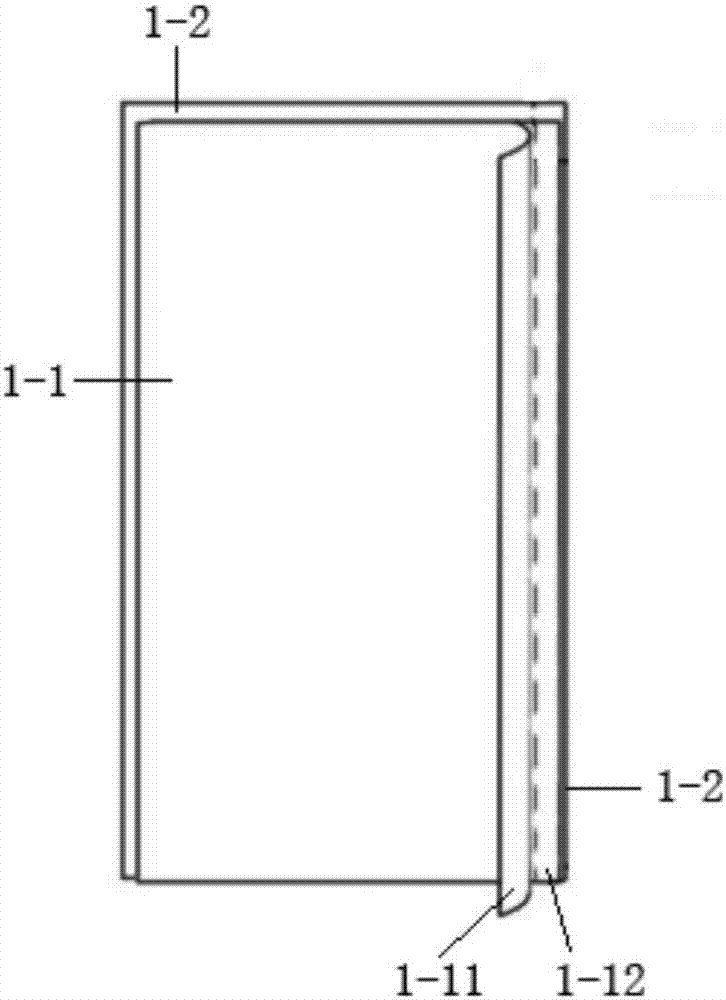

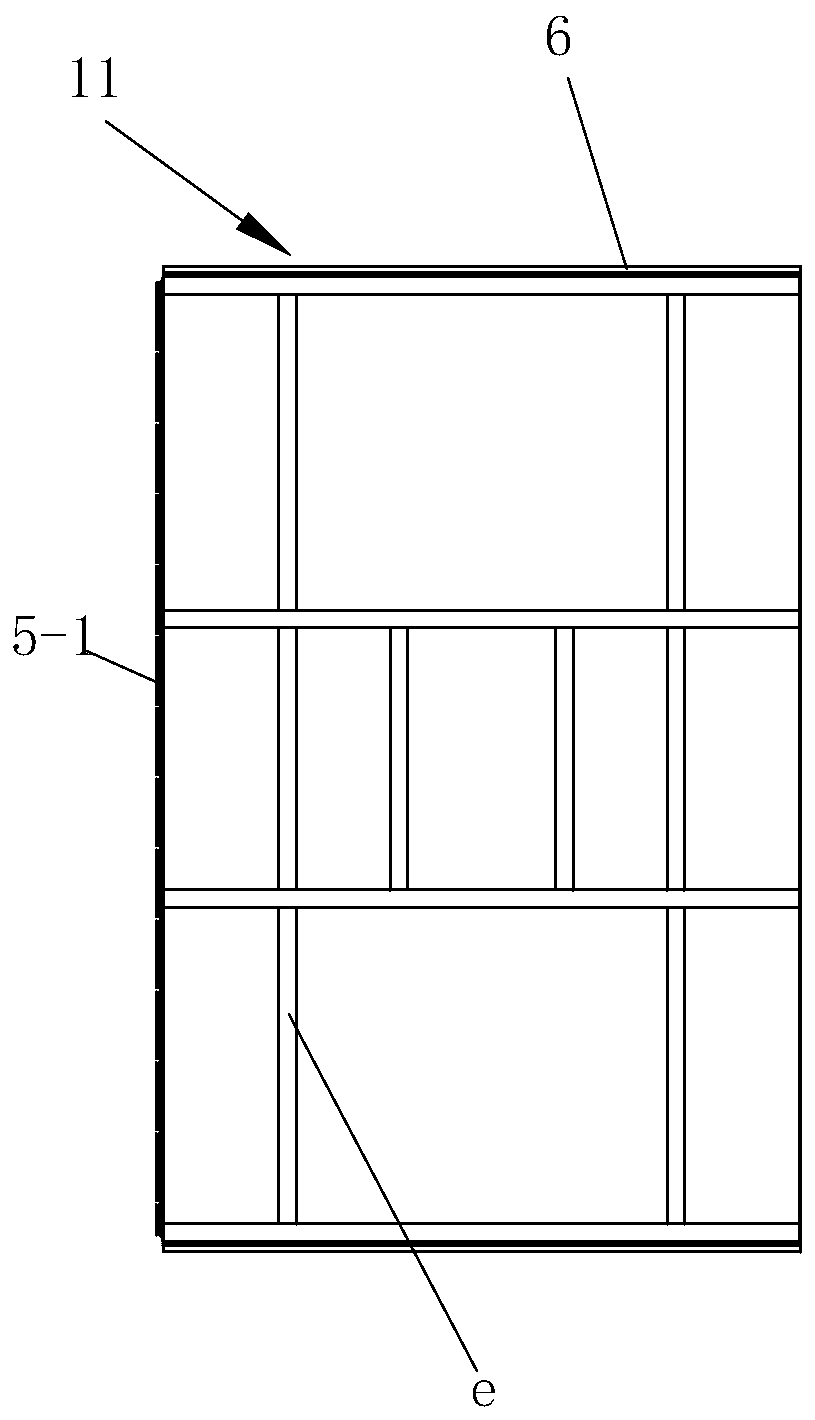

Large-area solid wood composite block floor as well as production method and installation method thereof

ActiveCN102888970AIncrease productivityRealize industrializationFlooringSolid woodManufacturing engineering

The invention provides a large-area solid wood composite block floor, and a production method and an installation method thereof. The block floor provided by the invention comprises a plurality of sub floor blocks, wherein each sub floor block is manufactured individually according to the specification and the shape of a preset design requirement; sub floor blocks have different specifications and different shapes, or parts of the sub floor blocks are same, and parts of the sub floor blocks are different; and all sub floor blocks are spliced to form the large-area solid wood composite block floor with an integral block pattern. On the basis of the traditional solid wood composite floor, the installation efficiency of the solid wood composite block floor in decoration is improved, the appearance quality of the solid wood composite block floor product is improved, and the large-area solid wood composite block floor can be directly installed in field and is free from being cut. According to the geometrical shape of the solid wood composite floor, a whole is broken into parts, the whole block floor is divided into parts of small units, and the field installation efficiency and quality can be improved. In addition, subsequent product complaint, especially the product complaint under the geothermal condition, can be avoided in a gumming-type installation mode.

Owner:ARMSTRONG (CHINA) INVESTMENT CO LTD

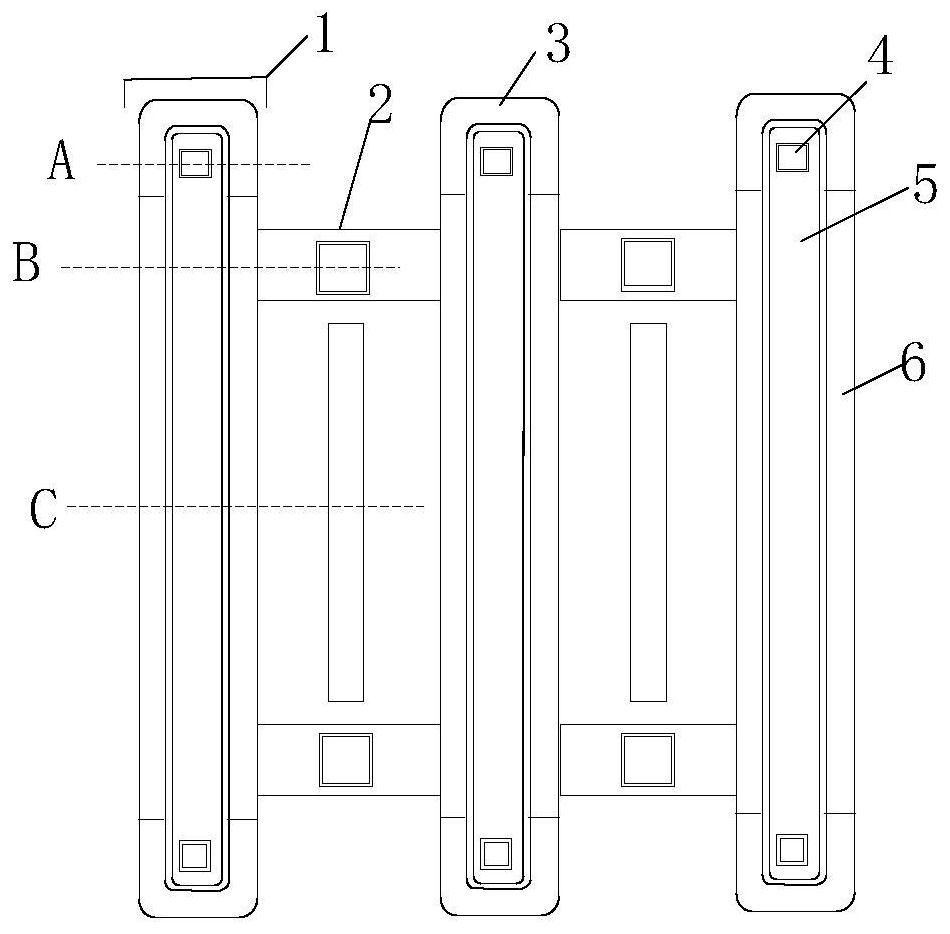

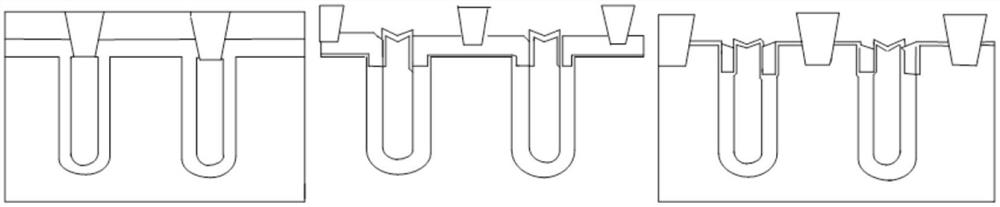

Levelling mechanism for assembly-type wallboard and levelling technology

PendingCN110939246ASolve the disadvantages of tightening and fixingEasy to operateCovering/liningsBuilding material handlingThreaded pipeScrew thread

The invention discloses a levelling mechanism for an assembly-type wallboard and a levelling technology. The mechanism comprises a wallboard body. The back face of the wallboard body is connected to ahanging part through a fixing bolt, and the connection plate is fixedly arranged on the wallboard through an expansion bolt. The wallboard body is provided with a levelling plate, a thread connectionblock is arranged in the bottom end of a hollow thread pipe in a threaded mode, a screw head is fixedly arranged on the thread connection block, a fixing screw is arranged in a clamping thread groovein a threaded mode, and an inner rod is movably arranged in the middle of the hollow thread pipe. According to the levelling mechanism for the assembly-type wallboard, a lengthened hollow thread rodis used for rotating and screwing the fixing screw, and the problem that due to the narrow gap between the wallboard and the wall, the bolts are not easily fastened directly by hand is solved. The levelling plate is arranged in the mechanism, wallboards different in thickness and material can be limited and guided, and the difference of height is avoided. The invention further discloses the levelling technology based on the levelling mechanism for the assembly-type wallboard. The mechanism is easy to operate and worthy of popularization.

Owner:安徽山水空间装饰股份有限公司

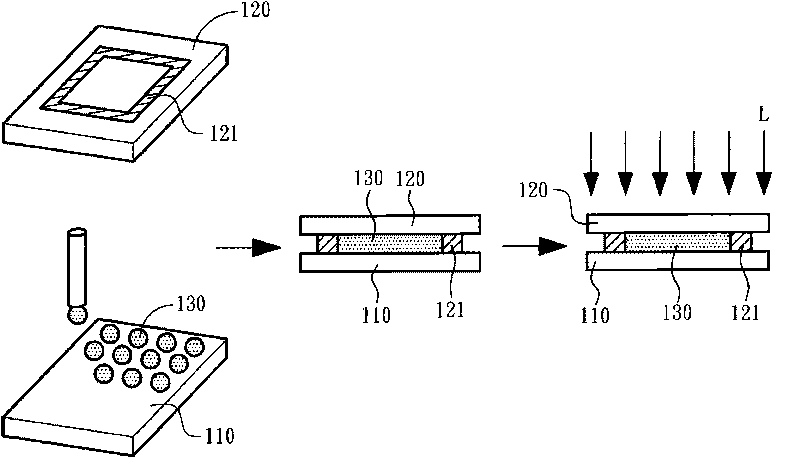

Liquid crystal filling method

ActiveCN101726930ANo difference in heightNo height differenceNon-linear opticsCrystallographyLiquid crystal

The invention provides a liquid crystal filling method which comprises the following steps of: providing a bearing table; placing a baseplate with a liquid crystal filling area on the bearing table, wherein the liquid crystal filling area is also provided with a buffer area; dripping liquid crystals into the liquid crystal filling area; and utilizing a wind cutter to enable the liquid crystals of the liquid crystal filling area to diffuse along one direction.

Owner:吴江汾湖科技创业服务有限公司

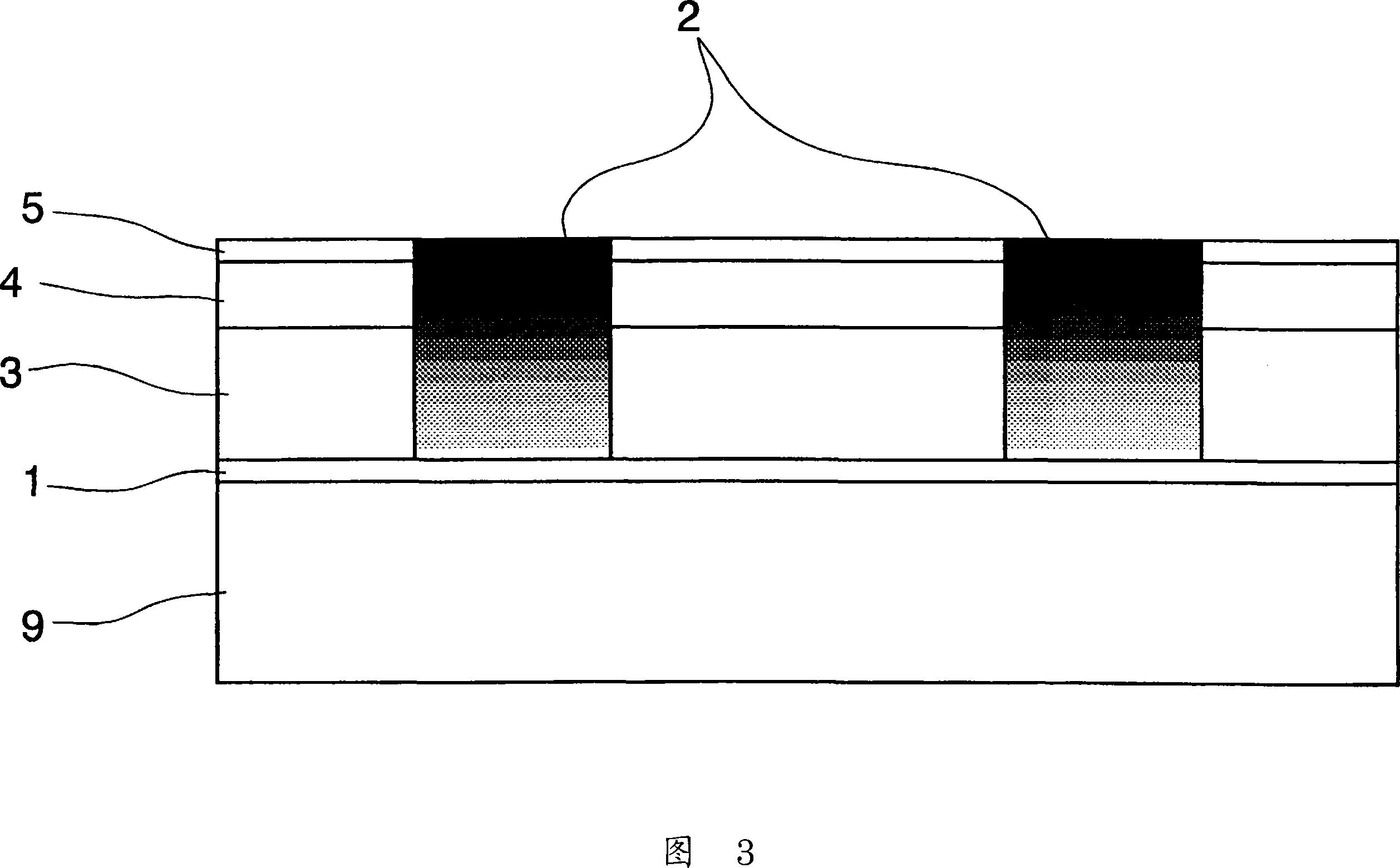

Magnetic recording medium and magnetic recording medium manufacturing method

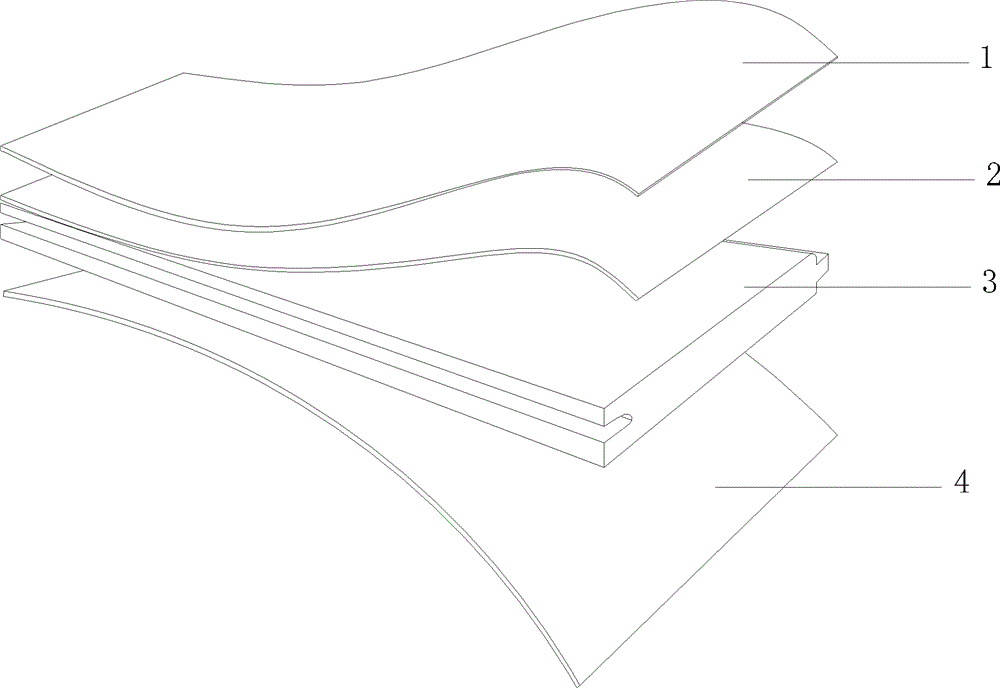

ActiveCN101027191AHeight differenceNo height differenceOther printing matterRecord information storageConcentration gradientRecording layer

The magnetic recording medium of the present invention has a pattern formed using a pattern-forming agent in a laminate of multiple layers including a base material and a magnetic recoding layer, wherein the pattern is recognized on the surface of the laminate opposite to the base material, and the pattern-forming agent is distributed through the thickness of the laminate, wherein a region between the center of the magnetic recording layer and a magnetic recording-reading side of the laminate has an area having a density gradient of the pattern-forming agent which gradually declines in the direction from the center of the magnetic recording layer to the magnetic recording-reading side.A magnetic recording medium has a picture formed by a picture forming reagent in a layered body formed by a plurality of layers including a basic layer and a magnetic recording layer. The picture can be recognized from a surface of the direction opposite to the basic layer of the layered body. The picture forming reagent is distributed in the film thickness direction and has a region having a concentration gradient gradually decreasing toward the direction of the magnetic recording reading side from the center portion of the magnetic recording layer in the region of the read side from the center portion of the magnetic recording layer in the layered body.

Owner:DIC CORP

Double-faced pile fabric piece split-splicing method and fabric piece split-splicing structure

ActiveCN107385695AReduce thicknessNo height differenceWork-feeding meansEngineeringMulti agent technology

The invention belongs to the technical field of clothing, and particularly provides a split splicing technique, including a double-faced pile fabric piece split-splicing method and a fabric piece split-splicing structure. According to the split-splicing technique, both splicing parts of two double-faced pile fabric pieces to be spliced are split into two layers, the two splicing layers of the double-faced pile fabric pieces are spliced with each other and fixed by stitching. The split-splicing technique has the advantages that the splicing parts are thin and the splicing stitch is flat and shallow. Tenderness and elegance of women can be shown completely when women wear the dresses made by the split-splicing technique. Further, the split-splicing technique is also applicable to making men' formal wear.

Owner:李建刚

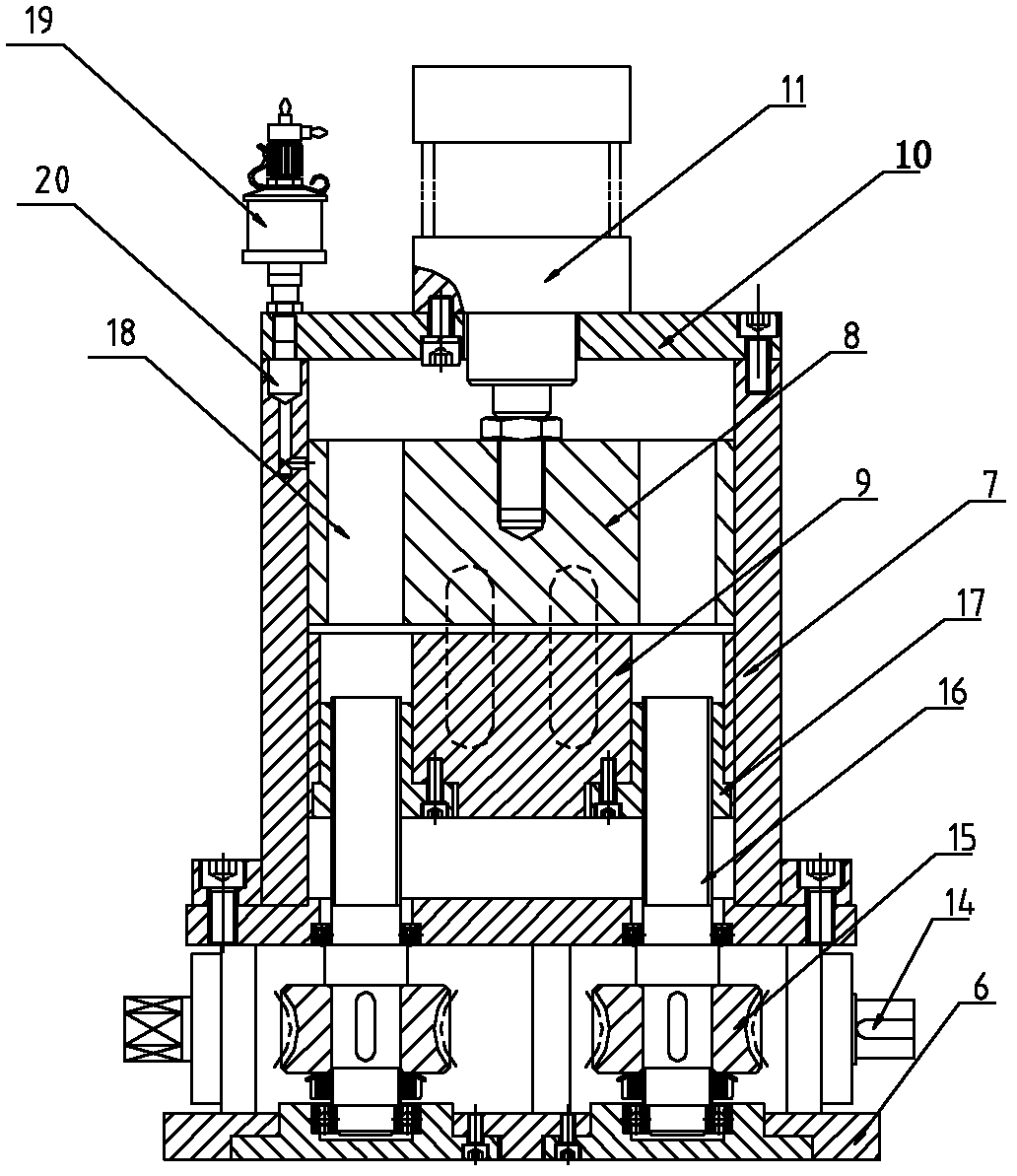

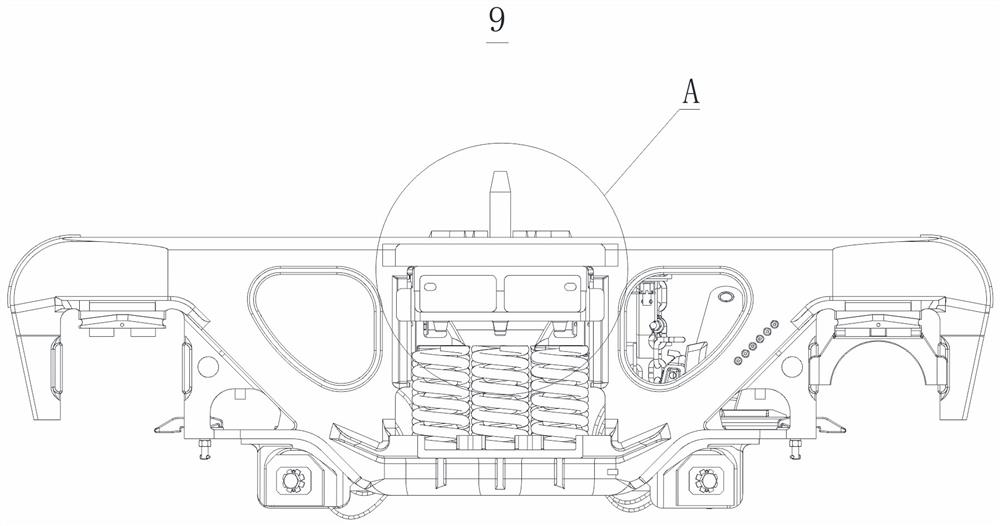

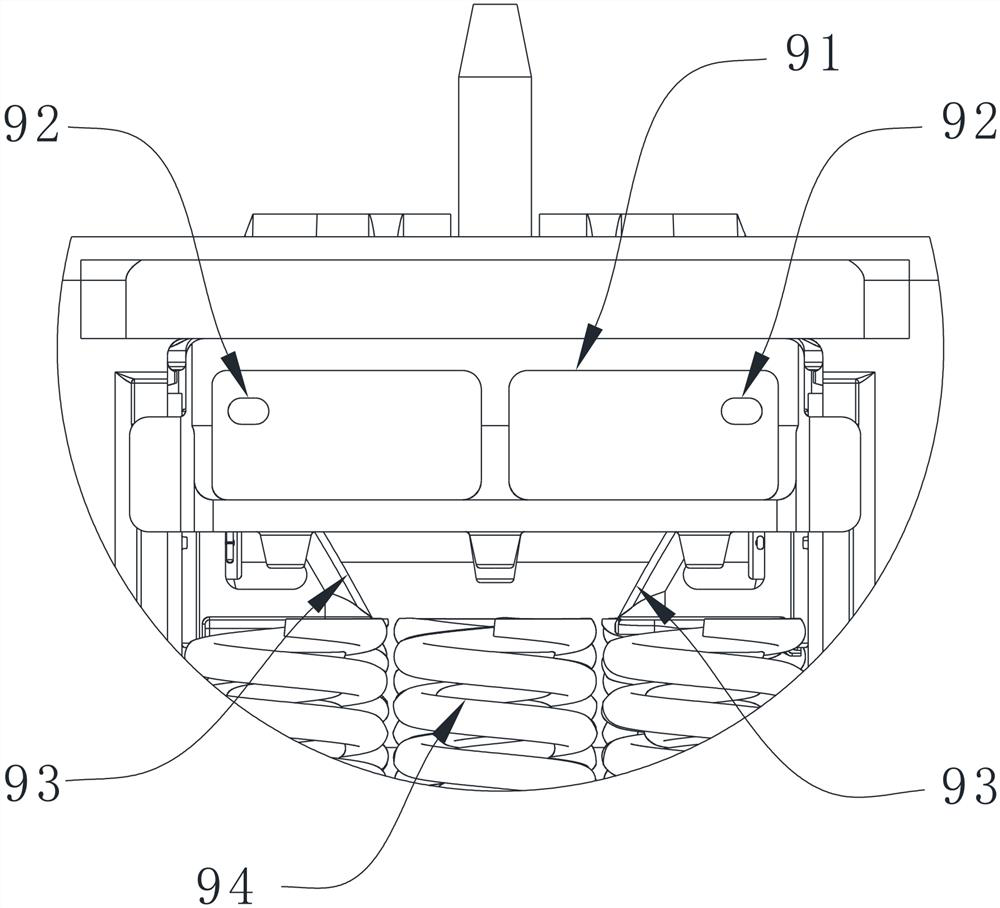

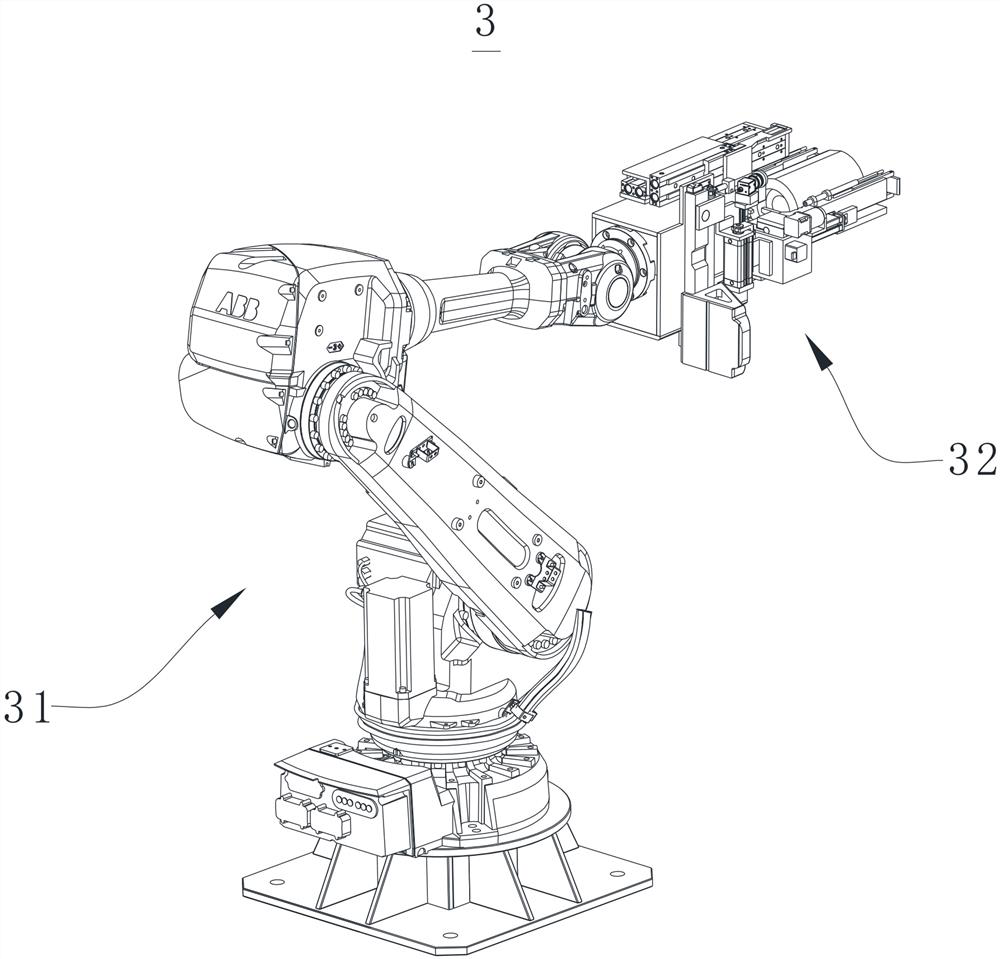

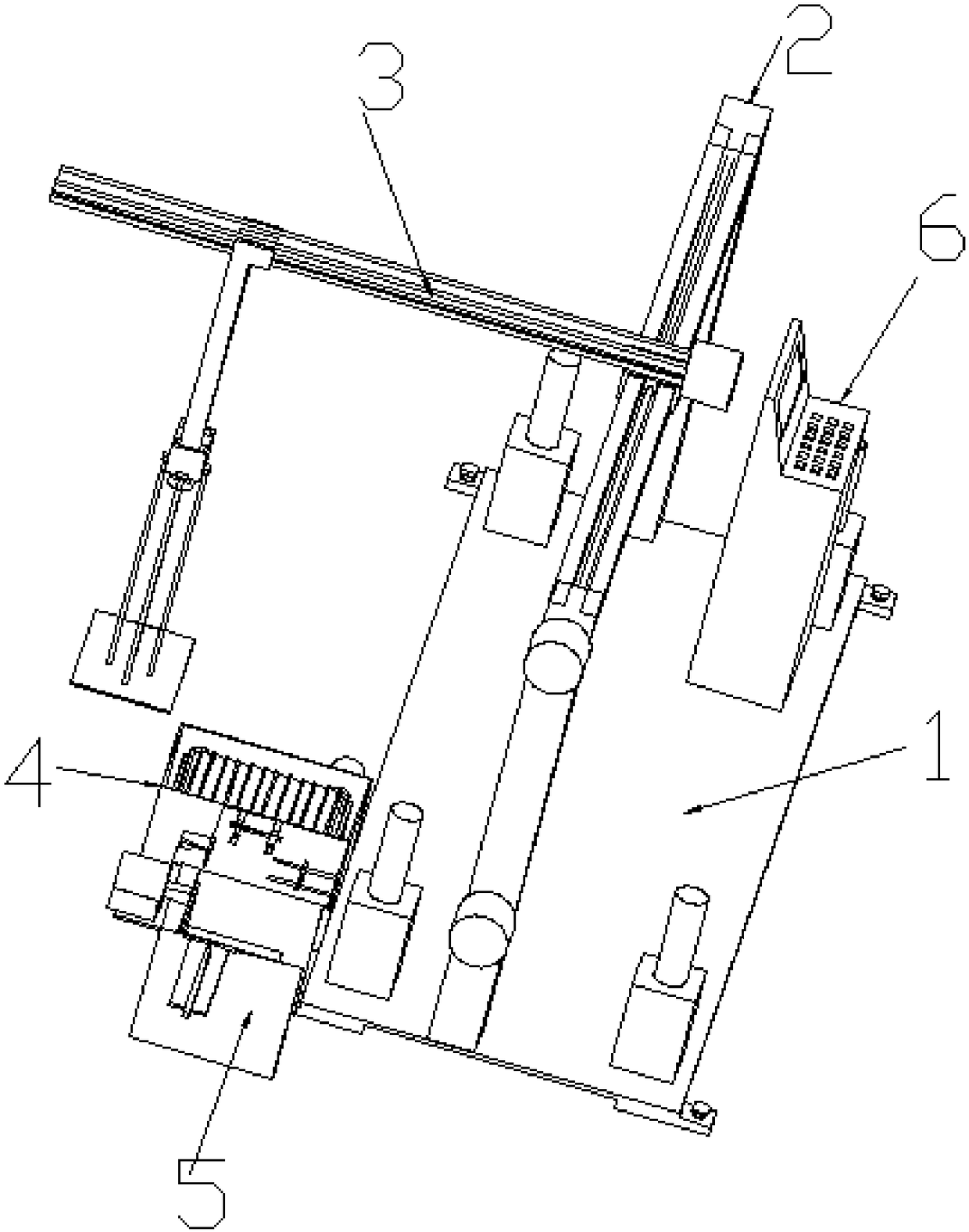

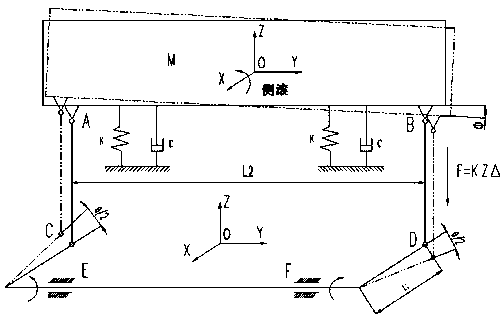

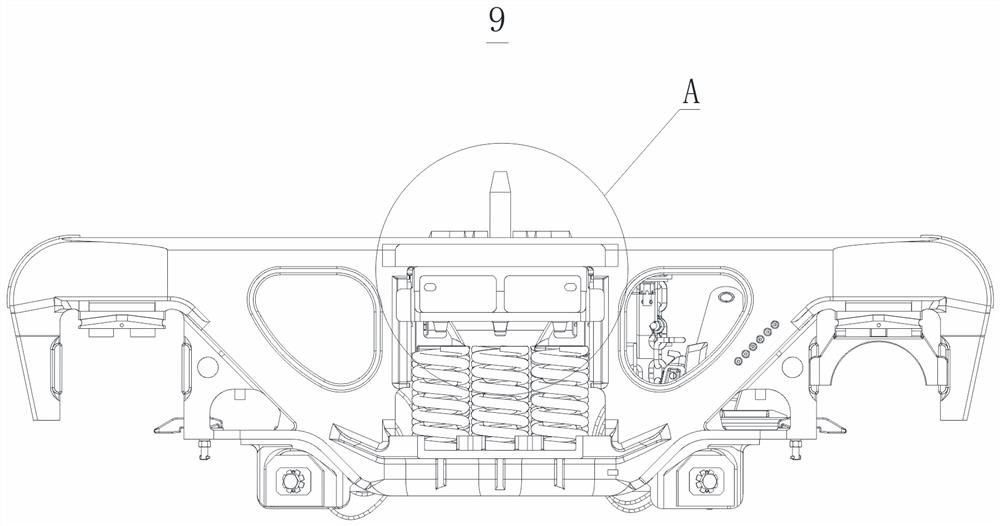

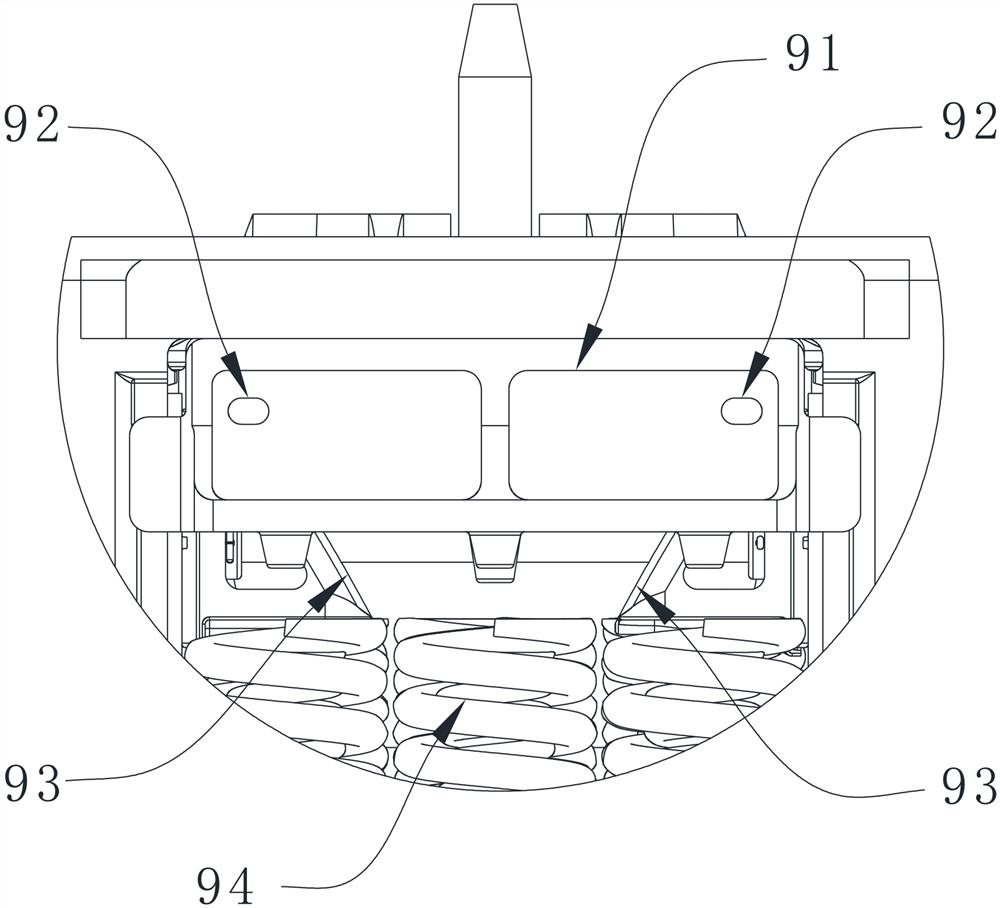

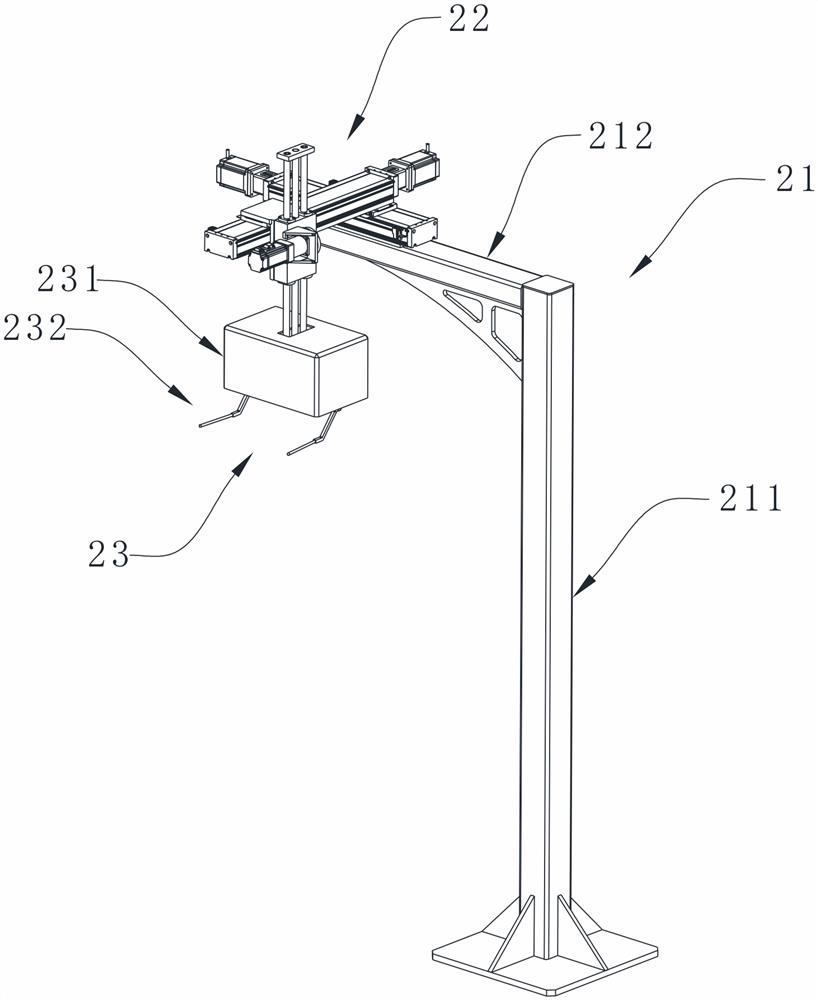

Bolster spring dismounting robot and bogie damping device dismounting system

ActiveCN113319564AEfficient separationGuaranteed separation effectVehicle componentsMetal working apparatusBogieTransfer line

The invention discloses a bolster spring dismounting robot and a bogie damping device dismounting system, and belongs to the technical field of railway vehicle bogie dismounting. The bogie damping device dismounting system comprises a bogie supporting device, a wedge supporting robot, a bolster spring and wedge transfer robot and the bolster spring dismounting robot; the bogie supporting device is used for supporting and jacking a bogie; the wedge supporting robot is used for supporting a wedge of the bogie; the bolster spring dismounting robot is used for dismounting and clamping a bolster spring of the bogie and is used for dismounting the wedge of the bogie; the bolster spring and wedge transfer robot is used for transferring the bolster spring and the wedge to the conveying line. The dismounting system is high in intelligent degree, the dismounting process of the bolster spring and the wedge is convenient, and the dismounted bolster spring and wedge can be accurately transferred, so that the labor intensity of workers is greatly reduced, and the dismounting efficiency is improved.

Owner:成都岁生科技有限责任公司

Floor tile gluing device with tile supply and cleaning functions

InactiveCN108331315AReduce the work of manual handling and fittingPrecise positioningBuilding constructionsEngineeringMechanical engineering

Owner:HUZHOU ZHONGCHEN CONSTR

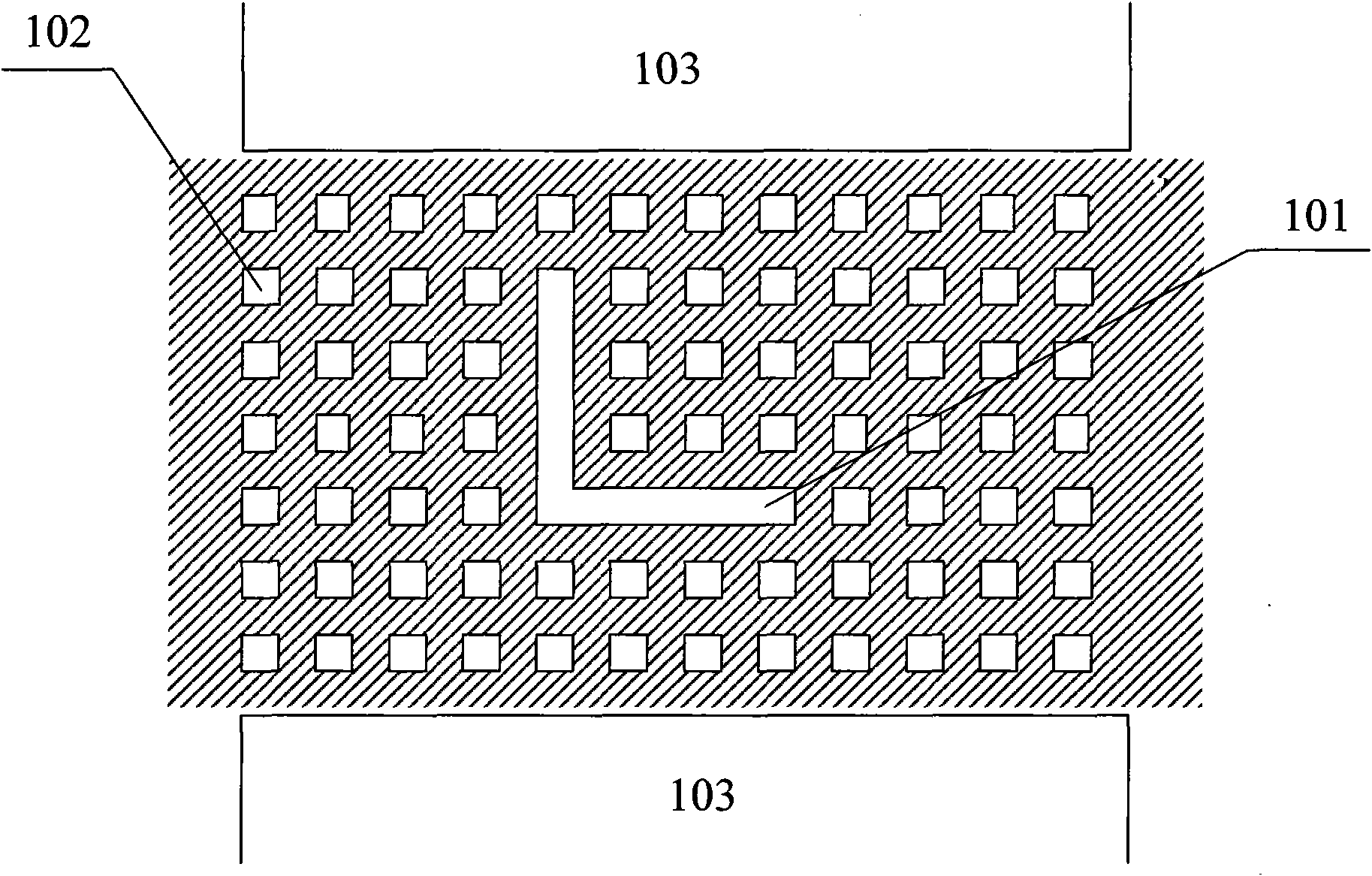

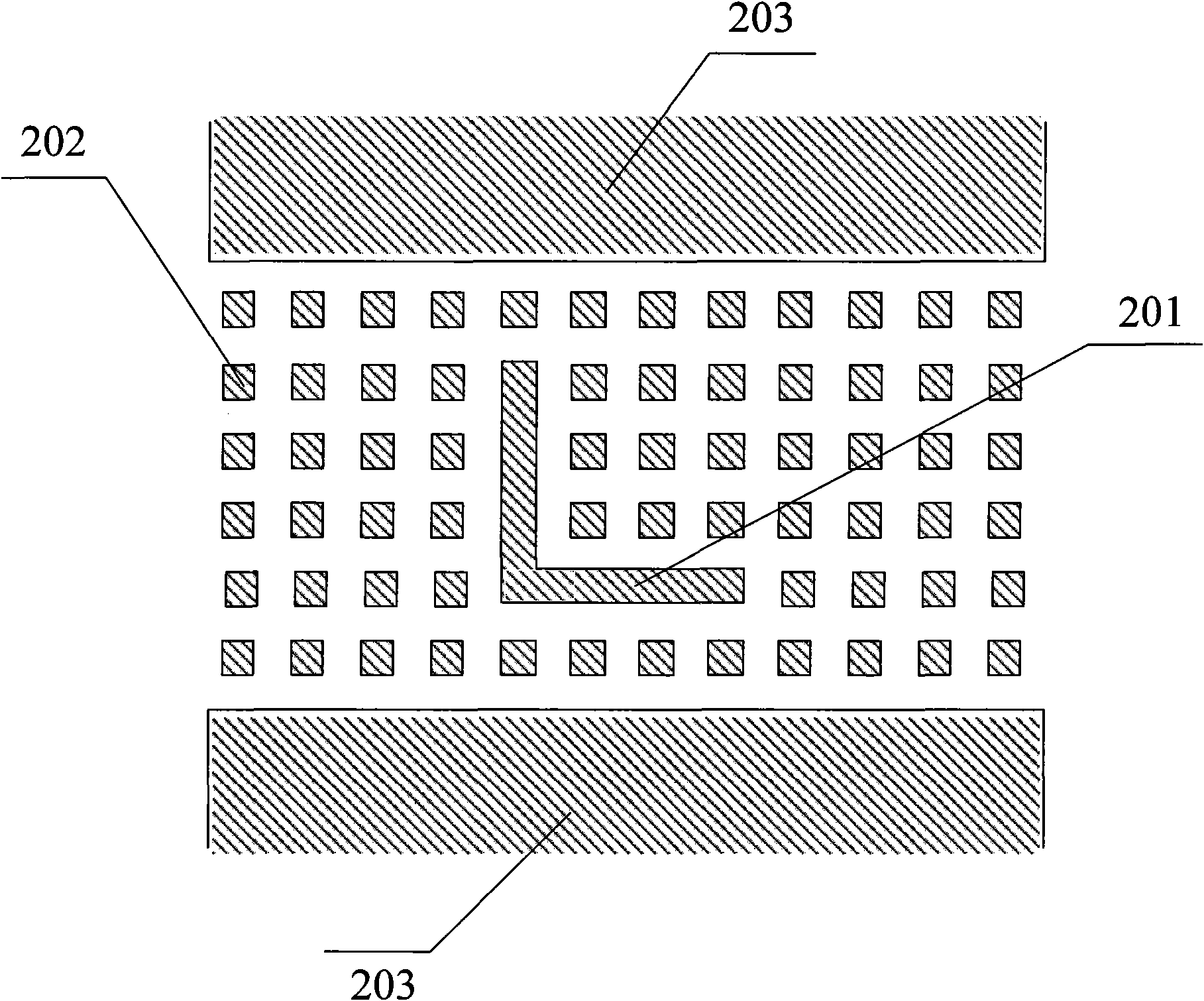

Measuring structure for improving accuracy of exposure conditions

InactiveCN102004397AIncrease graphics densityIncrease height differencePhotomechanical exposure apparatusMicrolithography exposure apparatusSemiconductorSemiconductor technology

The invention provides a measuring structure for improving the accuracy of exposure conditions, belonging to the technical field of semiconductors. The measuring structure comprises a main graph and a dummy graph, wherein the dummy graph is located beside the main graph; the density of the whole graph of the measuring structure is similar to the density of the graph in a device area inside the chip so that the measuring graph and the graph of the device area inside the chip are ensured to have approximately identical grinding velocity in the chemical and mechanical polishing process and the whole wafer is ensured to be more flattened. During photoetching exposure, the measuring graph and the optimum imaging focus in the device area inside the chip are located on the same plane, and the exposure condition defined by measuring the measuring graph is the optimum exposure condition of the graph of the device area inside the chip, thereby the accuracy of the photoetching exposure condition is effectively improved without affecting the capacity.

Owner:CSMC TECH FAB1

Vertical packaging machine subsidence type warehouse structure

ActiveCN106428847BNo height differenceReasonable structural designLarge containersPackaging machinesHeight differenceSedimentation

The invention discloses a sedimentation type warehouse body structure of a vertical packaging machine. The sedimentation type warehouse body structure comprises a warehouse body. A bag placing device is arranged around the warehouse body and provided with an inserting plate. A fixing base is arranged between the bag placing device and the warehouse body. An inserting shaft device is arranged at the lower end of the bag placing device. A guide rail groove is formed in the connecting position of the inserting shaft device and the warehouse body, and a stroke stepping device is arranged outside the inserting shaft device. The device is reasonable in structural design, easy to operate, safe and reliable. Falling packaging bags can tidily enter the warehouse body in order through cooperation of an inserting plate air cylinder and an inserting shaft air cylinder, and therefore the phenomenon that packaging bags in a traditional packaging machine directly fall into a large package from the warehouse body, and due to the too large height difference, placing is not tidy, and the packaging bags are damaged is avoided, and accordingly the product packaging efficiency is greatly improved.

Owner:HEFEI SANGUAN PACKING SCI & TECH

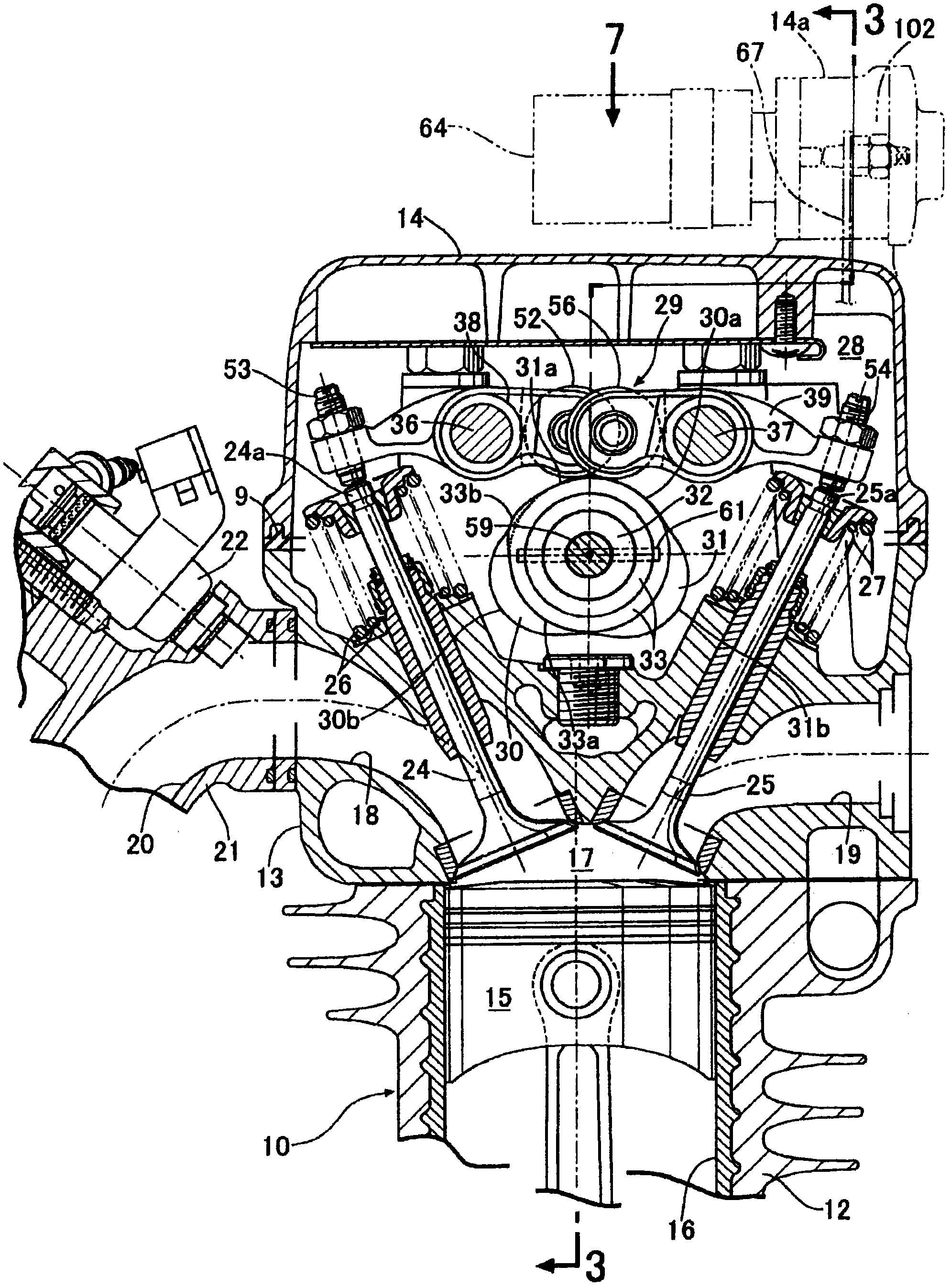

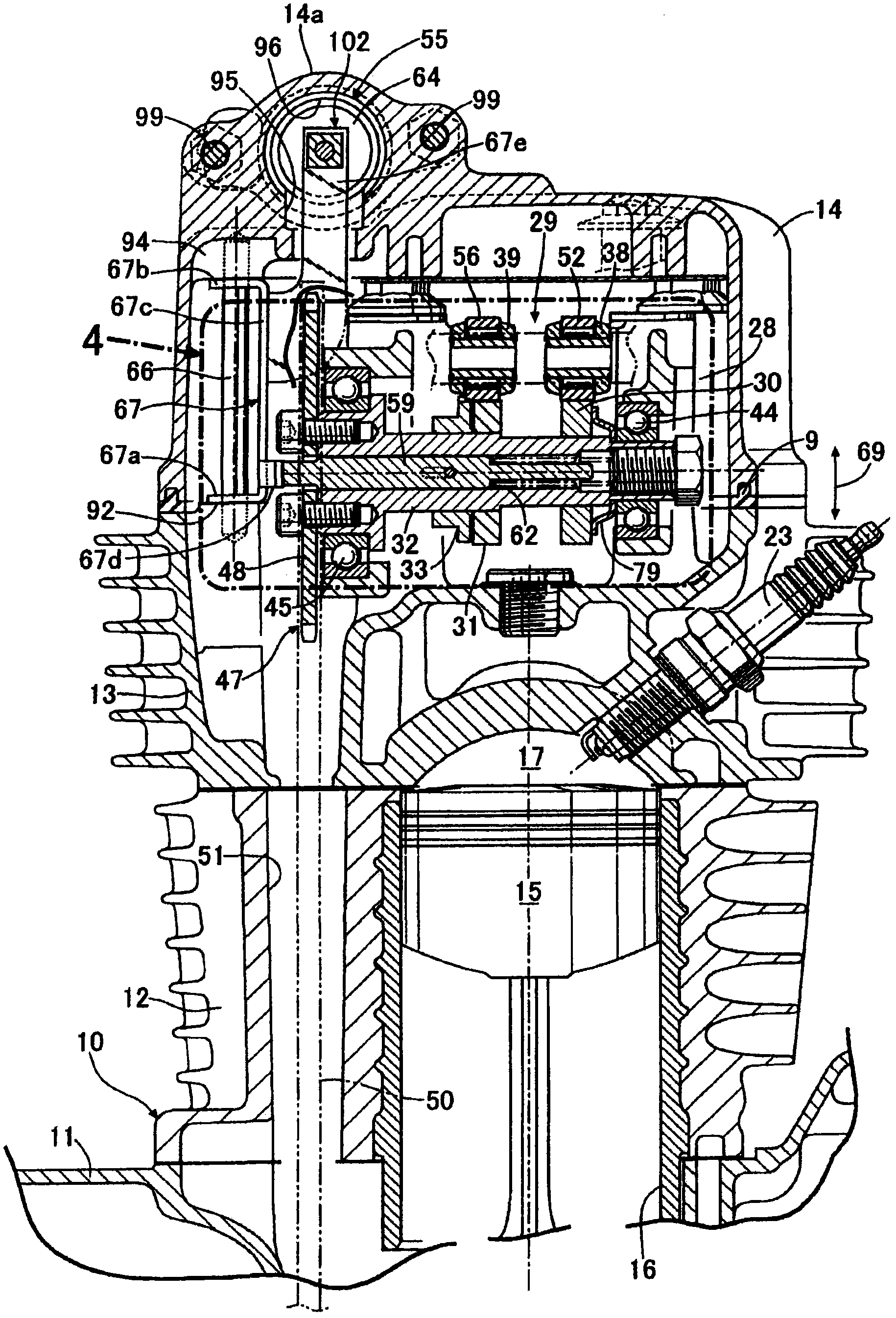

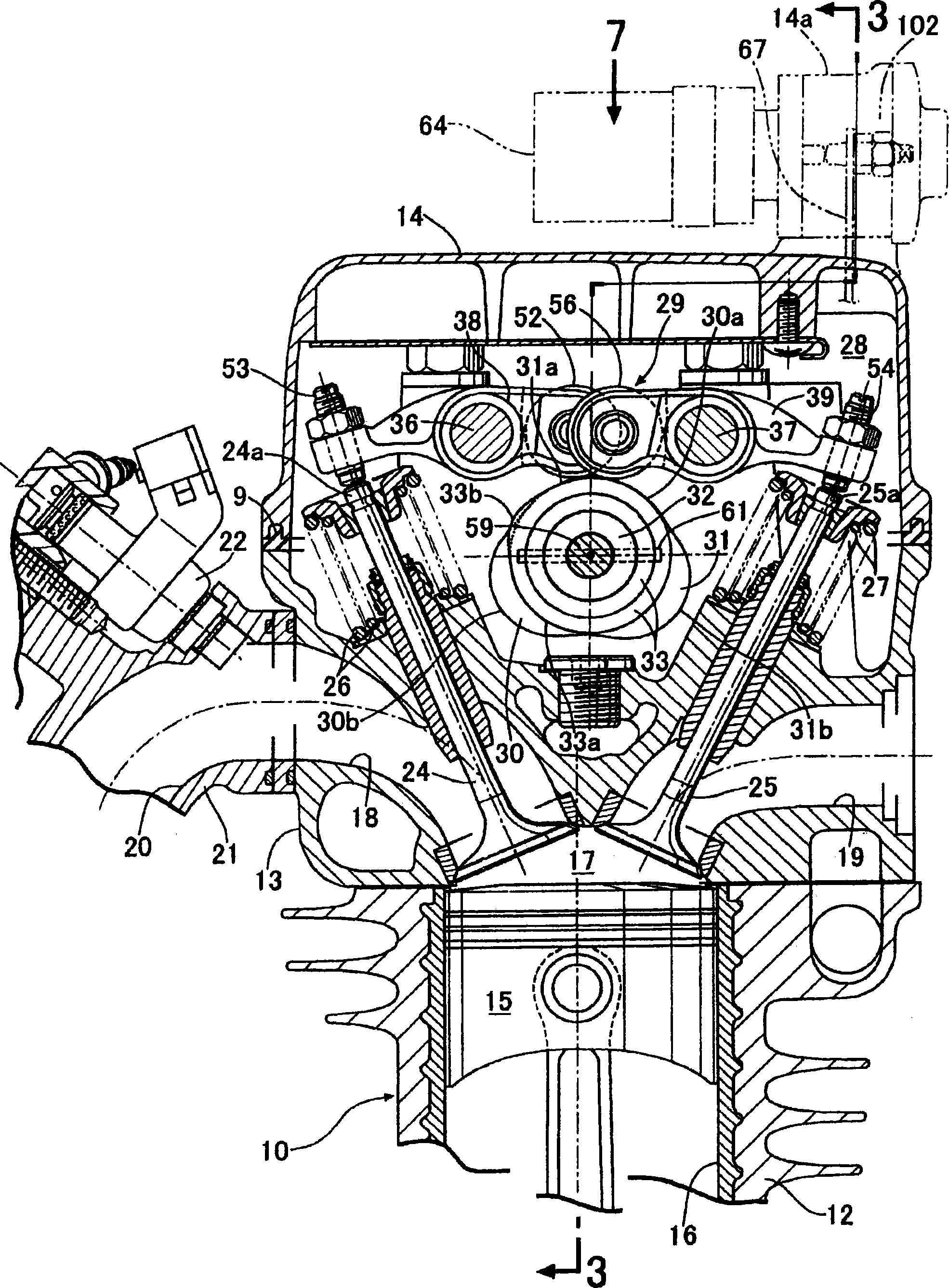

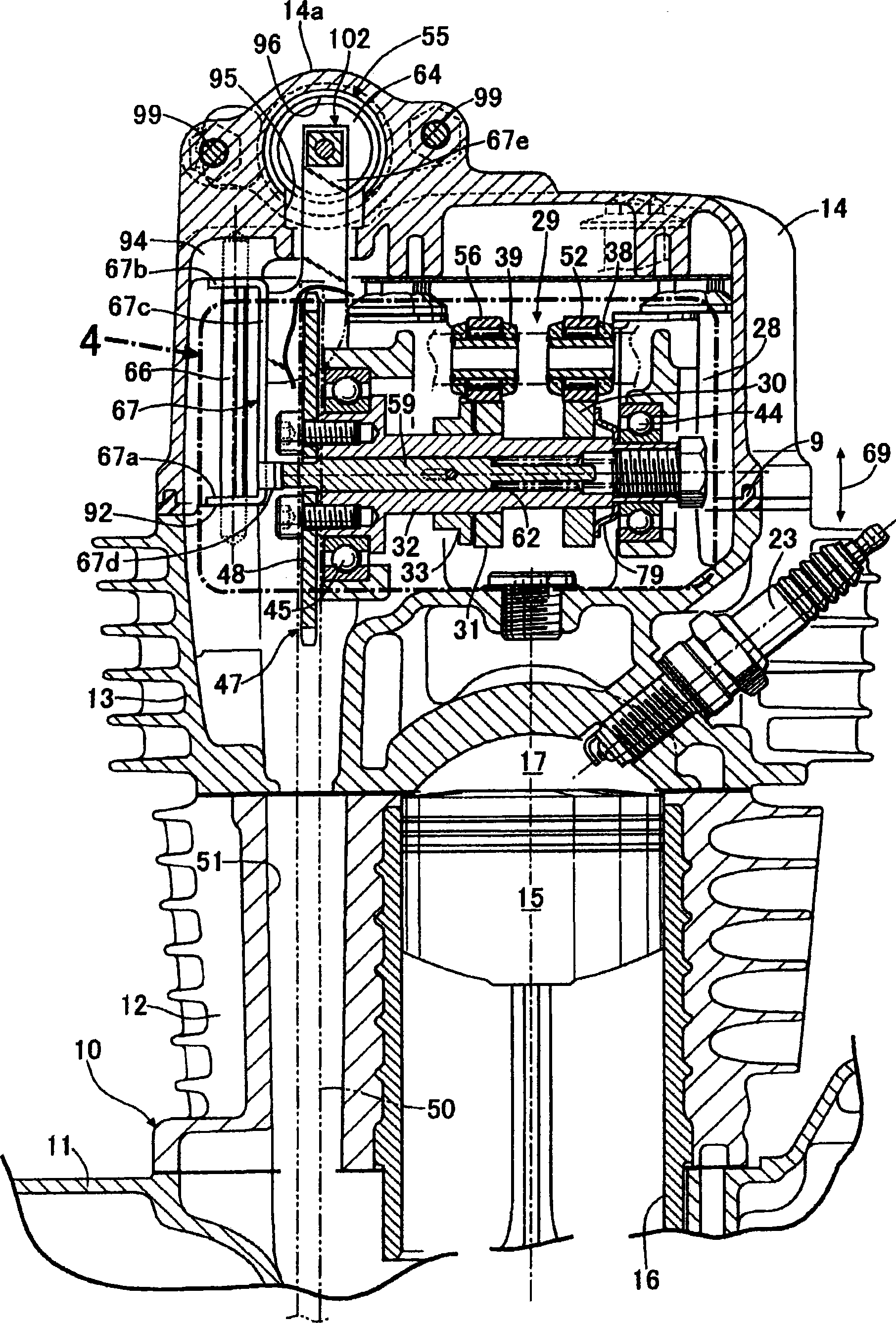

Variable stigmatic opening transmission device of engine

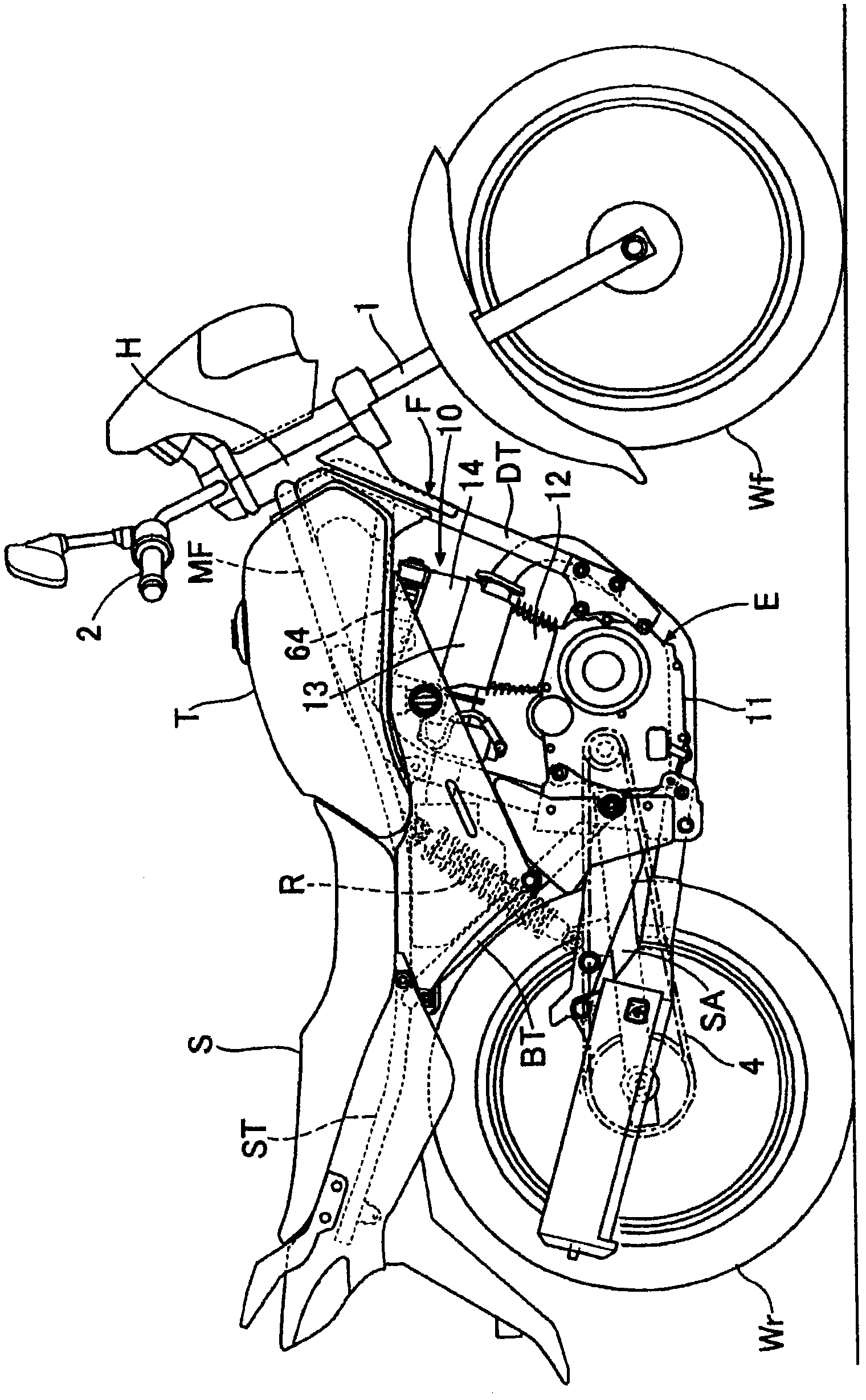

InactiveCN102080585AInhibit wearAvoid contactValve arrangementsInternal combustion piston enginesEngineeringCam

The invention provides a variable stigmatic opening transmission device of an engine, wherein the engine with elasticity applied on the valve closing direction is in linkage connection with a cam driven member and the cam driven member is equipped with a cam abutting part for the abutting against a first and a second cams.According to the device, when the second cam moves toward the first cam, the impact of the cam abutting part to the first cam is avoided and the generation of the strike sound is also avoided.The first cam (31) is fixed to a camshaft (32).The second cam (33) can axially movebetween the motion position that the second cam can abut against the cam abutting part (56) and approach the first cam (31) and the non-motion position that the second cam cannot abut against the camabutting part (56) and go far from the first cam (31). The second cam (33) supported by the camshaft (32) is not capable of rotating relative to an axis.The first cam side of the mountain portion (33b) of the second cam is equipped with an inclined surface and the inclined surface inclines toward the internal of the radial direction of the camshaft.

Owner:HONDA MOTOR CO LTD

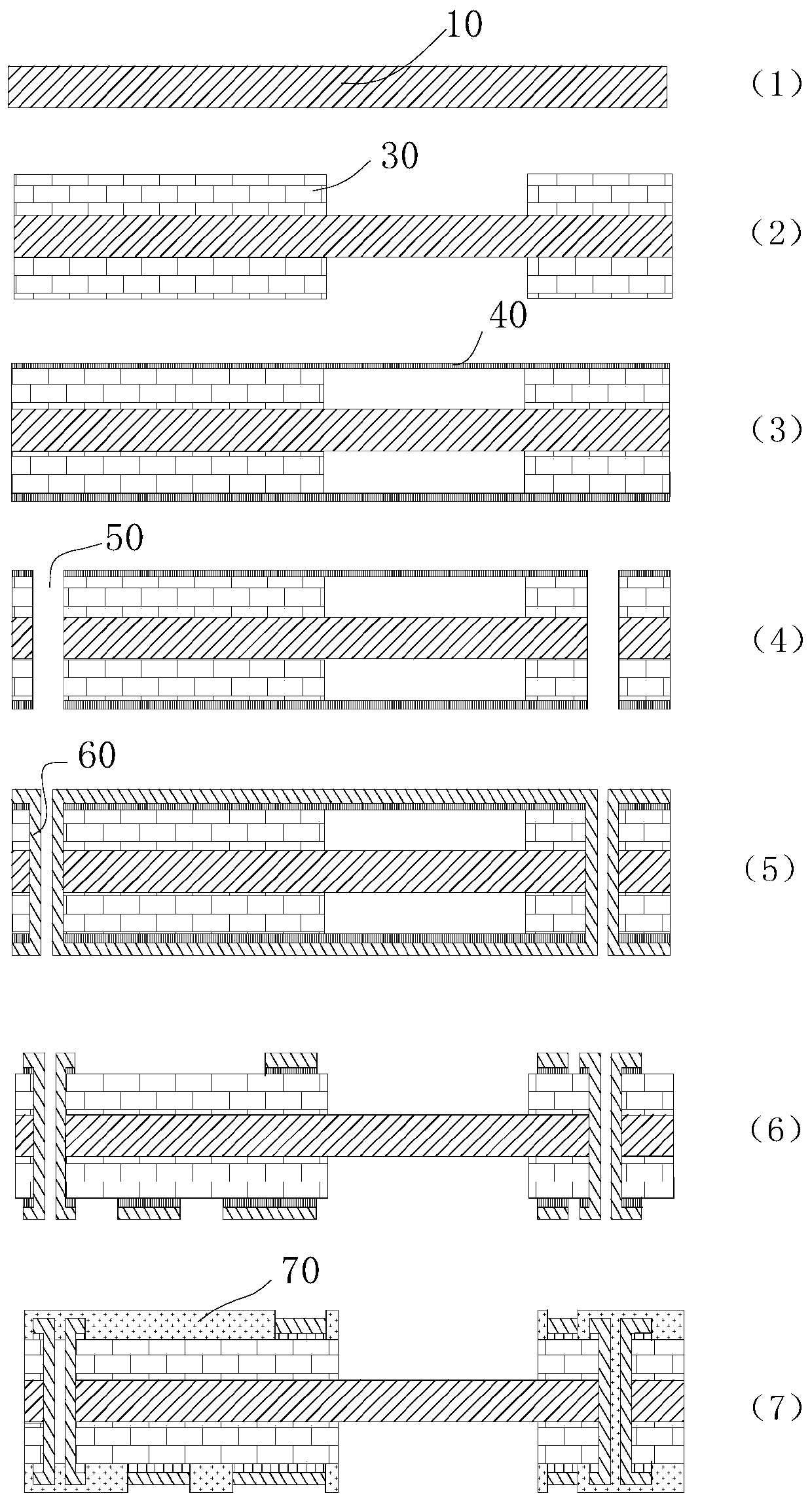

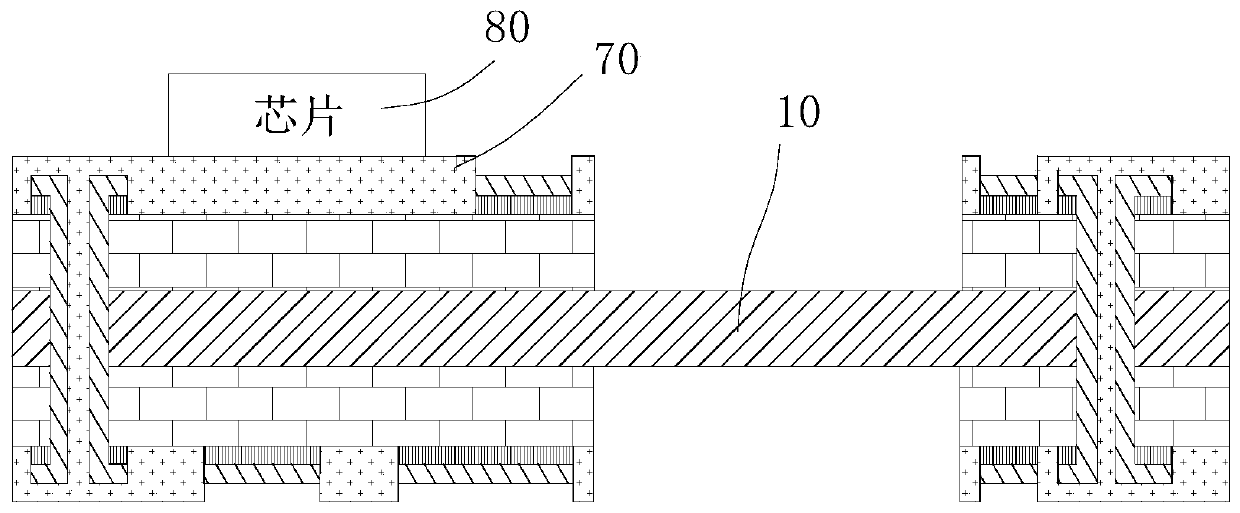

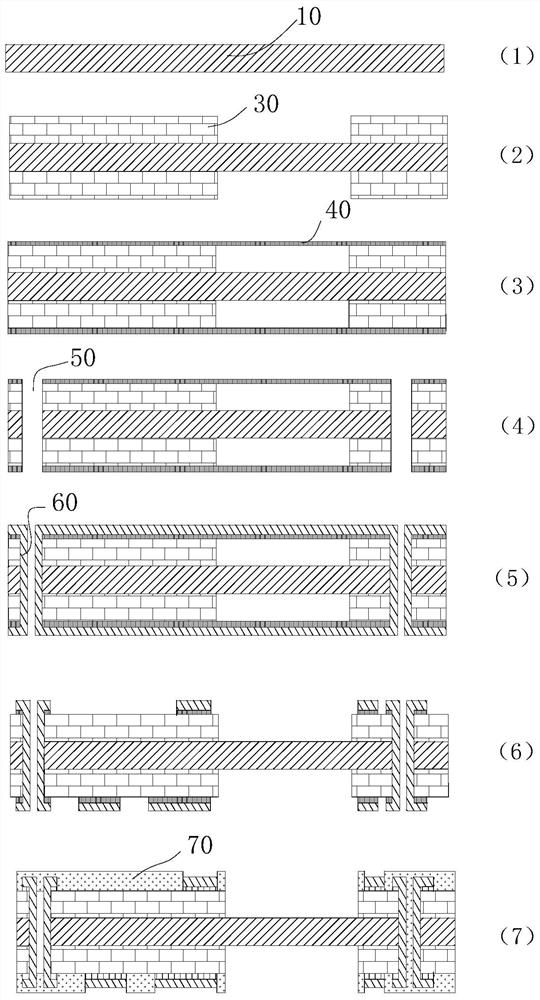

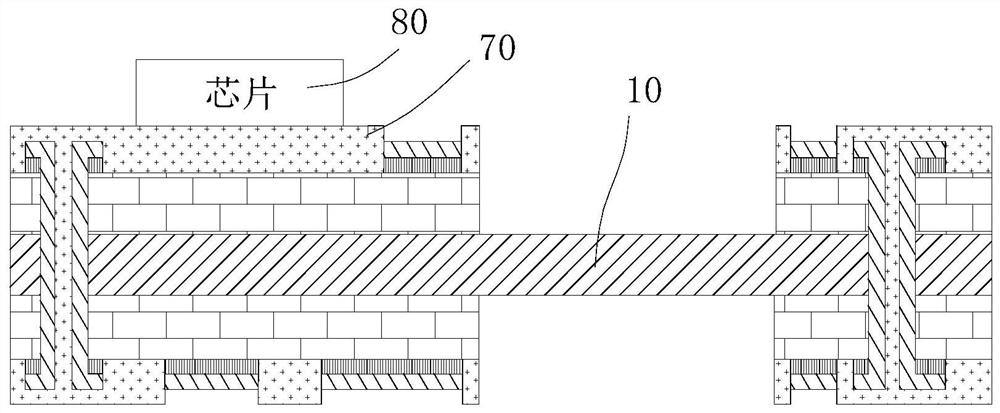

Preparation method of circuit board for CCMs

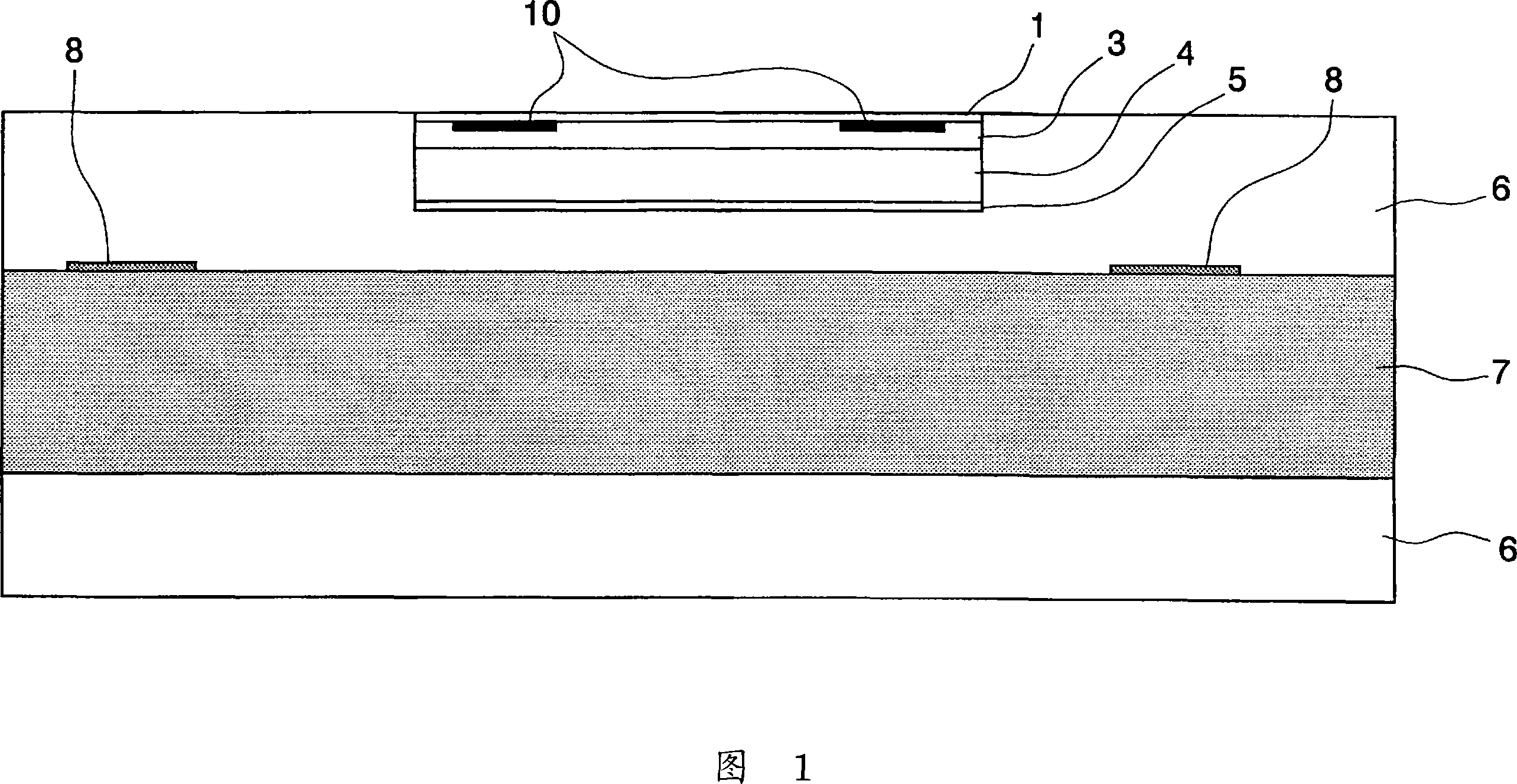

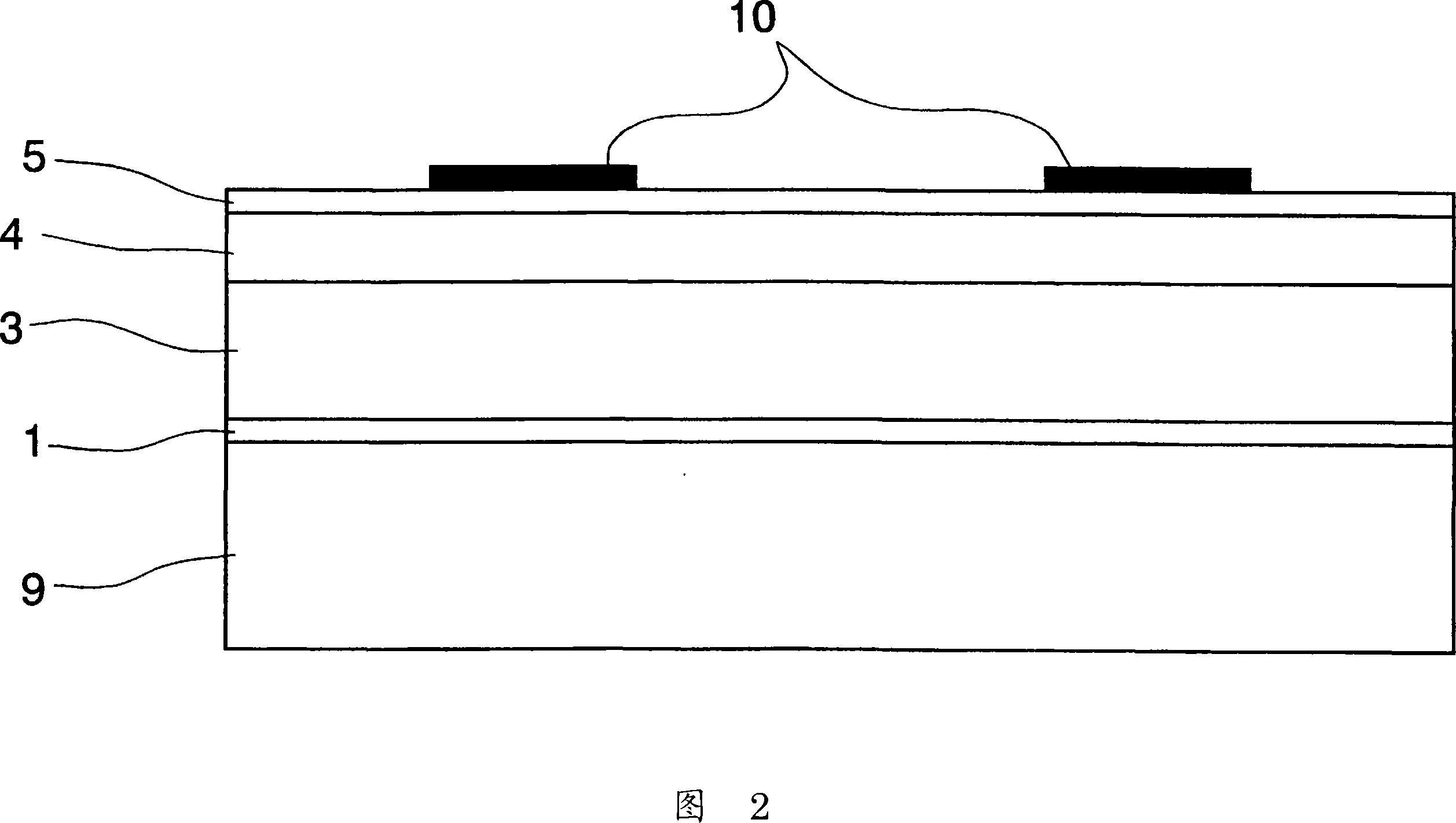

ActiveCN110677979AImprove the excellent rateImprove cooling effectPrinted circuit assemblingPrinted circuit non-printed electric components associationCMOSCopper foil

A preparation method of a circuit board for CCMs (CMOS Camera Module) comprises the following steps: inner core board making; insulating layer attaching; copper foil attaching and pressing; etching and windowing; seed copper; exposing and developing; copper column electroplating; grinding after film stripping; drilling; copper depositing and plating; outer circuit making; and solder resist making.A copper column is electroplated at the windowing position, a chip is directly attached to the copper column, and the heat dissipating capacity is improved. The strength of the steel column determines the deformation amount of the chip, and the deformation of the chip in a high-temperature environment can be ignored through a module assembling process. A grinding process is added after the coppercolumn is electroplated, so that the surface is smooth, and no height difference exists during chip attachment. In addition, the chip is attached to the copper column, the deformation is small, the resolution ratio is high, and the image blur rate is low. The technology is simple and reasonable. The prepared product has the advantages of good heat dissipation performance, high flatness, small deformation and high resolution ratio. The rate of good modules is increased.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

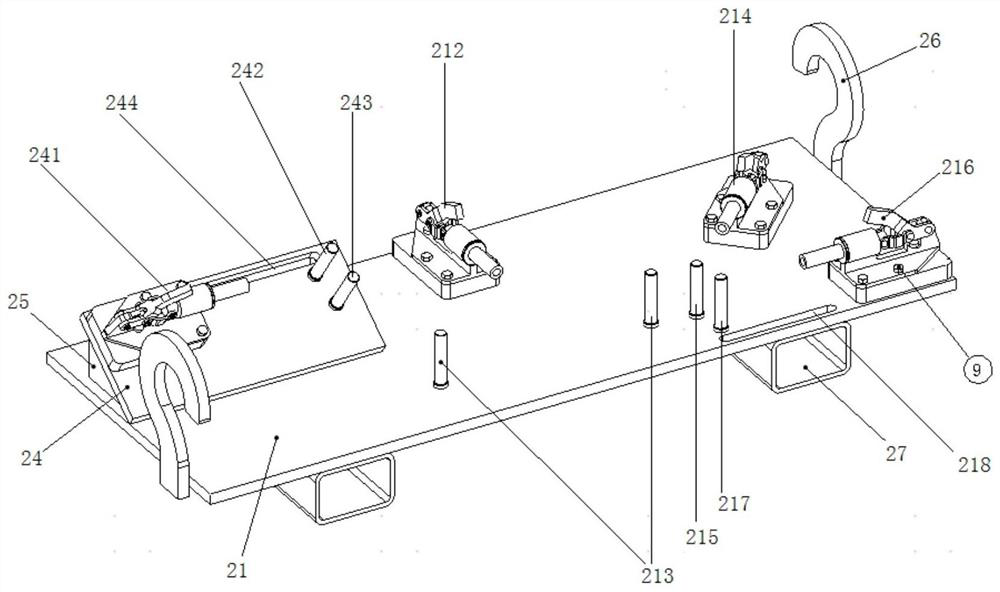

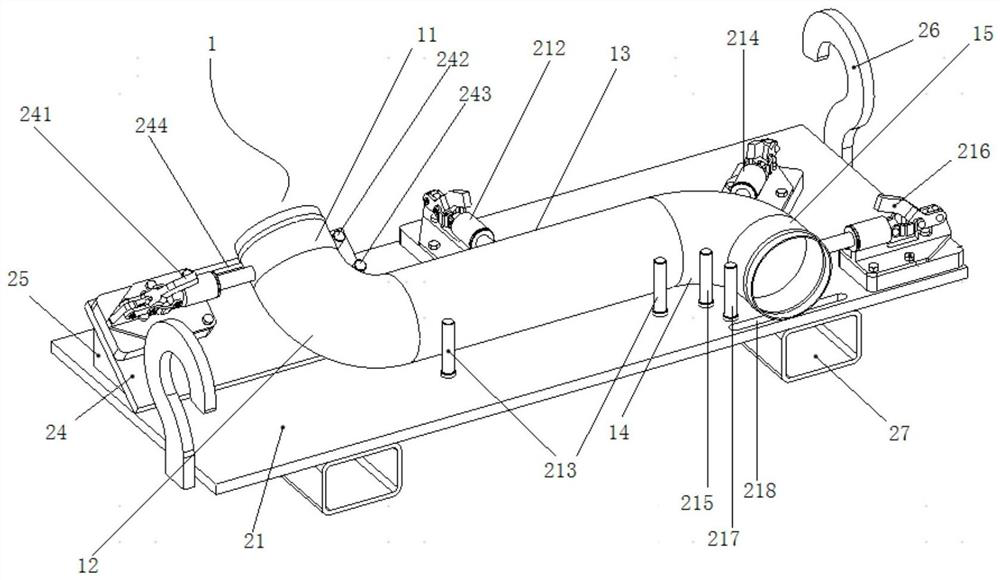

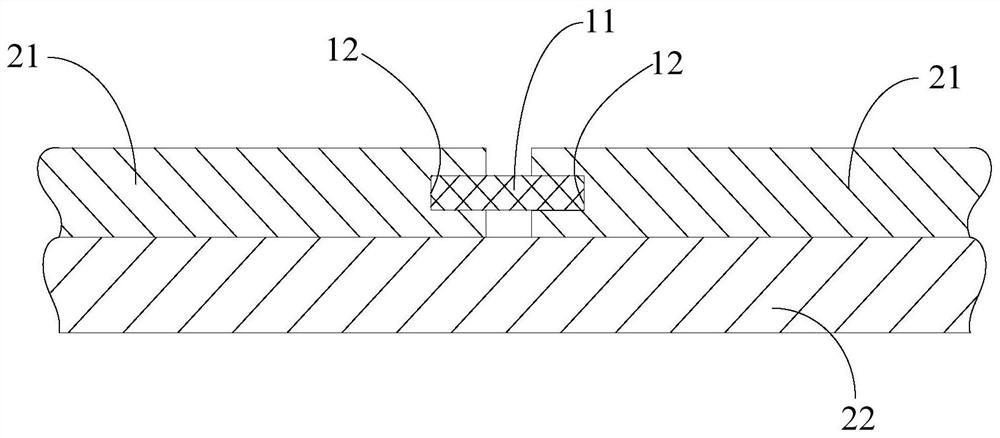

Assembling and welding method for space bent pipe of all-terrain vehicle and welding tool

PendingCN113369787ANo height differenceGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe

The invention discloses an assembling and welding method for a space bent pipe of an all-terrain vehicle and a welding tool. The assembling and welding method comprises the following steps: (1) assembling parts of the space bent pipe; and (2) conducting welding to form the space bent pipe. The welding tool comprises a main plate for conducting multi-point supporting on the bottom of the space bent pipe, and a positioning plate which is obliquely installed on the main plate and used for supporting an upwarp section of the space bent pipe; and part sections forming the space bent pipe are fixedly positioned on panel surfaces of the positioning plate and the main plate respectively. When welding needs to be conducted to form the space bent pipe, the part sections forming the space bent pipe are fixedly positioned on the panel surfaces of the positioning plate and the main plate respectively to be supported, thus it is guaranteed that no height difference exists in supporting of the part sections forming the space bent pipe, meanwhile, repeated adjustment is not needed, the problem that height difference exists in the different part sections of the space bent pipe is solved, and it is guaranteed that the overall space position precision of the space bent pipe which is formed after welding is conducted meets the design requirement.

Owner:GUIZHOU JONYANG KINETICS

Stone floor tile levelness maintaining device

PendingCN111749426AIncrease widthNo height differenceFlooringArchitectural engineeringStructural engineering

The invention discloses a stone floor tile levelness maintaining device. The stone floor tile levelness maintaining device comprises flexible embedded parts and embedded grooves formed on the sides ofstone floor tiles and used for allowing the embedded parts to be embedded. When the two sides of each embedded part are spliced on the corresponding stone floor tile, the two sides of the embedded part are embedded into the opposite embedded grooves of two adjacent stone floor tiles. The embedded grooves are formed on the sides of the stone floor tiles, when the stone floor tiles are spliced, each embedded part with certain flexibility is embedded into the opposite embedded grooves of two adjacent stone floor tiles; and during assembling, it can be ensured that the spliced position of two adjacent stone floor tiles keeps level, and even though the levelness of the ground where stone floor tiles are paved is not perfect, the device can ensure that no height difference is generated to joints of the adjacent stone floor tiles in the stone floor tiles with pavement completed.

Owner:上海爱迪技术发展有限公司

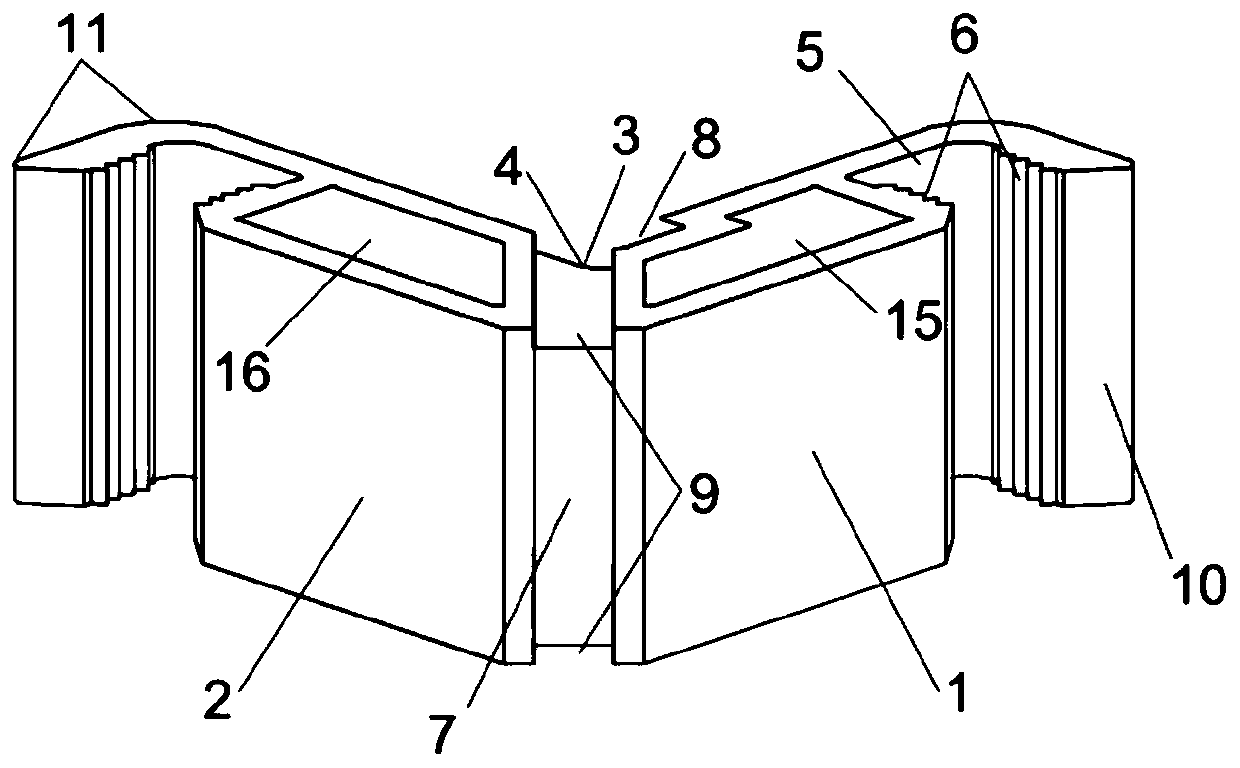

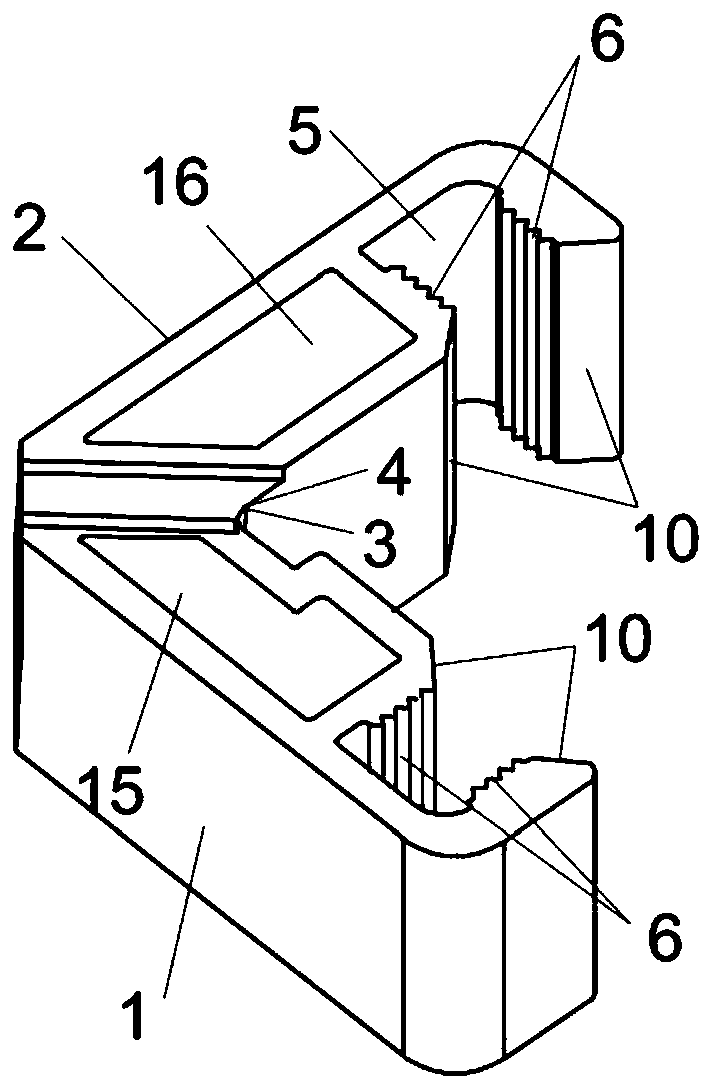

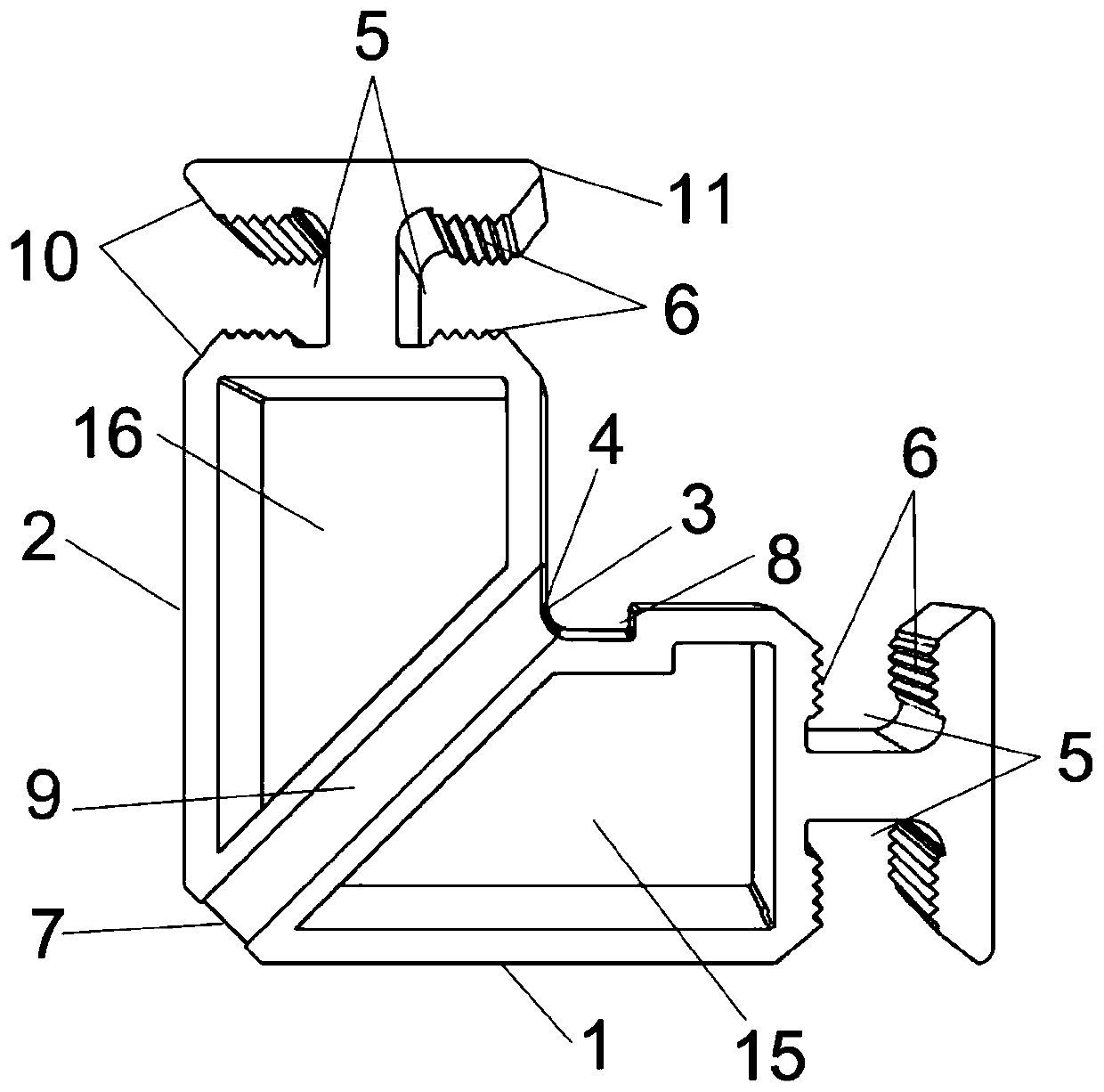

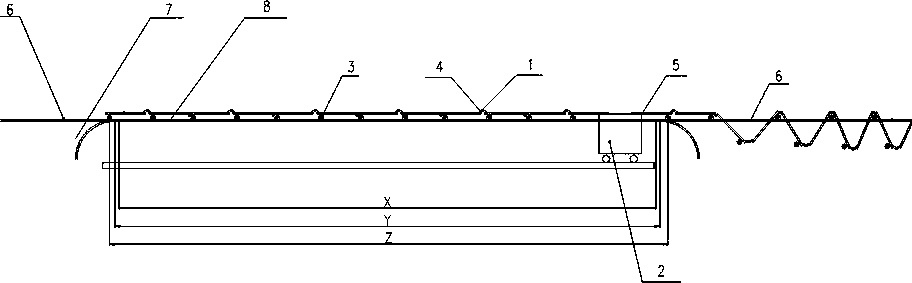

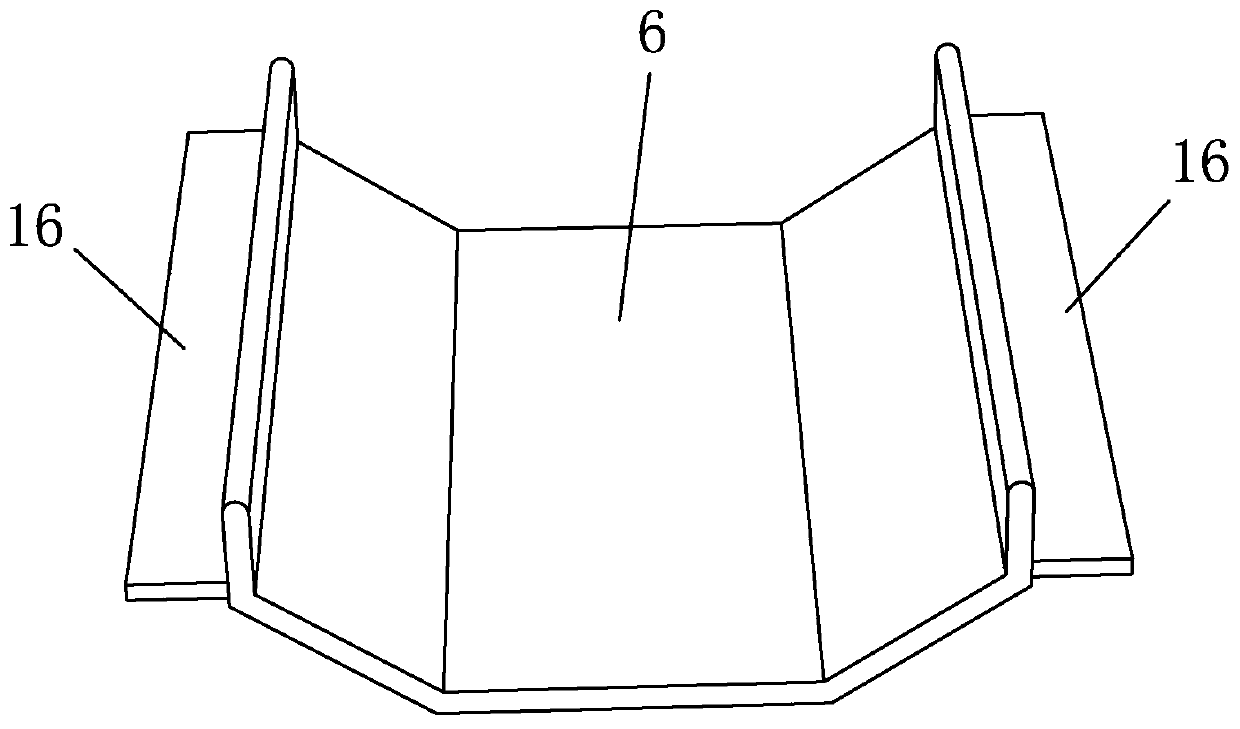

Windproof and waterproof glue injection corner connector and connecting structure thereof

PendingCN109989686AImprove general performanceImprove water tightnessDoors/windowsThermal breakEngineering

The invention provides a windproof and waterproof glue injection corner connector, which comprises a first fixing arm and a second fixing arm. The first fixing arm and the second fixing arm are in right-angle connection to form an L shape. An R-shaped limiting point is arranged on the first fixing arm; a positioning reference point is arranged on the second fixing arm; C-shaped grooves are formedin the ends of the first fixing arm and the second fixing arm; and threads are arranged in the C-shaped grooves. The invention also provides a connecting structure of the windproof and waterproof glueinjection corner connector. The windproof and waterproof glue injection corner connector and the connecting structure thereof are high in universality, and are suitable for assembling doors and window frame sashes of aluminum alloy section bars, heat insulation thermal break aluminum alloy section bars, aluminum-wood composite section bars, stainless steel section bars, and aluminum-plastic aluminum section bars and plastic steel section bars, accurate and rapid assembling of the door and window section bars through the glue injection corner connector can be achieved, the assembling quality is guaranteed, the labor cost is saved, the corner joint connecting strength can be improved, the water tightness, the air tightness, the heat preservation performance and the sound insulation performance of a door and window are improved, and the door and window K value (U value) coefficient is reduced.

Owner:施万库

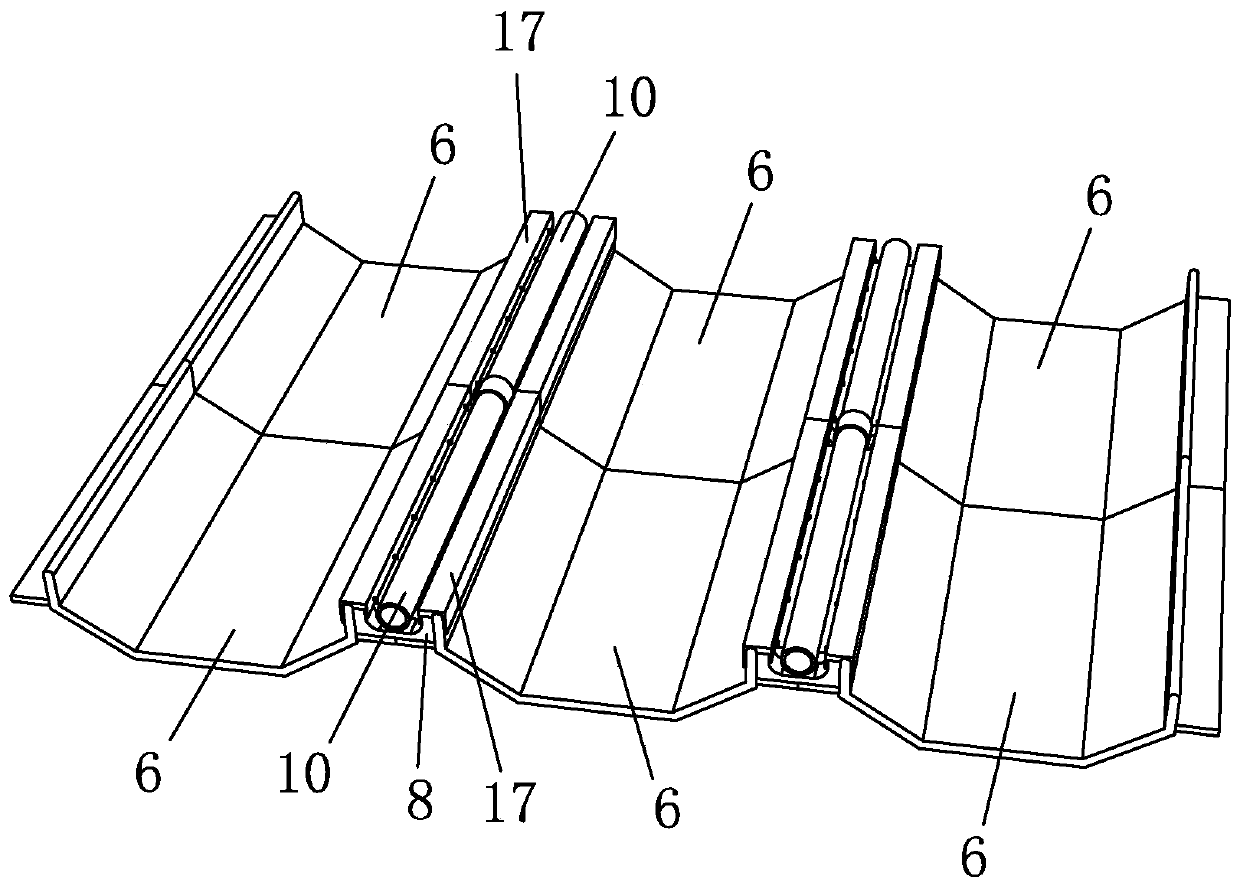

Safety cover plate

The invention provides a safety cover plate comprising a plurality of rectangular cover plate units with equal width, wherein the rectangular cover plate units are connected end to end by a hinge shaft so as to form a cover plate group with a foldable structure. The cover plate group is connected to a steel coil trolley from two sides, and can be folded or unfolded respectively along with the left or right movement of the trolley; a roller wheel is installed at the bottom of each cover plate unit which rolls on a track through the roller wheel; the track comprises a pair of horizontal tracks arranged on the outer side, the horizontal tracks are separated from the middle parts, middle tracks with the gauge smaller than that of the horizontal tanks are arranged on the inner sides of the separated parts of the horizontal tracks, and circular-arc tracks are arranged at two ends of the horizontal sections of the middle tracks; the even number rows of the cover plate units are all provided with two groups of roller wheels which correspond to the two groups of tracks, and only one group of roller wheels of the odd number rows of cover plate units correspond to the middle arc tracks. The safety cover plate has a simple structure, light weight and small frictional resistance, can run stably and reliably, does not have height difference, cannot affect the walking of people, and is high in safety.

Owner:WISDRI ENG & RES INC LTD

Splicing needle method for splicing and sewing double-sided fabrics

The invention provides a splicing needle method for splicing and sewing double-sided fabrics, which comprises the following steps: preparing manual needles and sewing threads at the position to be spliced for an upper cutting piece and a lower cutting piece of two double-sided fabrics; on the longitudinal cutting section of the upper cutting piece, the first needle entry point of the manual needleis lifted for the first time, knots are tied at the first needle entry point, and the threads pass through the top surface of the upper cutting piece obliquely upwards from the first needle entry point of the upper cutting piece; starting from the first needle outlet point, the manual needle and the sewing thread obliquely downwards pass through the top surface and the longitudinal cutting section of the upper cutting piece towards the left side to carry out the second step of needle walking; starting from the second needle feeding point, the manual needle threads obliquely downwards on the bottom surface of the lower cutting piece and passes out from the bottom surface to carry out the fourth step of needle walking; then, keep the stitch size spacing to be uniform and consistent, and sequentially and alternately sewing until the end. The spliced seam is very flat, and the stitches are connected like a plurality of triangles, so that an uncomfortable feeling caused by the thickness ofthe seam is avoided.

Owner:珠海无用文化创意有限公司

Floor tile fitting device with tile supply function

InactiveCN108468422AGuaranteed tidyNo height differenceBuilding constructionsCivil engineeringEngineering

The invention relates to the field of building decoration, in particular to a floor tile fitting device with a tile supply function. The device comprises a base component, a supporting frame component, a tile fitting component, a bonding material scraping component, a tile supply assembly and an operation and control platform. Not only are the functions of automatic fitting, aligning and positioning of tiles achieved, but also the device is provided with the tile supply assembly. The device has the advantage that the tile supply position is accurate and stable.

Owner:HUZHOU ZHONGCHEN CONSTR

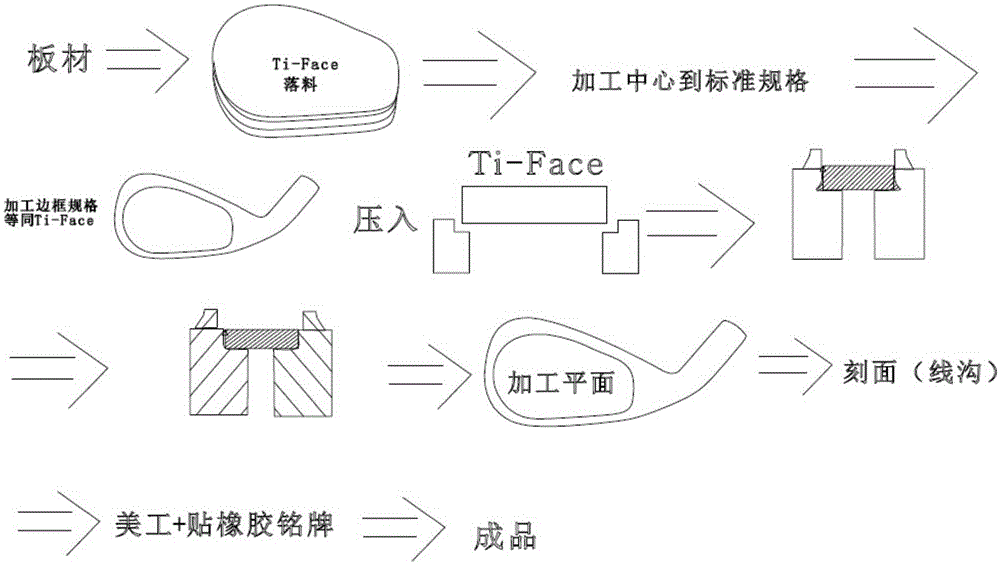

Processing and installing process for titanium alloy hitting panel of golf club

The invention relates to a processing and installing process for a titanium alloy hitting panel of a golf club. The processing and installing process comprises the procedures of blanking, processing of an installing groove and compression-joint embedding. In compression joint, titanium alloy deforms and is firmly fixed into the installing groove, meanwhile, an edge pressing lip is subjected to compression joint to cover a gap, and the hitting panel is further prevented from coming out; and finally, a whole plane is processed, and the flatness of the whole plane is guaranteed. By means of the processing and installing process, the problem that the hitting panel is not flatly and firmly installed is solved, and the product quality is guaranteed.

Owner:NINGBO DONGFANG SPORTS EQUIP CO LTD

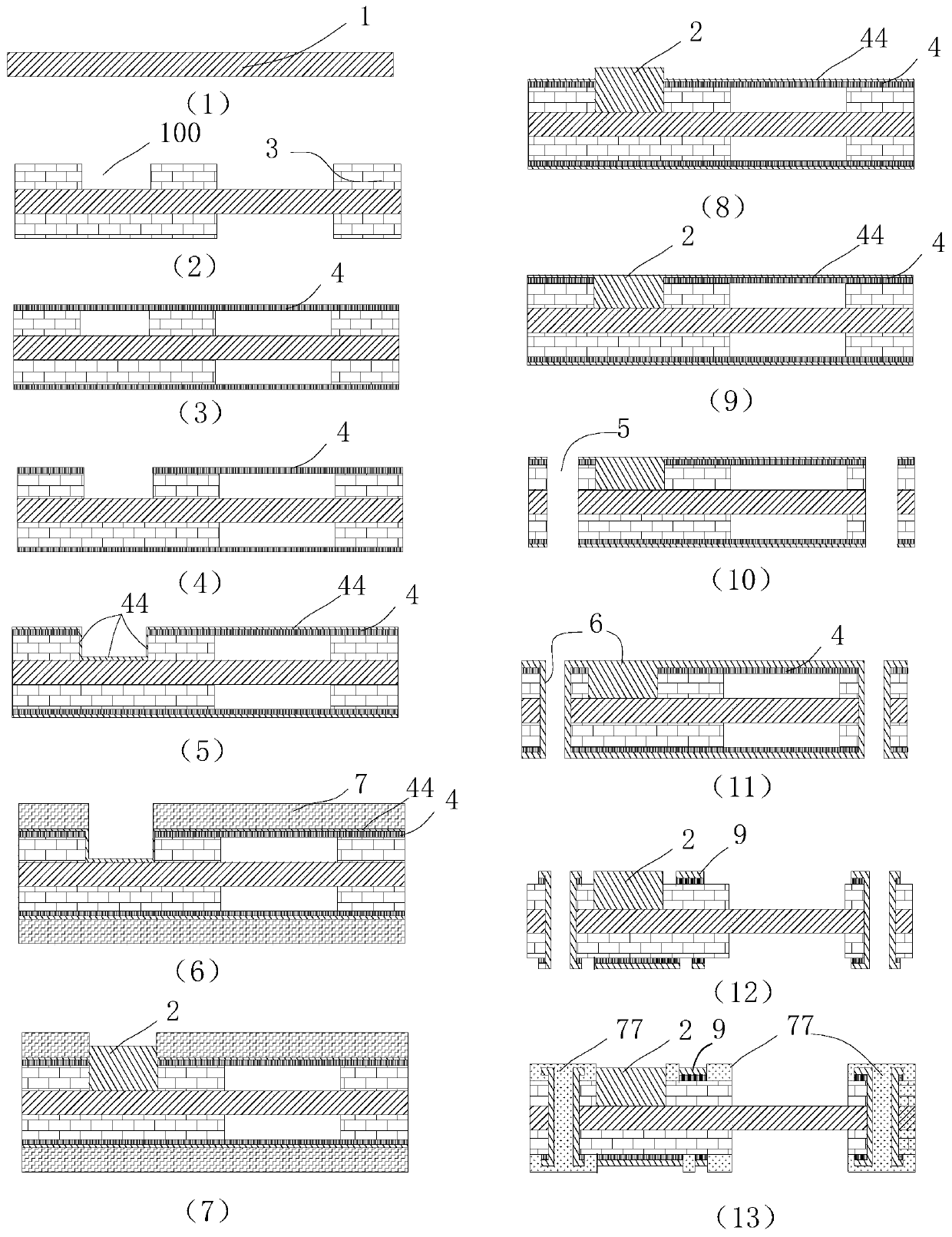

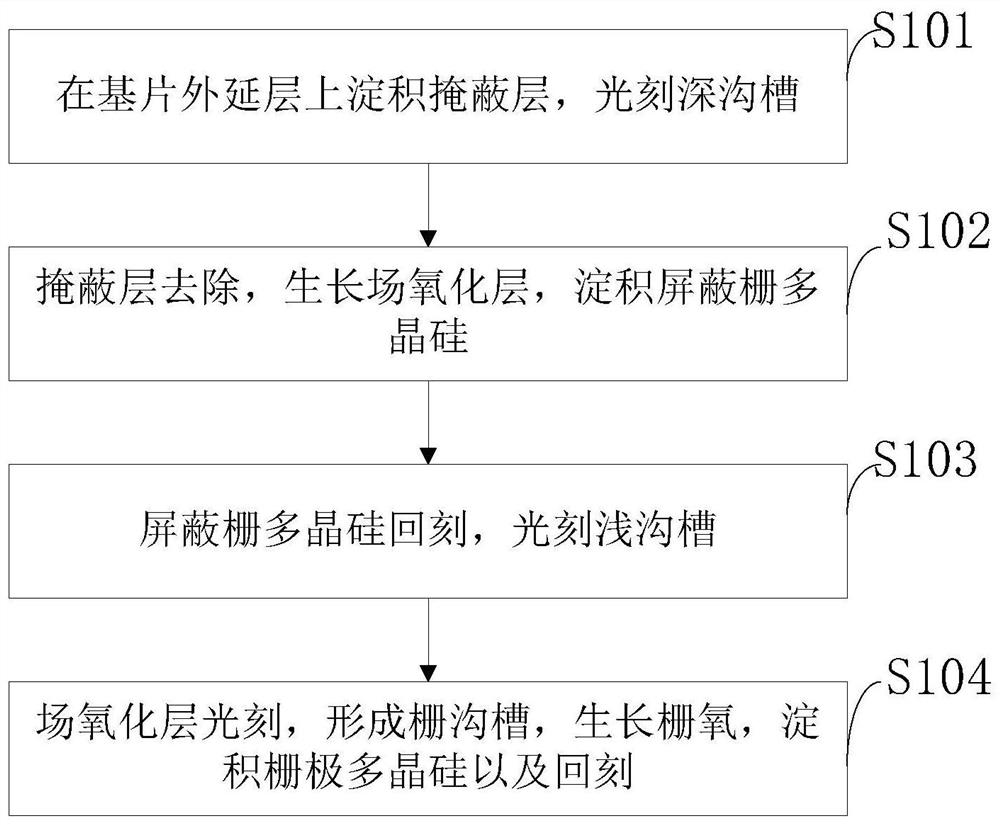

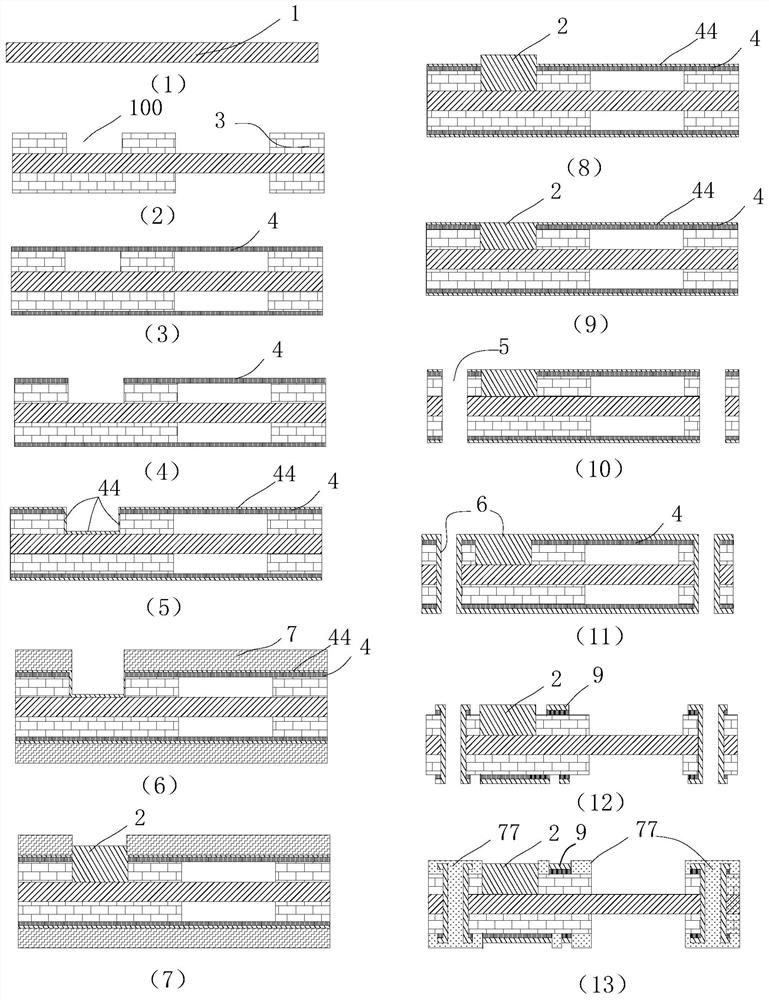

SGT-MOSFET and manufacturing method thereof

PendingCN113471078ANo height differenceAvoid photolithographySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETLithography process

The invention belongs to the technical field of semiconductors, and discloses an SGT-MOSFET and a manufacturing method thereof. The method comprises the steps: depositing a masking layer on a substrate epitaxial layer, and photoetching a deep groove; removing the masking layer, growing a field oxide layer, and depositing shielding gate polycrystalline silicon; etching back shielding gate polycrystalline silicon, and photoetching a shallow groove; and photoetching a field oxide layer, forming a gate groove, growing a gate oxide layer, depositing gate polycrystalline silicon, performing back etching, and performing subsequent manufacturing. According to the invention, a new manufacturing method is adopted to connect the shield gate polycrystalline silicon and the gate polycrystalline silicon contact hole; and the manufacturing method adopted by the invention does not involve a photoetching process of shield gate polycrystalline silicon and grid polycrystalline silicon, and the shield gate polycrystalline silicon and the grid polycrystalline silicon are basically flush with the surface of the silicon substrate after being etched, so that the height difference of the polycrystalline silicon is eliminated, and the shield grid polycrystalline silicon and the grid polycrystalline silicon are punched well without generating the risk of bridging of the shield grid polycrystalline silicon and the grid polycrystalline silicon.

Owner:SHANGHAI GREENPOWER ELECTRONICS

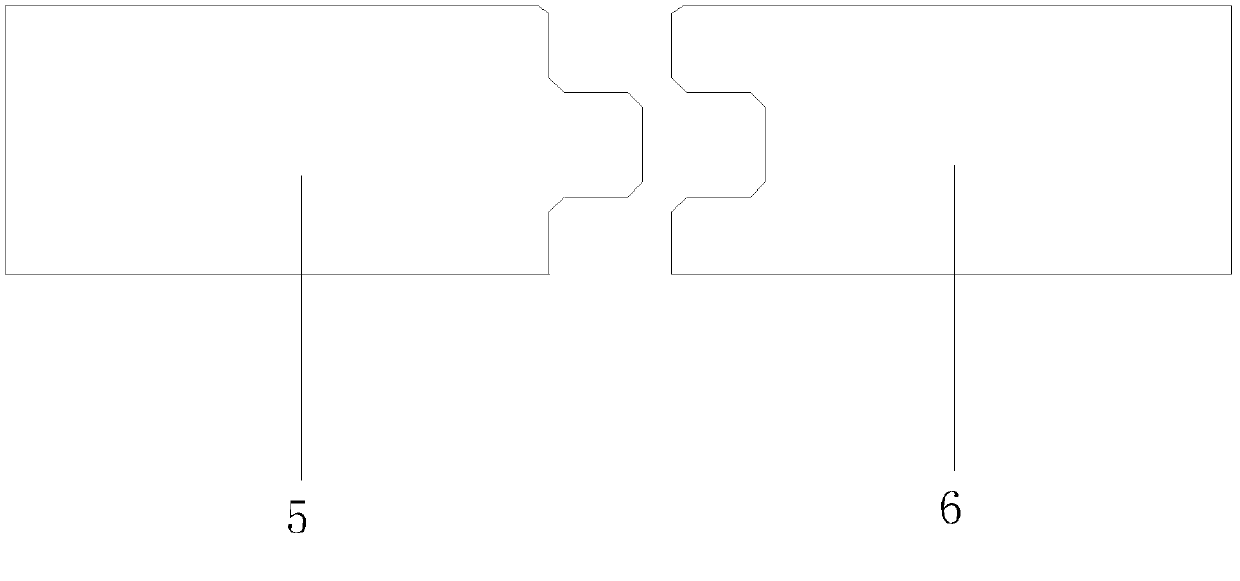

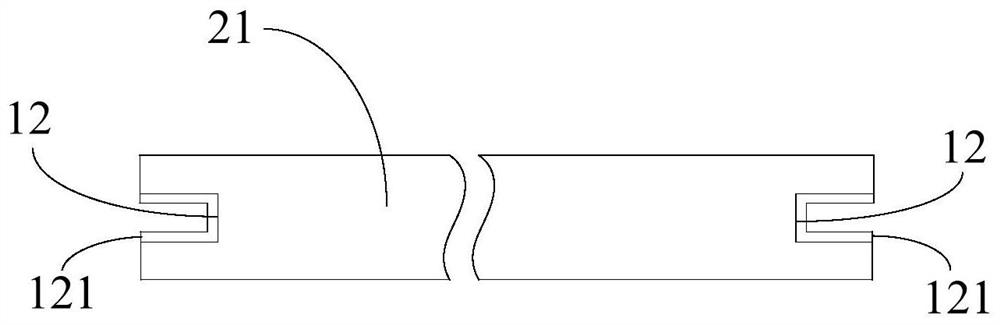

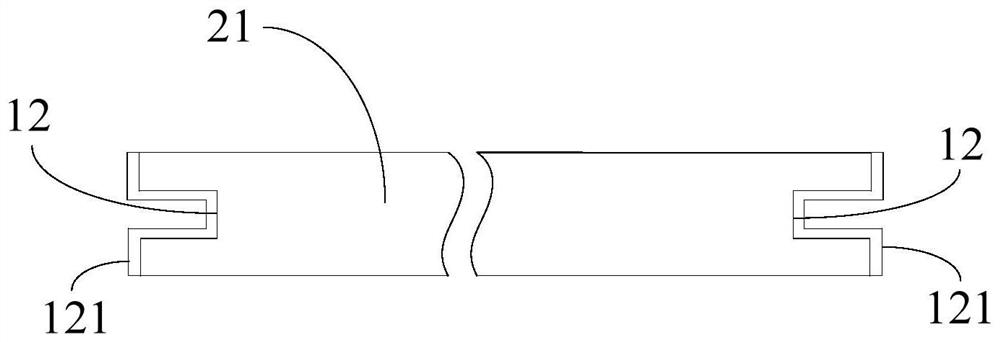

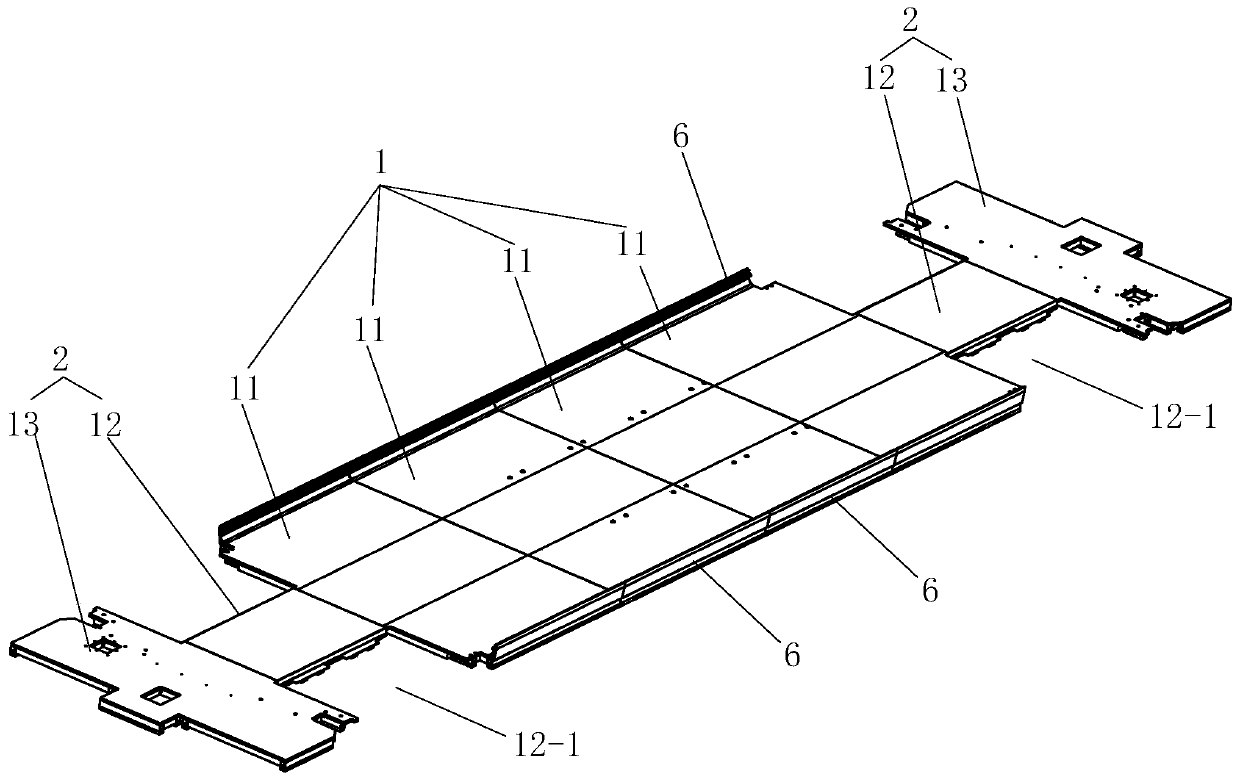

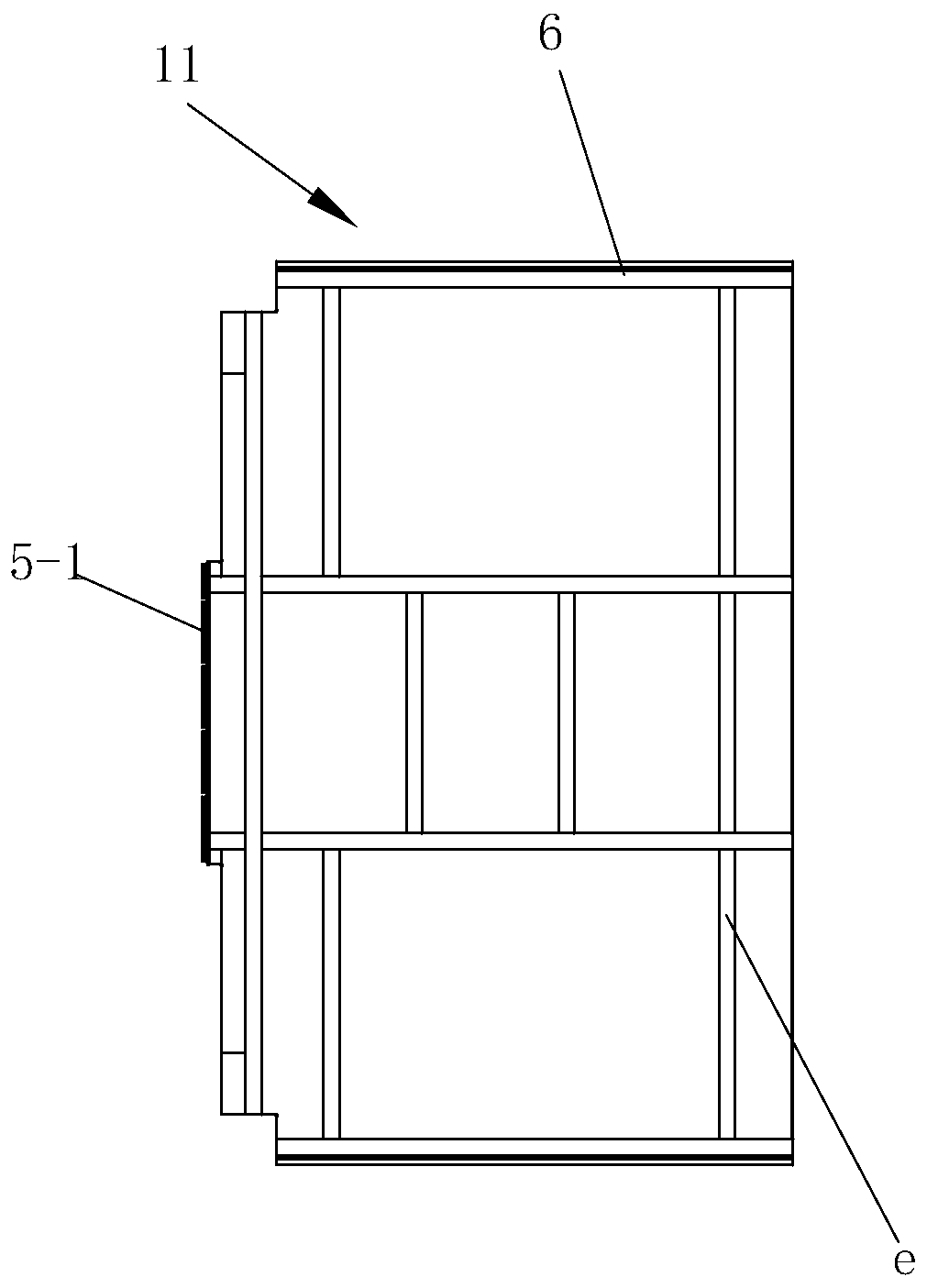

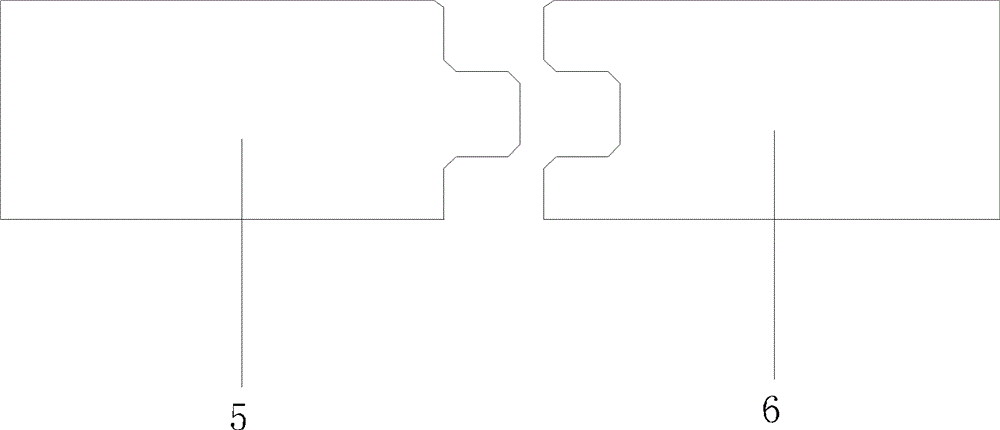

Modularized floor of passenger train

PendingCN110539804AGood size consistencyNo height differenceSuperstructure subunitsRailway passenger carHoneycomb

The invention discloses a modularized floor of a passenger train. The modularized floor of the passenger train is provided with a floor module, wherein the left side and the right side of a honeycombcomposite board of the floor module separately extend out of a sound-insulation and heat-insulation board to form a connecting portion of the floor module; a main floor is composed of a plurality of I-shaped floor modules, side section bars are separately arranged on the left side and the right side of each I-shaped floor module, a lower connector groove is formed in the lower portion of the innerside surface of each side section bar, the side section bars are clamped on the connecting portions of the I-shaped floor modules through the lower connector grooves and then are connected with the I-shaped floor modules, the inner side surface of the upper portion of each lower connector groove is arc-shaped, and floor cloth extends towards two sides and covers the arc-shaped inner side surfacesof the side section bars; and at least one of the front end and the rear end of each I-shaped floor module is provided with insertion section bars, the insertion section bars are embedded in the honeycomb composite board, and are divided into fork-shaped insertion head section bars and U-shaped insertion seat section bars, and the adjacent I-shaped floor modules are connected by inserting the fork-shaped insertion head section bars into the U-shaped insertion seat section bars which are matched with the fork-shaped insertion head section bars. The modularized floor of the passenger train is simple in connection structure and firm in strength, tools are not required during assembling of the modularized floor, and the modularized floor is quite convenient to assemble.

Owner:CHANGZHOU CHANGQING TRAFFIC TECH

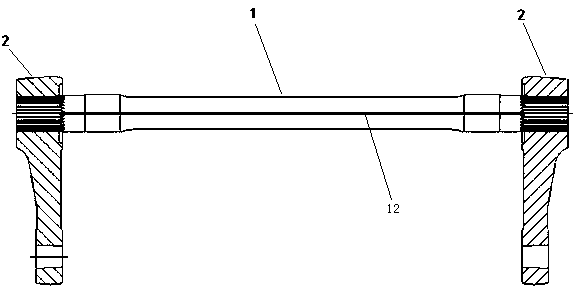

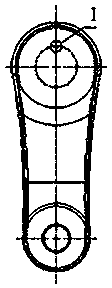

Anti-wrong installation method, product and product design method of spline-connected anti-roll torsion bar

ActiveCN107187459BImprove use reliabilityExtended service lifeBogie-underframe connectionsEngineeringDesign methods

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Large-area solid wood composite parquet floor, its production method and its installation method

ActiveCN102888970BRealize industrializationRealize standardized productionFlooringSolid woodMethods of production

Owner:阿姆斯壮地面材料(中国)有限公司

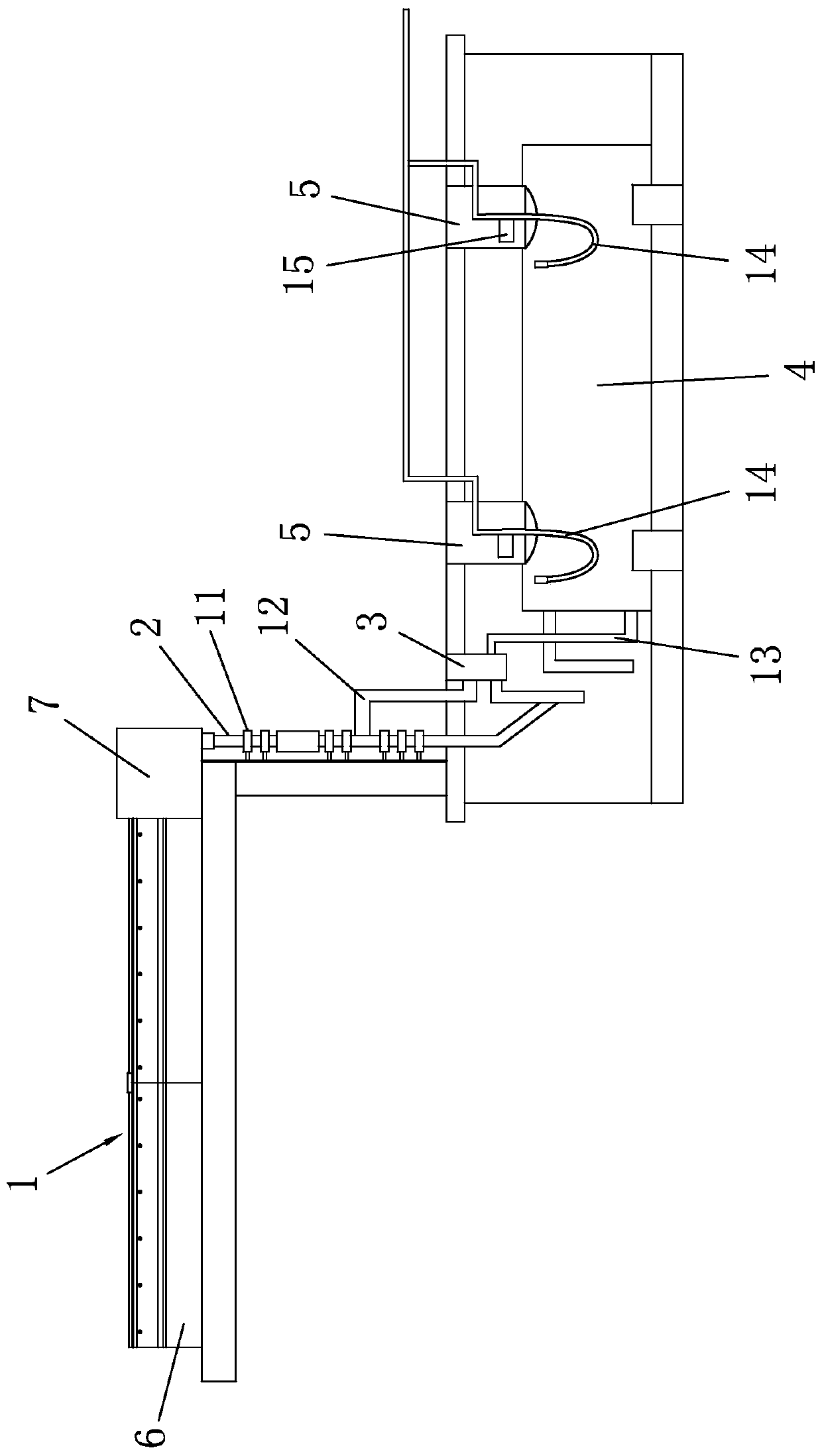

A roof rainwater treatment system and construction method

ActiveCN106677444BEasy to adjustImprove resource utilization efficiencyGeneral water supply conservationWater aerationPotable waterWater resources

The invention discloses a rainwater treatment system and a rainwater treatment construction method for a house roof. The rainwater treatment system comprises a rainwater collection pipe network, a rainwater stand pipe, a rotational flow filter device, a rainwater collection pool and rainwater fetching systems. The rainwater collection pipe network comprises flashings and a rainwater collection tank. The rainwater fetching systems are internally provided with rainwater fetching pipes and pressure control pumps. The rainwater treatment construction method comprises the steps of (a), paving of the flashings; (b), mounting of the rainwater collection tank on the roof; (c), mounting of the rainwater stand pipe on a wall; (d), excavation of a foundation pit; (e), mounting of the rotational flow filter device in the foundation pit; (f), arrangement of the rainwater collection pool; and (g), mounting of the rainwater fetching systems into the rainwater collection pool. The rainwater treatment system and the rainwater treatment construction method are used for collecting, filtering, purifying, storing and utilizing rainwater on the roof and can be used for an undrinkable water environment, the resource utilization efficiency of the rainwater is improved, waste is turned into wealth, water resource shortage is relieved, the construction steps are simple and low in difficulty, the construction quality is easy to control, the construction cost is low, and the number of involved construction equipment is small.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

A kind of preparation method of circuit board for CCM module

ActiveCN110677979BImprove the excellent rateImprove cooling effectPrinted circuit assemblingPrinted circuit non-printed electric components associationSolder maskImaging quality

A method for preparing a circuit board for a CCM module, the steps: making an inner core board; laminating the insulating layer: laminating and pressing copper foil; etching and opening: seed copper; exposure and development; electroplating copper pillars; after film removal Grinding; Drilling; Immersion Copper Plating; Outer Circuit Production; Solder Mask Production. The copper pillars are electroplated at the window, and the chip is directly attached to the copper pillars, which improves the heat dissipation. At the same time, the strength of the steel pillars determines the deformation of the chip. The chip undergoes a module assembly process, and the deformation in a high-temperature environment is negligible; the copper pillars After electroplating, a grinding process is added to make the surface smooth, and there is no height difference when the chip is attached; in addition, the chip is attached to the copper pillar, with small deformation, high resolution, and low paste failure. The process of the invention is simple and reasonable, and the prepared product not only has good heat dissipation performance and high flatness, but also has small deformation and high resolution rate, and effectively improves the excellent rate of the module.

Owner:NINGBO HUAYUAN ELECTRONICS TECH

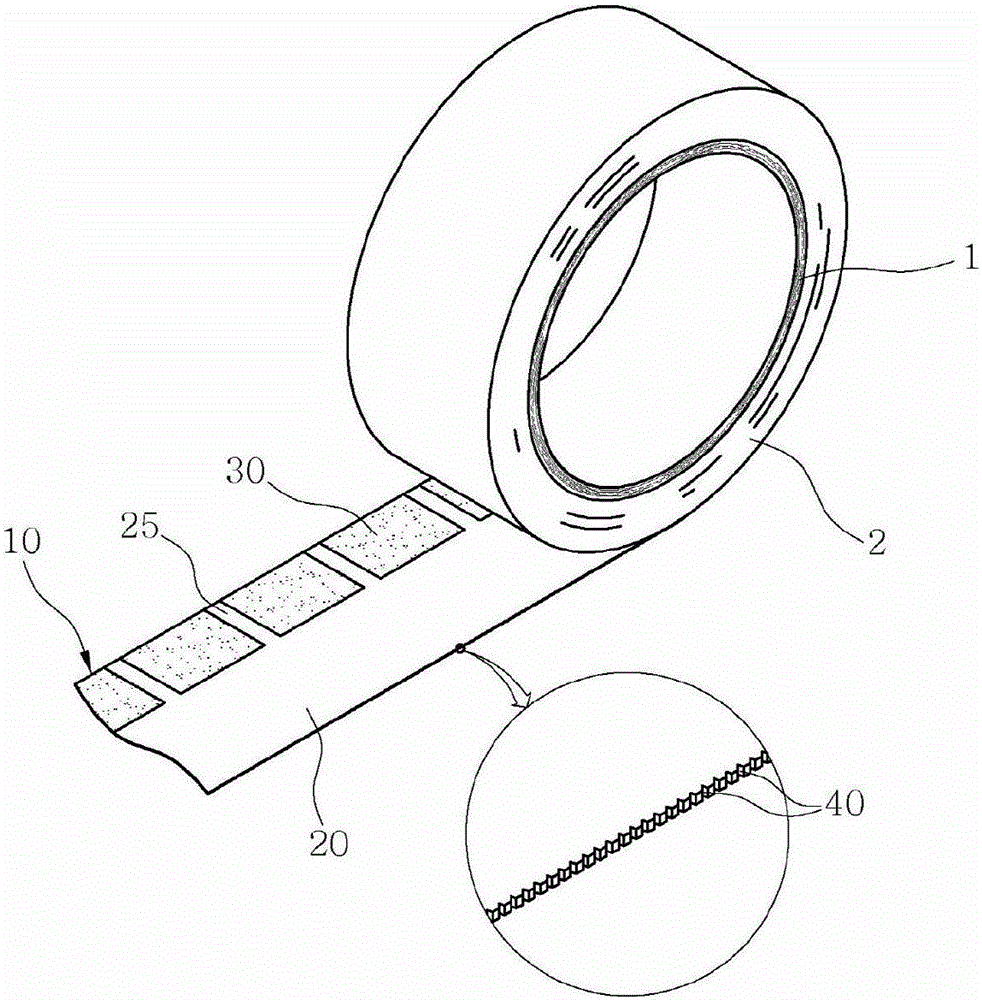

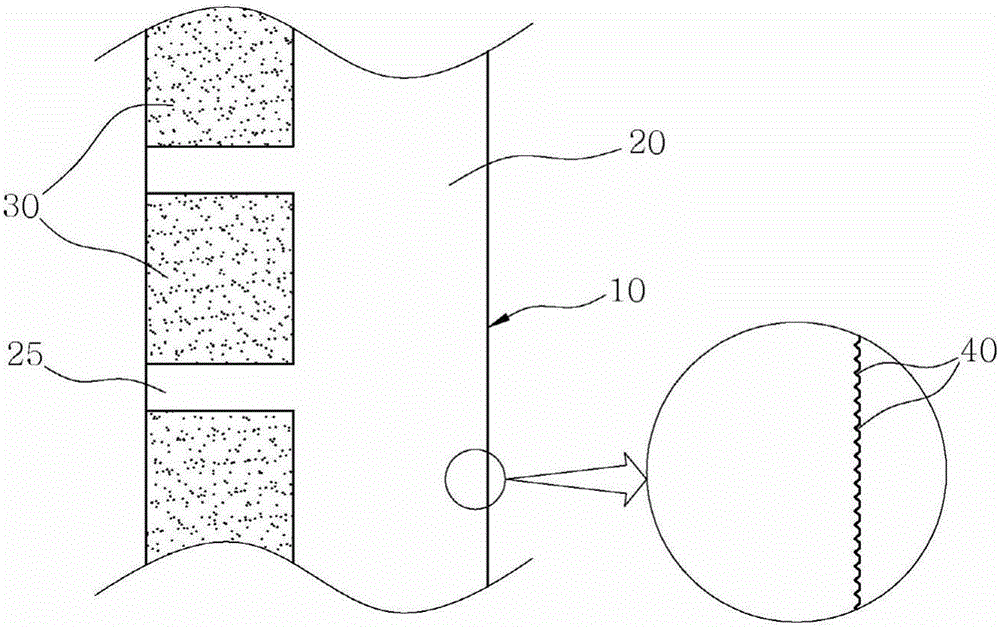

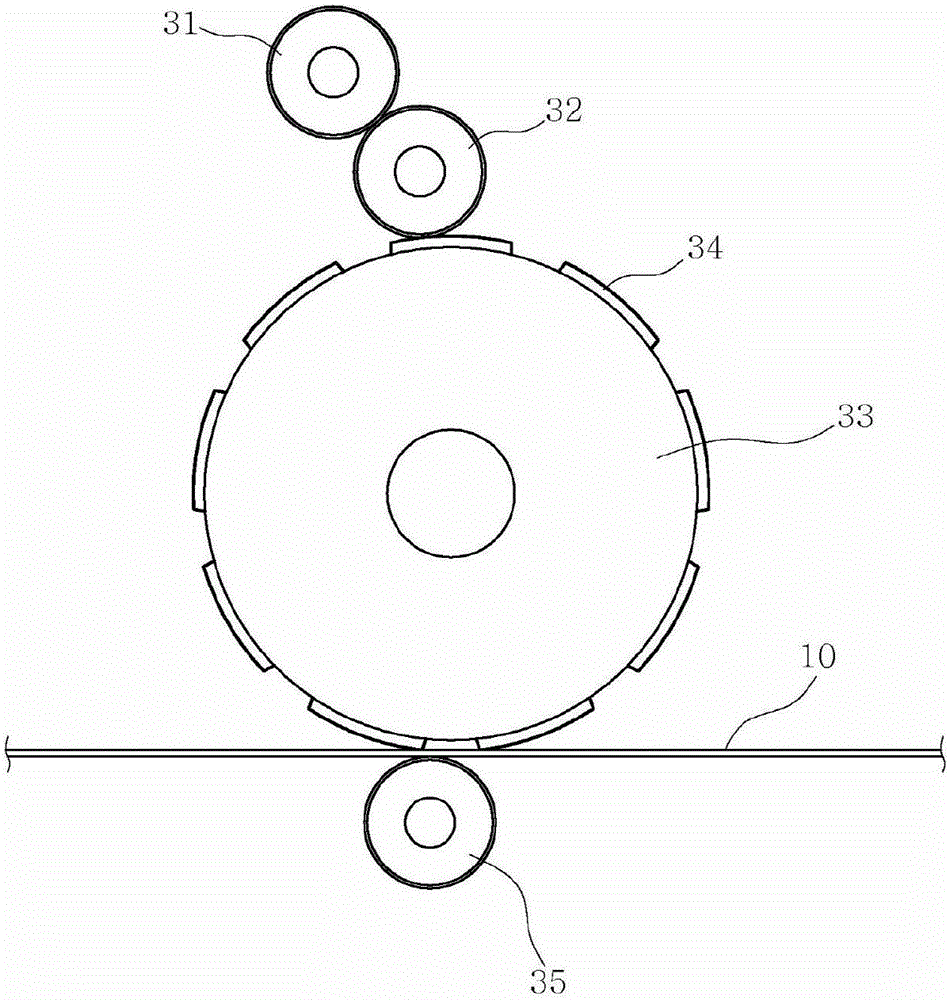

Partially non-adhesive tape for painting

InactiveCN106574153ANo height differenceEasy to disengageFilm/foil adhesivesSpraying apparatusAdhesive beltEngineering

The present invention relates to a partially non-adhesive tape for painting and, more specifically, to a partially non-adhesive tape for painting, comprising: a painting tape which is attached in order to form boundary lines during a painting operation; and partially non-adhesive surfaces which are longitudinally formed in the painting tape, wherein the partially non-adhesive surfaces are formed at regular intervals. Accordingly, the non-adhesive surfaces can be kept in contact with an object to be painted during a painting operation, and it is easy to cut the tape.

Owner:朱英姬

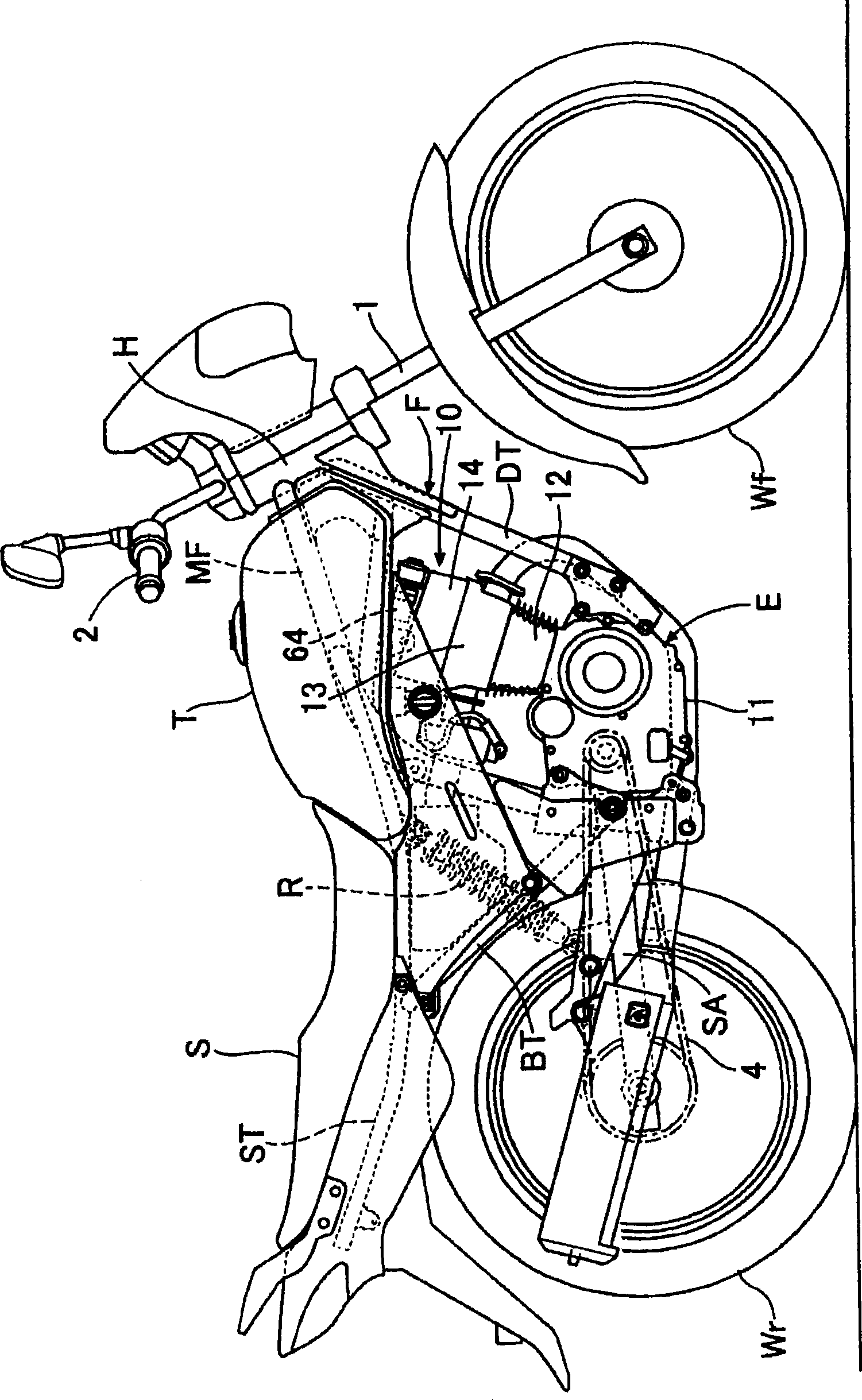

Variable valve transmission device of engine

InactiveCN102080585BInhibit wearAvoid contactValve arrangementsInternal combustion piston enginesCamLinkage concept

The invention provides a variable stigmatic opening transmission device of an engine, wherein the engine with elasticity applied on the valve closing direction is in linkage connection with a cam driven member and the cam driven member is equipped with a cam abutting part for the abutting against a first and a second cams.According to the device, when the second cam moves toward the first cam, the impact of the cam abutting part to the first cam is avoided and the generation of the strike sound is also avoided.The first cam (31) is fixed to a camshaft (32).The second cam (33) can axially movebetween the motion position that the second cam can abut against the cam abutting part (56) and approach the first cam (31) and the non-motion position that the second cam cannot abut against the camabutting part (56) and go far from the first cam (31). The second cam (33) supported by the camshaft (32) is not capable of rotating relative to an axis.The first cam side of the mountain portion (33b) of the second cam is equipped with an inclined surface and the inclined surface inclines toward the internal of the radial direction of the camshaft.

Owner:HONDA MOTOR CO LTD

A rail vehicle bogie wedge support robot

The invention discloses a rail vehicle bogie wedge support robot, which belongs to the technical field of rail vehicle bogie disassembly, and comprises a bracket, a three-degree-of-freedom mobile module and a wedge support module; the three-degree-of-freedom mobile module is used for the wedge support module The movement of the wedge support module includes a symmetrically arranged first support assembly and a second support assembly, and both the first support assembly and the second support assembly include a lateral movement assembly connected to the housing, a vertical movement assembly, a connecting rod hinged with the vertical moving assembly, and a wedge support rod hinged with the connecting rod and arranged longitudinally, the connecting rod can rotate upwards relative to the vertical moving assembly, and the wedge support rod can be horizontally positioned relative to the connecting rod direction turn. The present invention supports the wedge at the highest point inside the wedge, ensuring that there is no height difference between the wedge and the expected support height, and ensuring that the wedge is effectively separated from the pillow spring.

Owner:成都岁生科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com