Windproof and waterproof glue injection corner connector and connecting structure thereof

A technology of glue injection and corner coding, which is applied in the field of doors and windows, can solve the problems of increased transportation costs, high investment costs of mechanical equipment, and difficult cleaning of end-face glue, so as to improve the connection strength and firmness, improve the fatigue of the connection area, and ensure assembly quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

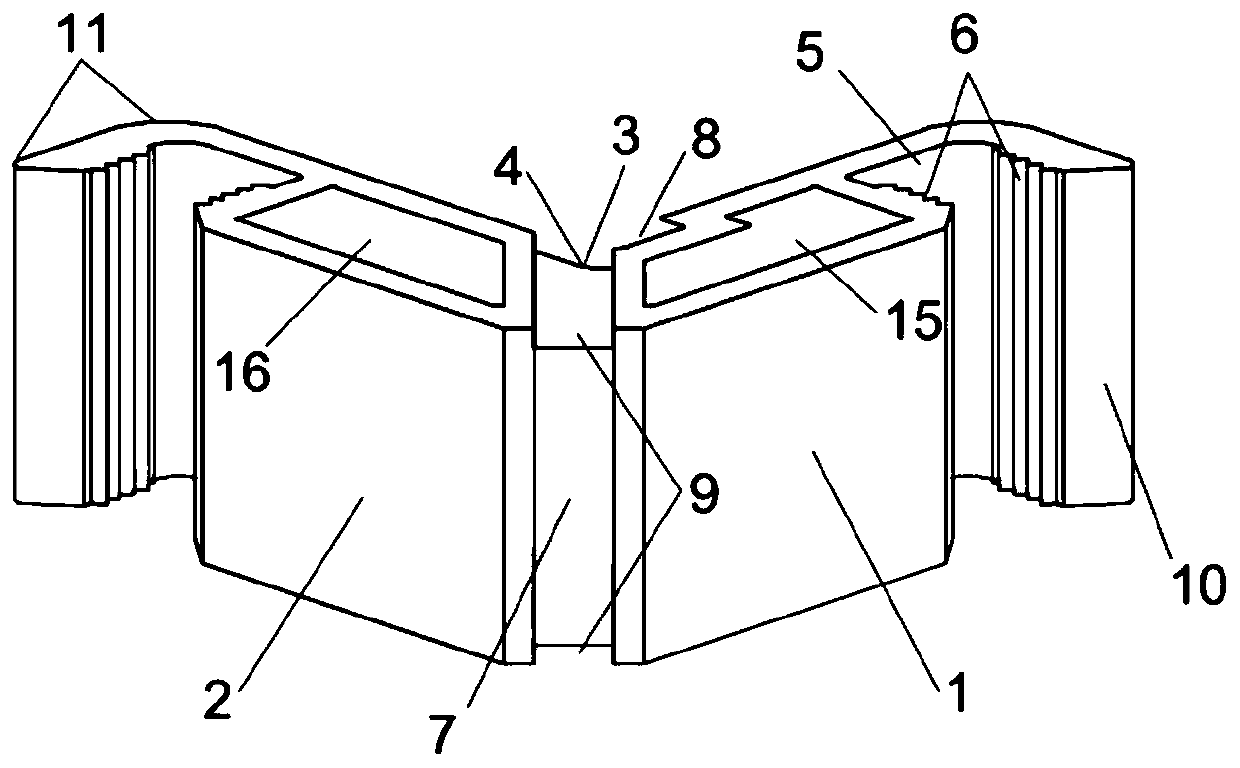

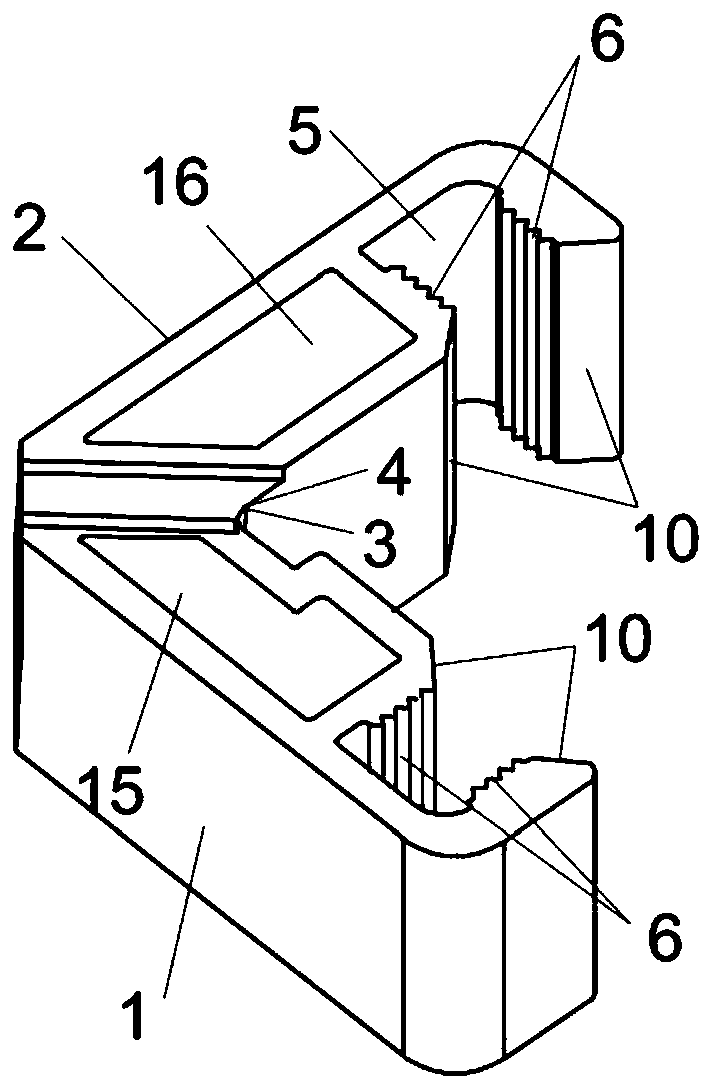

[0060] This embodiment provides a windproof and waterproof corner code, such as figure 1 As shown, a C-shaped slot 5 is respectively provided on the outer ends of the first fixed arm 1 and the second fixed arm 2, and the opening of the C-shaped slot 5 is formed by connecting the first fixed arm 1 and the second fixed arm 2. The outer side of the L-shaped; the inner two walls of the C-shaped groove 5 are provided with parallel thread lockways 6, the thread direction of the parallel thread lockway 6 is adapted to the direction when the screw is screwed into the C-shaped groove 5, and the parallel thread lockways The thread density of 6 matches the screw specification. The first fixed arm 1 is provided with an R-shaped limit point 3, and the R-shaped limit point 3 is located at the connection corner position between the first fixed arm 1 and the second fixed arm 2, (it should be noted that, as Figure 1-Figure 6 As shown, since the R-shaped limit point 3 is located on the connec...

Embodiment 2

[0064] This embodiment provides a windproof and waterproof corner code, such as figure 2 As shown, the difference between it and the windproof and waterproof glue-injected corner bracket of Embodiment 1 is that the windproof and waterproof glue-injected corner bracket of this embodiment is respectively provided with A C-shaped slot 5 , the opening of the C-shaped slot 5 faces the inner side of the L shape formed by the first fixed arm 1 and the second fixed arm 2 .

[0065] Correspondingly, the windproof and waterproof glue-injected corner code connection structure provided by this embodiment, such as Figure 8 As shown, the door and window profile is provided with a fixing hole 12 suitable for screws to pass through. The fixing hole 12 is located on the inner side of the L-shaped right angle formed by the door and window profile, and it locks with the parallel thread in the C-shaped groove 5 on the corner code. Corresponding to the position of the track 6; at the same time,...

Embodiment 3

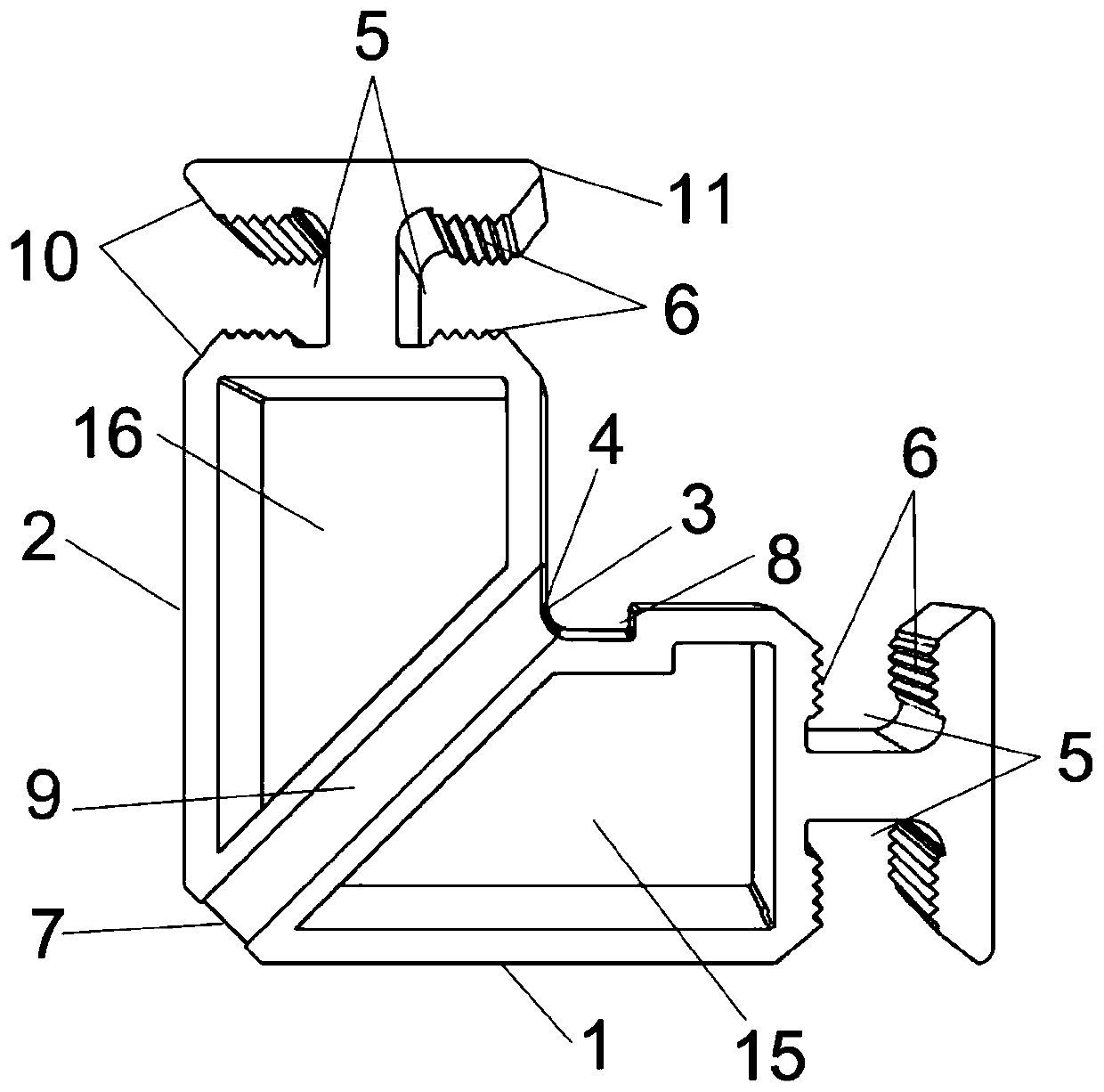

[0067] This embodiment provides a windproof and waterproof corner code, such as image 3 As shown, the difference between it and the windproof and waterproof glue-injected corner bracket of Embodiment 1 is that the windproof and waterproof glue-injected corner bracket of this embodiment is respectively provided with Two C-shaped slots 5, the two C-shaped slots 5 located at the end of the same fixed arm face the inner and outer sides of the L shape formed by the first fixed arm 1 and the second fixed arm 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com