Splicing needle method for splicing and sewing double-sided fabrics

A technology of double-sided fabrics and stitches, which is applied to sewing equipment, sewing machine components, and hand-sewn seams. Wrinkle inequality problem, to achieve both practicality and aesthetics, shallow stitching traces, thin stitching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content of the present invention will be further described below through specific examples.

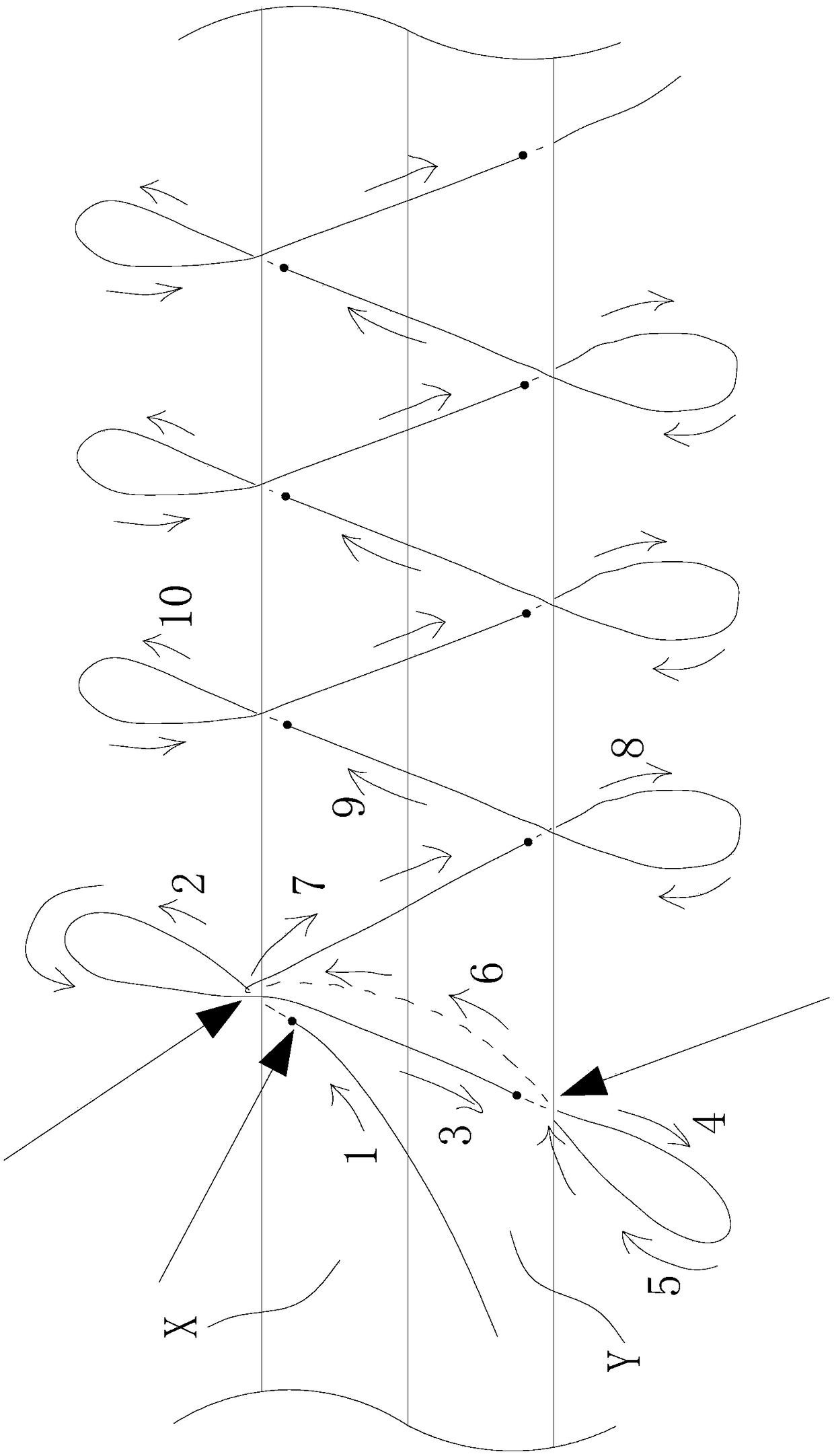

[0034] Stitching stitches for splicing and sewing double-sided fabrics, such as figure 1 with figure 2 shown, including the following steps:

[0035] a. Align the cut edges of the upper and lower pieces X and Y of the two double-sided fabrics to be spliced and place them neatly in a stacked up and down manner, and prepare manual needles and sewing threads, among which the sewing threads 20 yarn counts and 3 strands of thickness, the upper cut piece X and the lower cut piece Y are both cut from a double-sided fabric with a certain thickness made of natural wool material;

[0036] b. On the longitudinal cut section of the upper piece X, determine the position 2mm from the edge height of the upper side cloth of the upper piece X as the first needle-in point for the first needle-in of the manual needle, and then at the first needle-in point Tie the thread knot, and carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com