Anti-wrong installation method, product and product design method of spline-connected anti-roll torsion bar

An anti-roll torsion bar and spline connection technology, applied in the direction of the lateral relative movement device between the underframe and the bogie, can solve the problems affecting the service life of the product, the height difference of the connection holes, and affecting the driving safety, etc. Achieve the effect of prolonging service life, long service life and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

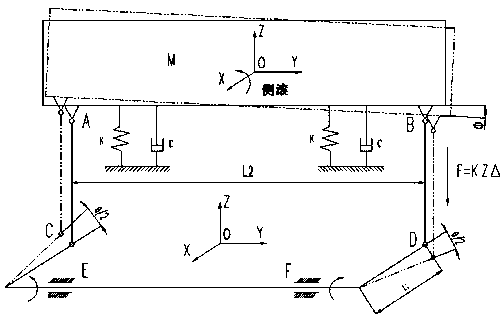

[0045] Attached below Figures 2 to 9 The embodiments of the present invention will be described in detail.

[0046] The anti-wrong installation method of splined anti-roll torsion bar is characterized in that the steps are as follows:

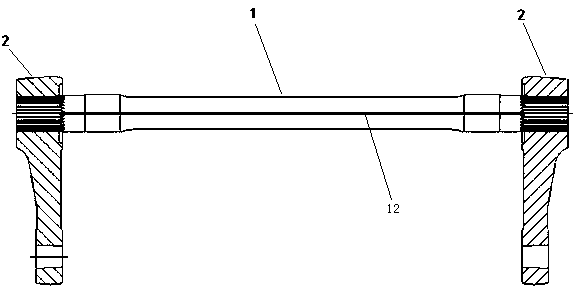

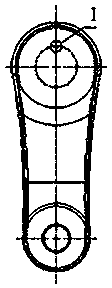

[0047] (1) An external spline 11 is processed at one end of the torsion bar shaft 1, and at least one special spline 11.1 is processed on the external spline 11, and the tooth height of the special spline 11.1 is smaller than that of the ordinary spline;

[0048] (2) Draw the marking line 12 axially on the inner side of the special tooth 11.1, and the marking line 12 extends to the other end of the torsion bar shaft 1;

[0049] (3) Machining an external spline 11 at the other end of the torsion bar shaft 1, and machining a special spline 11.1 axially aligned with the marking line 12 on the external spline 11;

[0050] (4) In the inner wall of the end of the spline connection between the torsion arm 2 and the torsion bar shaft 1, the inner sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com