Variable valve transmission device of engine

A transmission and engine technology, applied in the directions of engine components, combustion engines, machines/engines, etc., can solve problems such as corner wear, and achieve the effect of preventing the generation of hitting sound, suppressing hitting sound, and preventing hitting sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

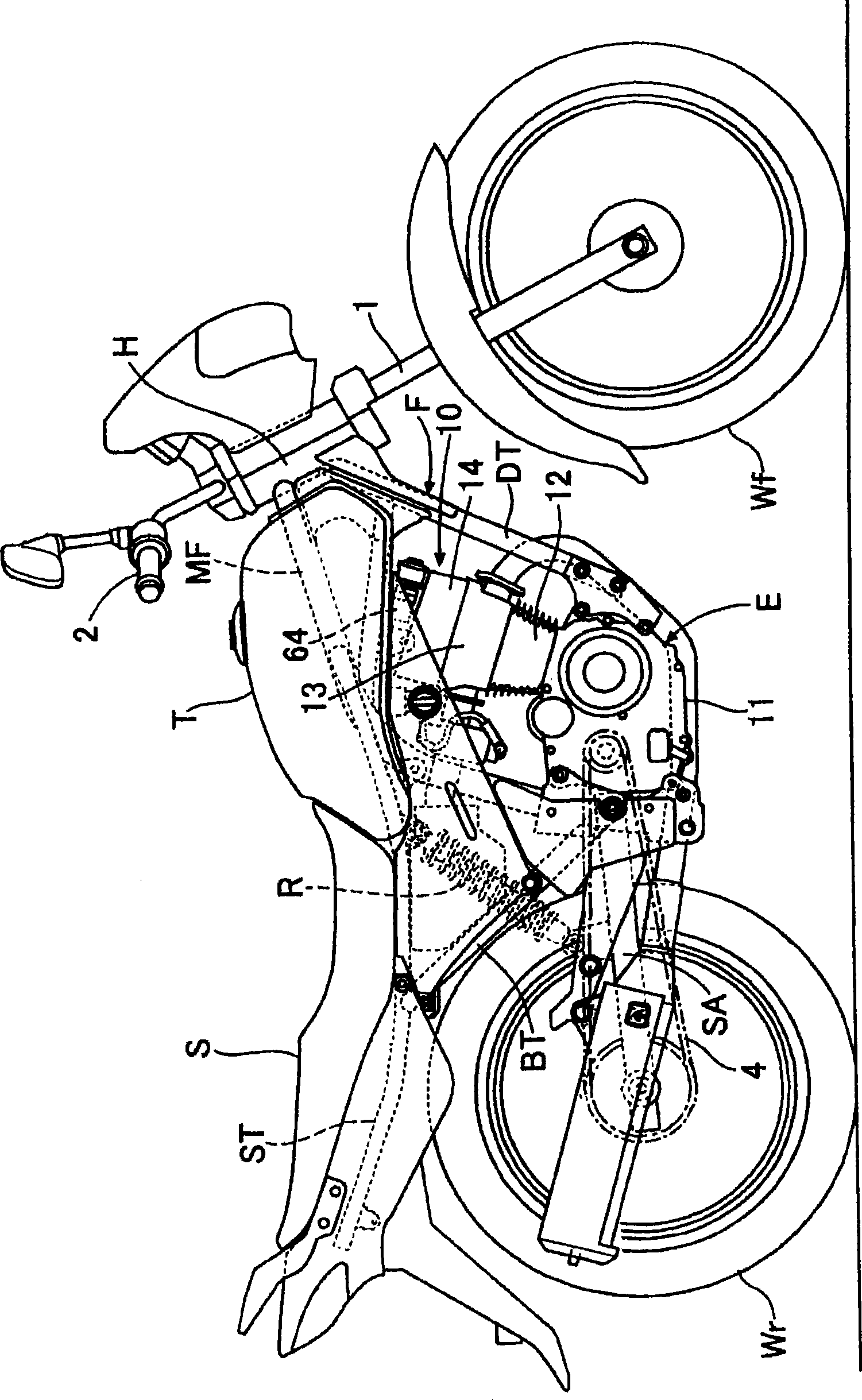

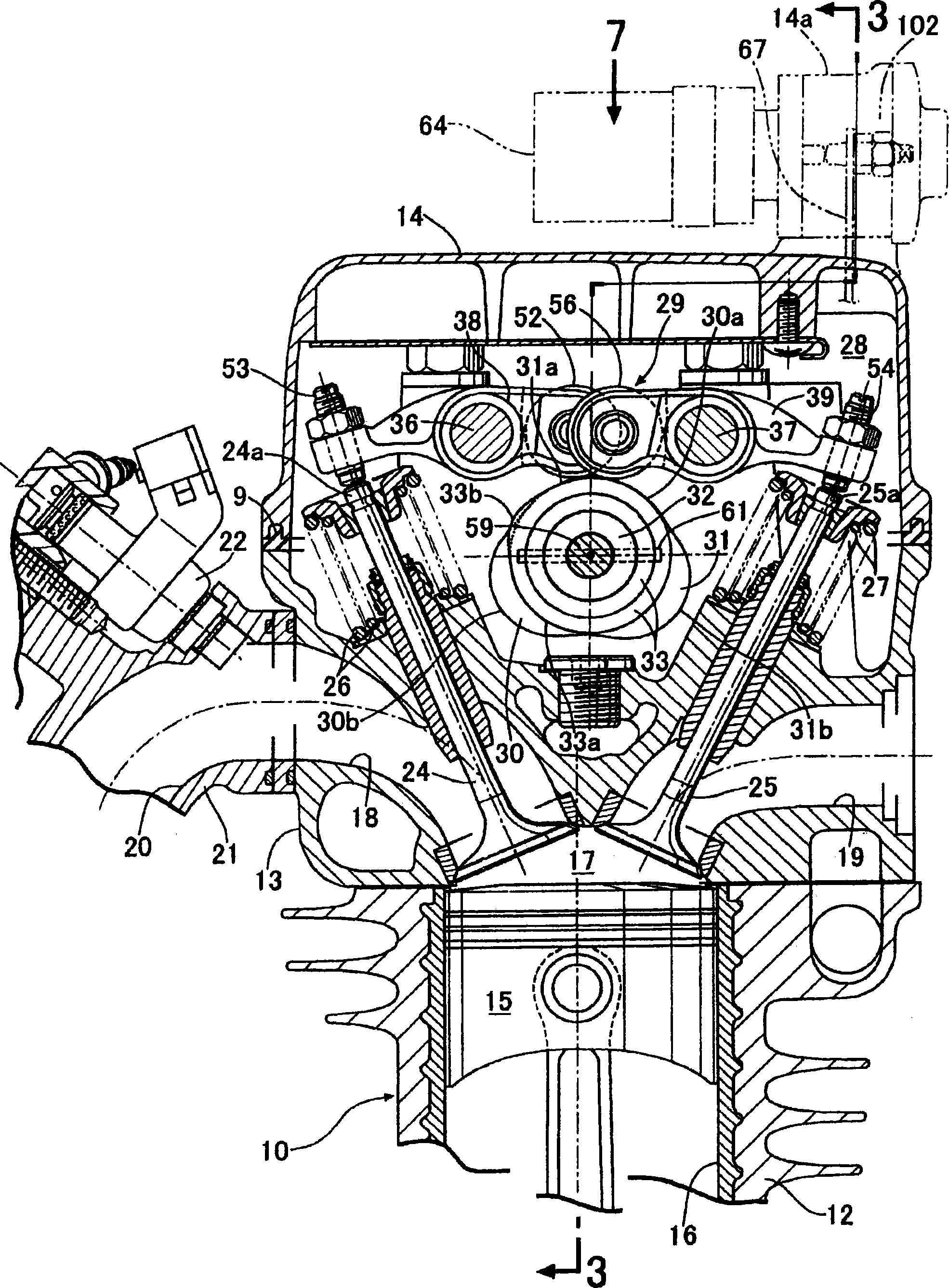

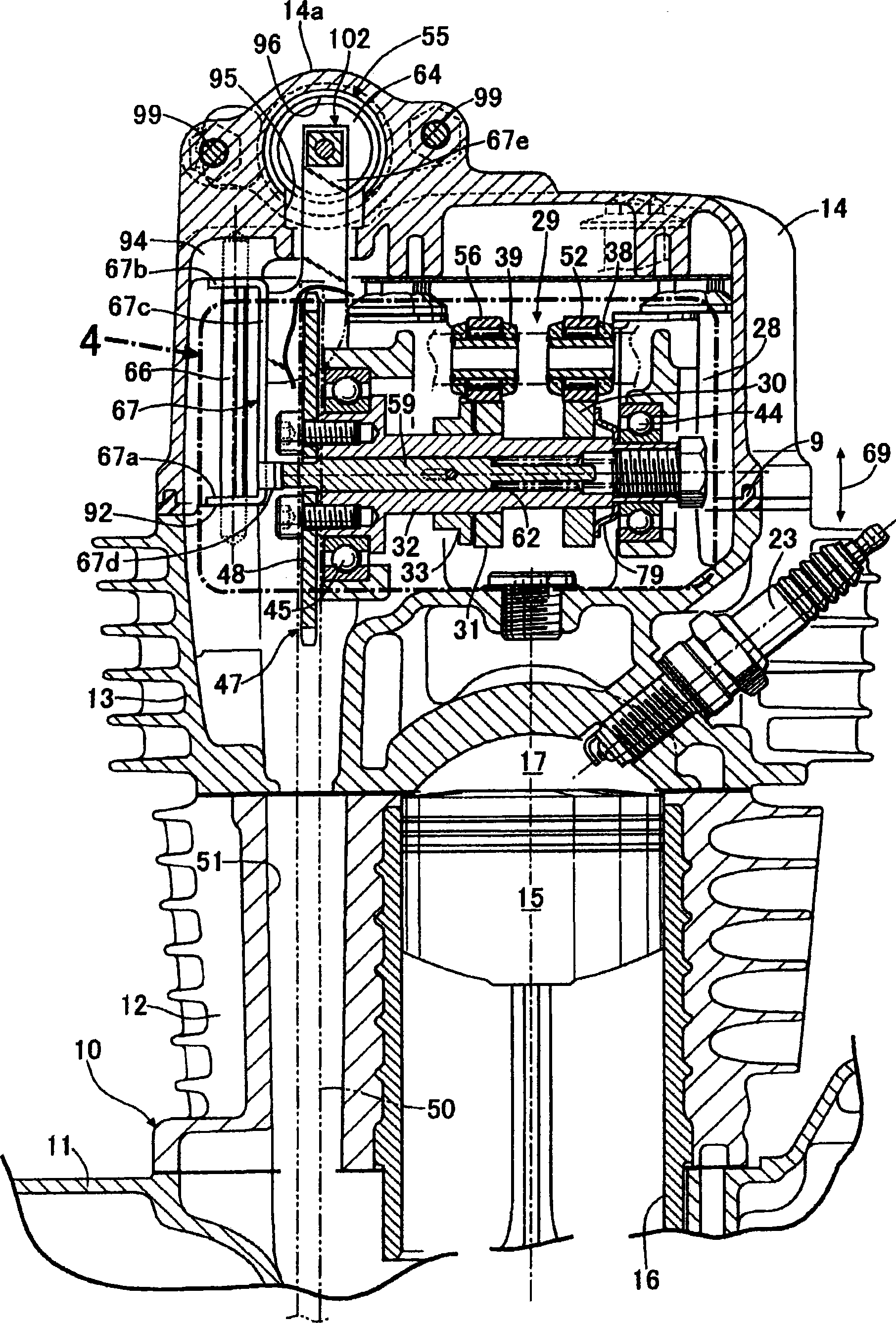

[0057] refer to Figure 1 to Figure 11 Embodiment 1 of the present invention is described, first, in figure 1 In this motorcycle, an engine E and a fuel tank T are mounted on a frame F of the motorcycle, and a front wheel Wf is supported at the front end of the frame F via a front fork 1. A vertically swingable swing arm SA that supports the rear wheel Wr is pivotally connected to an approximately central portion of the frame F, and a rear shock absorber R is provided between the swing arm SA and the frame F. In addition, the driving force of the engine E is transmitted to the rear wheel Wr via the chain transmission mechanism 4 .

[0058] The frame F includes: a head pipe H that supports the front fork 1 in a steerable manner; a down tube DT extending downward from the head pipe H and passing in front of the engine E; The main frame MF extending downward through the top and rear of the engine E; the seat tube ST whose front end is fixedly connected to the middle part of the...

Embodiment 2

[0103] refer to Figure 12 Embodiment 2 of the present invention will be described, and parts corresponding to those in Embodiment 1 will be shown with the same reference numerals and detailed description will be omitted.

[0104] An inclined surface 71B is formed on the side surface of the second exhaust-side cam 33 on the side of the first exhaust-side cam 31 (refer to Example 1), and the inclined surface 71B becomes larger as it goes toward the first exhaust-side cam 31 side. The camshaft 32 (refer to Example 1) is inclined so as to be inward in the radial direction. The inclined surface 71B is formed to have the same width over the entire circumference of the exhaust-side second cam 33 with reference to the outer peripheral surface of the exhaust-side second cam 33 , and the axis line of the camshaft 32 and the inclined surface 71B form the same width. The angle α is set to 5° to 45°, preferably 15° to 25°.

[0105] According to the second embodiment, the roller 56 (refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com