Double-faced pile fabric piece split-splicing method and fabric piece split-splicing structure

A technology of double-sided fleece and fabric sheets, which is applied in the field of clothing, can solve the problems of obvious uneven seams, uneven stitching marks, and affecting the aesthetics of clothing, so as to achieve flat seams and thin seams. , Stitching seams flat and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

[0031] In the present invention, terms such as "first, second" and "A, B" introduced are only for the convenience of expression to distinguish and identify, and they should not be understood as special limiting requirements for the sequence and the like.

[0032] 1. Conventional technology - single seam splicing method

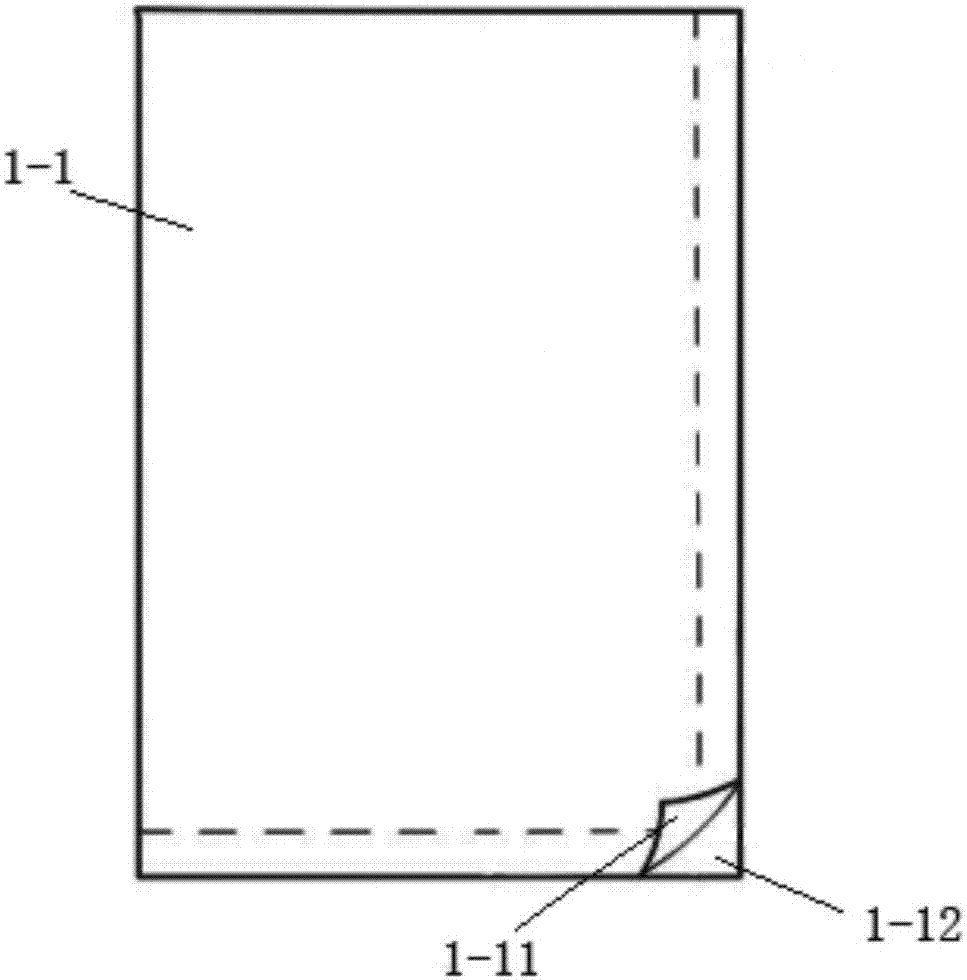

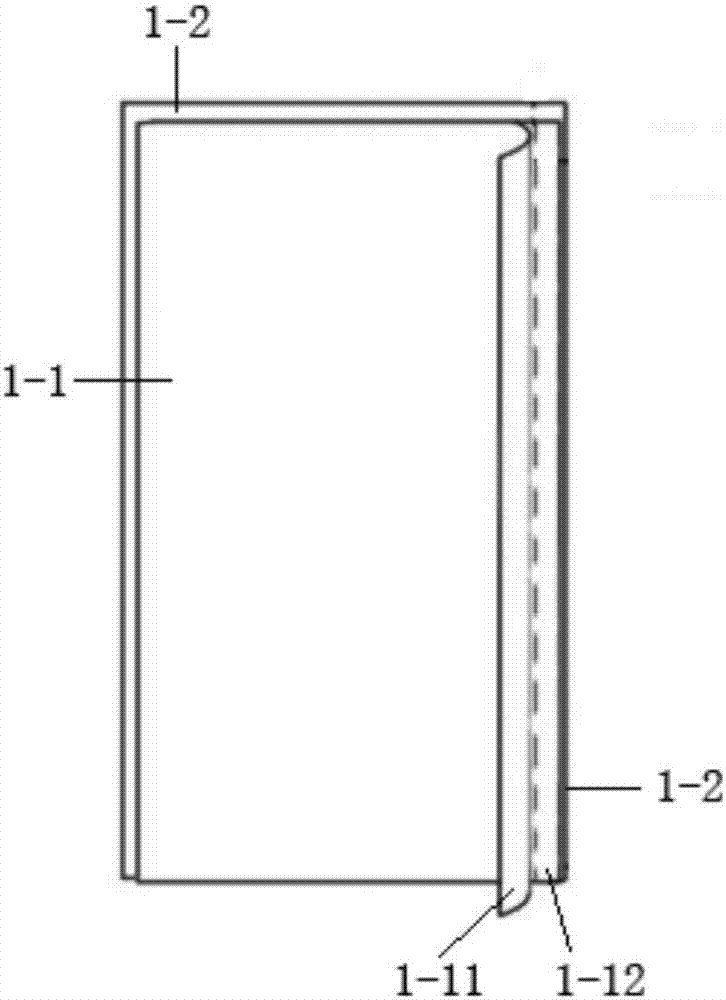

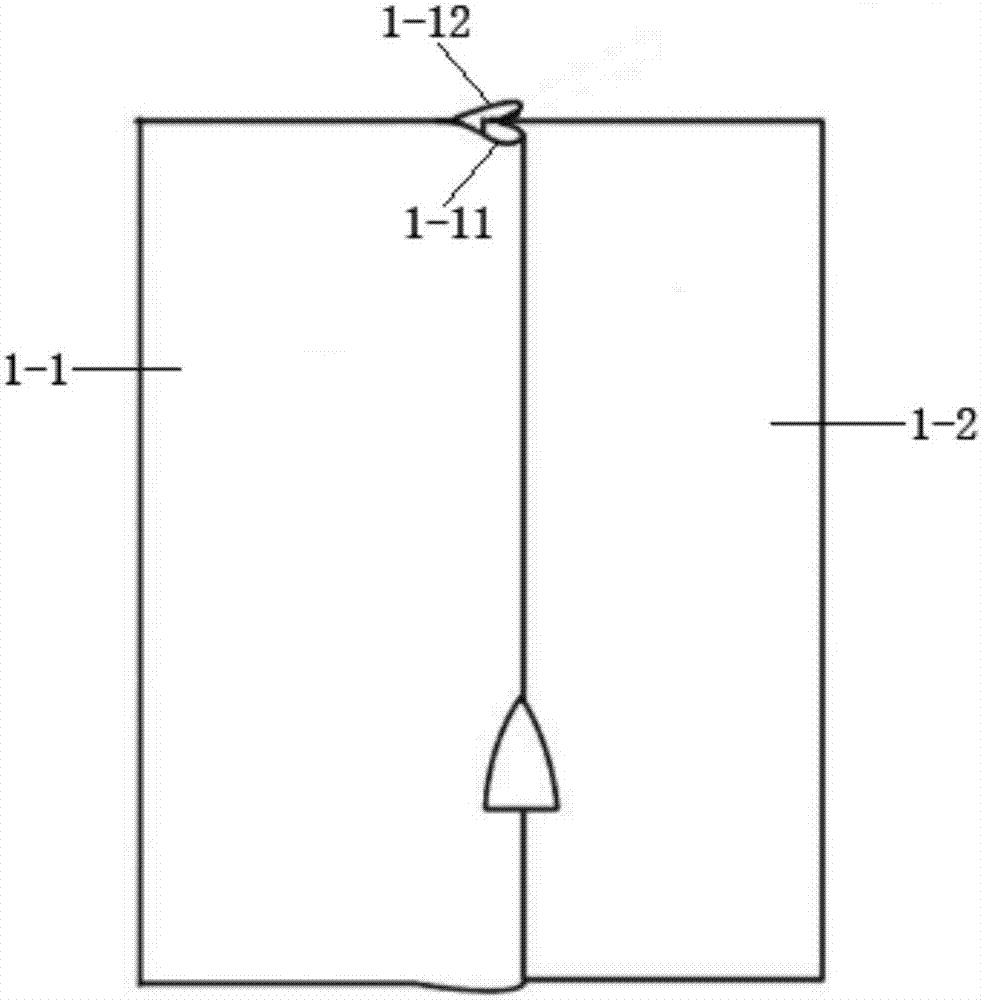

[0033] see Figure 1 ~ Figure 4 , a systematic display of the splicing process of the single-seam splicing method, Figure 5 A schematic diagram of the cross-sectional structure of two pieces of fabric spliced by the single seam splicing method is shown.

[0034] The specific steps of the single seam splicing method are as follows: see figure 1 Firstly, the spliced part of the first cut piece 1-1 is split into a two-layer structure, and the two-layer structure is respectively the first layer sheet 1-11 and the second layer sheet 1-12. see next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com