Liquid crystal filling method

A liquid crystal and filling area technology, applied in nonlinear optics, instruments, optics, etc., can solve problems affecting panel uniformity and display quality, sinking of the surrounding area, and bulging of the central area of the second substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

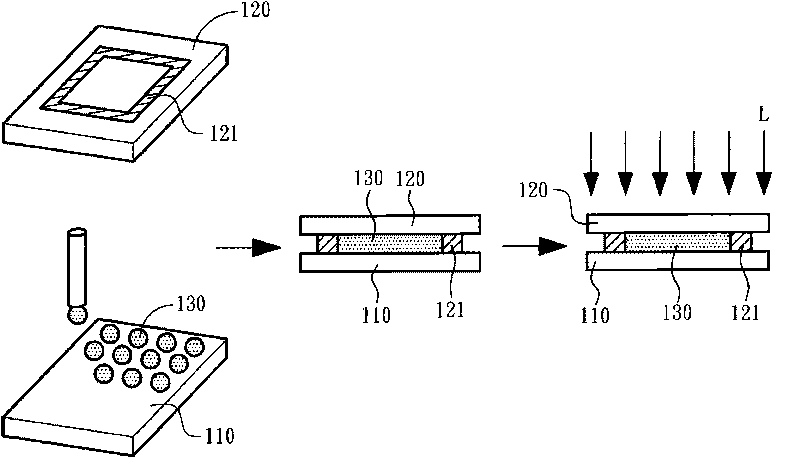

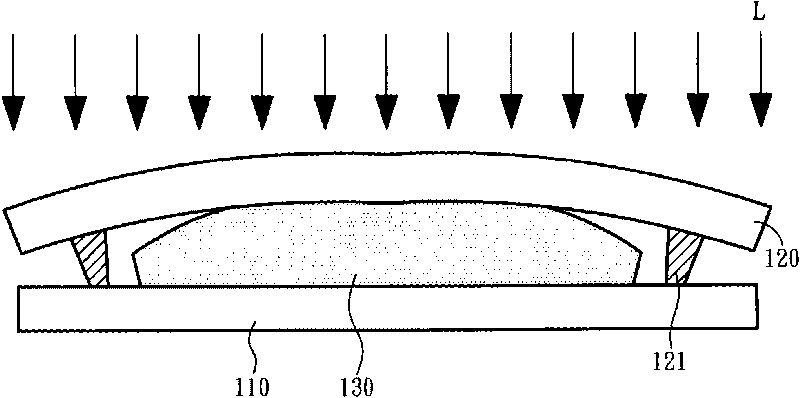

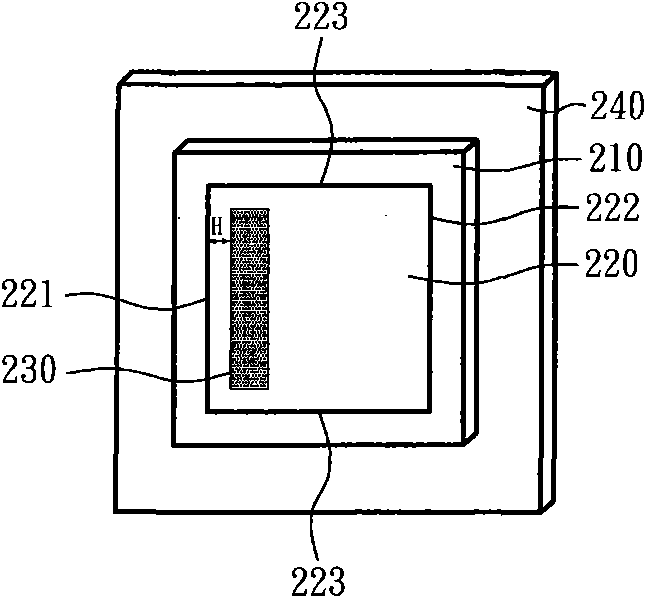

[0022] Please refer to Figure 2a to Figure 2c , which is a schematic diagram of the first embodiment of the liquid crystal filling method of the present invention, the steps are as follows, firstly, a carrying platform 240 is provided. A first substrate 210 is placed on the carrying platform 240, wherein the first substrate 210 has a liquid crystal filling region 220, and the liquid crystal filling region 220 has a first edge 221, a second edge 222 and two sides Side 223. The liquid crystal filling area 220 also has a buffer area A. As shown in FIG. A certain amount of liquid crystal 230 is dropped on the liquid crystal filling area 220 at a position of a buffer interval H from the buffer zone A near the first edge 221 . Such as Figure 2b As shown, the position of the air knife 270 is fixed, and the carrier table 240 carries the first substrate 210 and moves along a first direction D1, and the liquid crystal 230 is moved from the first edge 221 to the second edge by the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com