A rail vehicle bogie wedge support robot

A rail vehicle and bogie technology, which is applied in the field of rail vehicle bogie wedge support robots, can solve the problems that the wedge cannot be separated, and the wedge cannot be supported to the highest point, so as to improve disassembly efficiency, reduce robot actions, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

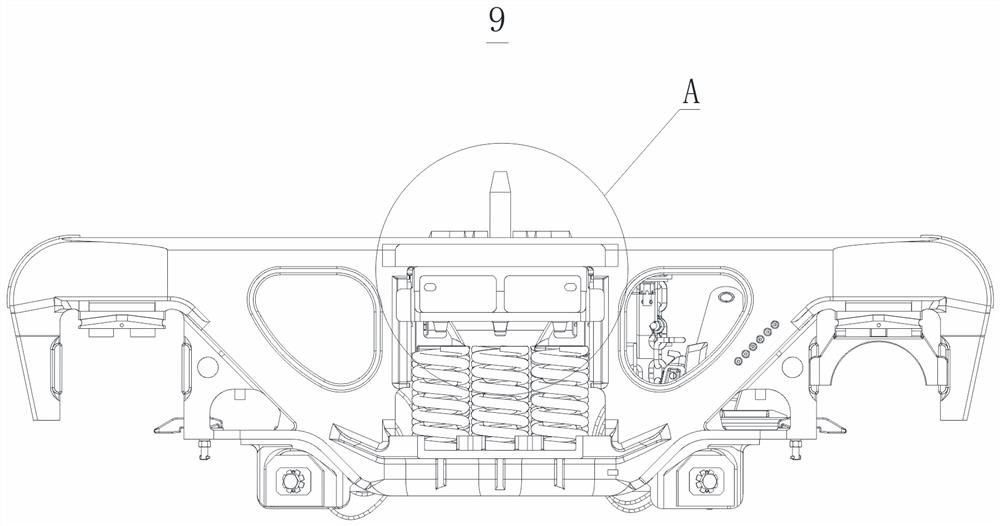

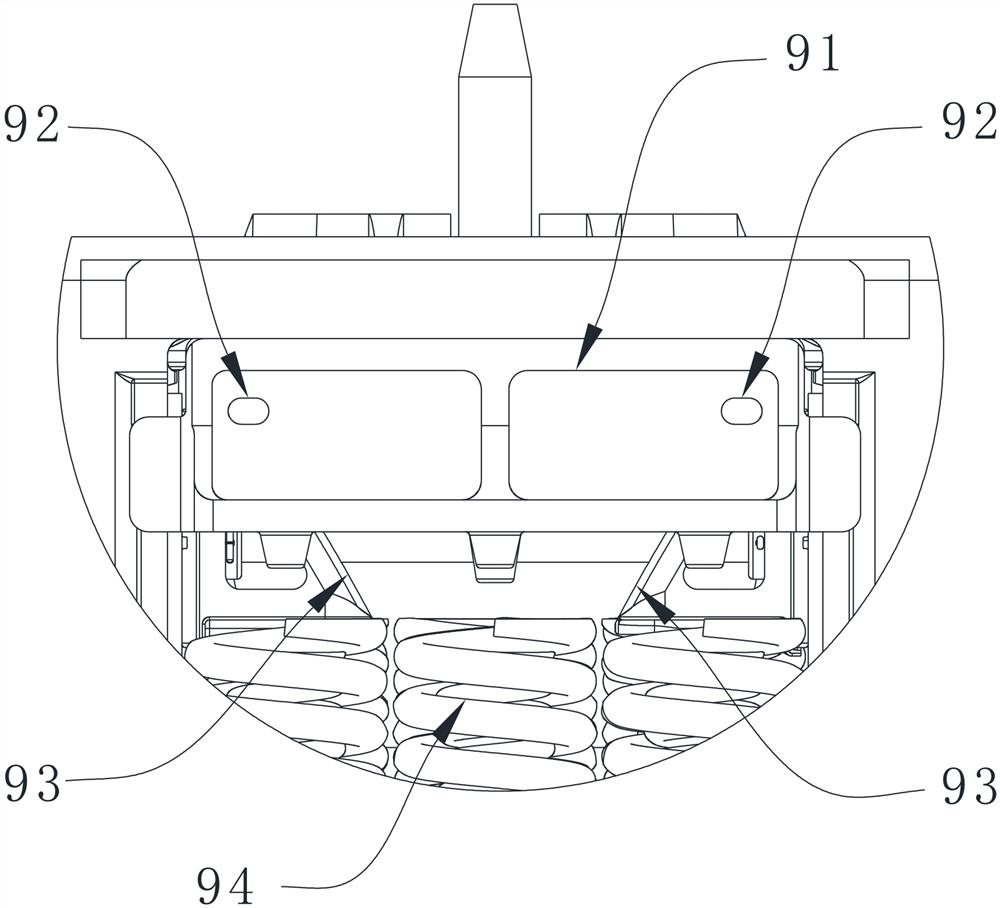

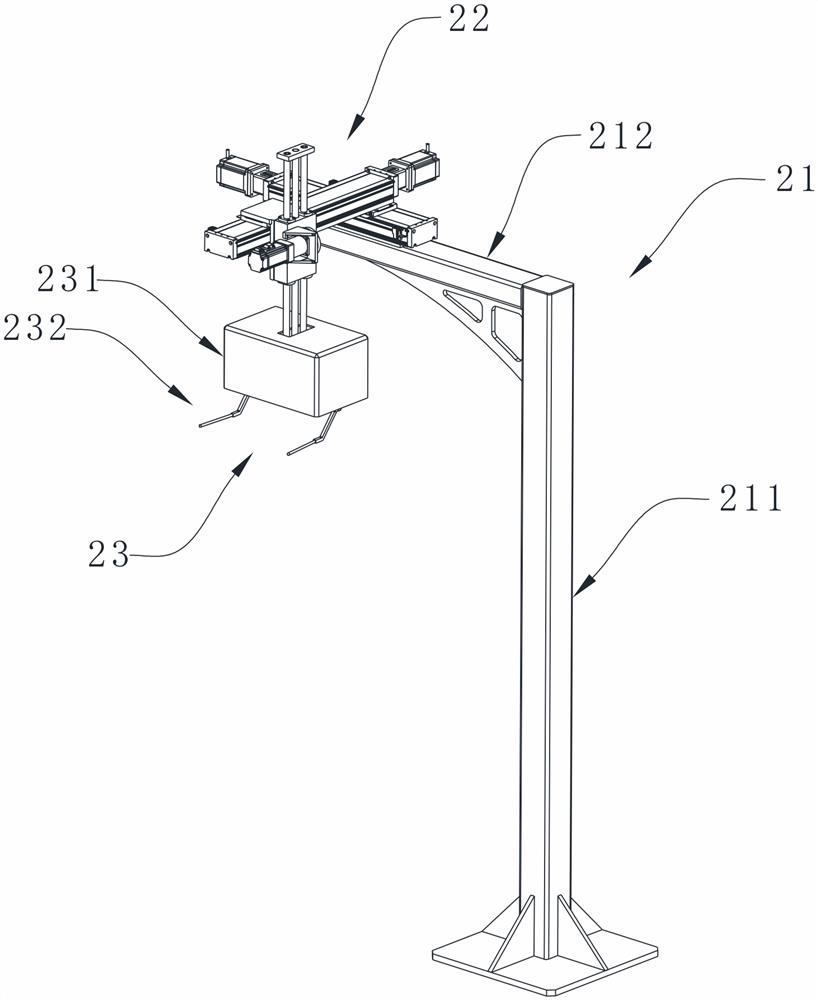

[0039] Please refer to image 3 , a rail vehicle bogie wedge support robot, comprising: a bracket 21, a three-degree-of-freedom movement module 22 and a wedge support module 23. The three-degree-of-freedom mobile module 22 is fixedly installed on the top of the bracket 21 , and the wedge support module 23 is suspended on the three-degree-of-freedom mobile module 22 . The three-degree-of-freedom moving module 22 drives the wedge support module 23 to move to correspond to the bolster 91, and the wedge support module 23 supports the wedge 93 inside the bolster 91, thereby separating the wedge 93 from the pillow spring 94 , to facilitate subsequent disassembly of the pillow spring 94.

[0040] The support 21 includes a vertical bar 211 and a cross bar 212. One end of the cross bar 212 is connected to the top of the vertical bar 211, and the other end of the cross bar 212 is connected to the three-degree-of-freedom mobile module 22, that is, the cross bar 212 is connected to the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com