Assembling and welding method for space bent pipe of all-terrain vehicle and welding tool

A technology of space bending and welding tooling, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of height difference of parts, the overall spatial position accuracy cannot meet the requirements, and the accuracy requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

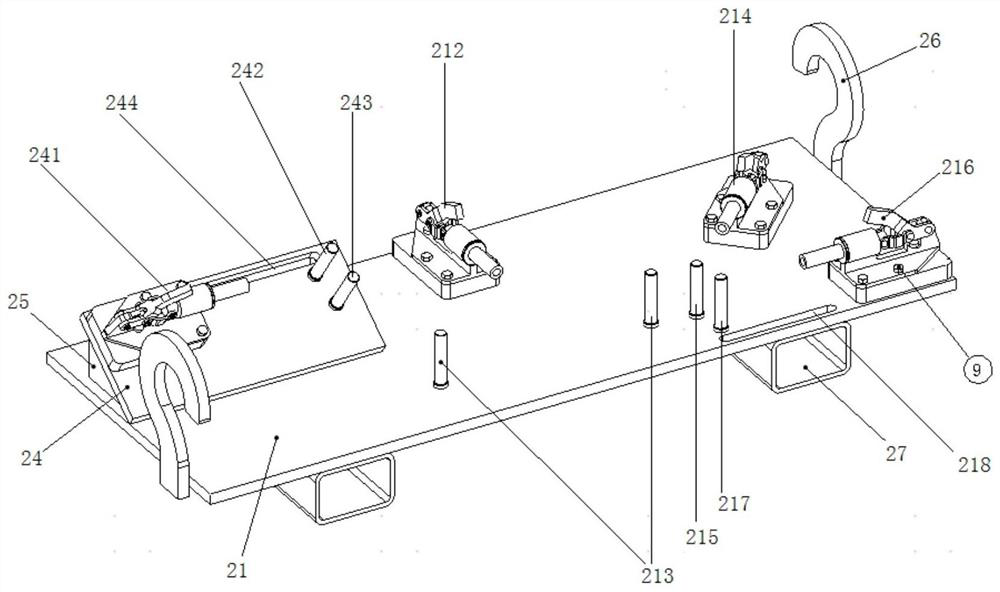

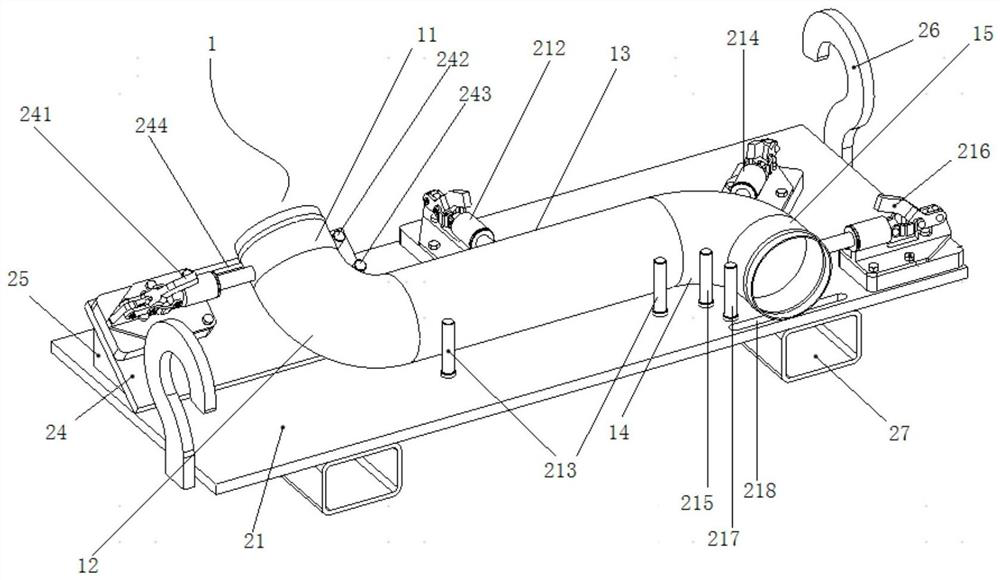

[0030] see Figure 1 to Figure 2 shown.

[0031] A method for assembling and welding an all-terrain vehicle space elbow of the present invention uses a welding tool and comprises the following steps:

[0032] Step 1. Assembling parts of the space elbow 1: the upturned section 11 of the space elbow 1 is placed on the upper panel layout of the positioning plate 24, the first elbow section 12, the straight pipe section 13, the second elbow section 14, the end flat The section 15 is placed on the panel layout of the main board 21 in turn, so that the prefabricated structure of the space elbow 1 can obtain multi-point support on the positioning plate 24 and the panel layout of the main board 21, and the space elbow 1 passes through the positioning pin A242, the positioning pin B243, the positioning pin The contact of C213, positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com