Preparation method of circuit board for CCMs

A technology of circuit boards and modules, which is applied in the fields of printed circuit manufacturing, electrical component assembly of printed circuits, printed circuits, etc., can solve the problems of affecting the flatness of chip attachment, increasing the thickness of circuit boards, and increasing production costs, so as to improve Excellent rate of modules, improved heat dissipation, low image blur effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

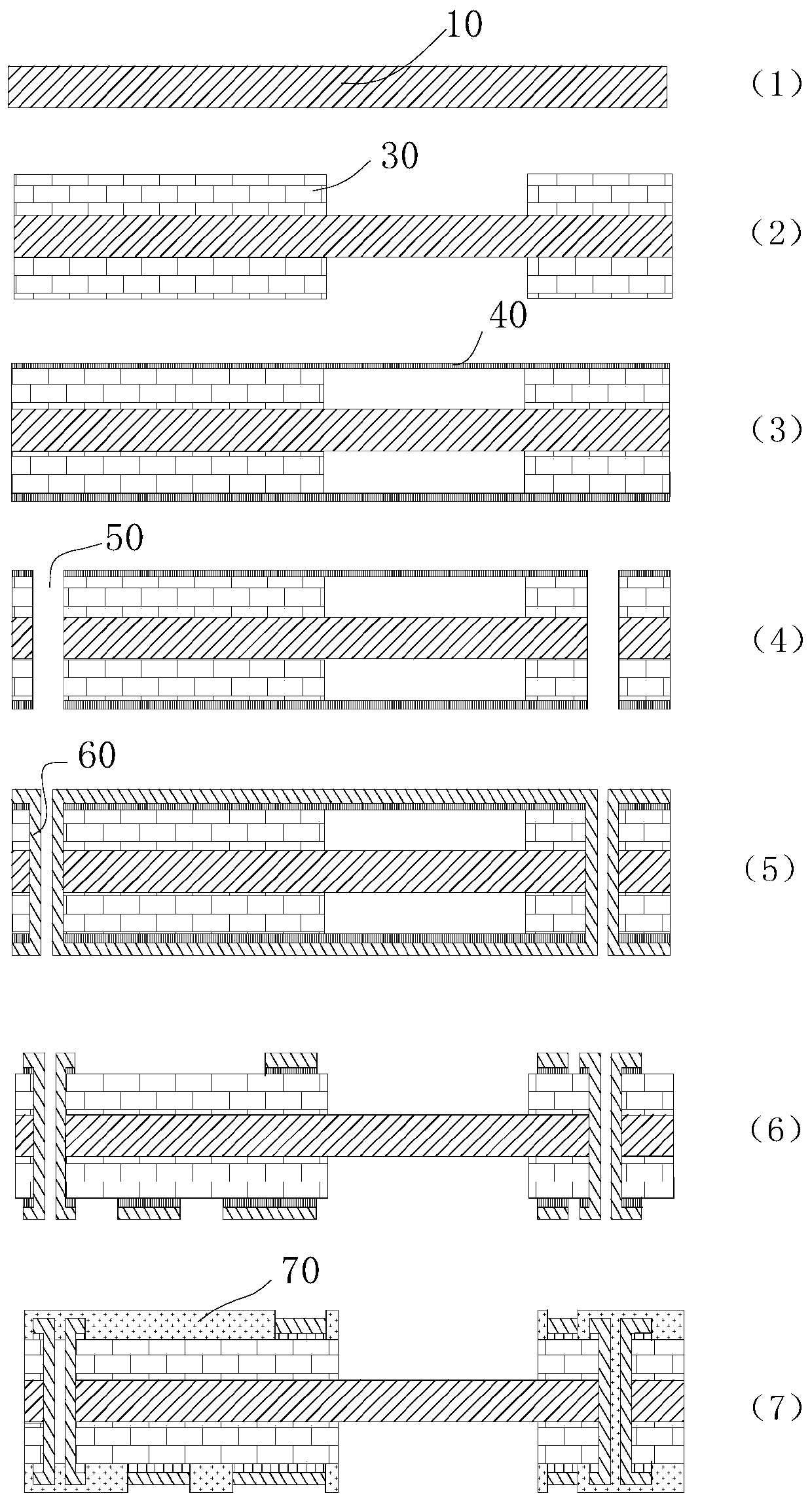

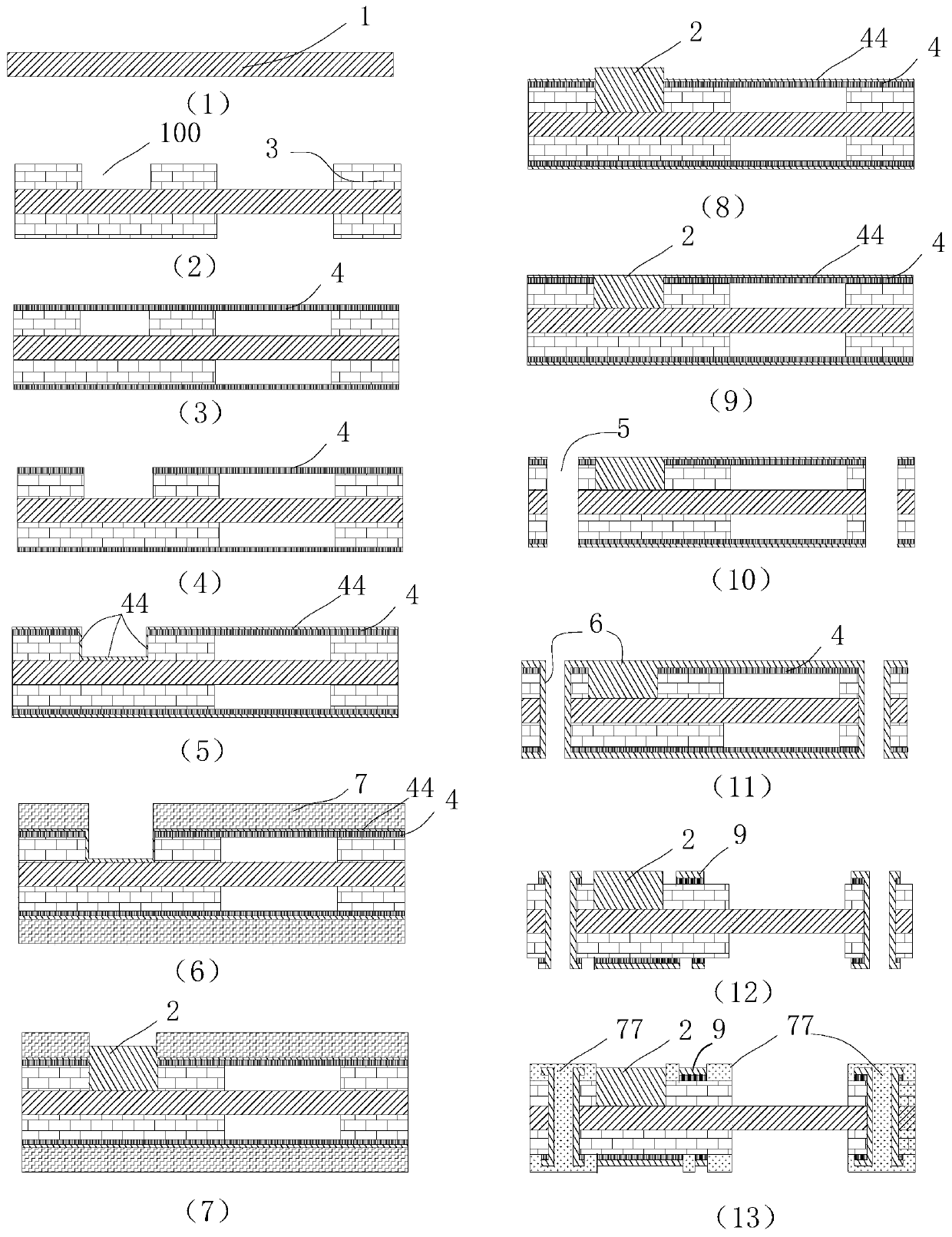

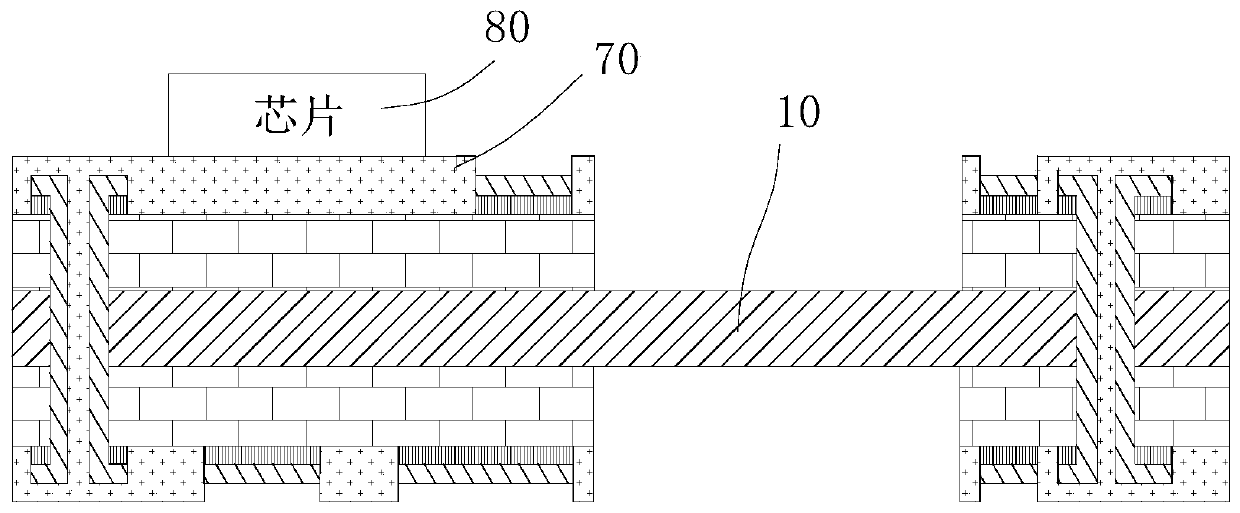

[0038] Such as figure 2 Shown, a kind of preparation method of circuit board for CCM module comprises the following steps:

[0039] 1) Fabrication of the inner core board 1: the inner core board 1 is made of a double-sided soft board pasted with a covering film;

[0040] 2) Lamination of the insulating layer 3: Laminate the prepreg of hard board epoxy resin and glass fiber cloth on the inner core board 1, and open the window 100 in advance corresponding to the chip area of the inner core board 1, and the size ratio of the opening 100 The unilateral expansion of the copper pillar 2 is 0.14-0.16 mm; of course, other prepregs commonly used in this technical field can also be used for the prepreg;

[0041] 3) Bonding and pressing copper foil 4: Paste a layer of pure copper foil 4 on the surface of the insulating layer 3, and after lamination,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com