Modularized floor of passenger train

A railway passenger car, modularization technology, applied in the direction of vehicle components, superstructure, superstructure sub-assembly, etc., can solve the problems of inconvenient assembly, etc., and achieve the effect of convenient assembly, guaranteed quality and good size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

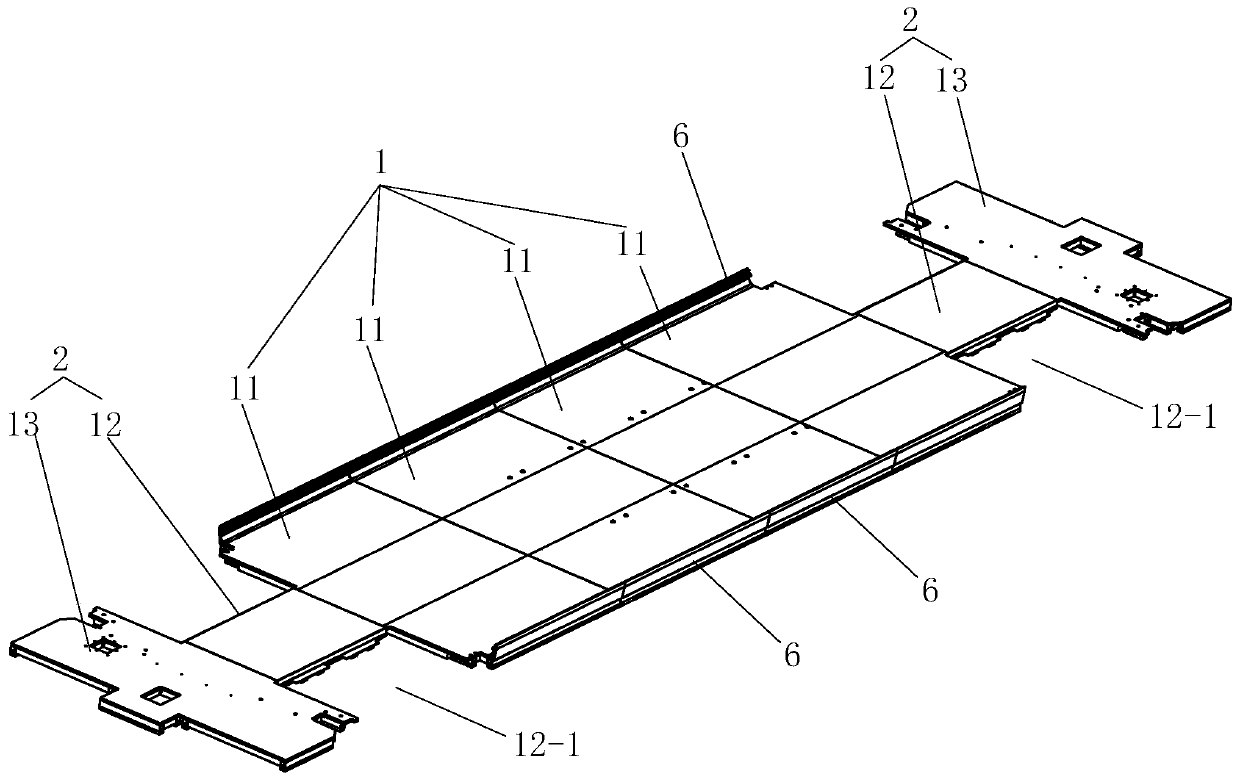

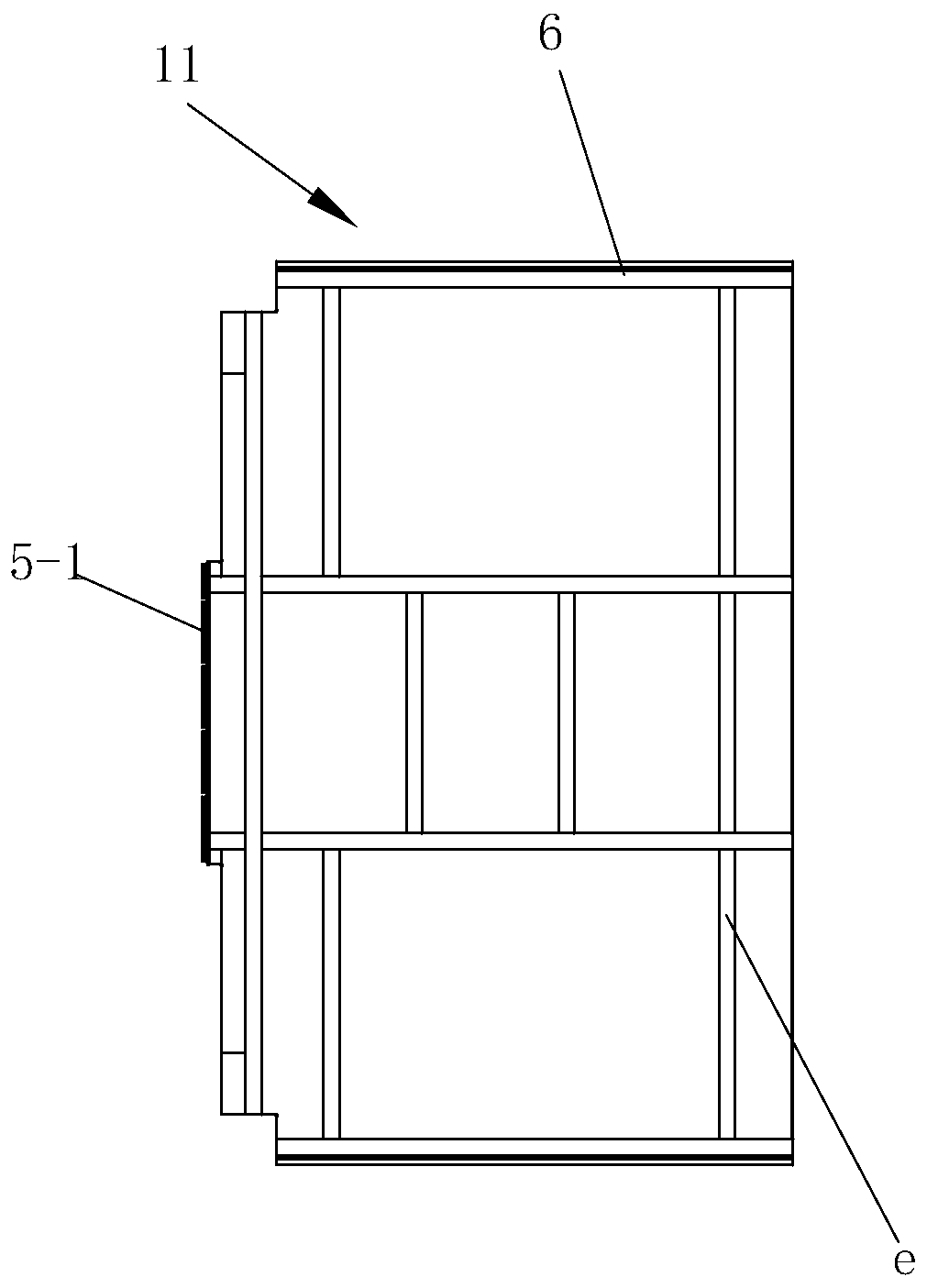

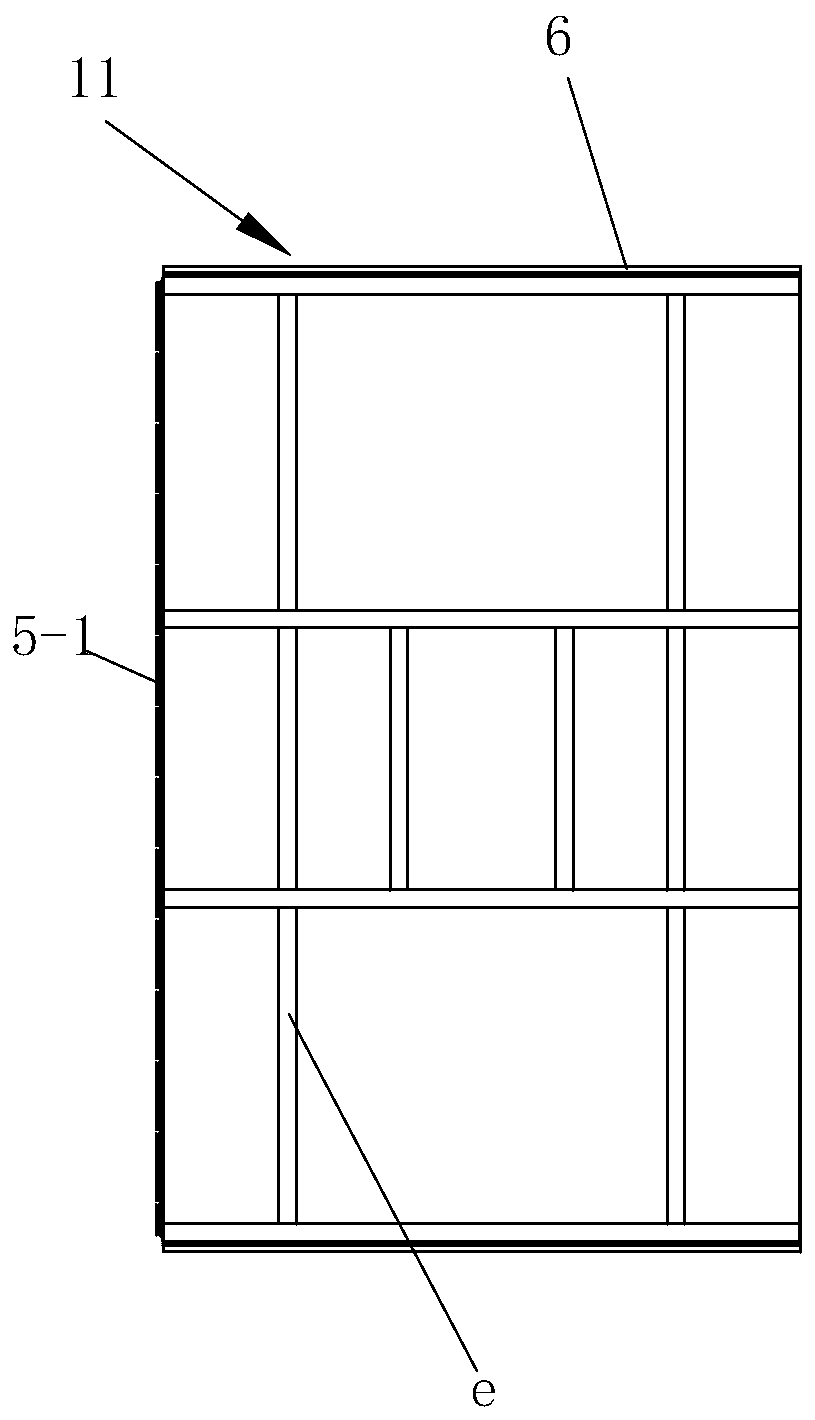

[0029] See Figure 1 to Figure 10 , this embodiment is a conventional floor, with a main floor 1, the main floor 1 has several type I floor modules 11, and the type I floor modules 11 are composed of floor cloth a, honeycomb composite board b and sound insulation The heat insulation board c, wherein the sound insulation and heat insulation board c is provided with a grid-shaped metal support frame d, and the type I floor module is supported by the rubber part e which is under the metal support frame d and fixed on the vehicle frame. The honeycomb composite board b can be made of aluminum, and the sound and heat insulation board c can be made of glass wool felt 2, melamine foamed cotton or synthetic rubber foamed material. The above-mentioned structure makes the main floor have a good effect of shock absorption and noise reduction. The left and right sides of the honeycomb composite panel b of the type I floor module protrude from the sound and heat insulation panel c to form ...

Embodiment 2

[0035] See Figures 11 to 15 , this embodiment is a specific floor, with a main floor 1, the front end of the main floor 1 is connected with a front raised floor 3 through a transition module 15, the rear end is connected with a door entrance area floor 2, and the door entrance area floor 2 is connected with a rear raised floor floor 4. The front raised floor 3 leads to the driver's cab, and the rear raised floor leads to other passenger compartments.

[0036] The front raised floor 3 has two Type I floor modules 11, and the transition module 15 has the same composition as the Type I floor modules 11. The middle of the Type I floor module 11 connected to the transition module 15 has a step 11-1. The left and right sides of the transition module 15 are respectively provided with side profiles 6 , and the connection method between the side profiles 6 and the transition modules 15 is shown in the connection between the side profiles 6 and the Type I floor module 11 in Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com