Disposable attaching fixture for foam rubber protective film of touch screen

A protective film and touch screen technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of large investment, unstable product yield, low work efficiency, etc., to improve efficiency, save costs, stick smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

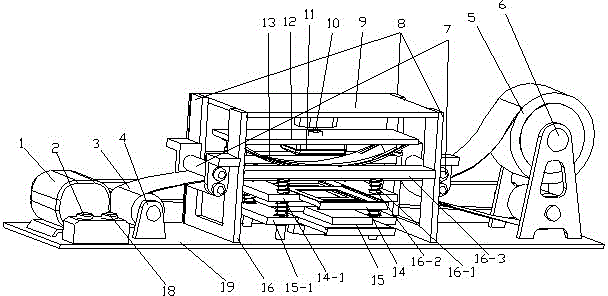

[0006] like figure 1 As shown, the main support 8 is fixed on the middle part of the bottom plate 16, and a protective film running limit roller 7 is respectively fixed on the outer walls of the main support 8 in the same direction as the protective film, and the receiving rollers are respectively fixed on the front and rear bottom plates 17 of the main support 8. Support 4, put the roller support 6, the backing paper collection roller 3 is placed on the collection roller support 4, the protective film release roller 5 is placed on the roller support 6, so that the two protective films run against the roller 7, the protective film collection roller 3, The protective film release roller 5 is on the same central axis, the motor 1 is fixed on the bottom plate 16, and the bottom paper collection roller 3 and the protective film release roller 5 are driven by a belt to rotate. Fix the hydraulic system fixing plate 9 on the uppermost end surface of the main bracket 8, the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com