Gluing device for processing front baffle

A front baffle and gluing technology, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of easy overflow of glue, uneven bonding, and affecting work efficiency, etc., to improve product quality and work efficiency, and tightly bond Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

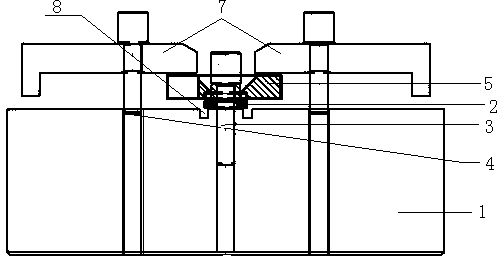

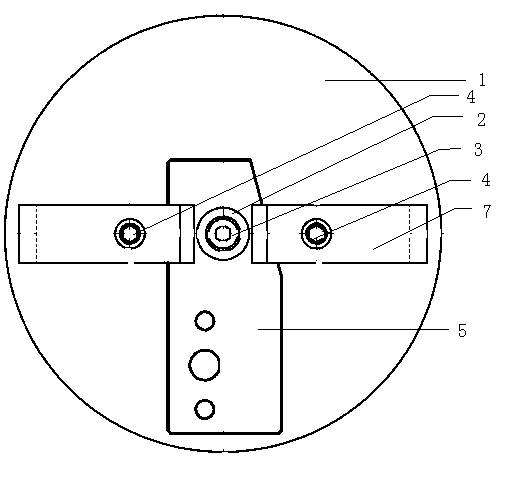

[0011] The gluing device for processing the front baffle as shown in the figure includes a base 1, a pressing piece 7 and a ring 2, wherein the base 1 is cylindrical, and its center is longitudinally provided with a main threaded hole 3, and the main thread An auxiliary threaded hole 4 is provided on both sides of the hole 3, a groove 8 is provided on the end surface of the base 1, and the groove 8 is located on the outer periphery of the main threaded hole 3, and the ring 2 is made of diamond material, and the surface is polished , the ring 2 is placed above the main threaded hole 3 of the base 1, a layer of glue is coated on the contact surface between the ring 2 and the base 1, and the ring 2 is bonded to the base 1 by glue On the end face, a gasket 5 is provided on the ring, and the gasket 5 is tightly connected with the main threaded hole 3 through bolts. The gasket 5 is provided with two pressing pieces 7, and the pressing pieces 7 The cross-sectional shape is "L", and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com