Surface enhanced Raman scattering substrate and preparation method thereof

A surface-enhanced Raman and substrate technology, used in diffusion elements, sputtering, ion implantation, etc., can solve the problems of complex procedures and long-term processing, and achieve good reproducibility and high measurement limit. , the effect of large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

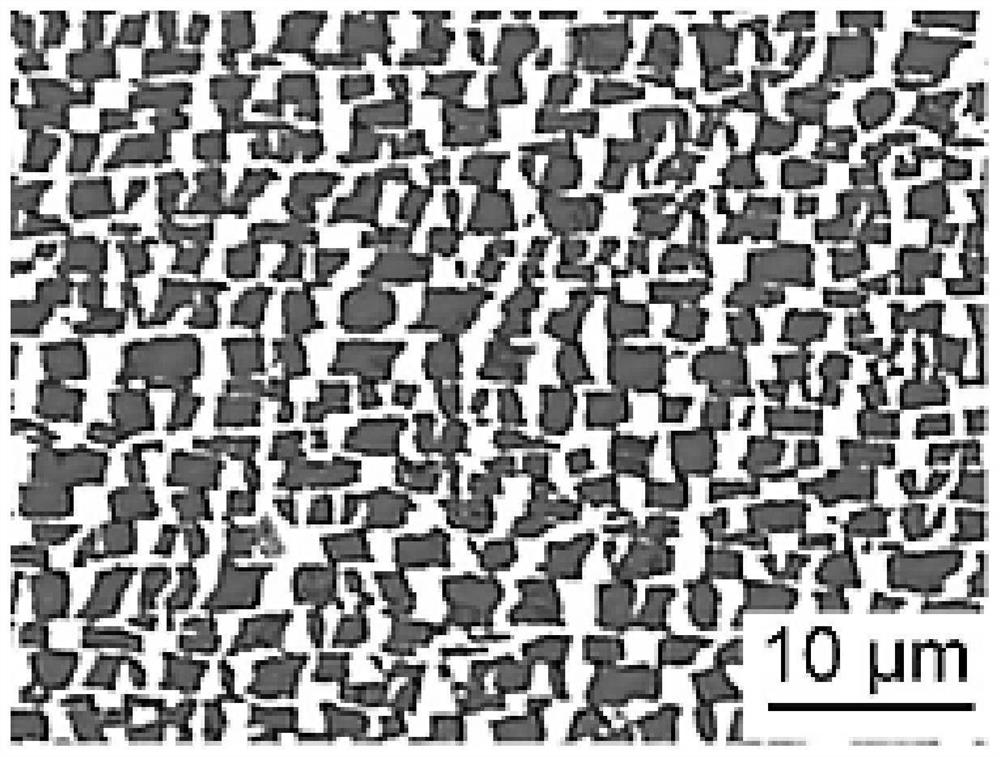

[0036] A layer of gold is deposited on the flexible PEI polymer substrate. The electron beam evaporator is deposited on a golden nanofil film having a thickness of 20 nanometers on a thickness of 125 microns and a length of 10 cm and a width of 10 cm, a width of 10 cm, a smooth surface smooth, so that it becomes a gold / PEI film, deposition rate. for The deposition time was 6 minutes, and the thickness of the gold nano film was 20 nm. During the deposition, the temperature of the vacuum chamber is maintained below 60 ° C to prevent the PEI film from being thermally expanded or deflated due to internal stress, resulting in a gold film to produce defects or wrinkles. After the vapor deposition, dried in an oven at 150 ° C for 30 min, so that the gold nano film and PEI were more combined, and the gold nanofil film was cracked as the crack of the PEI film was determined during subsequent stretching.

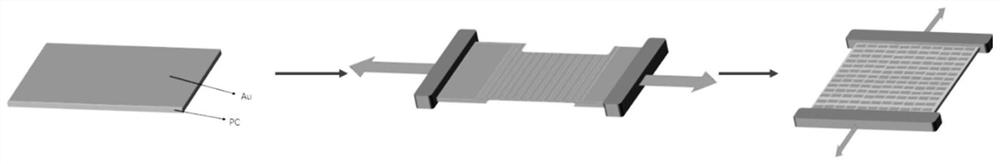

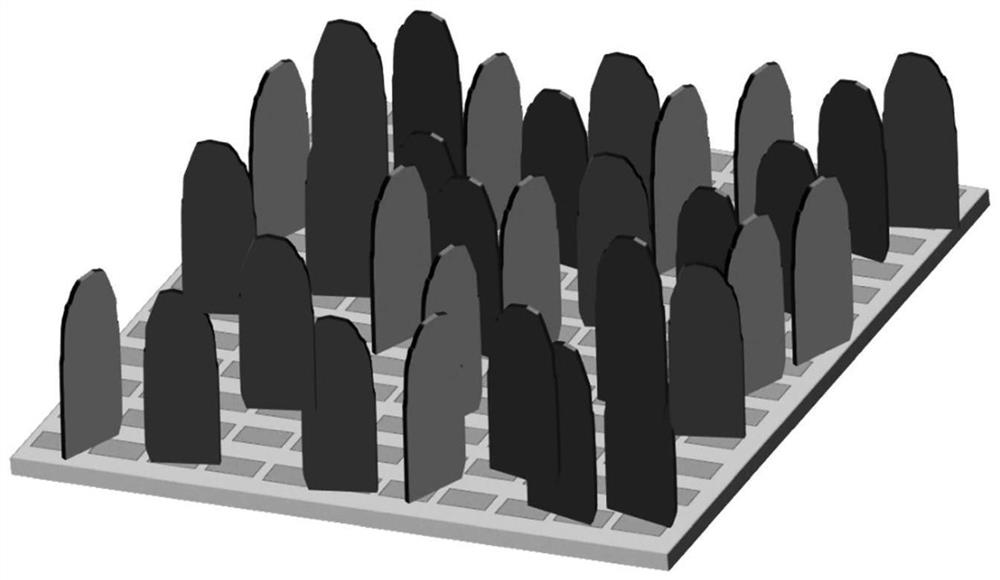

[0037] like Figure 1 The X-direction is performed using a gold / PEI film, the str...

Embodiment 2

[0042] A layer of gold is deposited on the flexible PEI polymer substrate. The electron beam evaporator is deposited from a golden nanometers having a thickness of 40 nanometers on a PEI film having a thickness of 125 microns and a length of 10 cm and a width of 10 cm and a width, which becomes a gold / PEI film, deposition rate. for The deposition time was 10 minutes, and the thickness of the gold nano film was 40 nm. During the deposition, the temperature of the vacuum chamber was 55 ° C and dried in an oven at 160 ° C after 20 min after the vapor deposition.

[0043] A piece of gold / PEI film is used for stretching in the X direction, and the stretching speed is 0.02 mm / second, stretched for 15 minutes. The PEI film passes through a necklace process, and stress is applied to the gold film by surface adhesion. When the stress exceeds the mechanical breakage strength, the gold film is broken into a strip. The prepared film was re-stretched in the Y direction to produce a two-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com