Patents

Literature

33results about How to "Improve bonding interface" patented technology

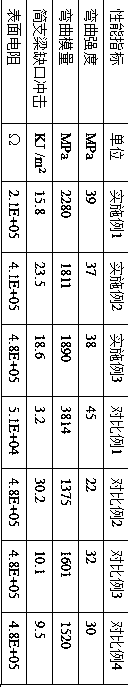

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

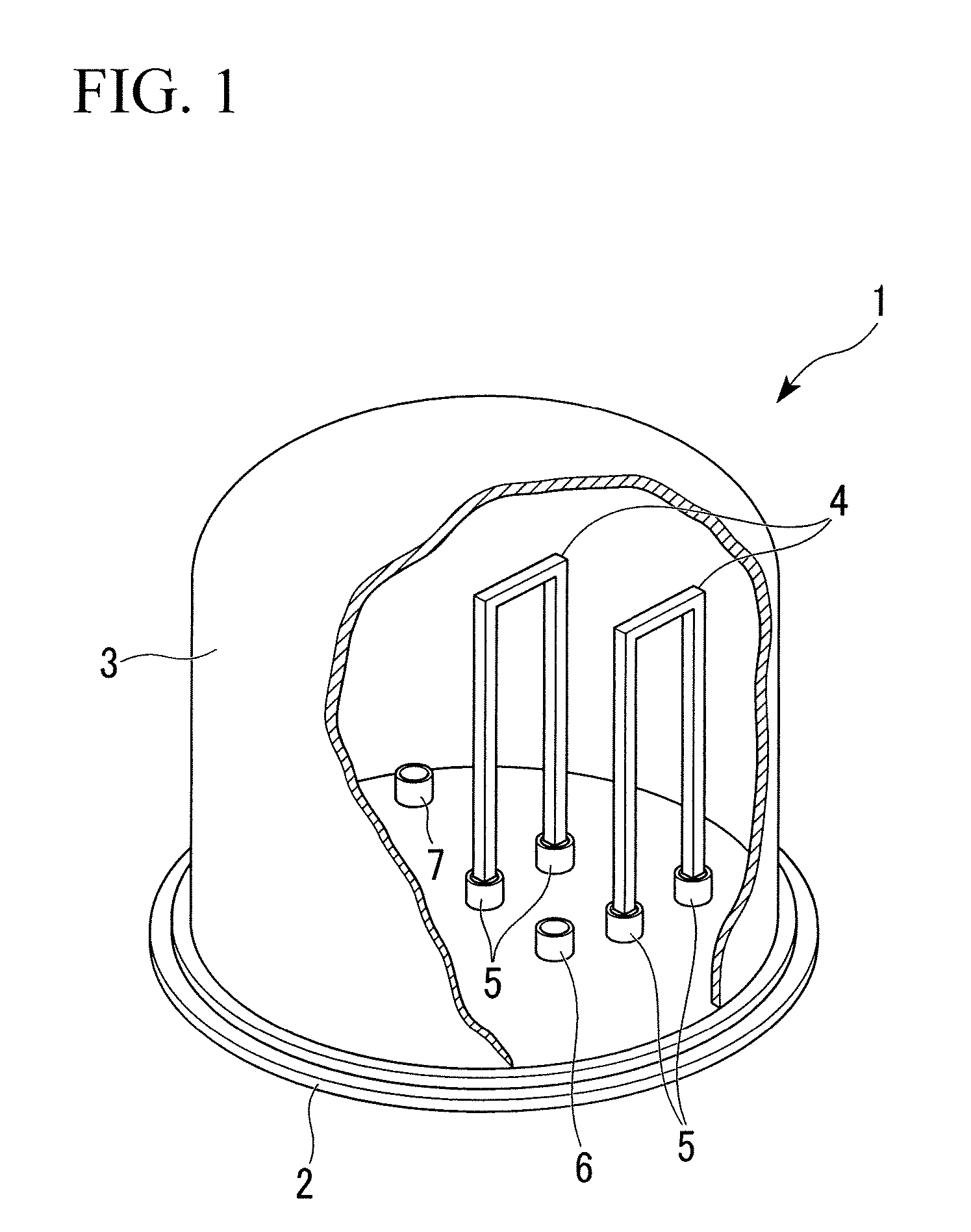

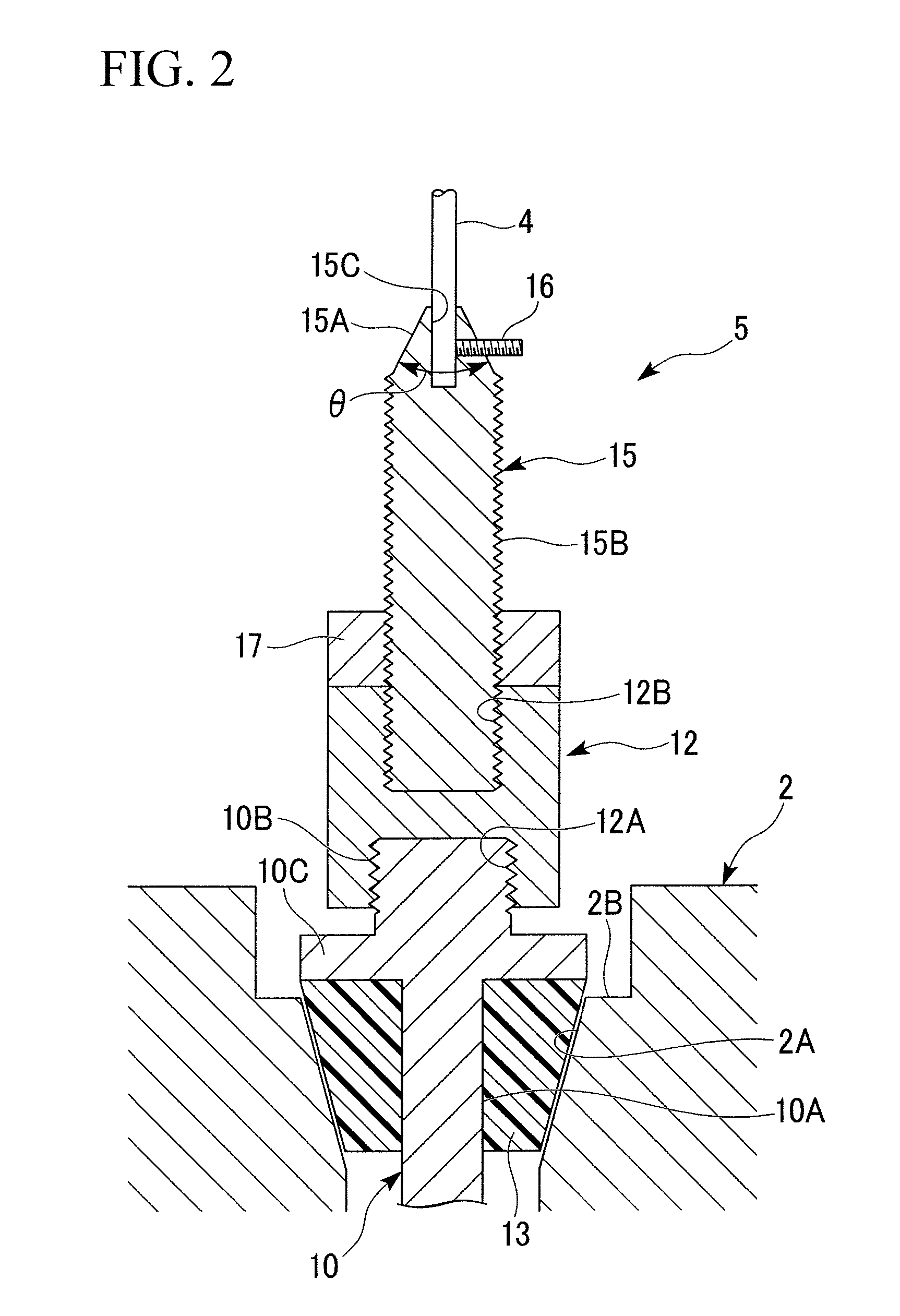

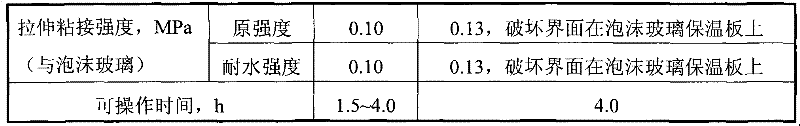

Polycrystalline silicon reactor

ActiveUS20090238992A1Strong adhesionStable productionDielectric heatingCrucible furnacesGas supplyAtmosphere

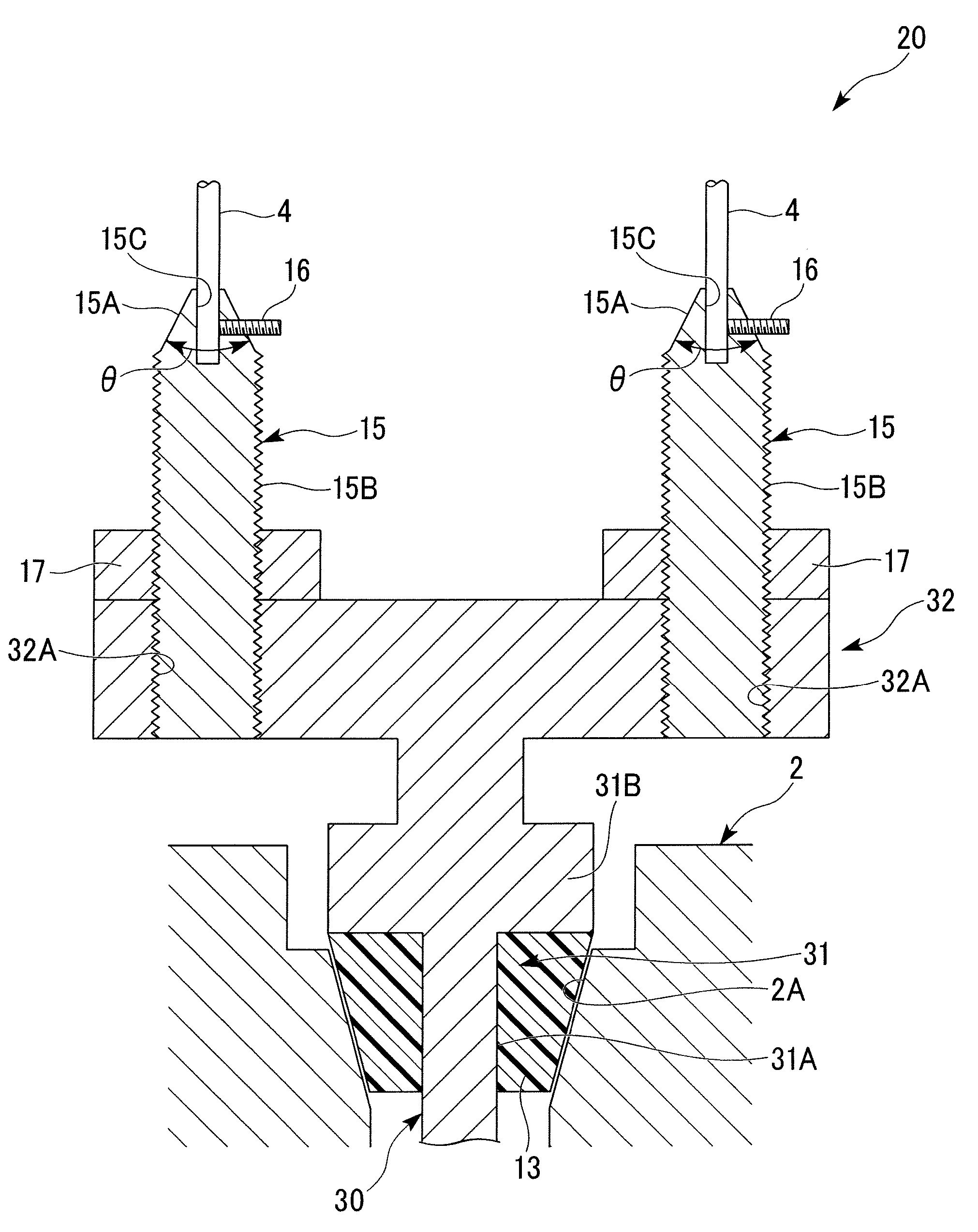

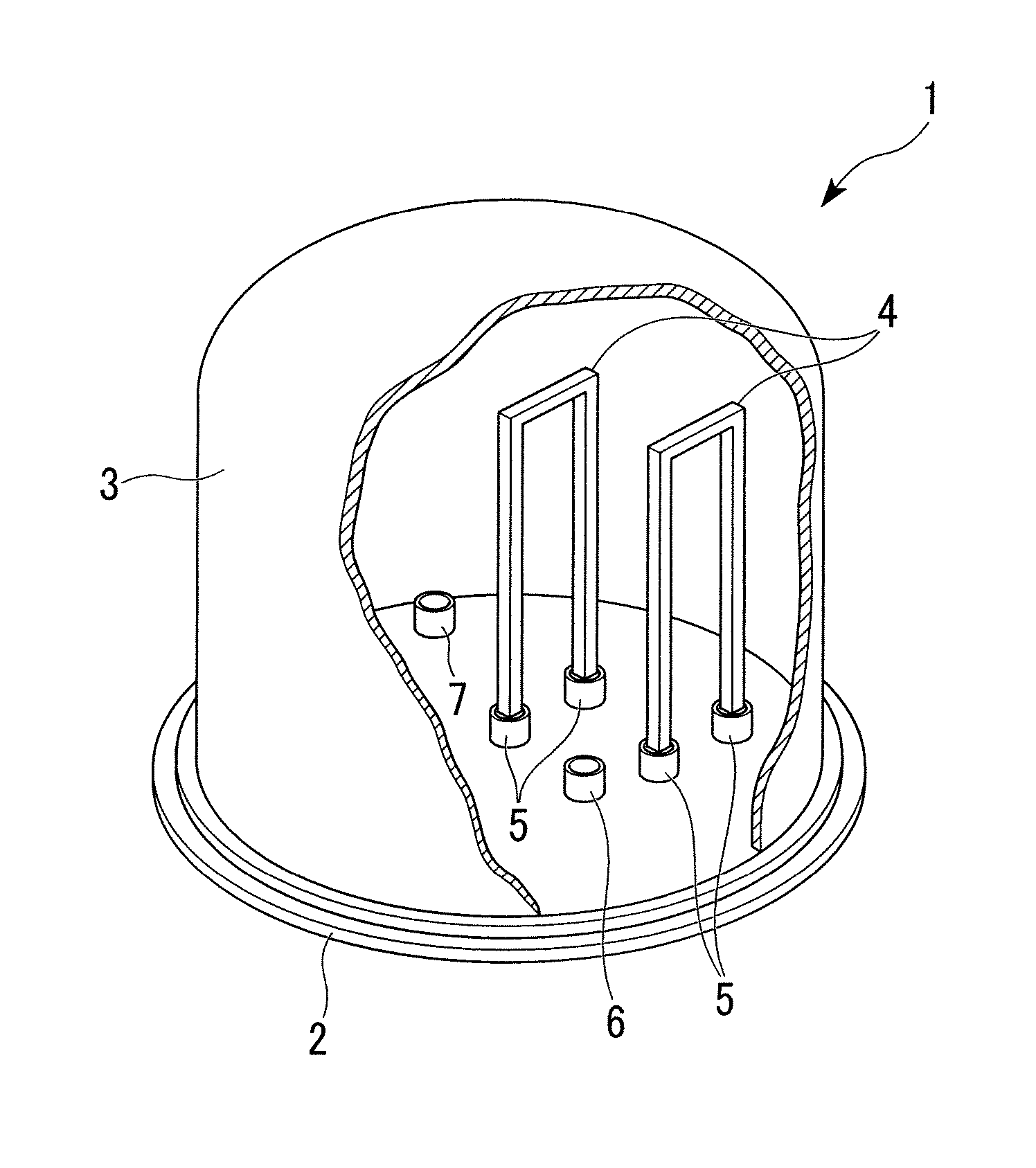

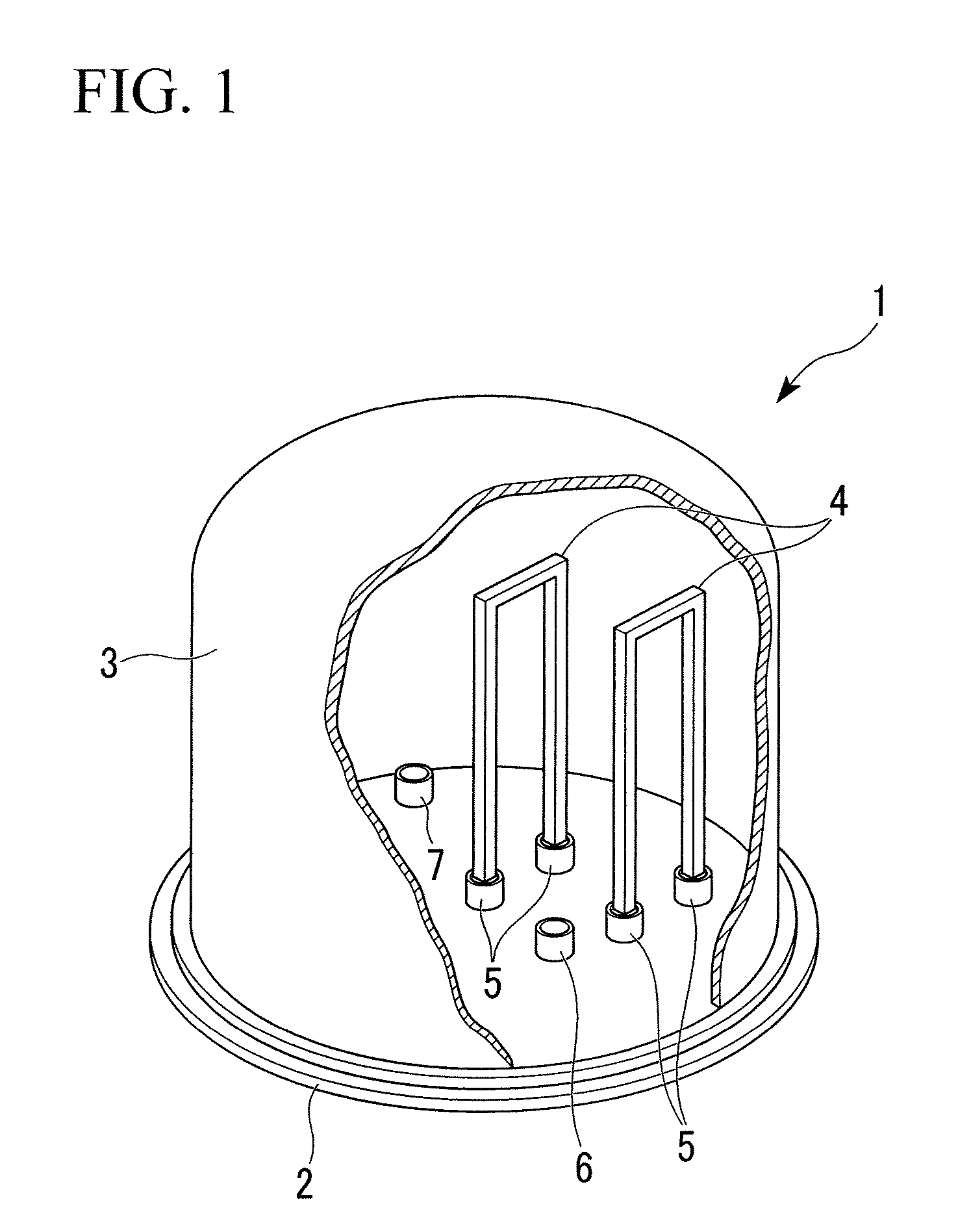

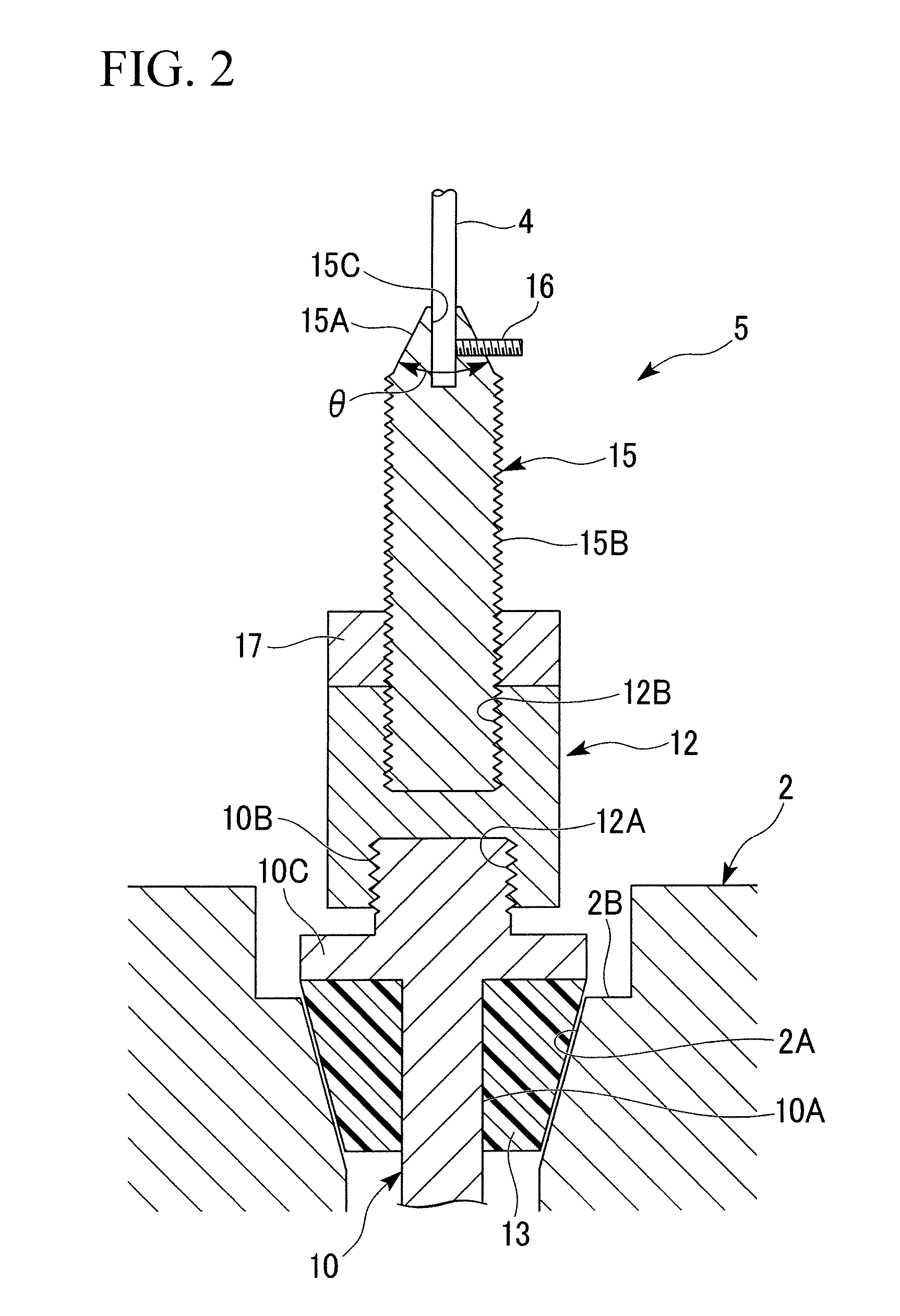

A polycrystalline silicon reactor 1 which can prevent polycrystalline silicon which deposits on the surface of an electrode 5 holding a silicon seed rod 4 from being peeled off is provided. In a polycrystalline silicon reactor 1 which applies an electric current to a silicon seed rod 4 provided within a furnace, thereby heating the silicon seed rod 4, brings a source gas supplied into the furnace into reaction, and deposits polycrystalline silicon on the surface of the silicon seed rod 4, the reactor includes, at a bottom plate 2 (furnace bottom) of the furnace, an electrode holder 10 provided so as to be electrically insulated from the bottom plate 2 (furnace bottom), and a seed rod holding electrode 15 connected to the electrode holder 10, and holding the silicon seed rod 4 toward the upside. Concavo-convex portions (male thread portion) 15B exposed to a furnace atmosphere is provided at an outer peripheral surface of the seed rod holding electrode 15.

Owner:HIGH-PURITY SILICON CORP

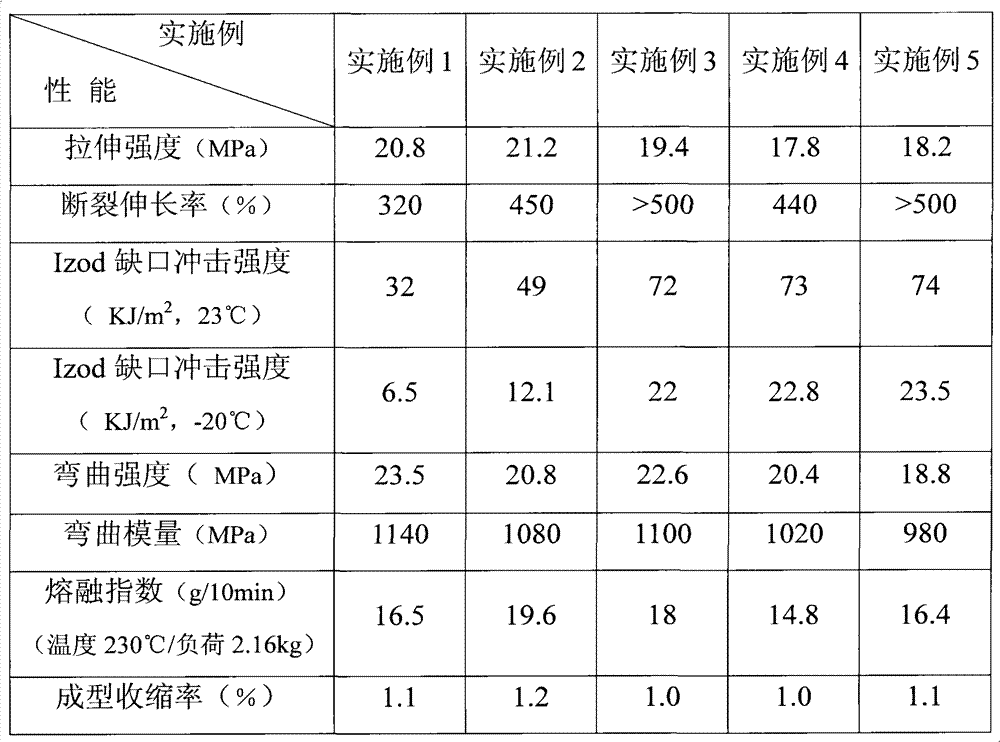

Composite material for vehicle bumper and preparation method thereof

The invention relates to a composite material for a vehicle bumper and a preparation method thereof. The composite material comprises the following ingredients: 60-80wt% of polypropylene, 5-20wt% of metallocene ethylene / hexene copolymer, 10-20wt% of nano calcium carbonate, 0.4-0.8wt% of antioxidant, 0.2-0.5wt% of lubricant. The preparation method comprises the following steps: uniformly mixing the ingredients according to the ratio in a mixer, mixing, extruding, cooling and dicing the mixture in a double screw extruder to obtain the composite material for the vehicle bumper. According to the invention, the polypropylene / metallocene ethylene / hexene copolymer / nano calcium carbonate composite material is prepared by using metallocene ethylene / hexene copolymer as an elastomer component and nano calcium carbonate with a particle size of less than 100nm as an enhancing toughening component, with the advantages of good impact resistance, good low temperature resistance, good weatherability, and good rigid, being capable of being sprayed, and being suitable for ornaments with high requirement of toughness such as the vehicle bumper.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

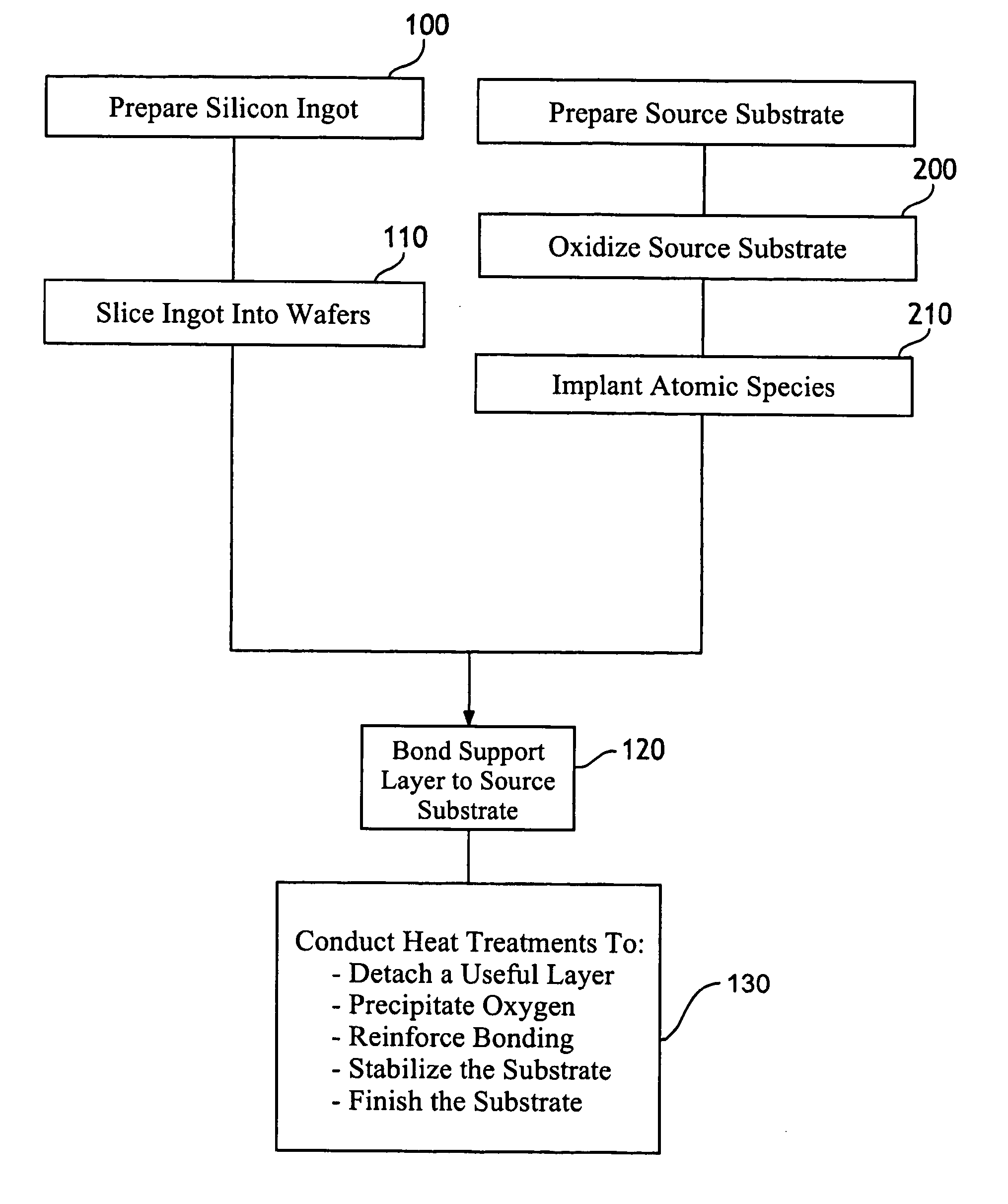

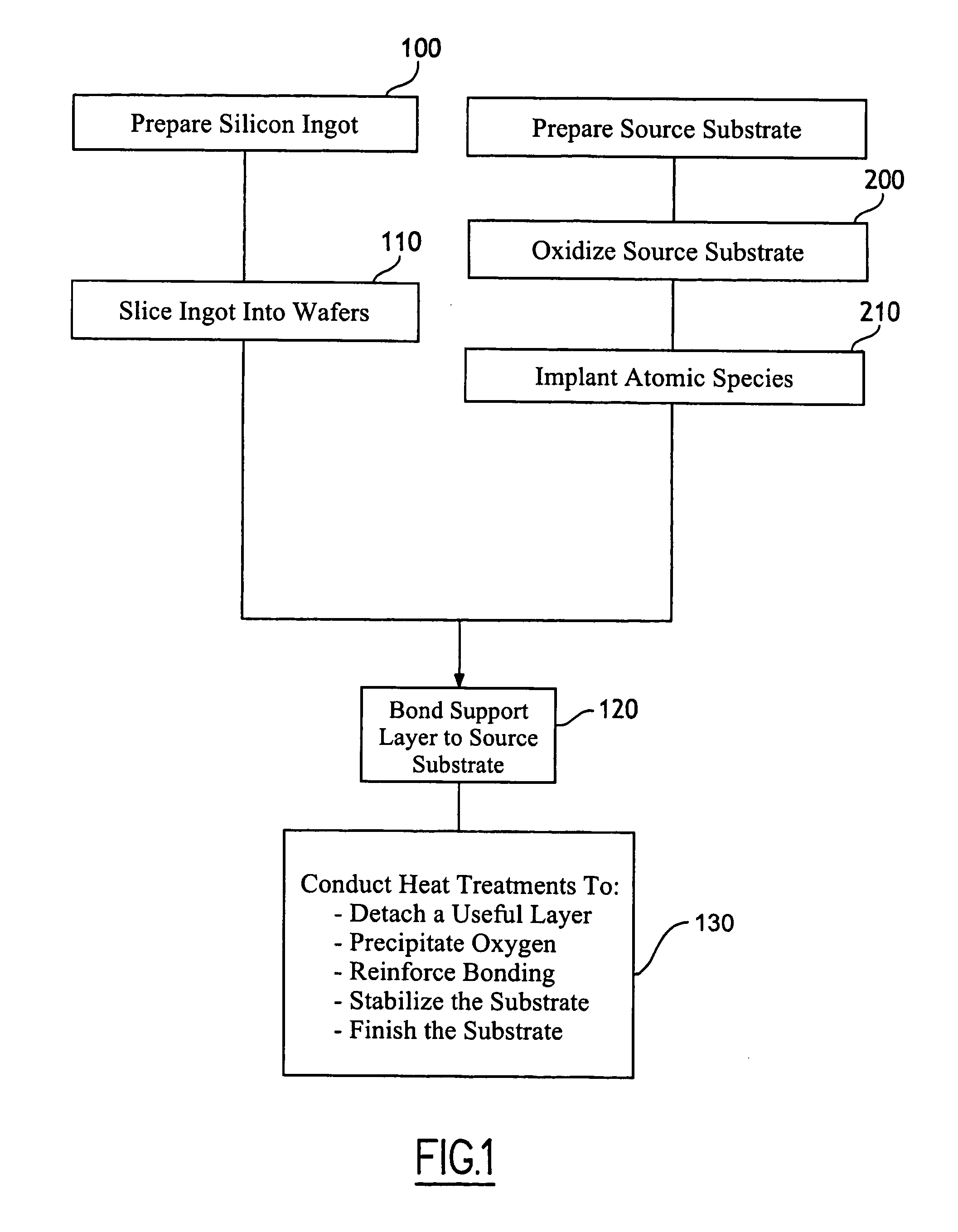

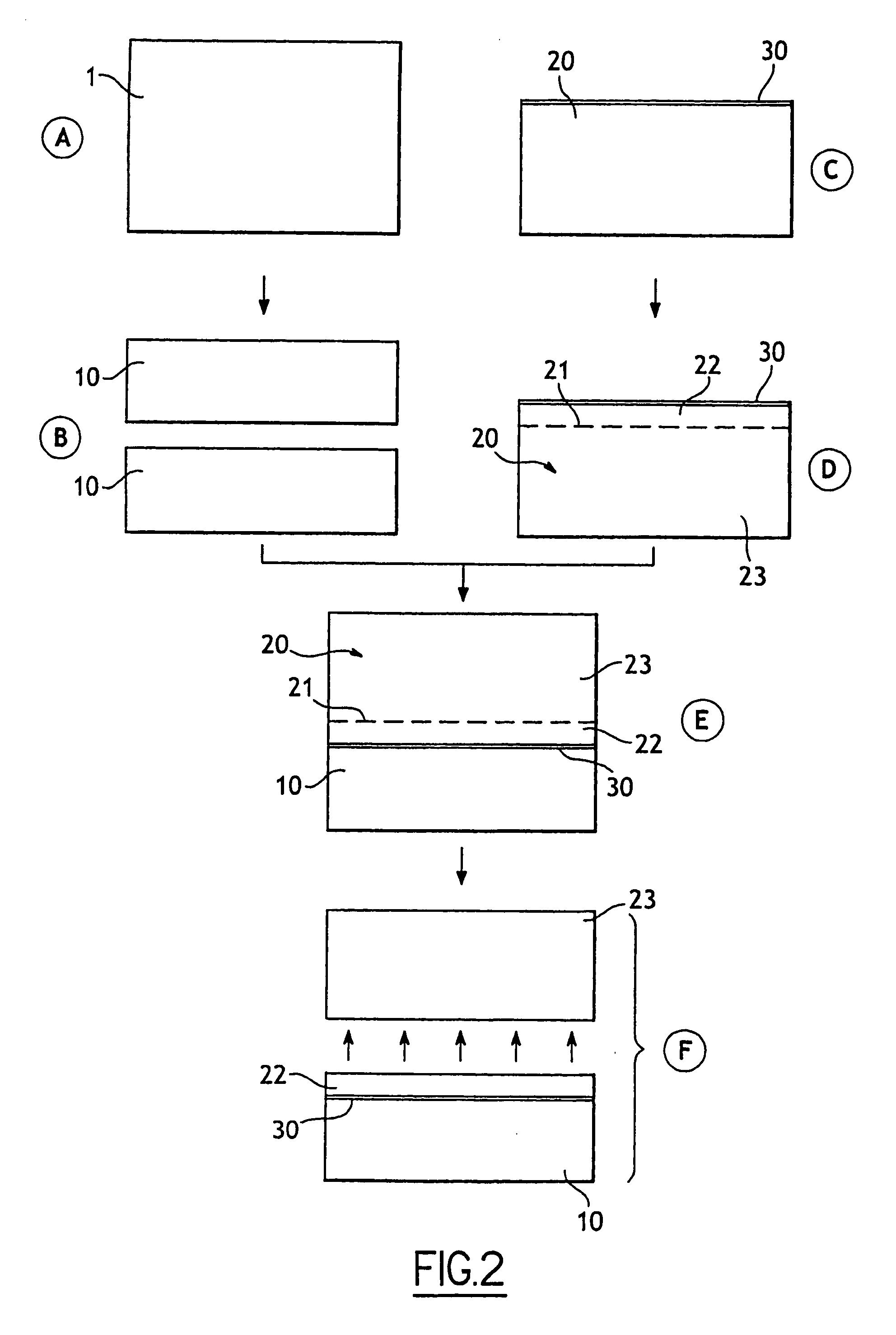

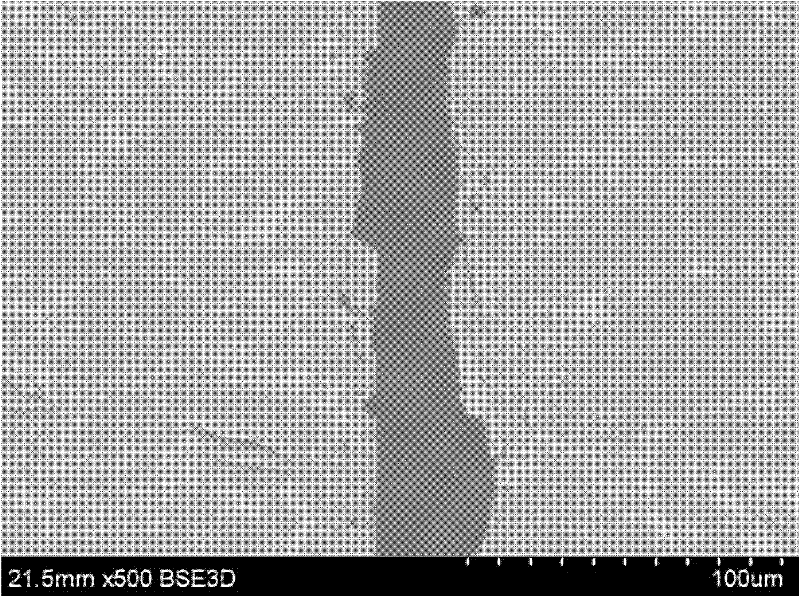

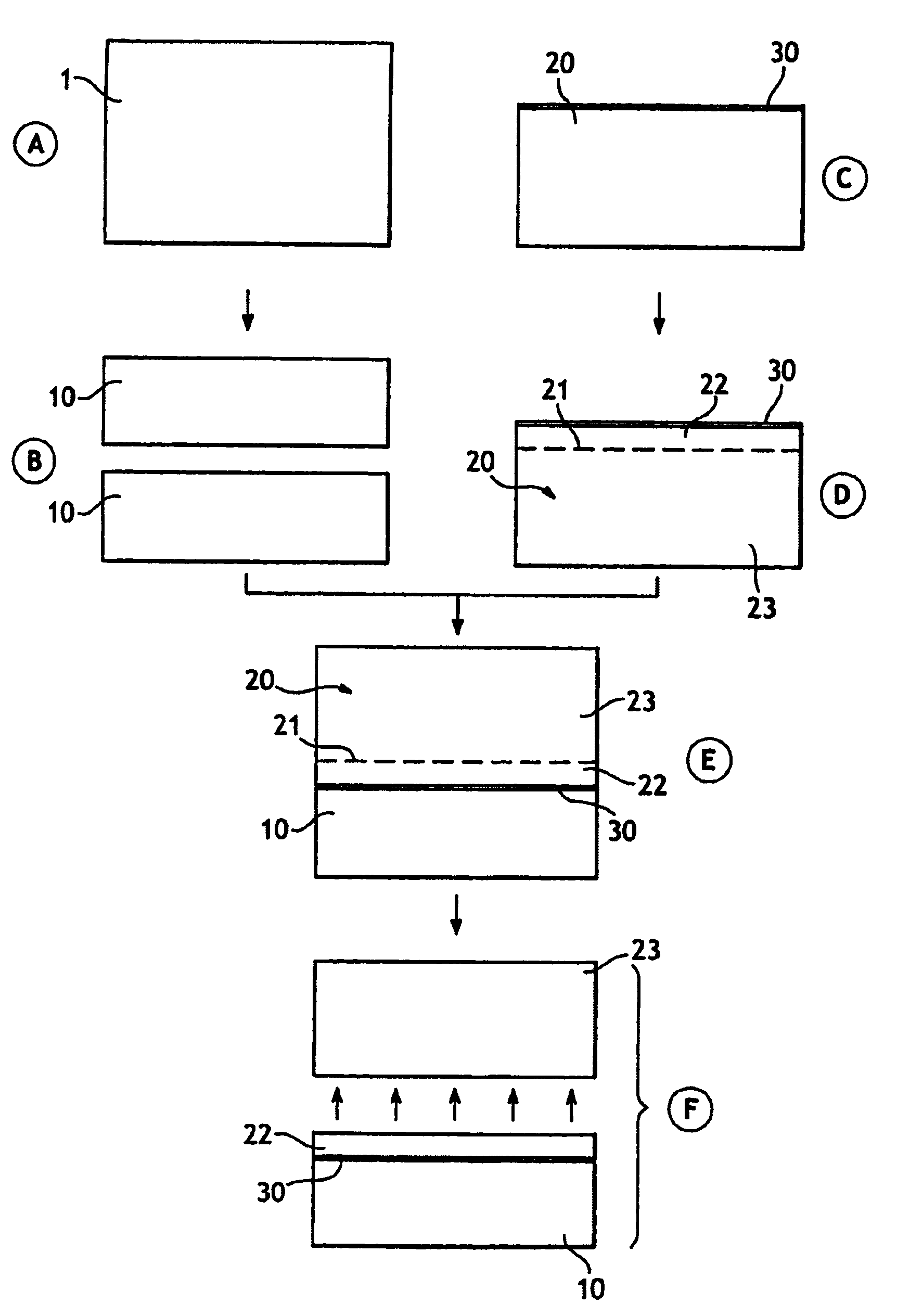

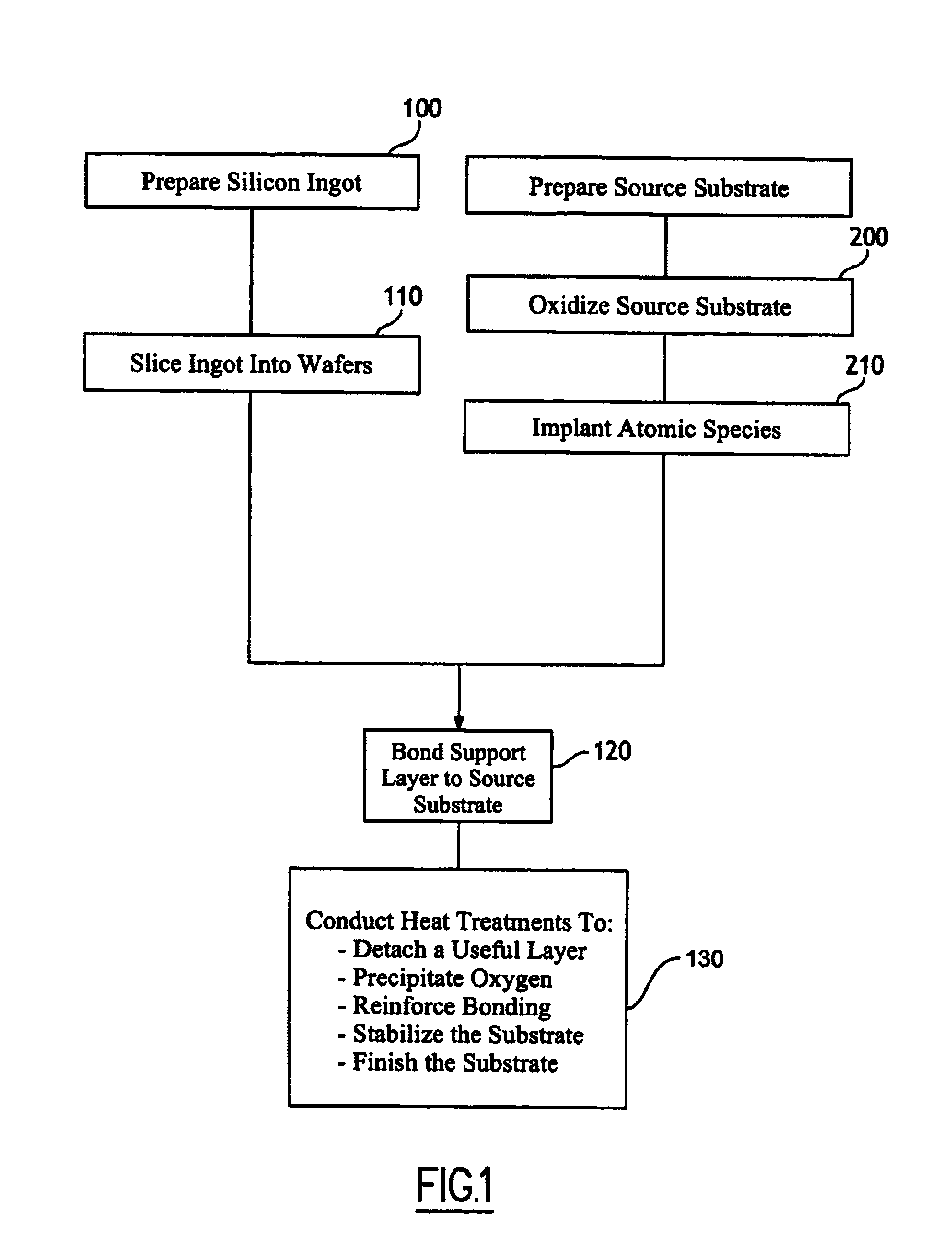

Method for limiting slip lines in a semiconductor substrate

ActiveUS20050202658A1Reduce generationImprove bonding interfaceSemiconductor/solid-state device manufacturingSlip lineEngineering

A method for limiting slip lines in a semiconductor substrate including a support layer and a useful semiconductor layer that is transferred to the support layer. The method includes precipitating at least a portion of interstitial oxygen in the support layer by a series of heat treatments conducted after bonding of the useful semiconductor layer to the support layer. The heat treatments occur at a temperature and a time sufficient to reduce the generation of slip lines therein.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

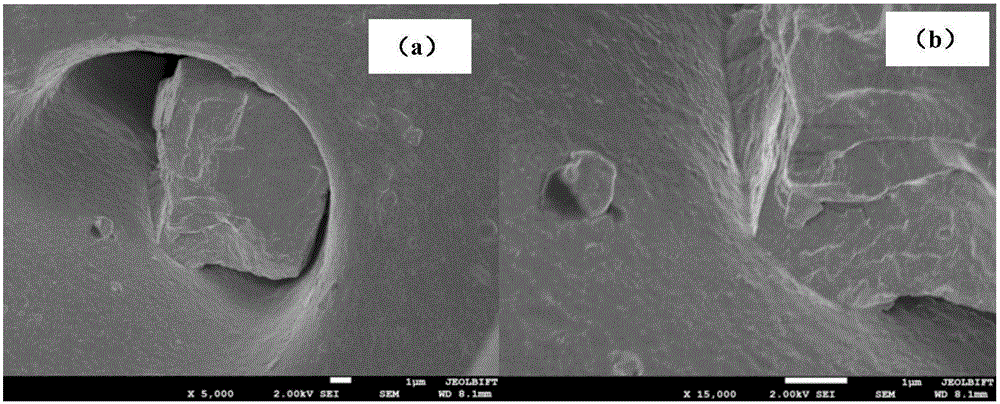

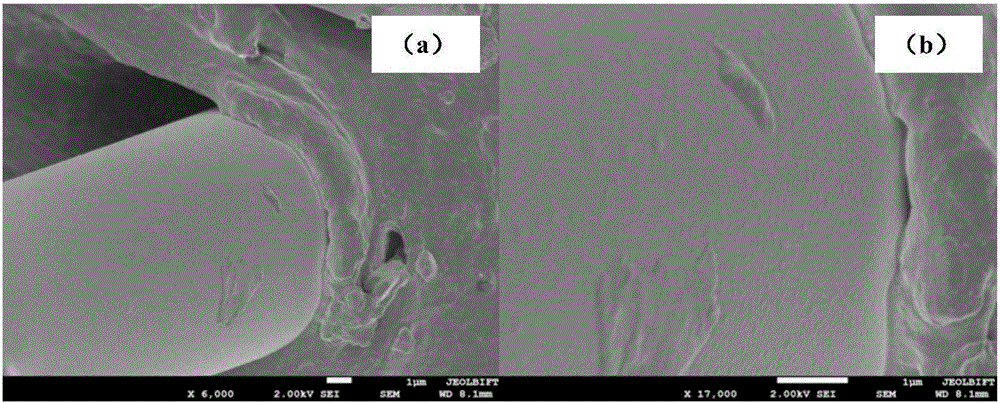

Double-component epoxy adhesive for bonding ceramics, preparation method and using method thereof

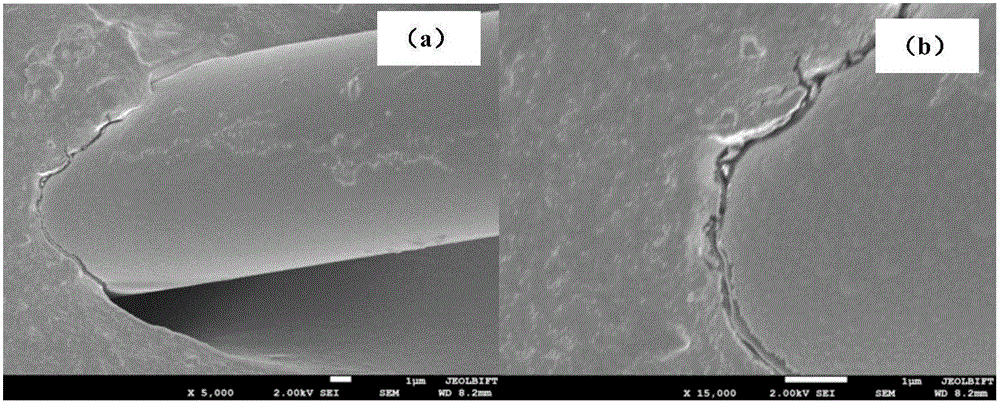

InactiveCN102220101AReduce internal stressHigh bonding strengthNon-macromolecular adhesive additivesCarboxyl rubber adhesivesFiberCarbon nanotube

The invention relates to a double-component epoxy adhesive for bonding ceramics, a preparation method and using method thereof, belonging to the adhesive field, and aiming at solving the technical problem that the interfacial stress is overhigh owning to great difference of linear expansion coefficients when the existing epoxy adhesive is used for bonding the ceramics. The component A of the double-component epoxy adhesive is prepared by E-44 epoxy resin, E-51 epoxy resin, carboxy terminal butadiene-acrylonitrile, ground quartz, carbon fiber, carbon nano tube, SiC crystal whisker and ultraviolet absorber UV-531, the component B of the double-component epoxy adhesive is prepared by 3-diethylin propylamine, silane coupling agent KH-550, accelerating agent DMP-30 and ground quartz, and the double-component epoxy adhesive is prepared by a mixing method. When the adhesive is used, the adhesive is coated on a surface to be adhered for superimposition and solidification; and the shearing strength of the adhesive can reach more than 60MPa when the adhesive is used for bonding SiC ceramic; the bonding interface is good, an obvious mechanical embedding function is realized between an adhesive layer and a parent metal, and the defects such as cracks, air holes and the like do not exist in the adhesive layer.

Owner:HARBIN INST OF TECH

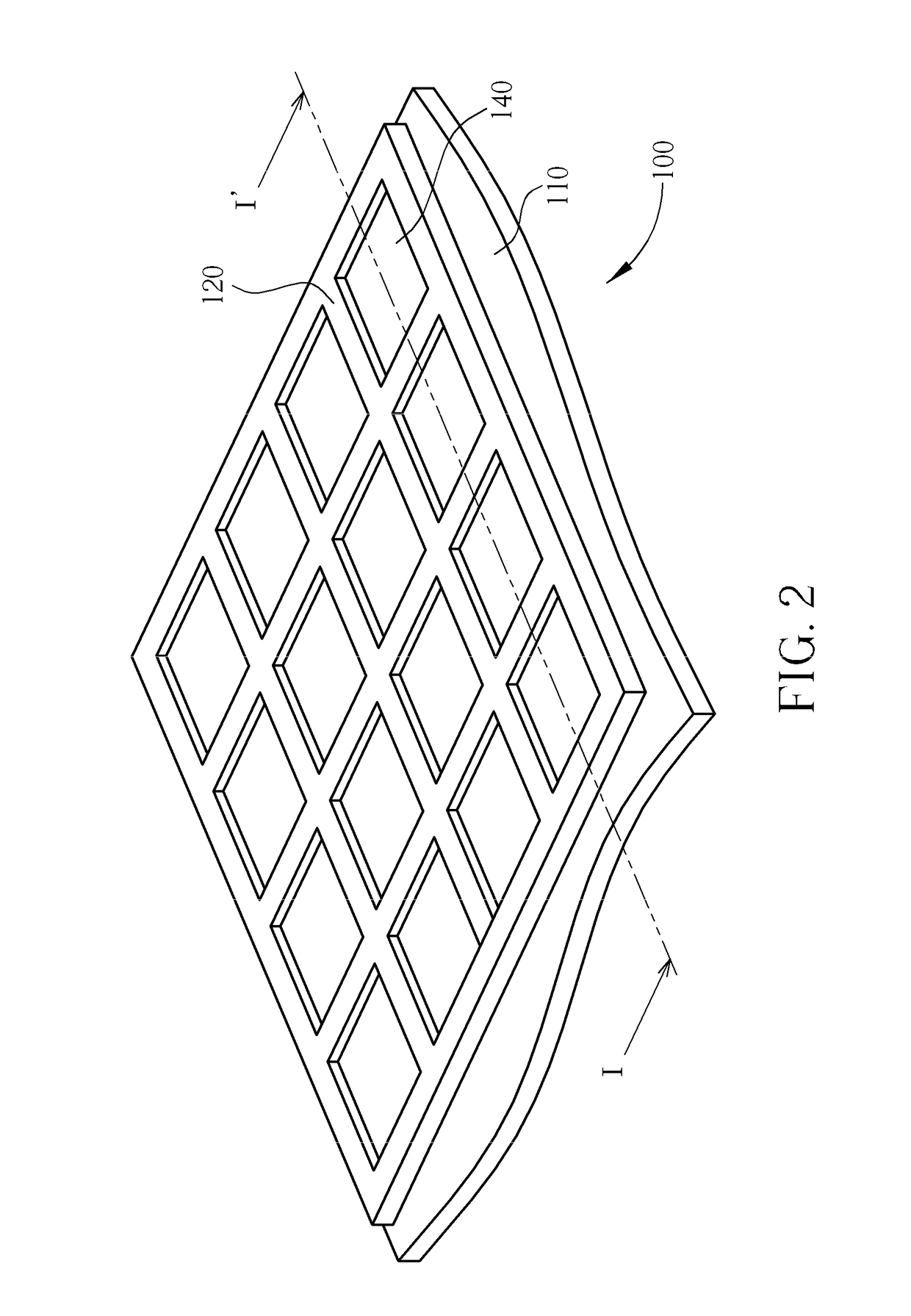

Honeycomb sandwich layer structure and preparation method thereof

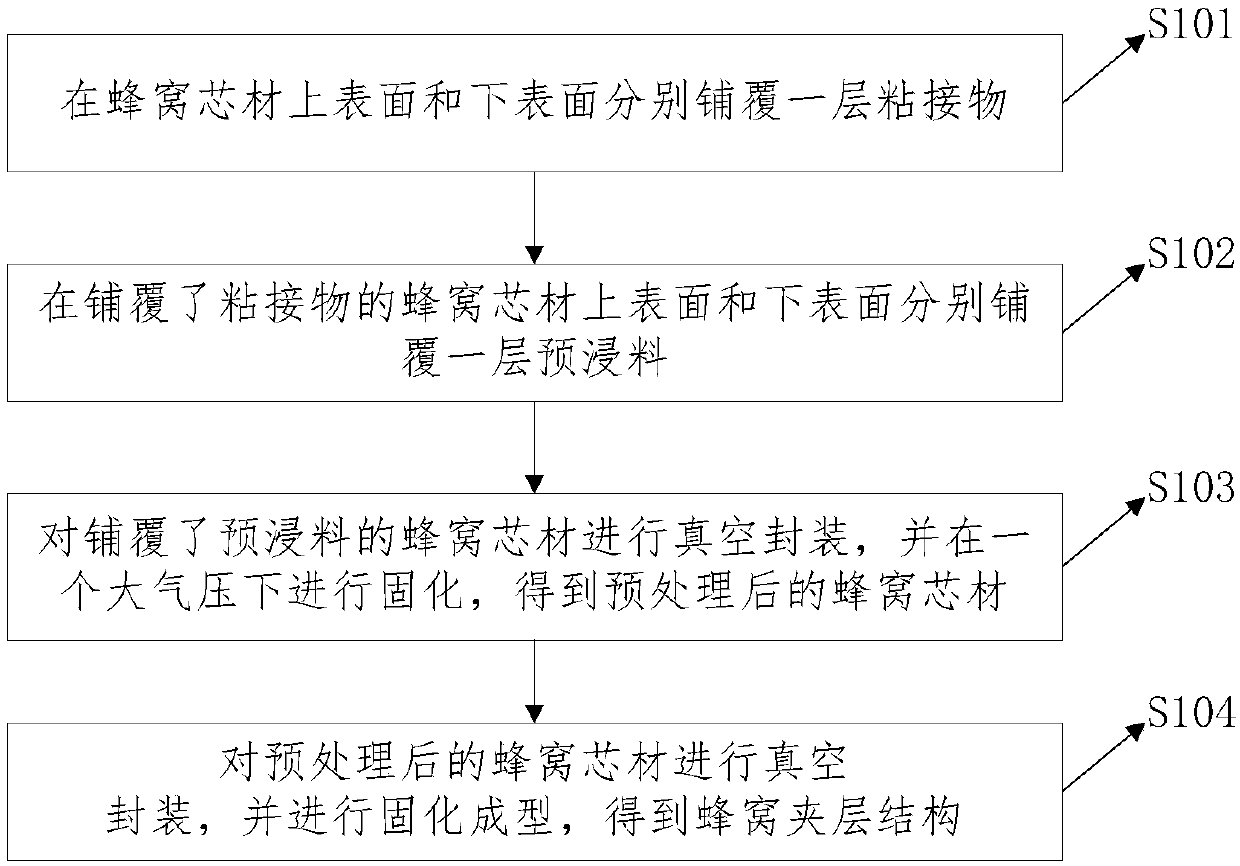

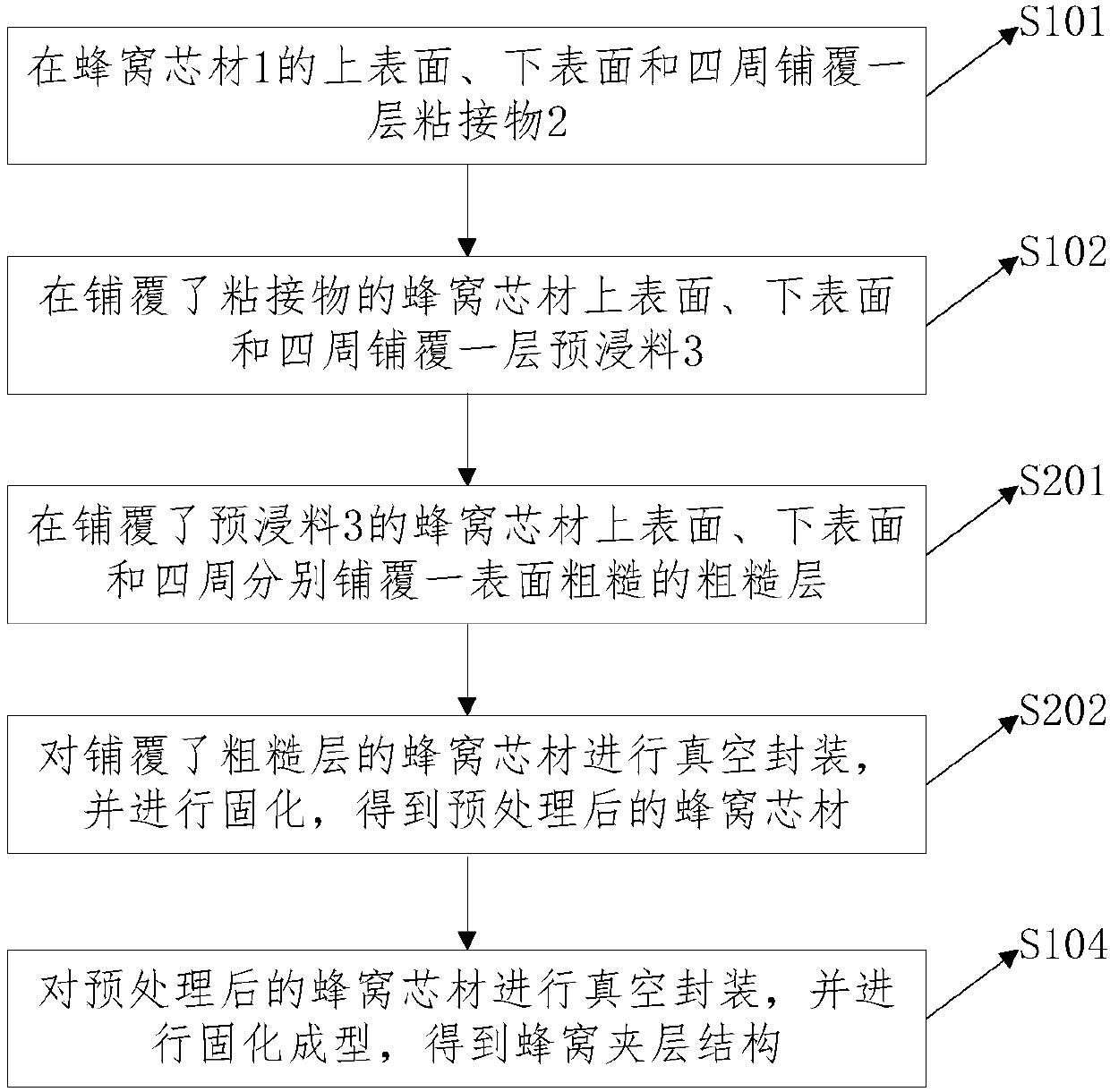

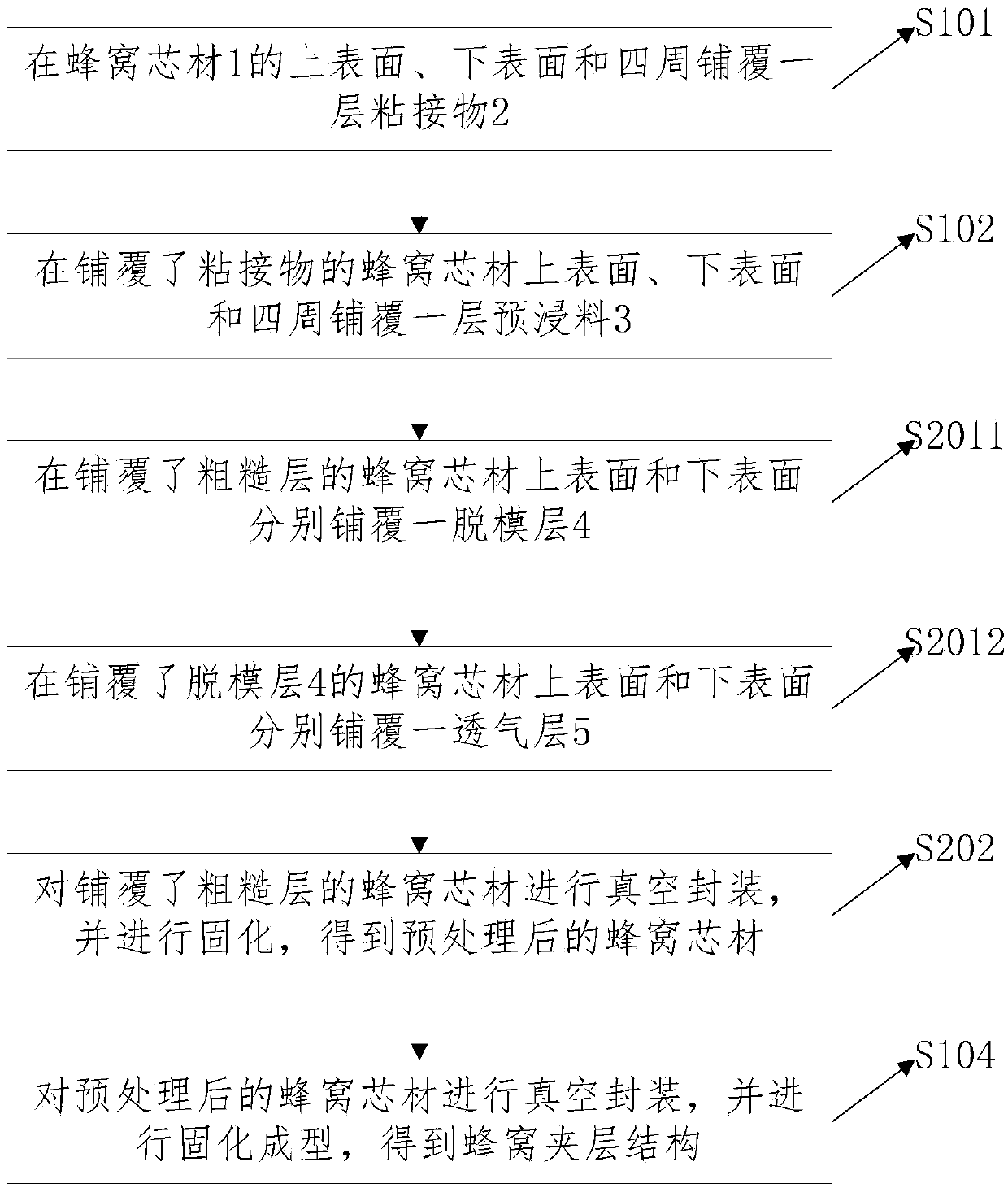

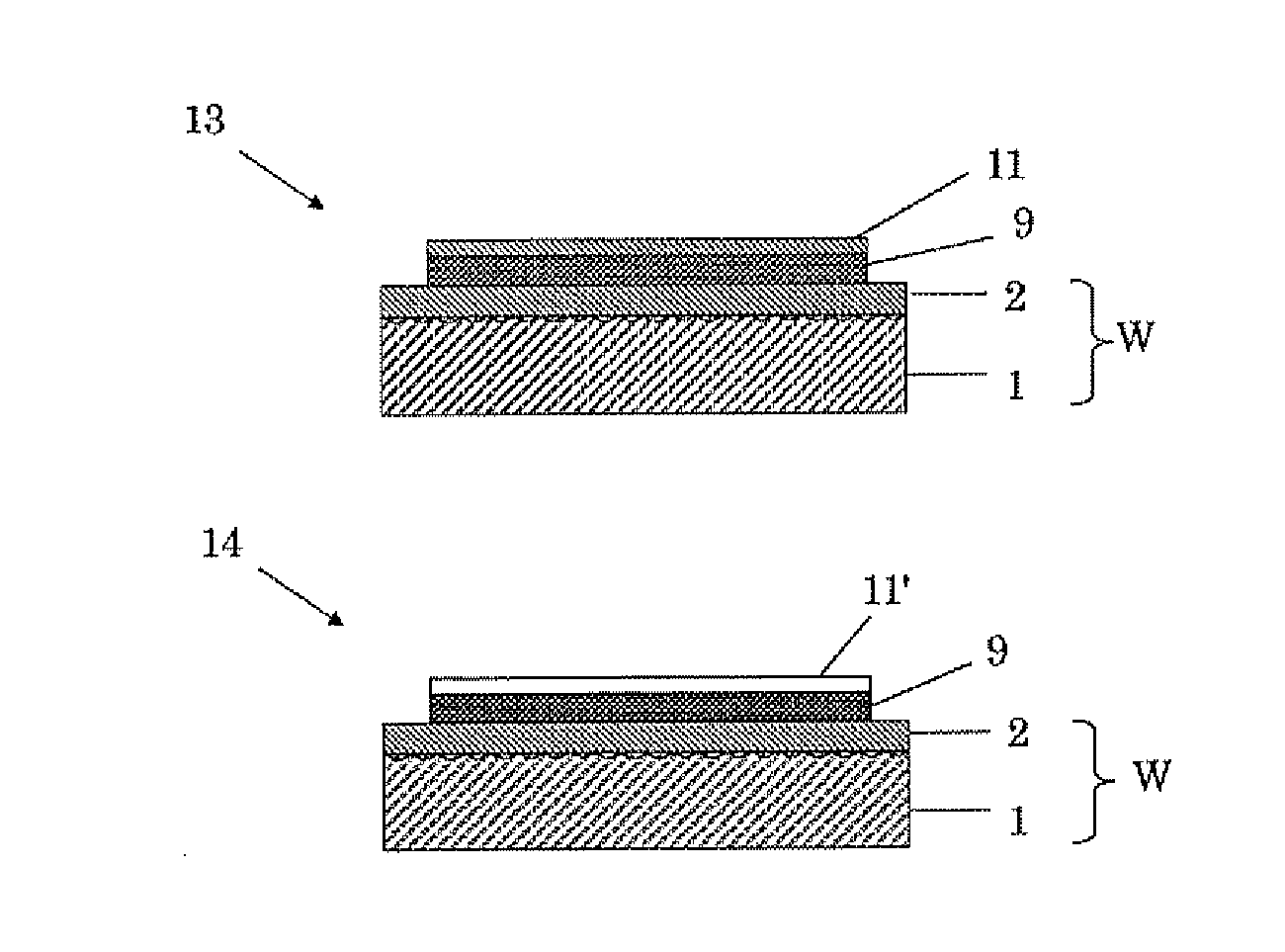

InactiveCN108045002APrevent collapseReduce manufacturing costLamination ancillary operationsSynthetic resin layered productsHoneycombAtmospheric pressure

The invention discloses a honeycomb sandwich layer structure and a preparation method thereof. The preparation method comprises the following steps of coating the upper surface and the lower surface respectively of a honeycomb core material with a layer of sticking substances; coating the upper surface and the lower surface of the honeycomb core material coated with the sticking substances with alayer of prepreg respectively; vacuumizing the honeycomb core material coated with the prepreg and curing the honeycomb core material coated with the prepreg under an atmospheric pressure to obtain the pretreated honeycomb core material; vacuumizing the pretreated honeycomb core material and curing the pretreated honeycomb core material to make the pretreated honeycomb core material shape up so asto obtain the honeycomb sandwich layer structure. The honeycomb sandwich layer structure is low in cost, and can prevent collapse of honeycomb materials.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

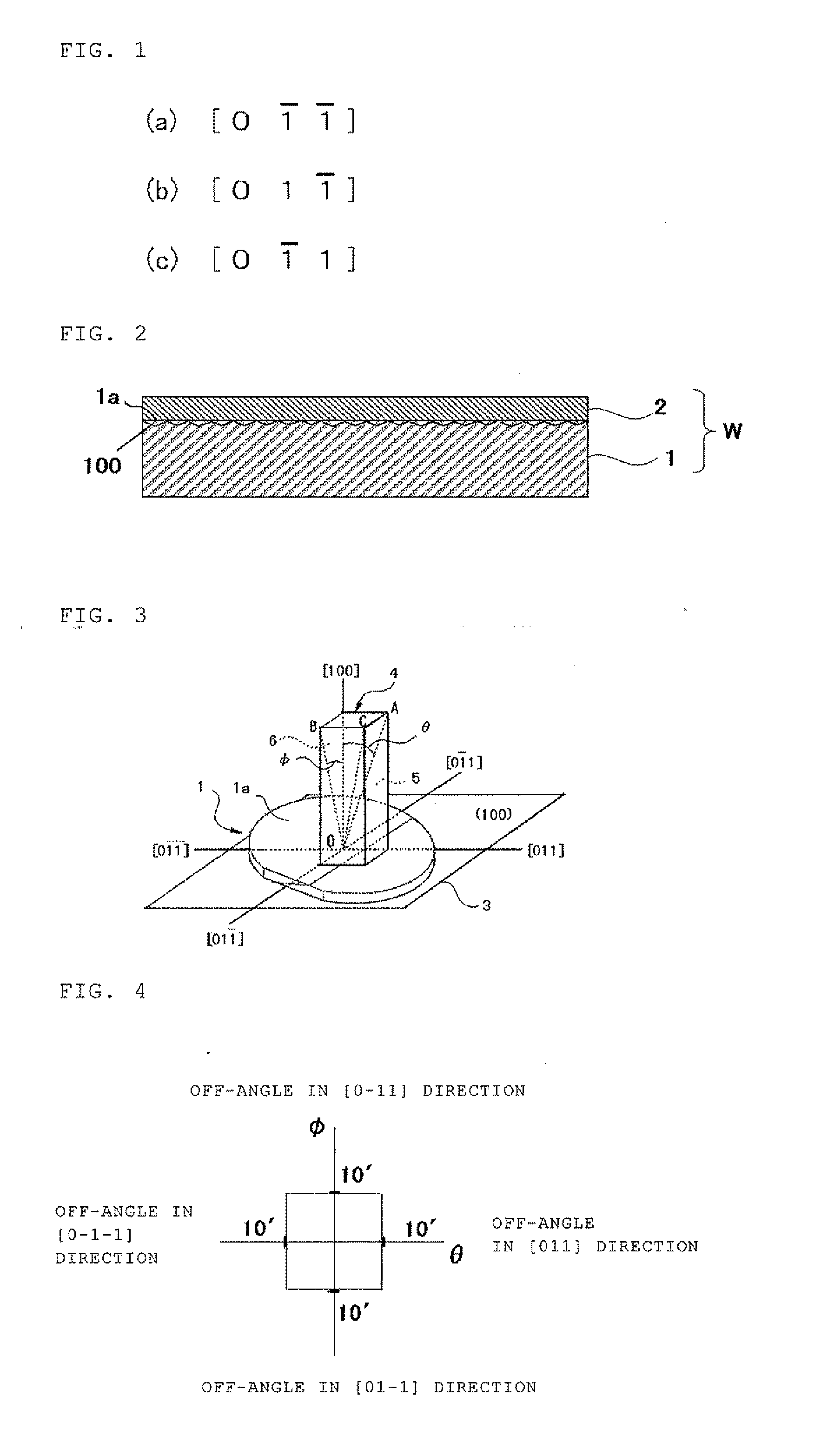

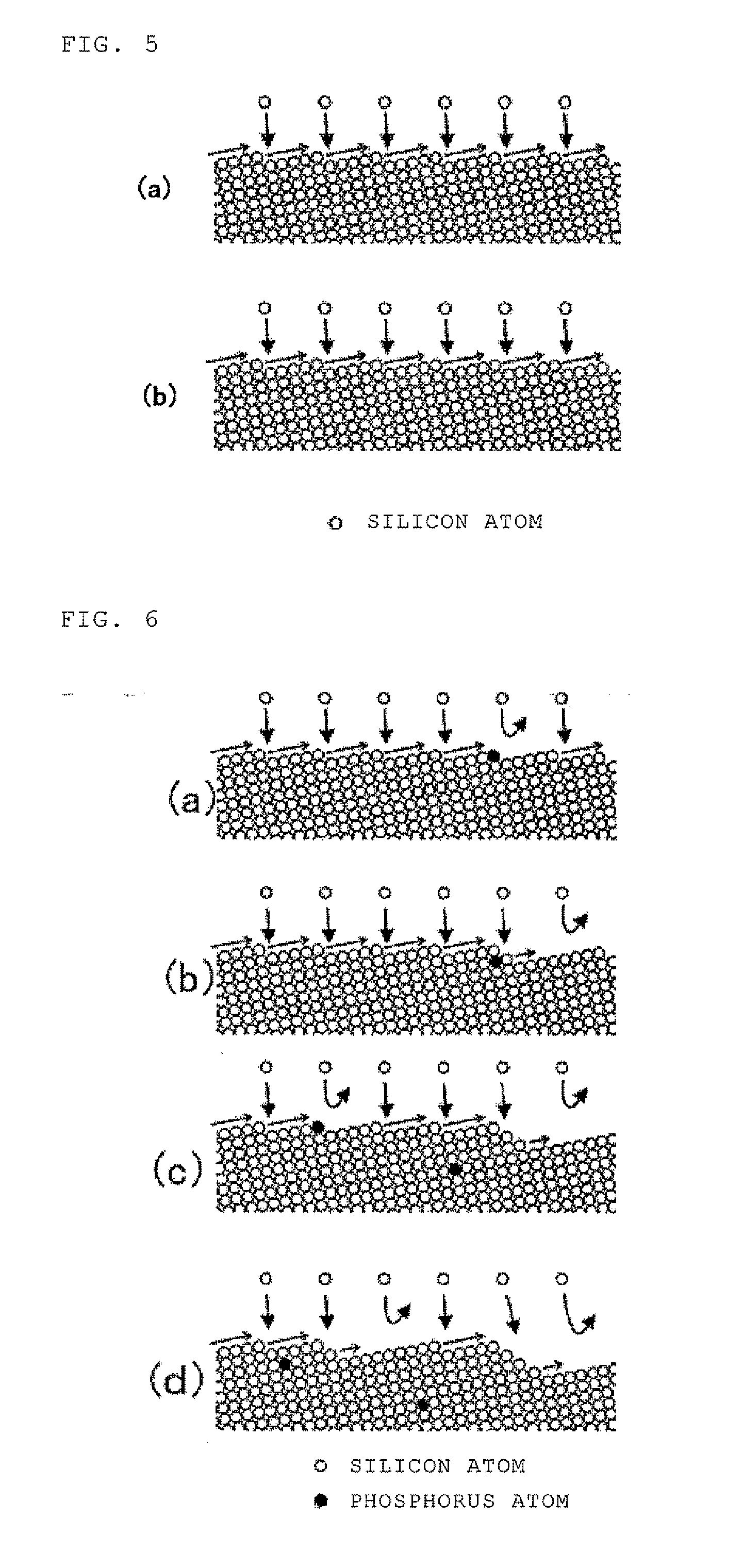

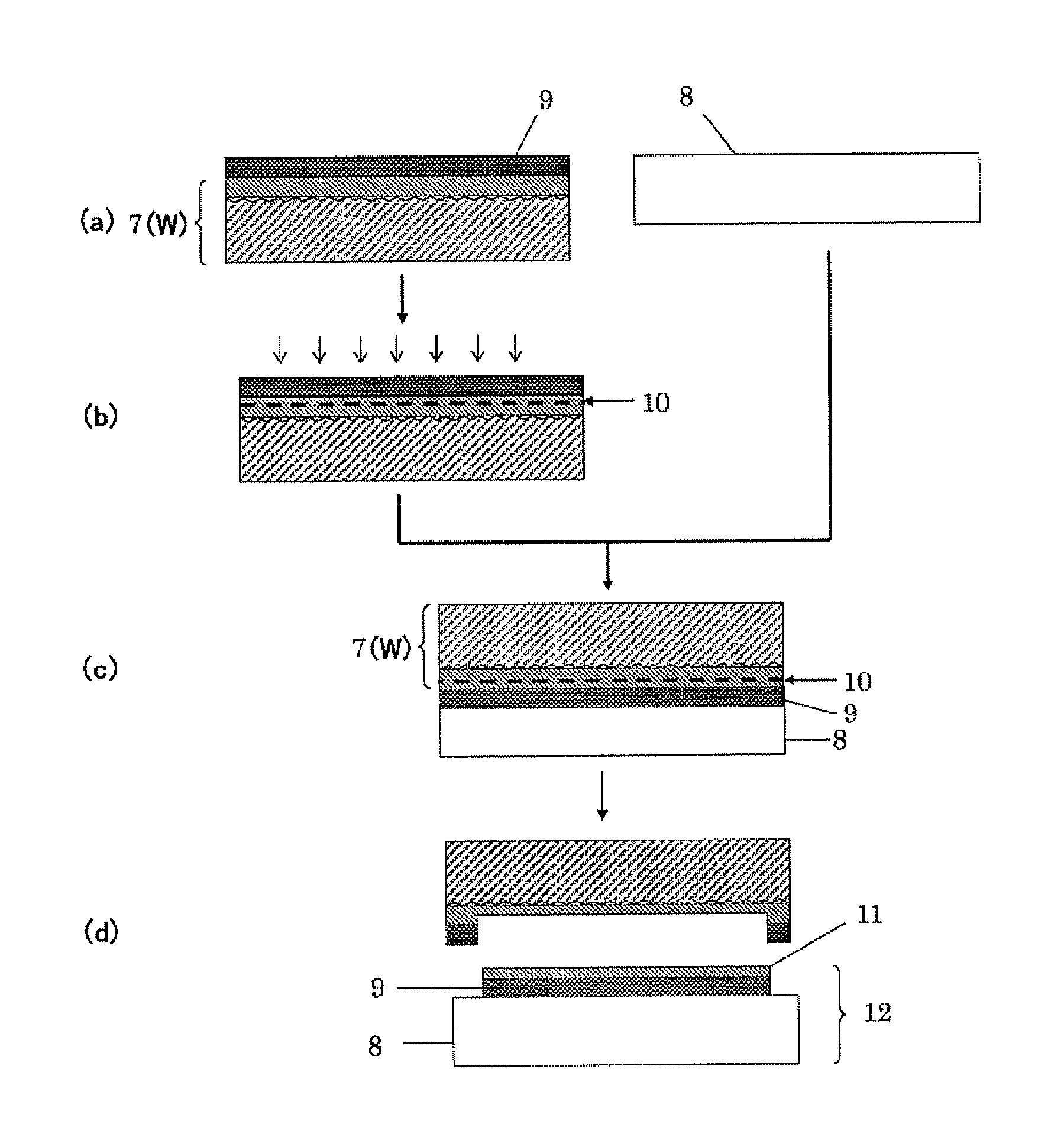

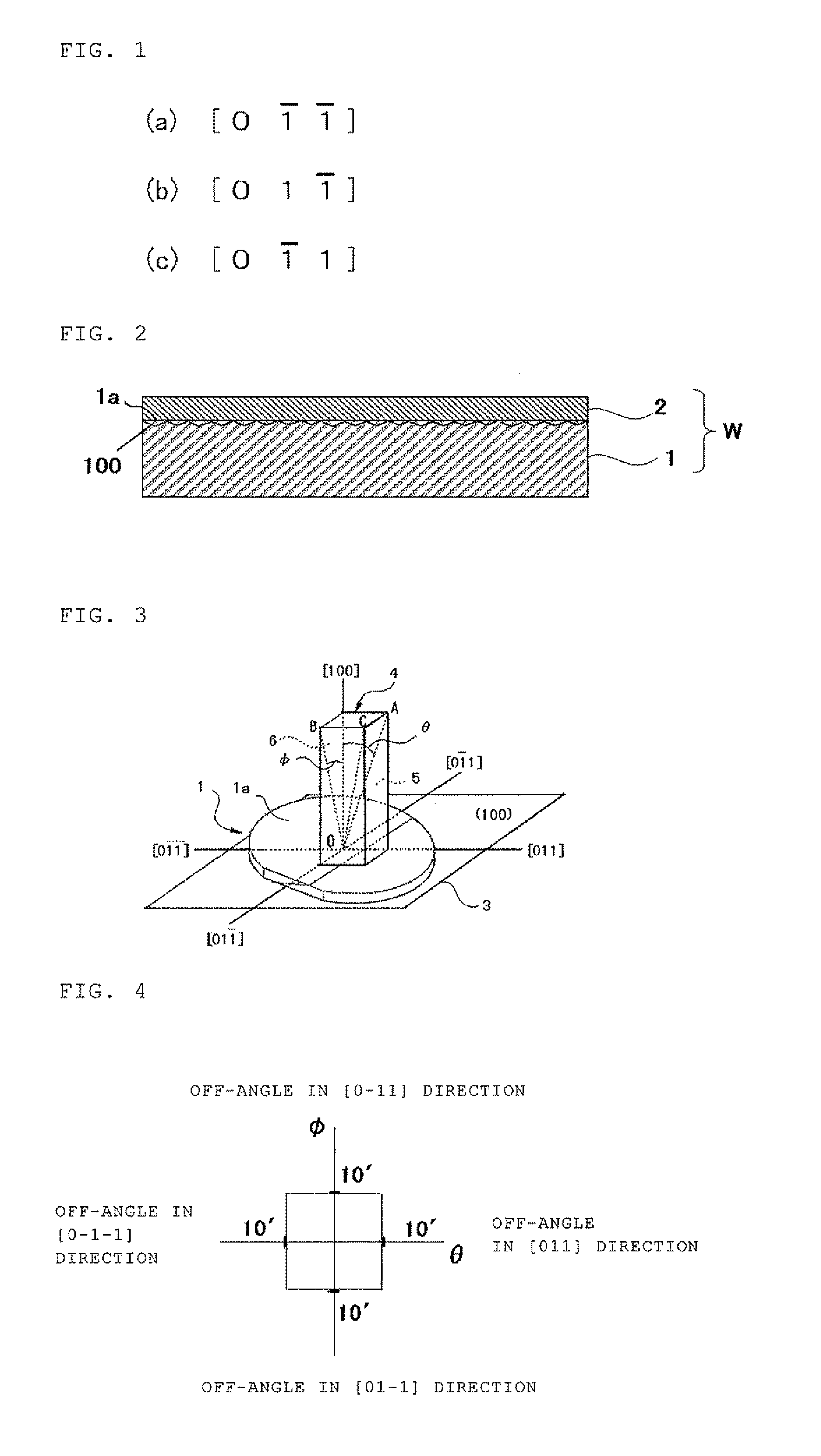

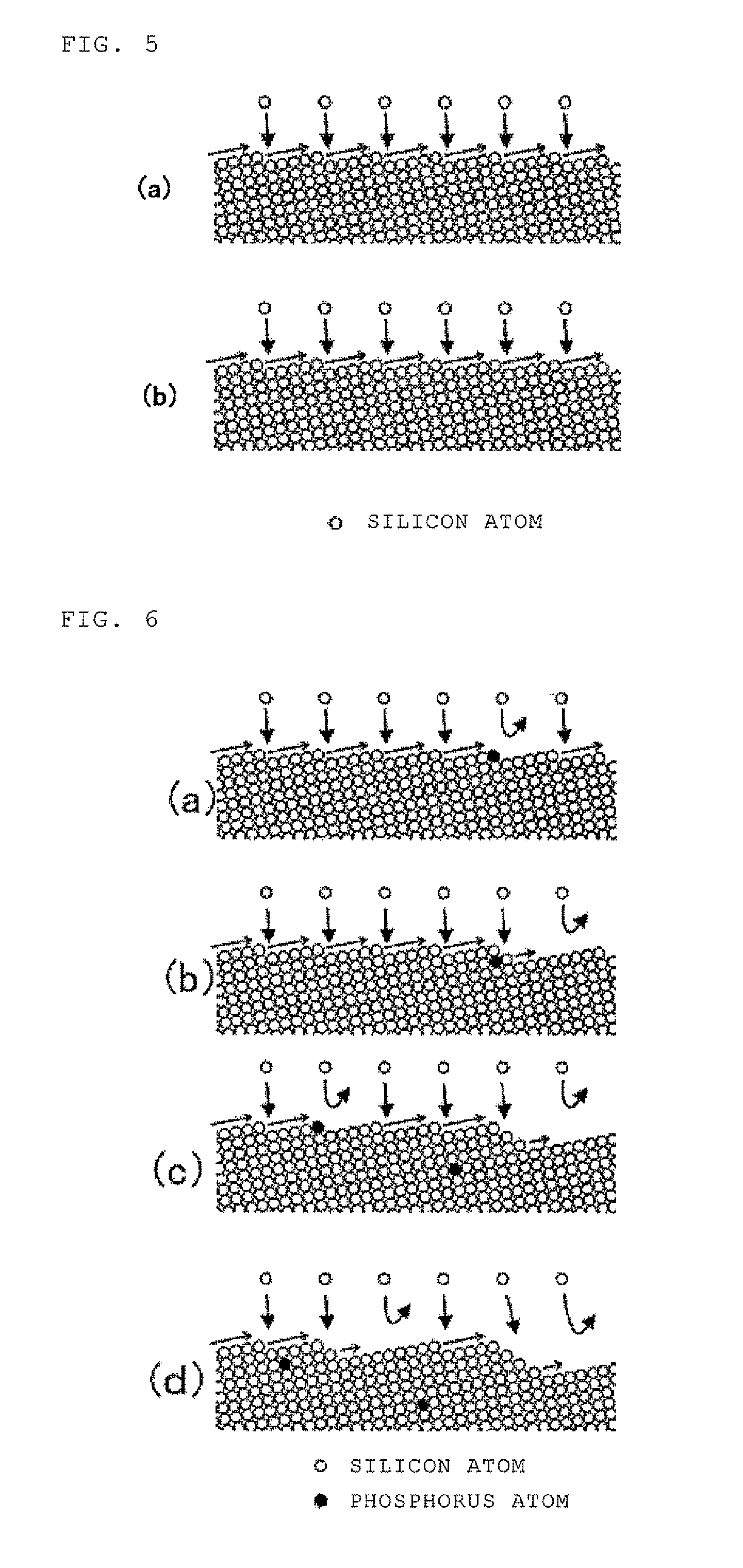

Silicon epitaxial wafer, method for manufacturing the same, bonded soi wafer and method for manufacturing the same

ActiveUS20120326268A1Quality improvementImprove bonding interfaceSemiconductor/solid-state device manufacturingSemiconductor devicesDopantSingle crystal substrate

A silicon epitaxial wafer having a silicon epitaxial layer grown by vapor phase epitaxy on a main surface of a silicon single crystal substrate, wherein the main surface of the silicon single crystal substrate is tilted with respect to a [100] axis at an angle θ in a [011] direction or a [0-1-1] direction from a (100) plane and at an angle Φ in a [01-1] direction or a [0-11] direction from the (100) plane, the angle θ and the angle Φ are less than ten minutes, and a dopant concentration of the silicon epitaxial layer is equal to or more than 1×1019 / cm3. Even when an epitaxial layer having a dopant concentration of 1×1019 / cm3 or more is formed on the main surface of the silicon single crystal substrate, stripe-shaped surface irregularities on the epitaxial layer are inhibited.

Owner:SHIN-ETSU HANDOTAI CO LTD

Wear-resistant and slip-resistant rubber and preparation method thereof

The invention discloses wear-resistant and slip-resistant rubber and a preparation method thereof. The preparation method includes the steps of firstly, using silane coupling agent to modify short fibers to obtain modified short fibers, wherein the short fibers are at least one of carbon fibers, glass fibers and basalt fibers, and the use amount of the silane coupling agent is 0.1-1.5% of the mass of the short fibers; secondly, weighing natural rubber, cis-butadiene rubber, nitrile butadiene rubber and the modified short fibers to serve as the rough blank; mixing part of the rough blank; thirdly, adding magnesium oxide, silane, stearic acid, accelerant and active agent into the rest of rough blank, and mixing with the mixed materials obtained in the second step, wherein the accelerant and the active agent are sequentially added into the rough blank; fourthly, performing vulcanization shaping on the mixed materials obtained in the third step to obtain the wear-resistant and slip-resistant rubber. The wear-resistant and slip-resistant rubber has the advantages that an outsole made of the wear-resistant and slip-resistant rubber is good in wear resistance and slip resistance, and the wear-resistant and slip-resistant rubber is suitable for being used to produce the outsole of a tennis shoe and other outsoles with high wear resistance and slip resistance requirements.

Owner:湖北福力德鞋业有限责任公司 +2

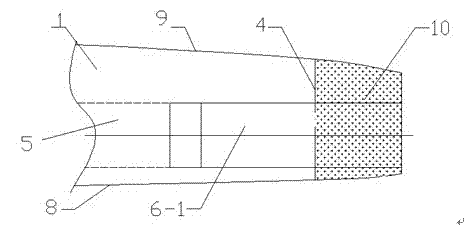

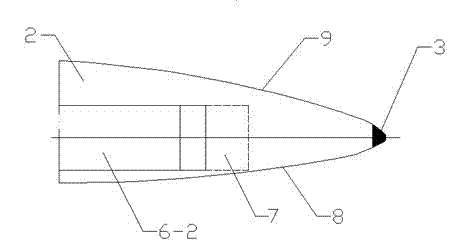

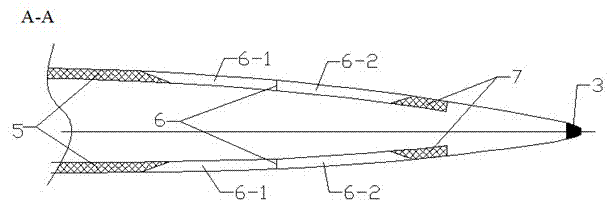

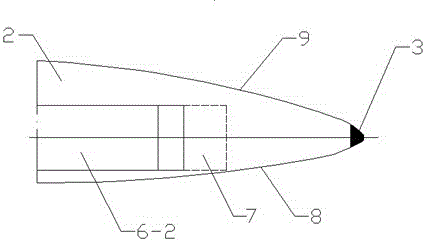

Method of beam cap connection for lengthening wind turbine generator blades

ActiveCN103573563ASafe and reliable structureImproved stiffness distributionFinal product manufactureWind energy generationClassical mechanicsStructural engineering

The invention relates to the method of beam cap connection for lengthening wind turbine generator blades. The method is particularly adopted for connecting beam caps of the blades in the lengthening and improving process of existing wind turbine generator blades. Each reinforced beam cap is manufactured in a beam cap reserved zone between one existing beam cap of one blade and the corresponding beam cap of one blade tip lengthening section, so that the problem of connection of every two existing beam caps is solved. The blades which are lengthened and improved through the method for connecting the beam caps of the wind turbine generator blades are safe and reliable in structure.

Owner:BEIJING KHANWIND TECH

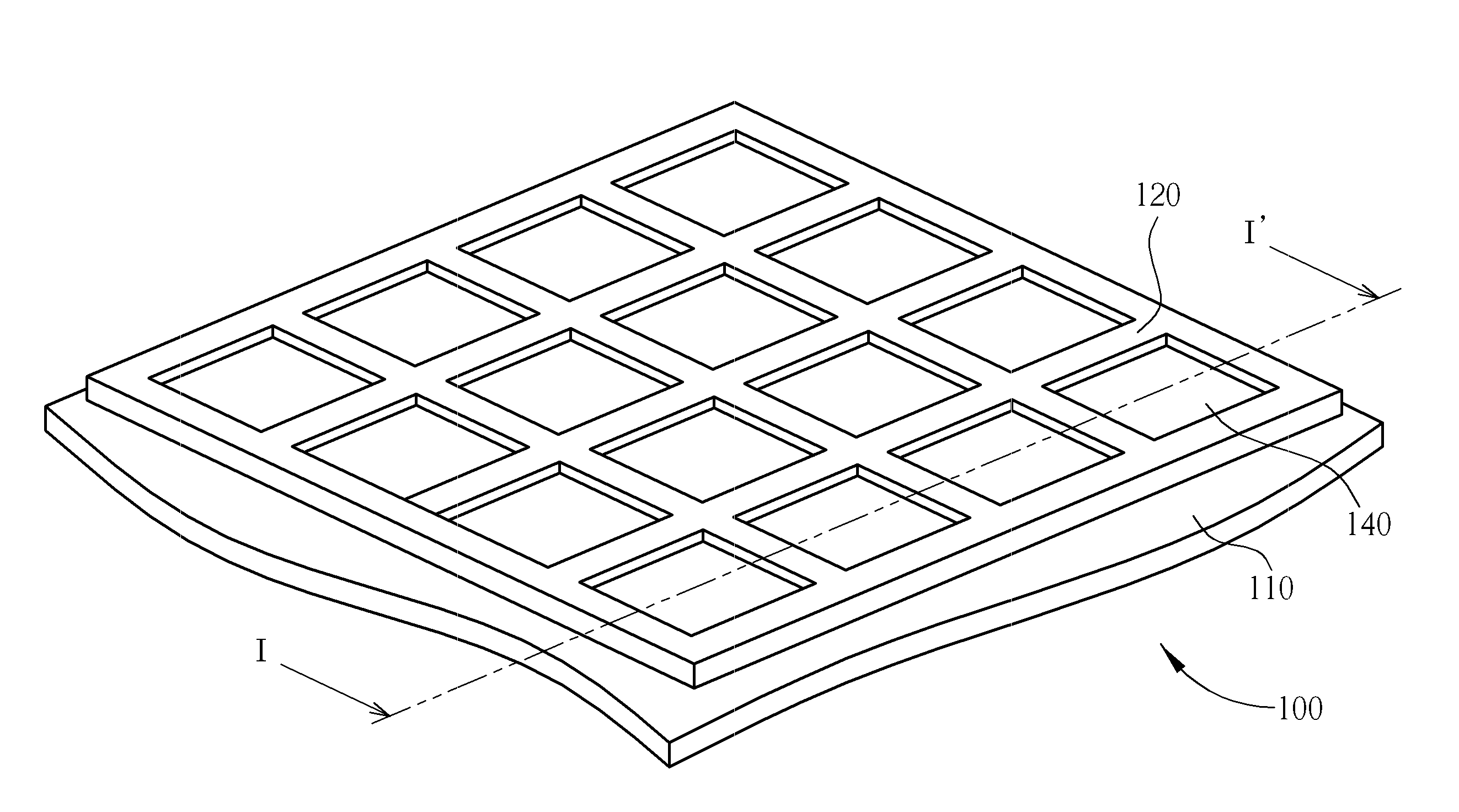

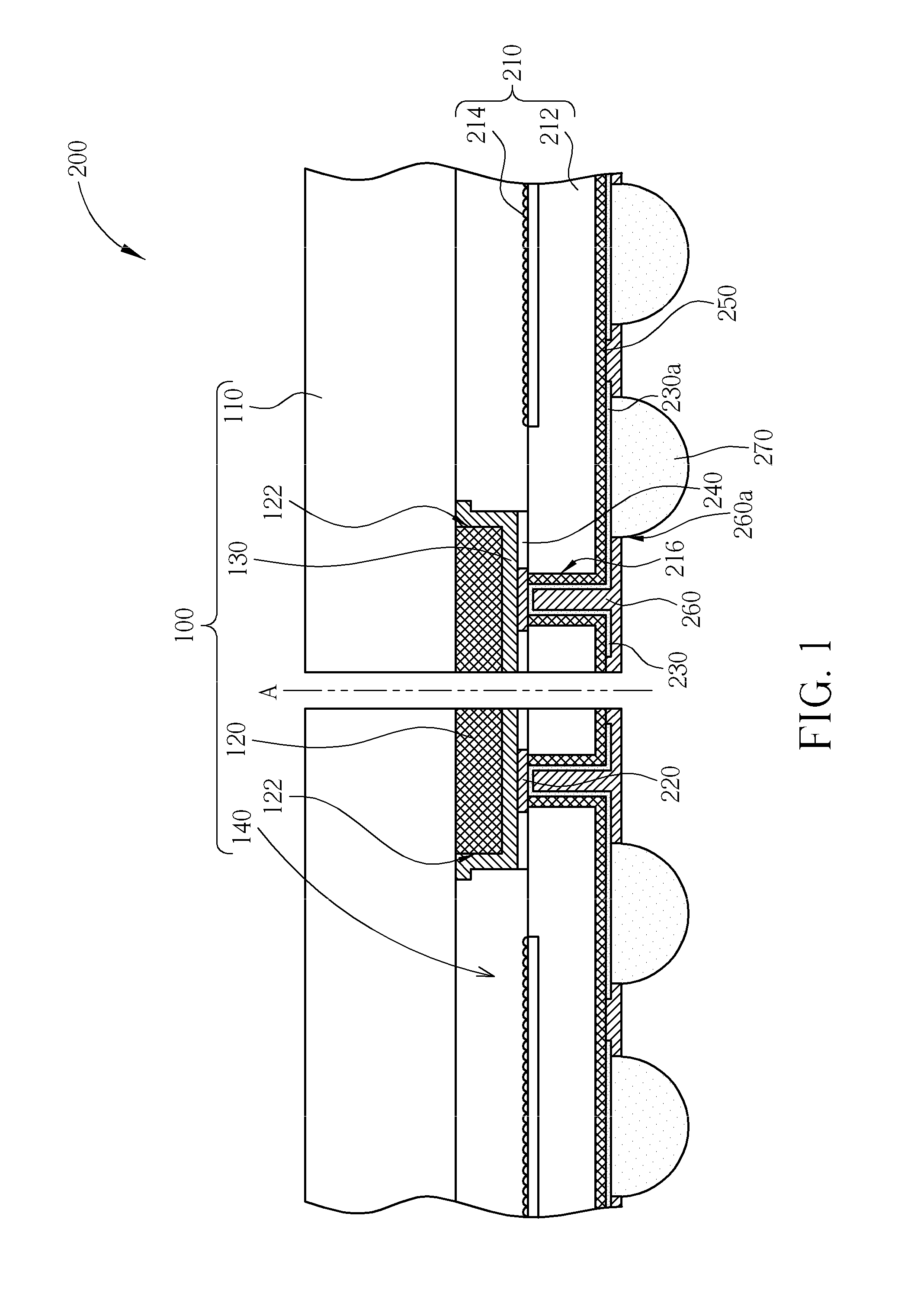

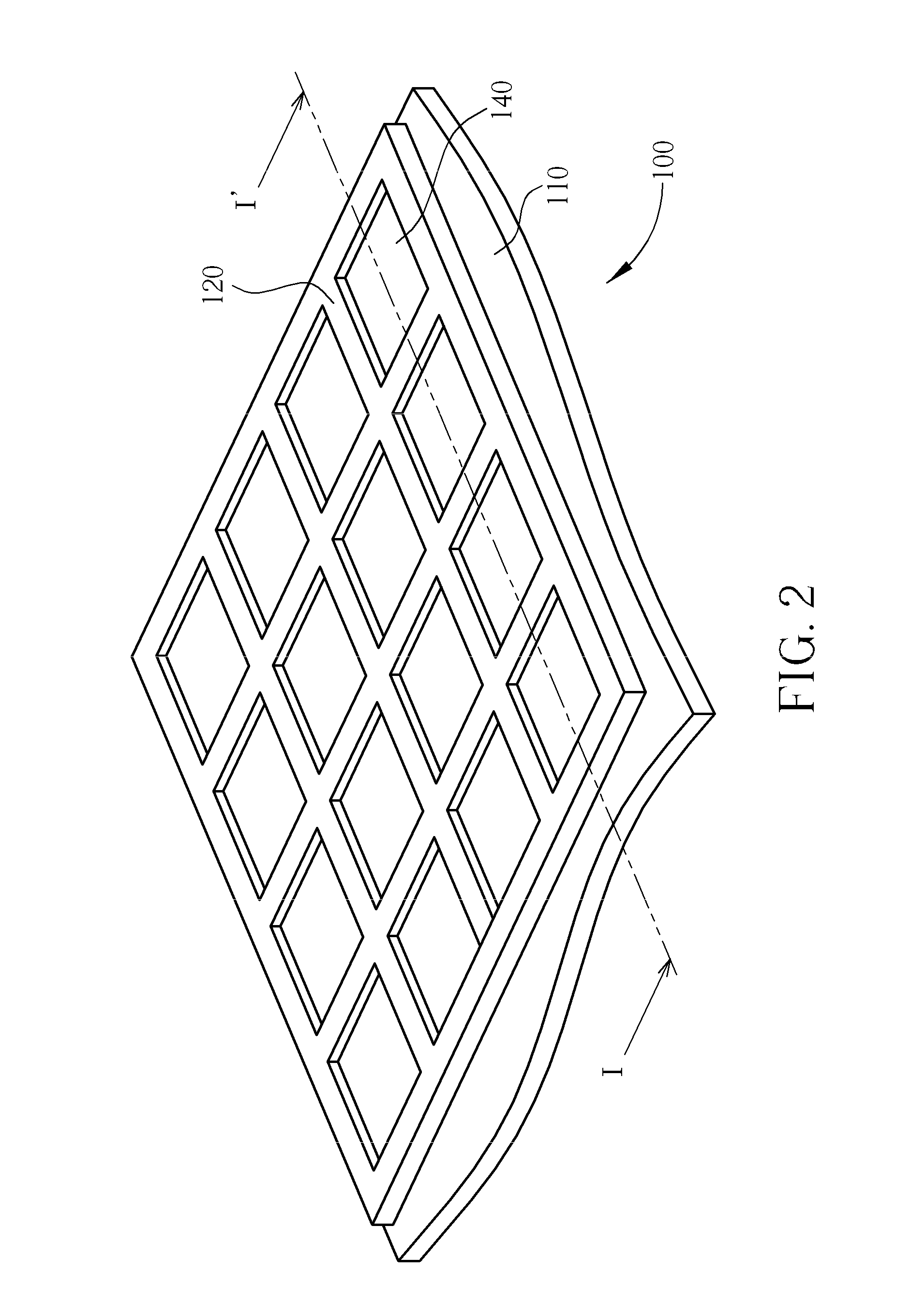

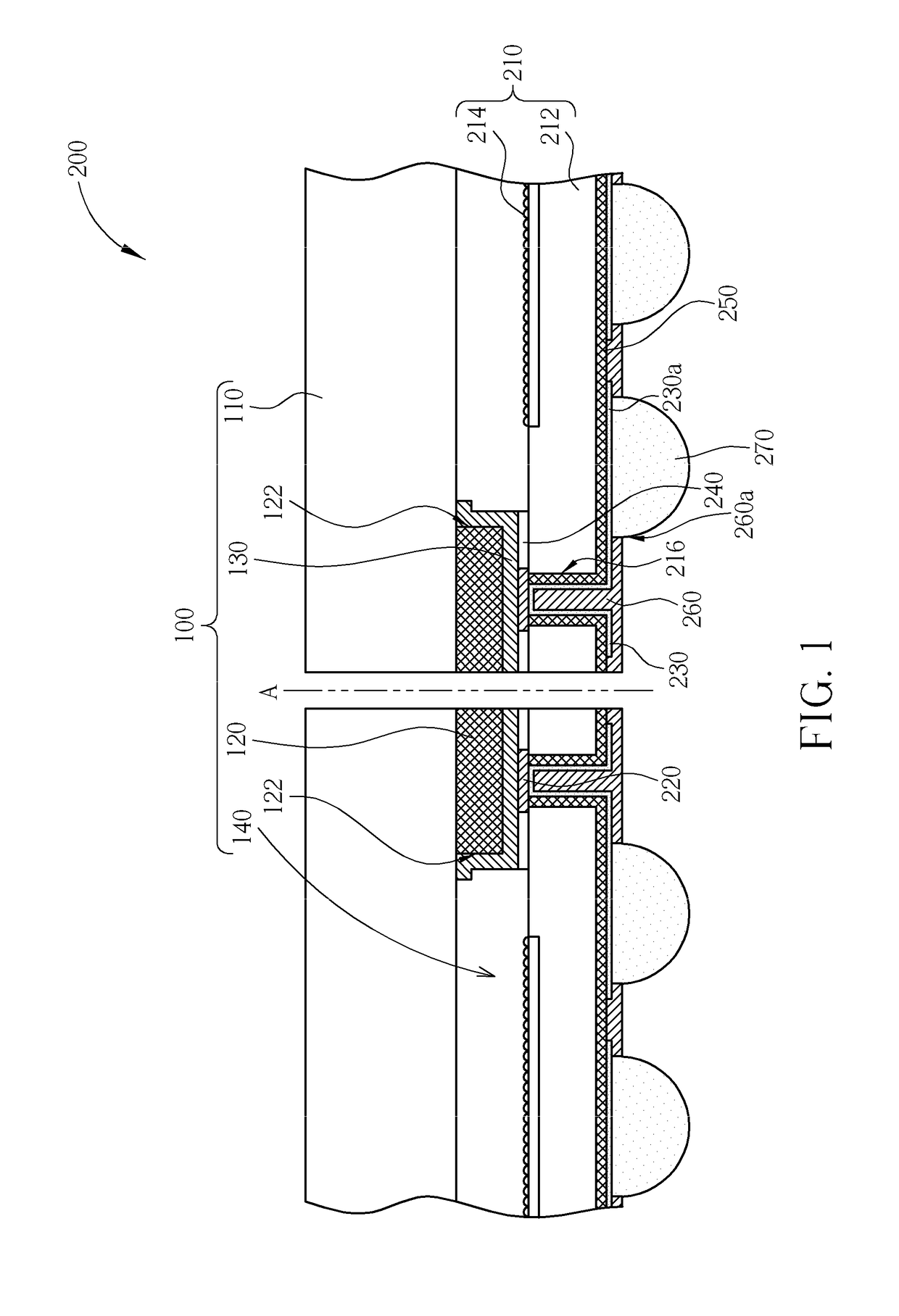

Optical cover plate with improved solder mask dam on galss for image sensor package and fabrication method thereof

ActiveUS20110228390A1Improve reliabilityImprove image qualitySemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

An optical cover plate for image sensor package includes a transparent substrate, at least an annular dam structure, and a barrier layer. The annular dam structure is disposed on the transparent substrate and encompasses a light-receiving area. The barrier layer conformally covers at least a sidewall of the annular dam structure. A method of manufacturing the optical cover plate, an image sensor package and fabrication method thereof are also disclosed.

Owner:XINTEC INC

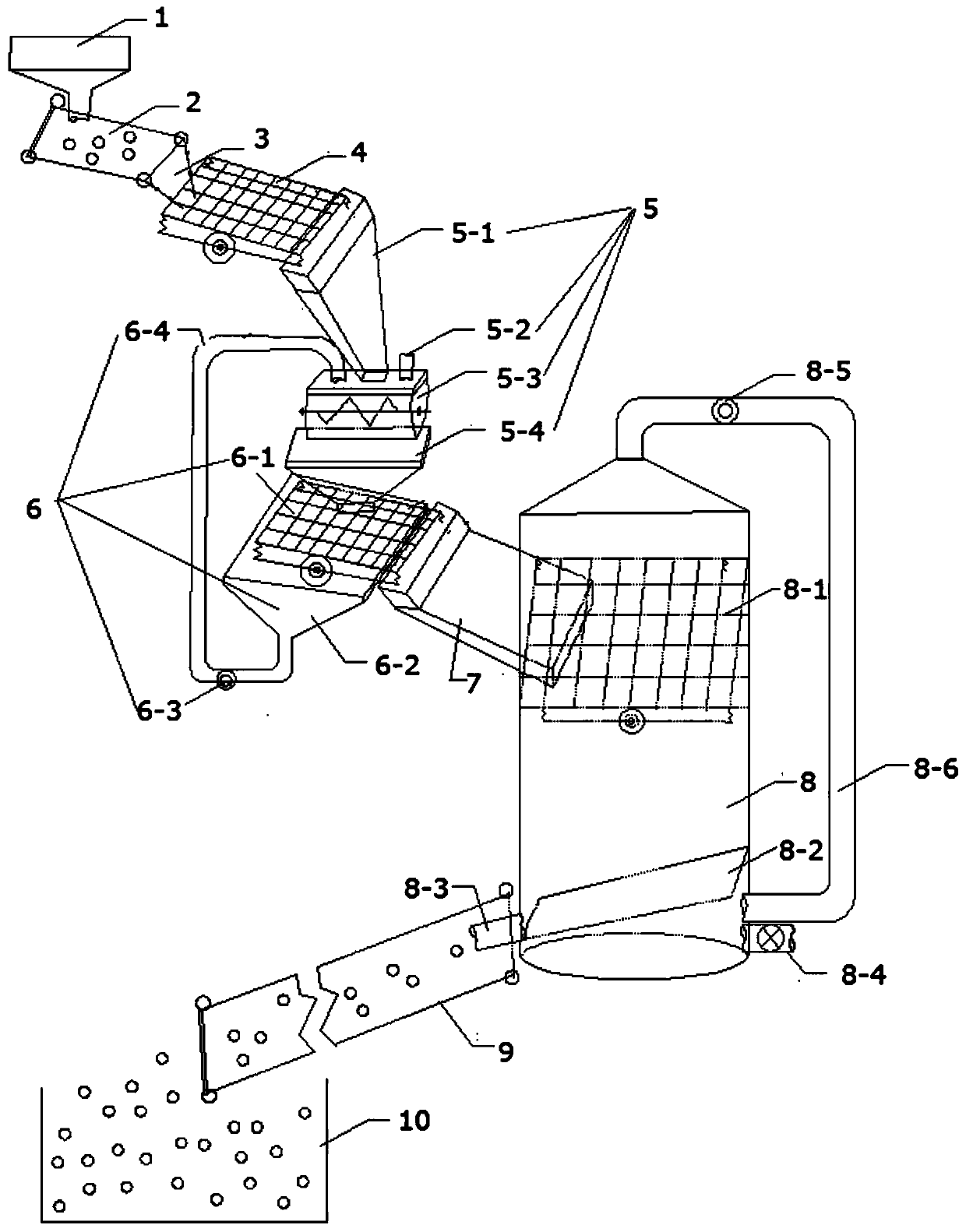

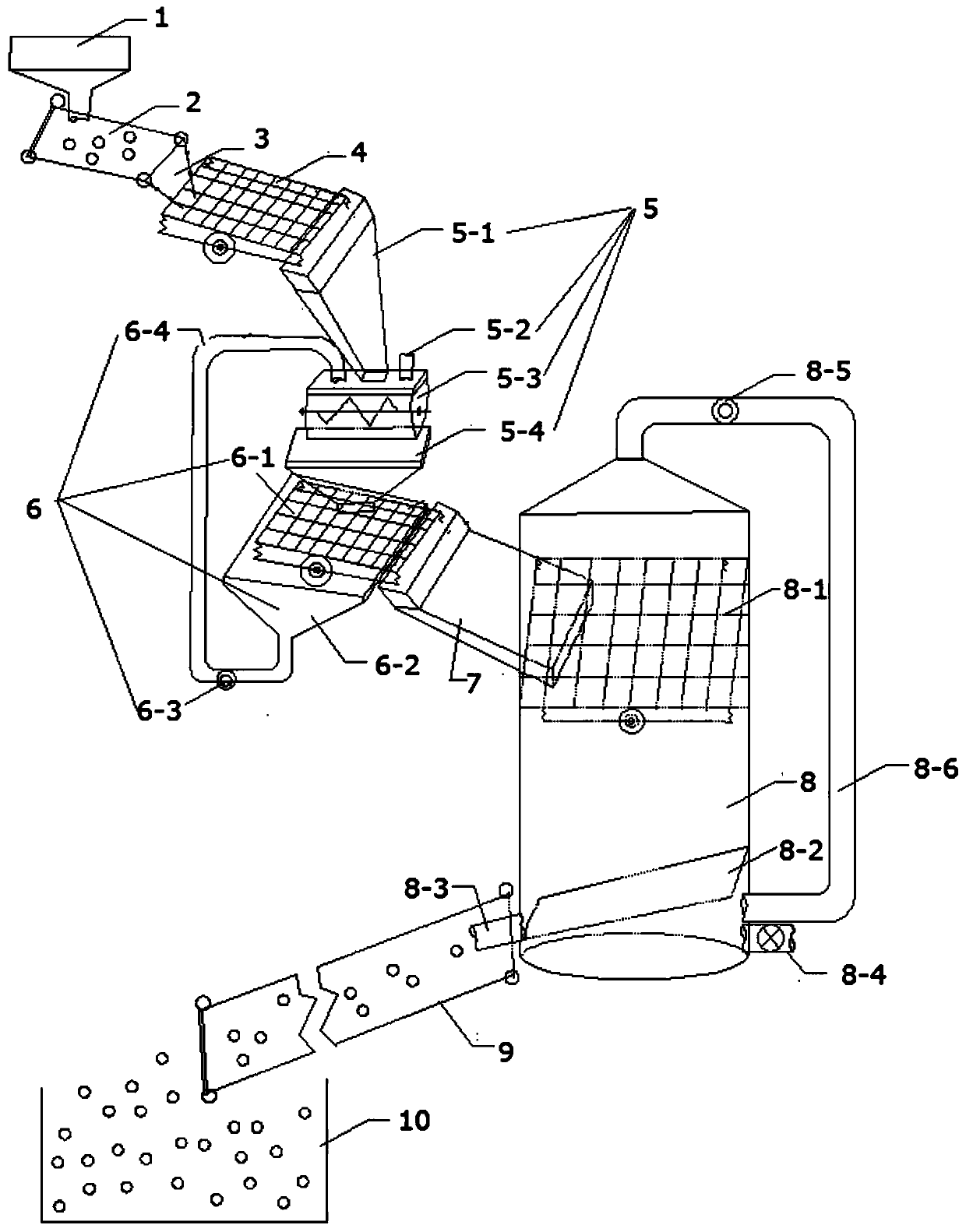

Aggregate surface strengthening method and equipment

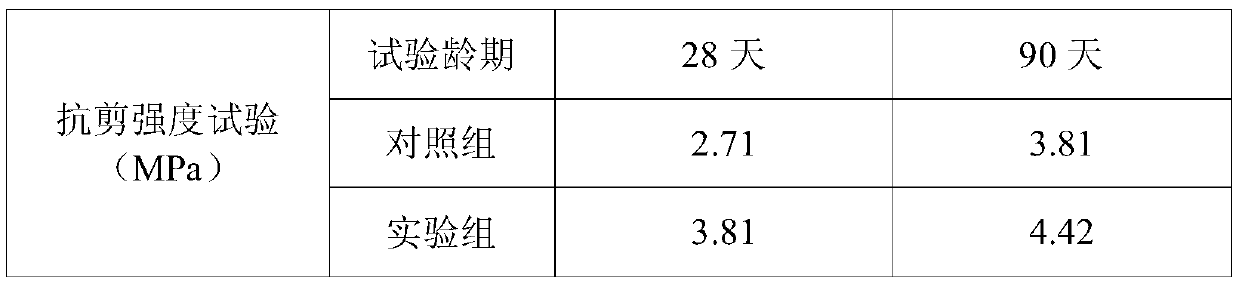

InactiveCN111116075AImprove bonding interfaceSurface enhancement achievedSolid waste managementAluminateCellulose

The invention provides an aggregate surface strengthening method and equipment, and belongs to the technical field of aggregate strengthening. The aggregate surface strengthening method provided by the invention comprises the following steps: sequentially carrying out shaping treatment, wetting treatment and first screening treatment on aggregate, then mixing the aggregate with aluminate cement slurry, and then sequentially carrying out second screening treatment, third screening treatment and maintenance treatment. The aluminate cement slurry (with the mass ratio of aluminate cement to waterto the polycarboxylate superplasticizer to hydroxypropyl methyl cellulose is 1: (0.20-0.6): (0.002-0.20): (0.002-0.004)) with specific composition is adopted to wrap the aggregate, so that the strength of the aggregate is improved, and the second screening treatment, the third screening treatment and the maintenance are controlled, so that the surface strengthening of the macropore (with the sizeof greater than or equal to 0.1 mm) and porous aggregate(with the porosity is greater than or equal to 30%) is realized. The method and equipment are suitable for mass production.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

Silicon epitaxial wafer, method for manufacturing the same, bonded SOI wafer and method for manufacturing the same

ActiveUS8823130B2Quality improvementImprove bonding interfaceTransistorSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A silicon epitaxial wafer having a silicon epitaxial layer grown by vapor phase epitaxy on a main surface of a silicon single crystal substrate, wherein the main surface of the silicon single crystal substrate is tilted with respect to a [100] axis at an angle θ in a [011] direction or a [0-1-1] direction from a (100) plane and at an angle φ in a [01-1] direction or a [0-11] direction from the (100) plane, the angle θ and the angle φ are less than ten minutes, and a dopant concentration of the silicon epitaxial layer is equal to or more than 1×1019 / cm3. Even when an epitaxial layer having a dopant concentration of 1×1019 / cm3 or more is formed on the main surface of the silicon single crystal substrate, stripe-shaped surface irregularities on the epitaxial layer are inhibited.

Owner:SHIN-ETSU HANDOTAI CO LTD

Rubber recycled concrete and preparation method thereof

InactiveCN113072336AWith high elasticityLow elastic modulusSolid waste managementRiver sandChemistry

The invention relates to rubber recycled concrete and a preparation method thereof. The mass ratio of cement to natural coarse aggregate to recycled coarse aggregate to natural fine aggregate to recycled fine aggregate to water to rubber powder to nano silicon dioxide to a polycarboxylic acid water reducing agent is 1: (2.03-2.12): (0.87-0.91): (1.04-1.14): (0.47-0.49): (0.46-0.52): (0.011-0.057): (0.005-0.031): (0.011-0.026), the water-binder ratio of the rubber recycled concrete is 1: (2-2.17), the recycled fine aggregate and the recycled coarse aggregate are waste gas concrete, the natural fine aggregate is natural river sand, the natural coarse aggregate is limestone gravel, the particle size of the recycled fine aggregate is 0.075-4.75 mm, the particle size of the recycled coarse aggregate is 5-20 mm, the particle size of the natural fine aggregate is 0.075-4.75 mm, and the particle size of the natural coarse aggregate is 5-25 mm. According to the rubber recycled concrete disclosed by the invention, waste gas concrete and rubber can be utilized, the rubber recycled concrete has excellent mechanical properties, and the problem of poor compression resistance of recycled concrete in the prior art is solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Polycrystalline silicon reactor

ActiveUS8703248B2Increase surface areaImprove bonding interfaceDielectric heatingInduction heatingGas supplyAtmosphere

A polycrystalline silicon reactor which can prevent polycrystalline silicon which deposits on the surface of an electrode holding a silicon seed rod from being peeled off is provided. In a polycrystalline silicon reactor which applies an electric current to a silicon seed rod provided within a furnace, thereby heating the silicon seed rod, brings a source gas supplied into the furnace into reaction, and deposits polycrystalline silicon on the surface of the silicon seed rod, the reactor includes, at a bottom plate of the furnace, an electrode holder provided so as to be electrically insulated from the bottom plate, and a seed rod holding electrode connected to the electrode holder, and holding the silicon seed rod toward the upside. Concavo-convex portions exposed to a furnace atmosphere is provided at an outer peripheral surface of the seed rod holding electrode.

Owner:HIGH-PURITY SILICON CORP

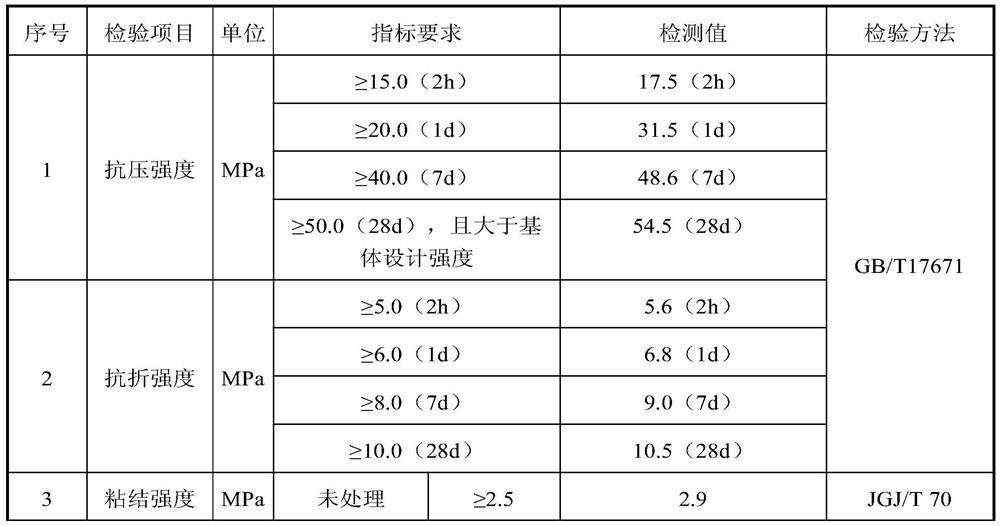

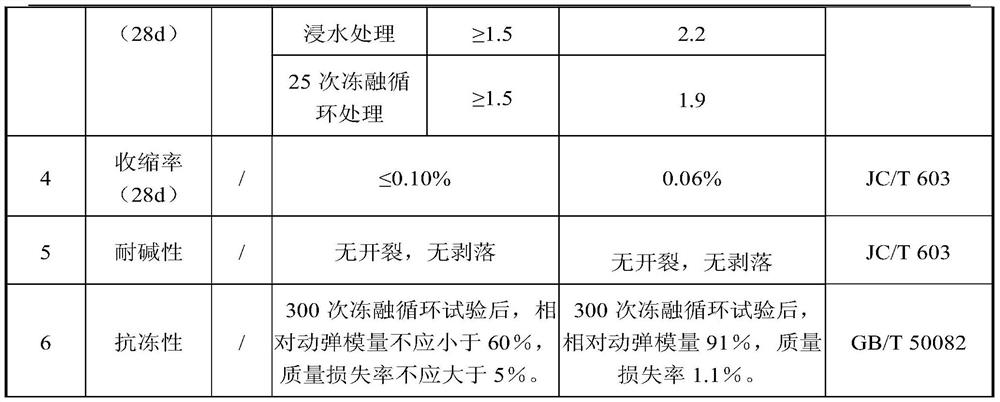

Repair mortar, and preparation method and construction method thereof

ActiveCN111517745AImprove thixotropyLow costSolid waste managementBuilding repairsFiberPolymer science

The invention provides repair mortar, and a preparation method and a construction method thereof. The repair mortar comprises the following raw materials: Portland cement, an expanding agent, a polymer emulsion, a viscosity modifier, water, a powder water reducing agent, composite fibers, super absorbent resin and sand. The preparation method comprises the following steps: S1, uniformly mixing wollastonite acicular powder, potassium feldspar powder and the polymer emulsion to prepare a mixture A; S2, uniformly mixing the Portland cement, magnesium oxide, a viscosity modifier, the powder waterreducing agent, the composite fibers, the super absorbent resin and the sand to obtain a mixture B; and S3, uniformly mixing water with the mixture A and the mixture B to prepare the repair mortar. The construction method comprises the following steps: step W1, pretreating a construction surface of a concrete matrix to be repaired; and step W2, directly molding the repair mortar prepared in the step S3 on a pretreated construction surface. The repair mortar provided by the invention has good thixotropy.

Owner:NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR +1

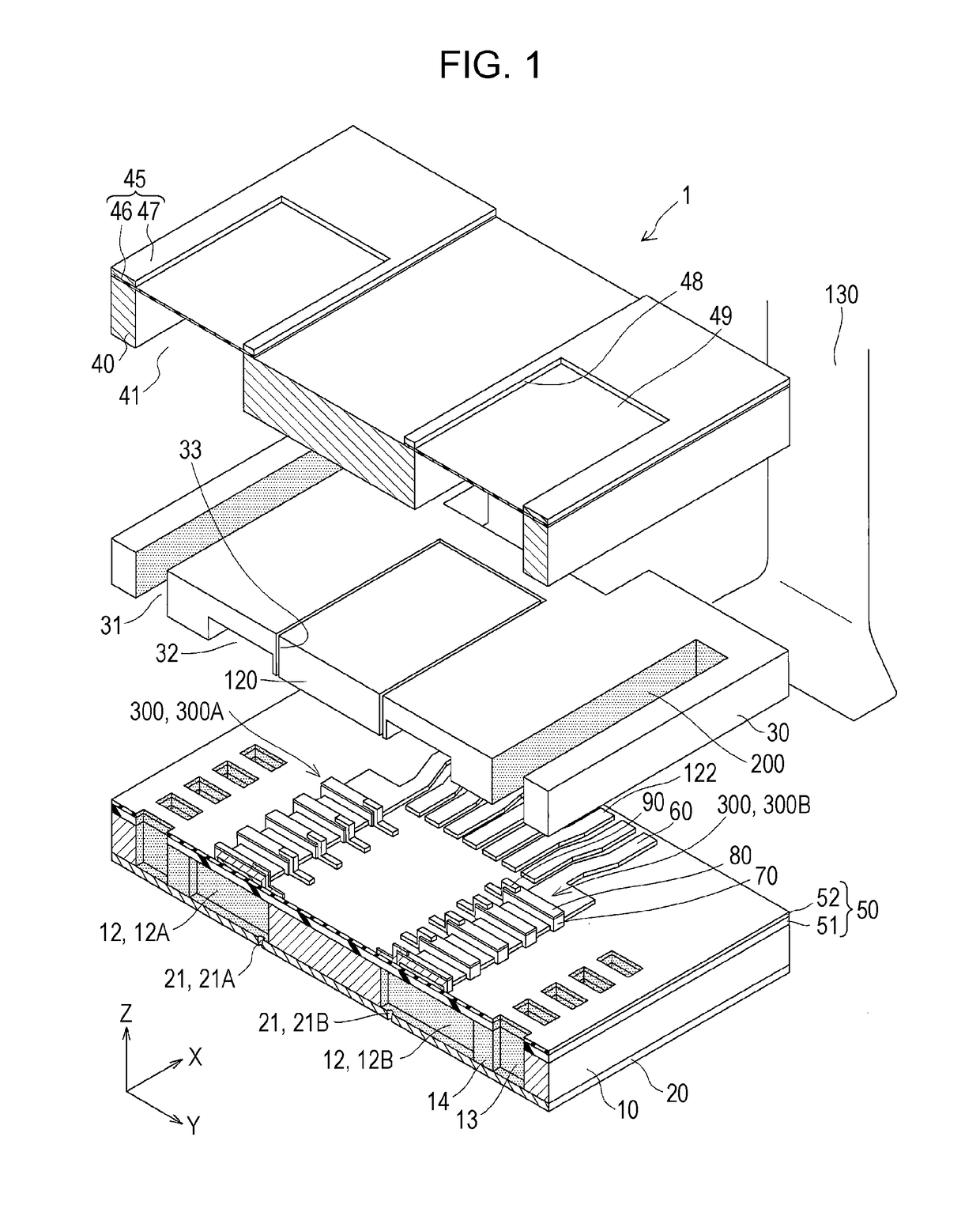

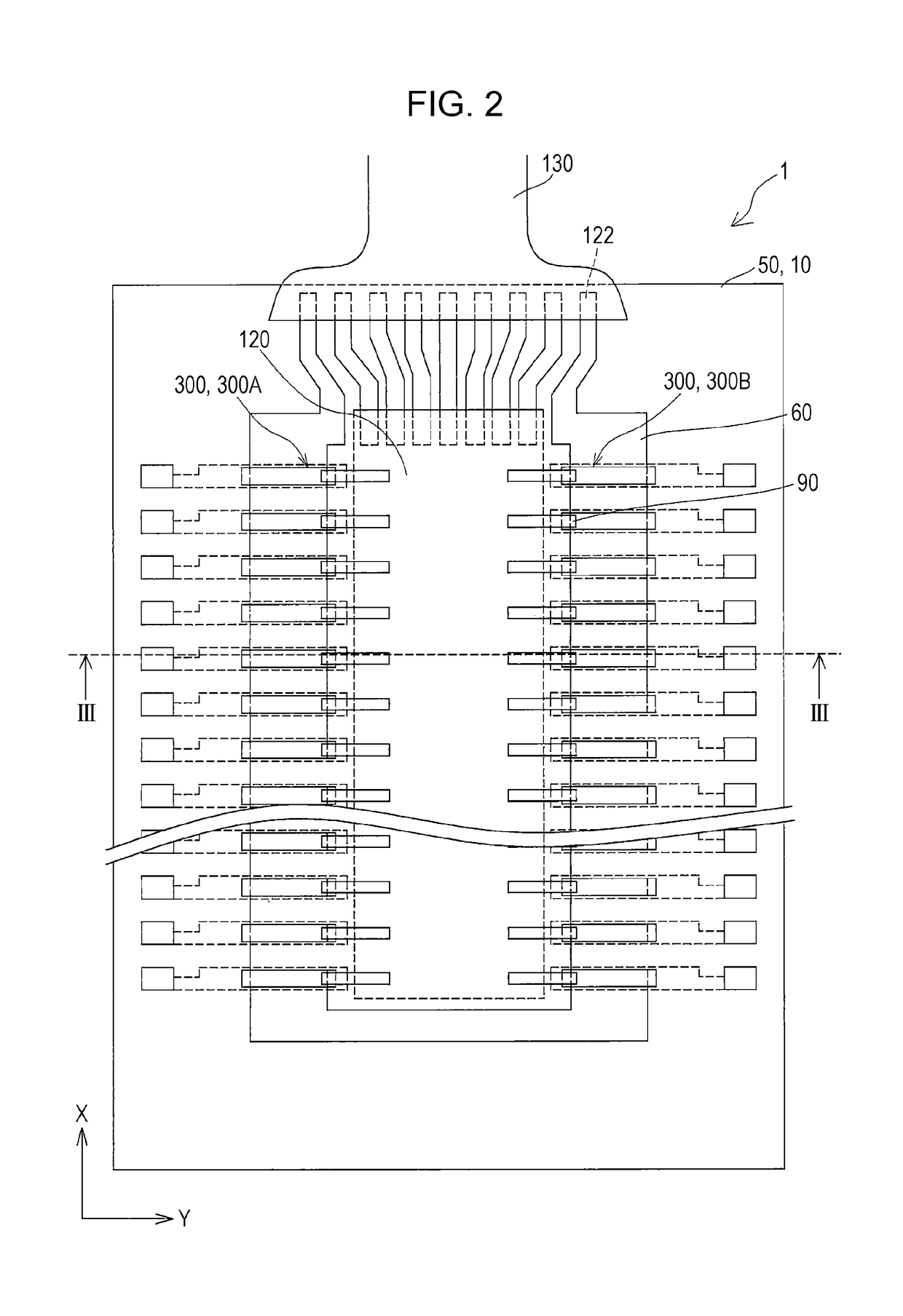

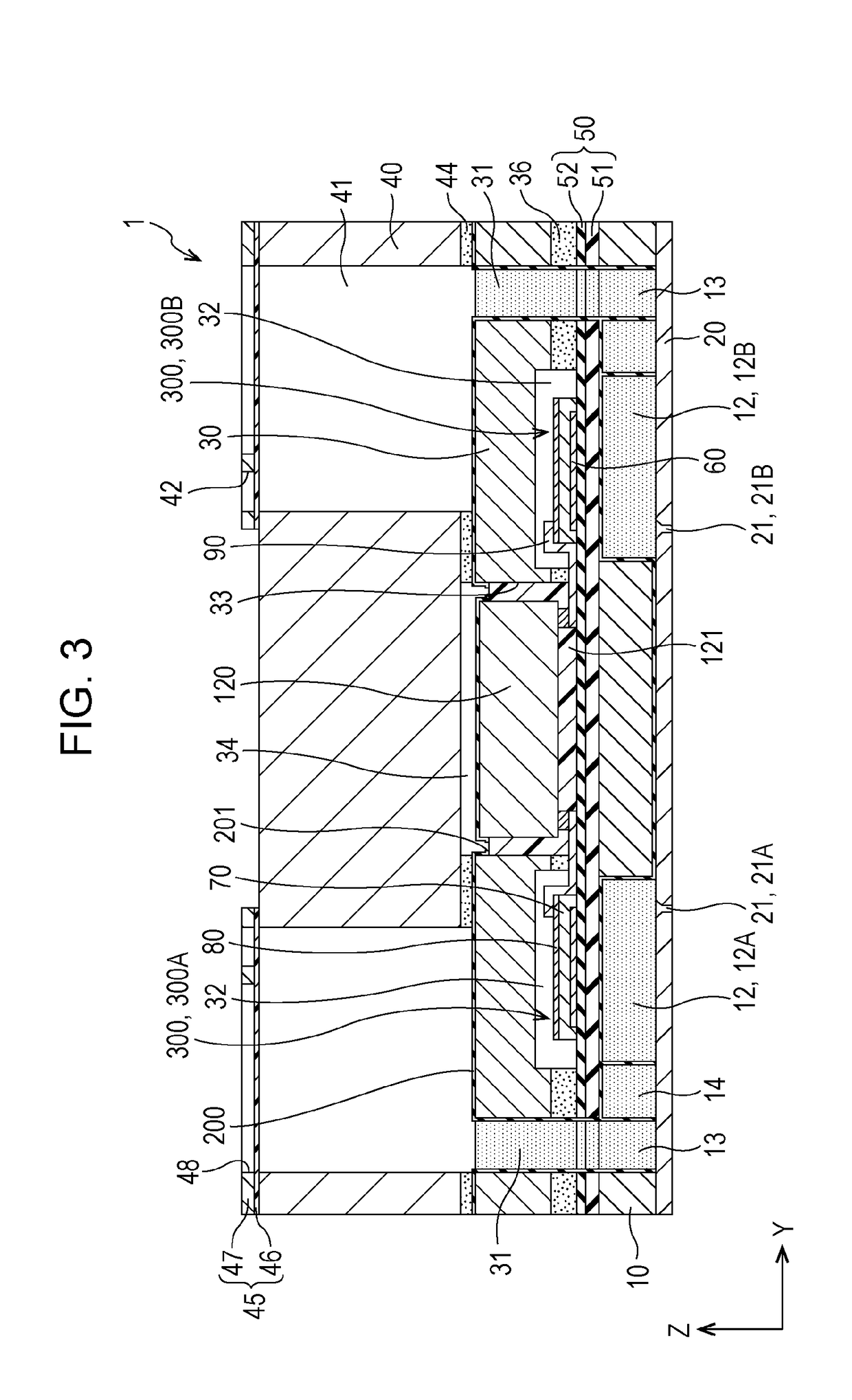

Liquid ejecting head, liquid ejecting apparatus, and piezoelectric device

ActiveUS20190077149A1Avoid pollutionInhibit migrationPrintingPiezoelectric/electrostrictive devicesElectrical and Electronics engineeringPiezoelectric coefficient

A liquid ejecting head includes a flow path forming substrate, a vibration plate that is formed on one surface side of the flow path forming substrate, a plurality of piezoelectric elements that are provided on the vibration plate, a protective substrate that is bonded to the one surface side of the flow path forming substrate and has a flow path, a flow path member that is bonded to a side of the protective substrate opposite to the flow path forming substrate, a drive circuit that is mounted in a space formed so as to be surrounded by the flow path forming substrate, the protective substrate, and the flow path member, a filler that is filled between the drive circuit and the protective substrate, and a protective film that is formed on an inner wall, in which the protective film has an exposure hole exposing a surface of the filler.

Owner:SEIKO EPSON CORP

High rigidity high toughness polypropylene anti-static composite material and preparation method thereof

The invention discloses a high rigidity high toughness polypropylene anti-static composite material and a preparation method thereof. In the prior art, the cost of the materials of a thin-wall light anti-static turnover box, a foldable anti-static turnover box, and an anti-static turnover car chassis with a large load capacity is high, and the performance of the materials is not good. In order tosolve the problems mentioned above, the invention provides a high rigidity high toughness polypropylene anti-static composite material. The cost of the composite material is low. The composite material can be easily applied to industrial production and application, and is an ideal material for producing a thin-wall light anti-static turnover box, a foldable anti-static turnover box, and an anti-static turnover car chassis with a large load capacity.

Owner:ZHEJIANG SANWEI ANTI ELECTROSTATIC EQUIP

Method for limiting slip lines in a semiconductor substrate

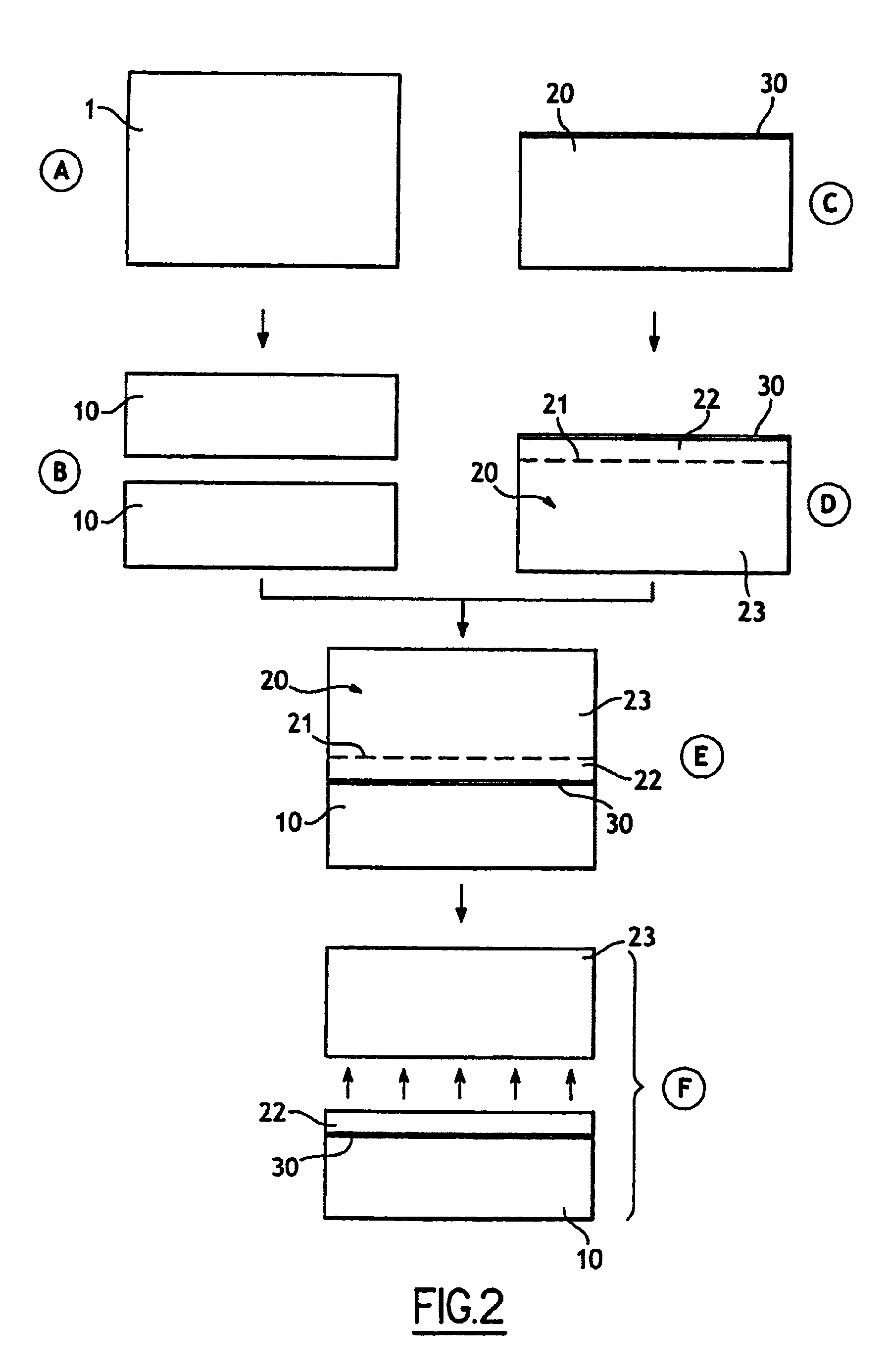

ActiveUS7001832B2Reduce generationImprove bonding interfaceSemiconductor/solid-state device manufacturingSlip lineEngineering

A method for limiting slip lines in a semiconductor substrate including a support layer and a useful semiconductor layer that is transferred to the support layer. The method includes precipitating at least a portion of interstitial oxygen in the support layer by a series of heat treatments conducted after bonding of the useful semiconductor layer to the support layer. The heat treatments occur at a temperature and a time sufficient to reduce the generation of slip lines therein.

Owner:SOITEC SA

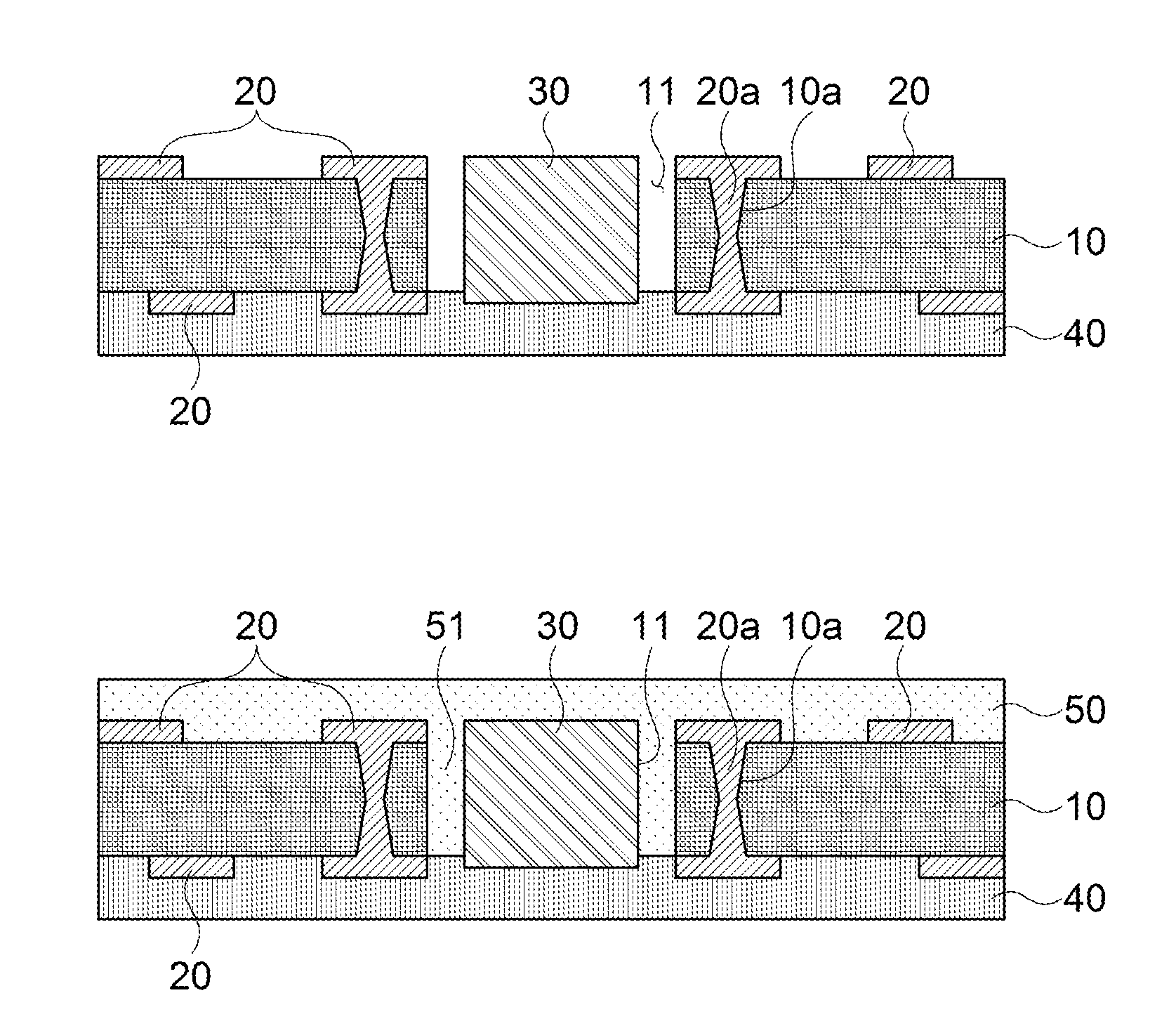

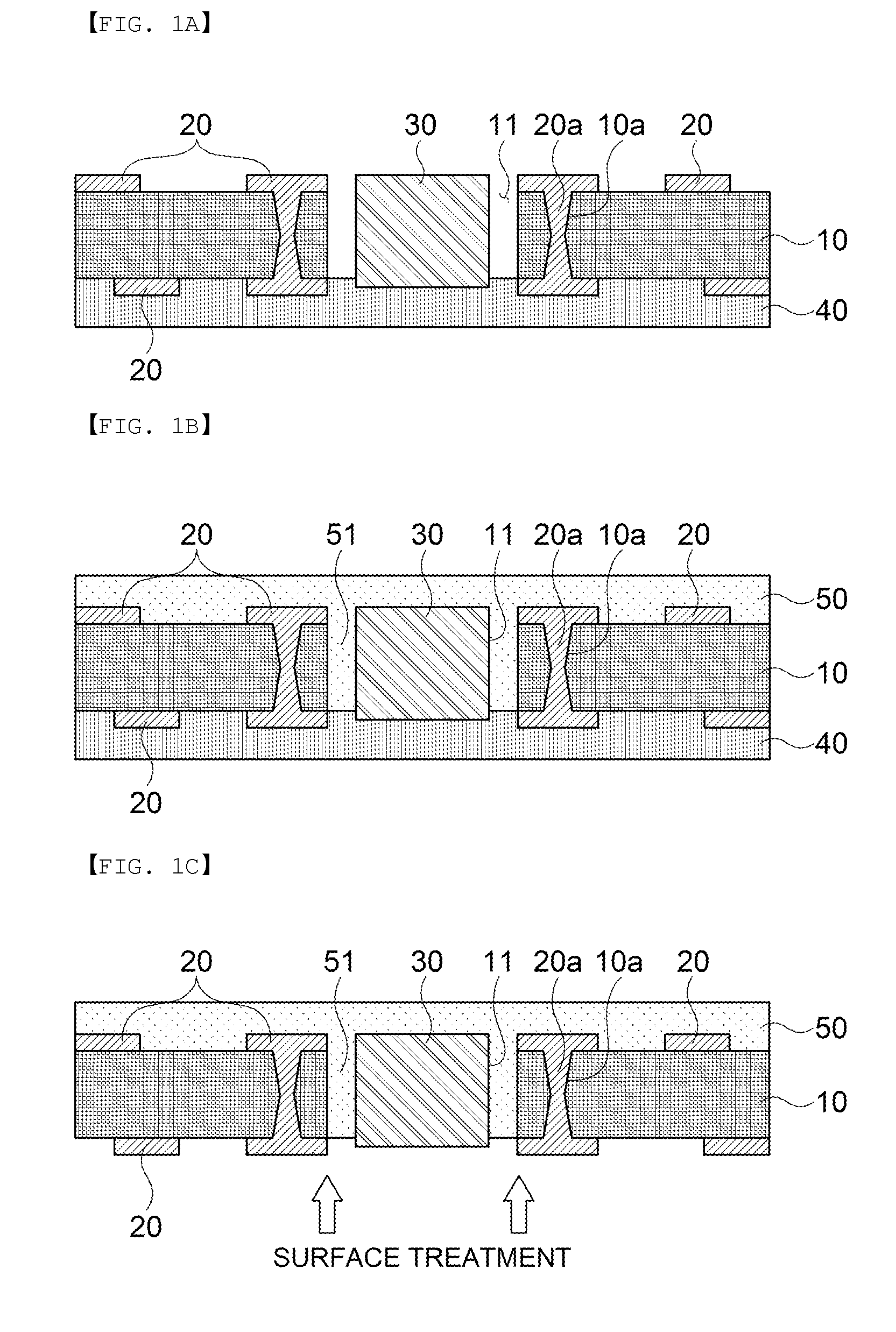

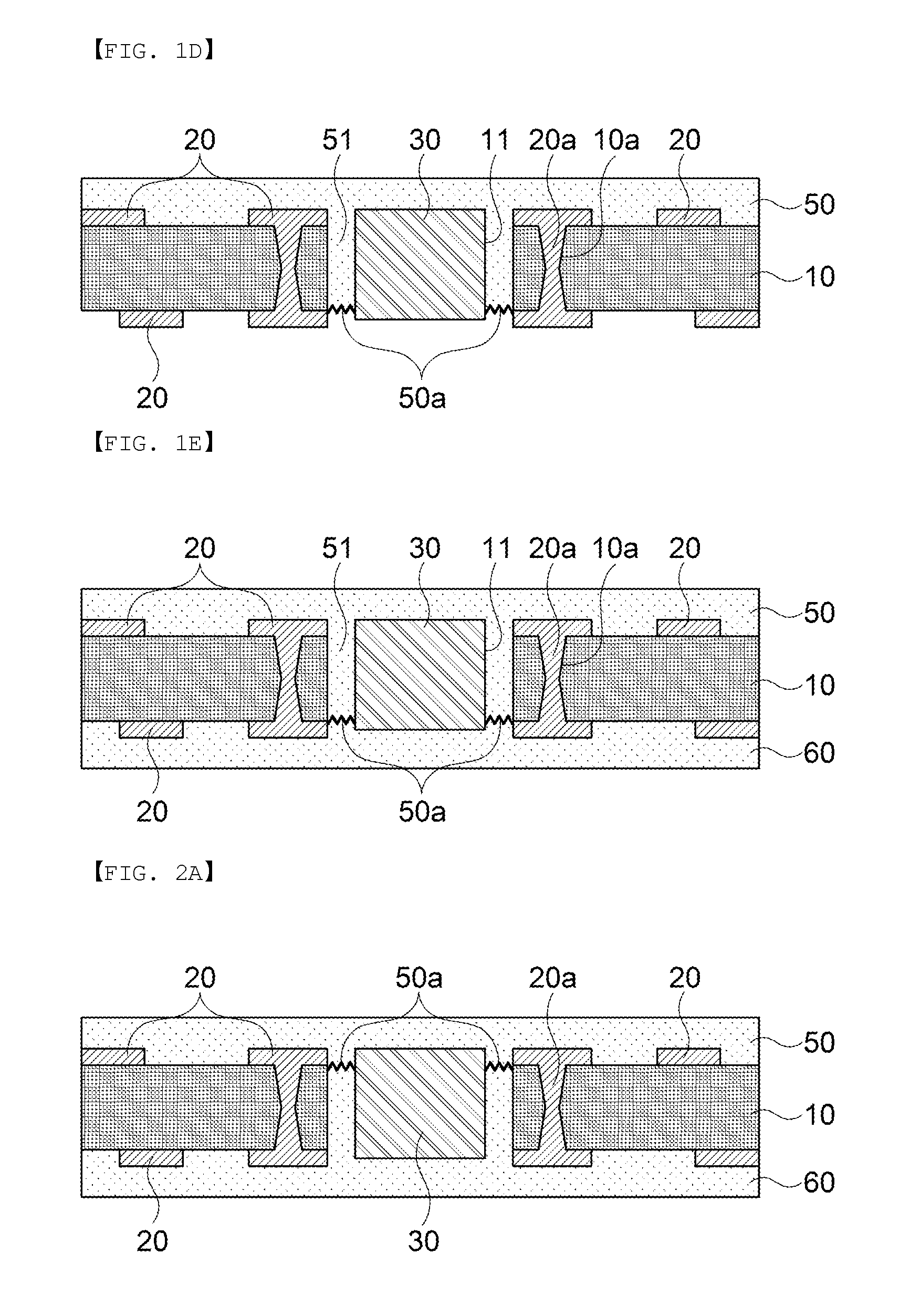

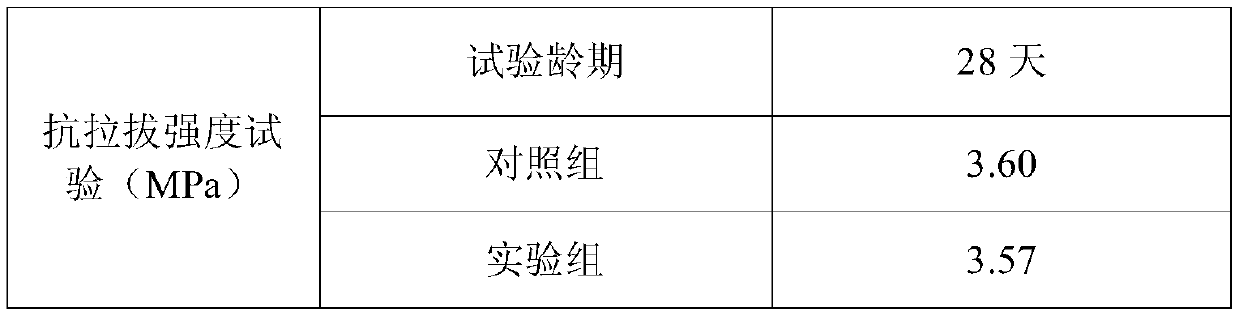

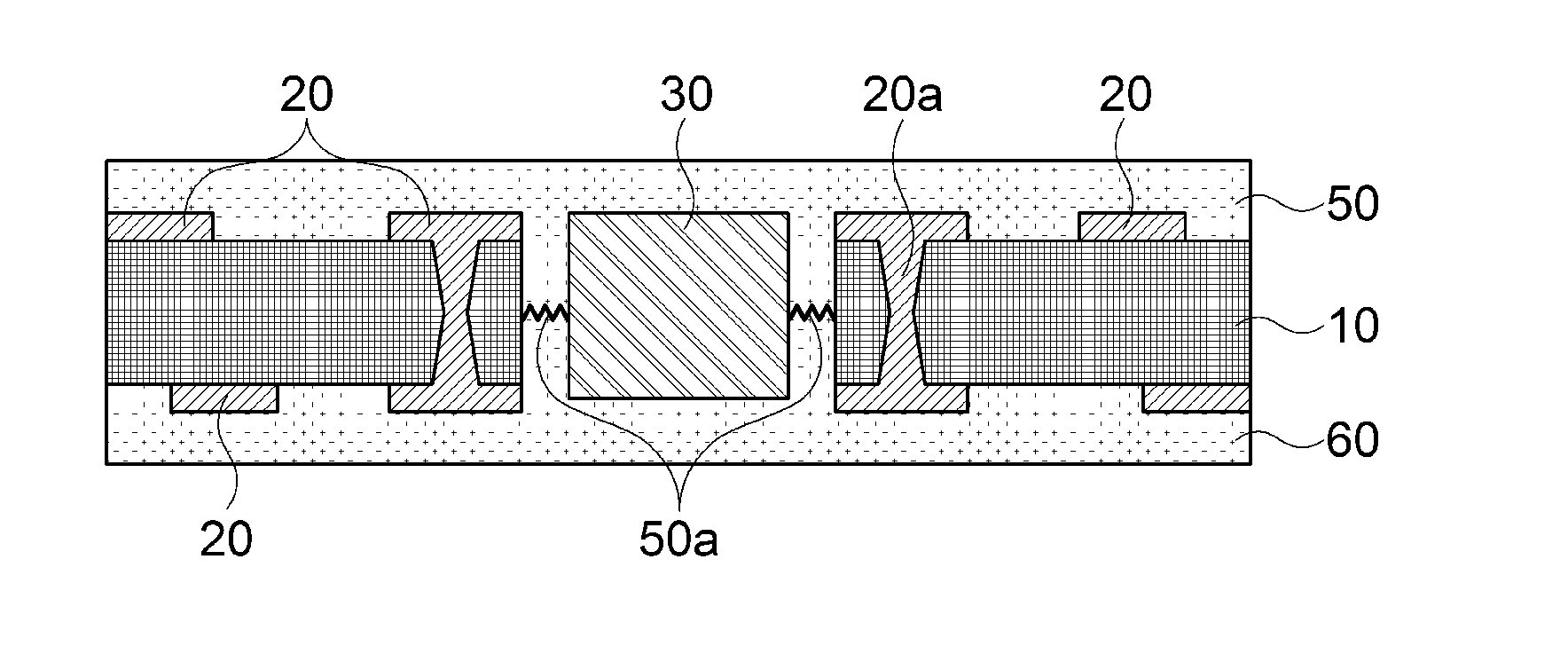

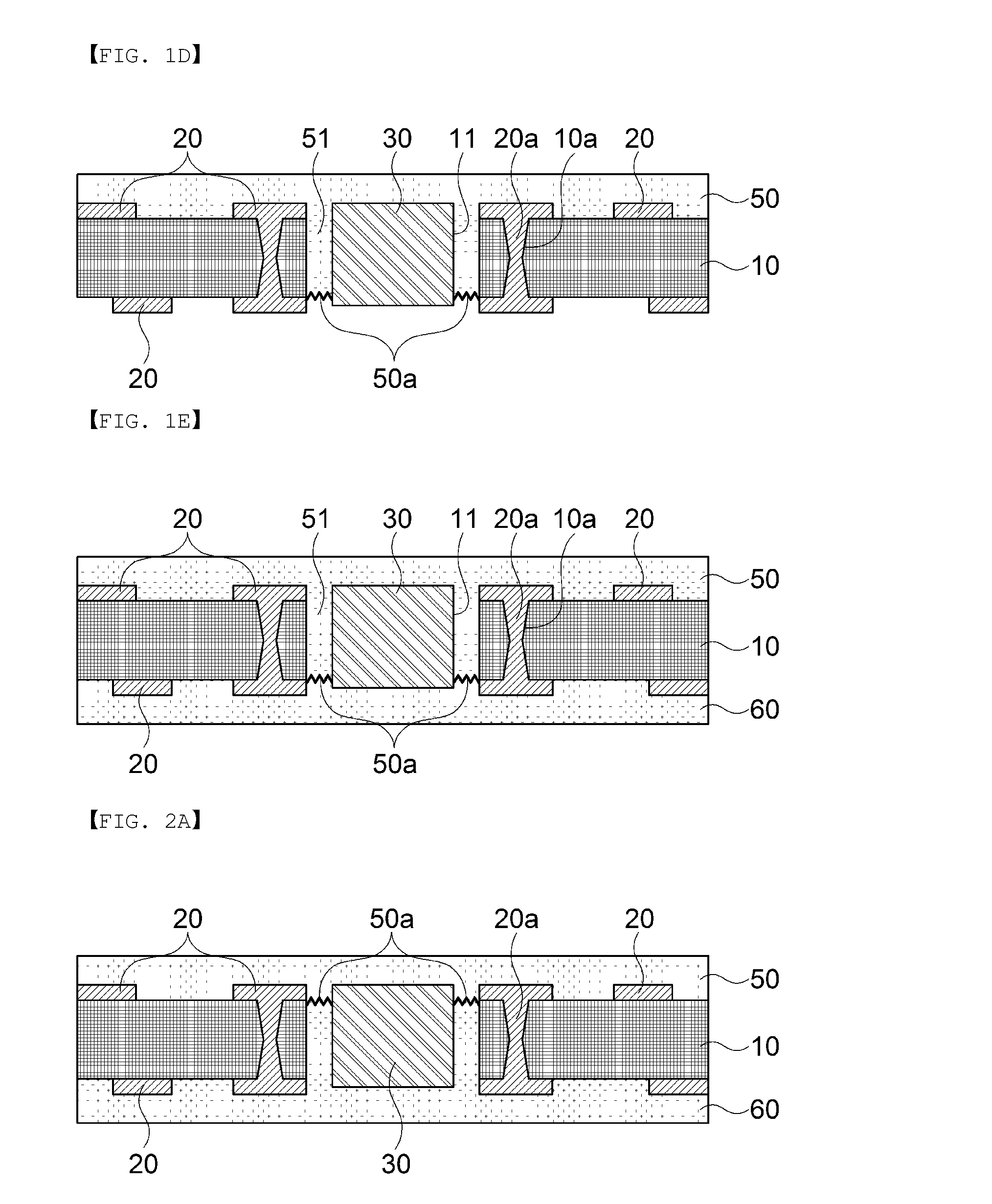

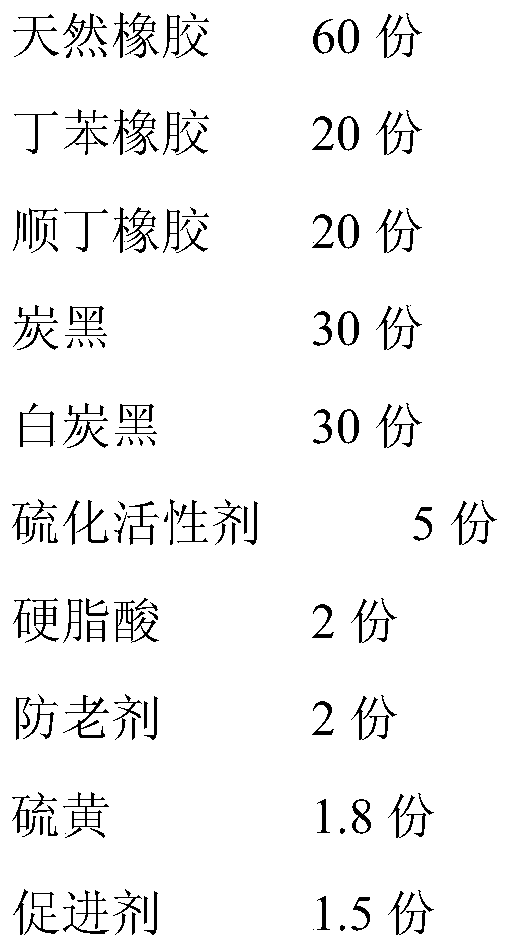

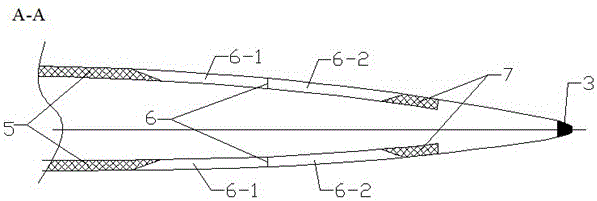

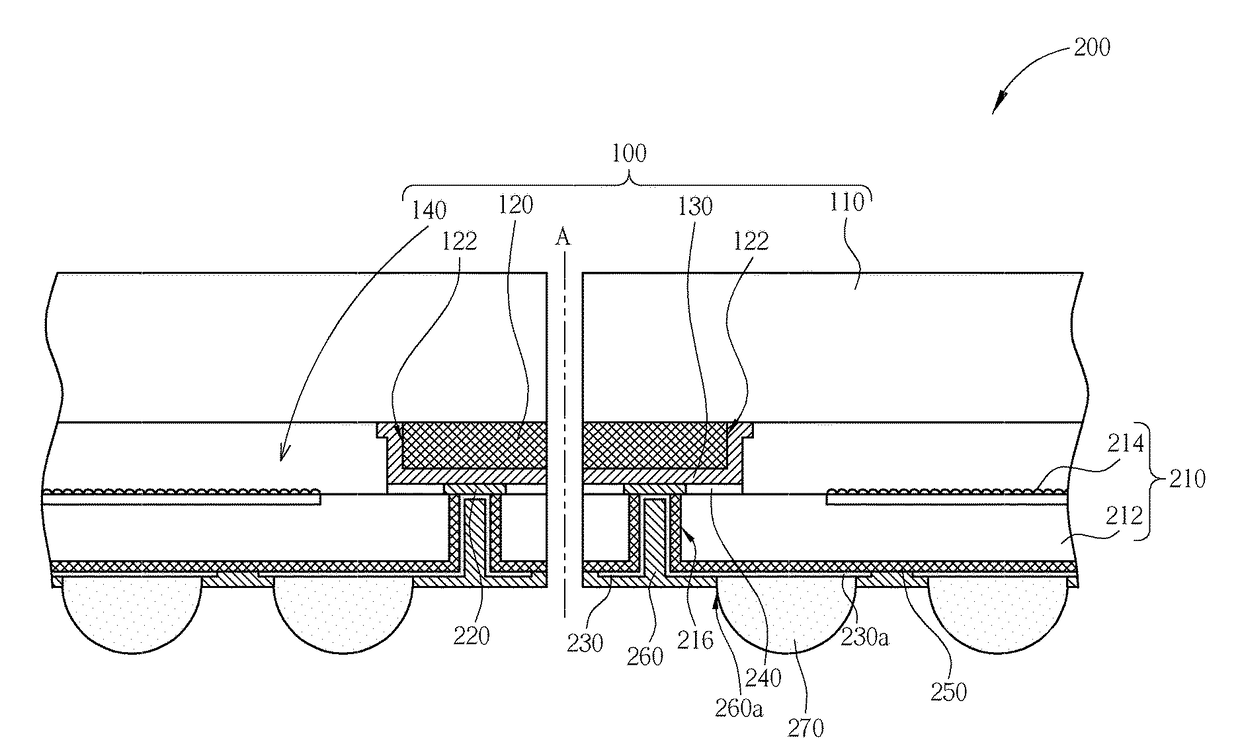

Method for manufacturing electronic component embedding substrate and electronic component embedding substrate

InactiveUS20150049445A1Improve the bonding force between layersImprove surface roughnessPrinted circuit assemblingPrinted circuit aspectsEngineeringSurface roughness

Disclosed herein are a method for manufacturing an electronic component embedding substrate and an electronic component embedding substrate. The method for manufacturing an electronic component embedding substrate includes: inserting an electronic component into a cavity formed in a core substrate; stacking a first insulating layer on one side of the core substrate into which the electronic component is inserted; performing surface treatment on the other side of the core substrate opposite to a direction in which the first insulating layer is stacked to improve a surface roughness of at least an exposed surface of the first insulating layer; and stacking a second insulating layer on the other side of the core substrate so as to be bonded to the exposed surface of the first insulating layer of which the surface roughness is improved. In addition, disclosed herein is the electronic component embedding substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Powdery rough surface agent for concrete and preparation method thereof

InactiveCN111533573ANon-disturbance and destabilizationDoes not affect the structureRough surfaceStructural engineering

The invention belongs to the field of concrete, and particularly discloses a powdery rough surface agent for concrete and a preparation method of the powdery rough surface agent, which have the advantages of low packaging cost, convenience in transportation, ready-to-use preparation, long storage period and the like compared with a slurry powdery rough surface agent in the prior art. When the powdery rough surface agent for the concrete is in use, only water needs to be added and stirred into paste, after concrete pouring is completed, the powdery rough surface agent for the concrete is brushed or sprayed on the surface of the concrete, after the concrete is finally set for 24 to 72 hours, the surface of the concrete is washed with normal-pressure water, the slurry on the surface of the concrete can be washed away by 2.0-5.0 mm very easily, the effect that the aggregate is fully exposed on the surface of the concrete is achieved, the stability of the surface of the concrete is not disturbed or damaged, the internal structure of the concrete is not affected, and a good bonding interface is provided for lower-layer construction and surface decoration of the concrete.

Owner:河南砥柱工程检测有限公司 +1

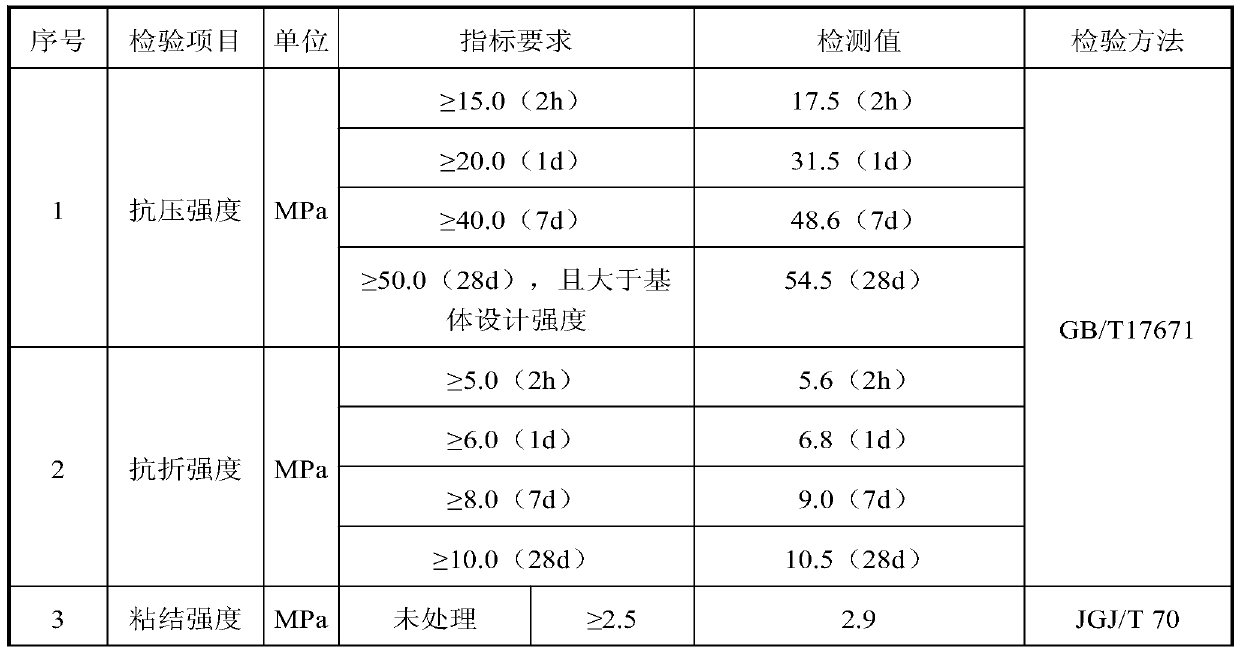

Preparation method of high-strength anti-crack and anti-impact concrete and high-strength anti-crack and anti-impact concrete

InactiveCN114349407AStimulate gelling propertiesPromote generationSolid waste managementCement productionBreaking strengthCompressive strength

The invention provides a preparation method of high-strength anti-crack and anti-impact concrete and the high-strength anti-crack and anti-impact concrete prepared by the method. According to the method provided by the invention, industrial solid wastes such as the copper slag and the slag are utilized, so that the consumption of cement is reduced, the economic cost is saved, and meanwhile, natural resources are protected. The wet grinding treatment mode improves the pozzolanic activity of the copper slag and the slag to a greater extent, so that the impact-resistant concrete has higher compressive strength, breaking strength and tensile strength.

Owner:HUBEI UNIV OF TECH

Method for manufacturing electronic component embedding substrate and electronic component embedding substrate

InactiveUS20160212856A1Improve bonding interfaceImprove surface roughnessElectrical connection printed elementsMultilayer circuit manufactureSurface roughnessEngineering

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

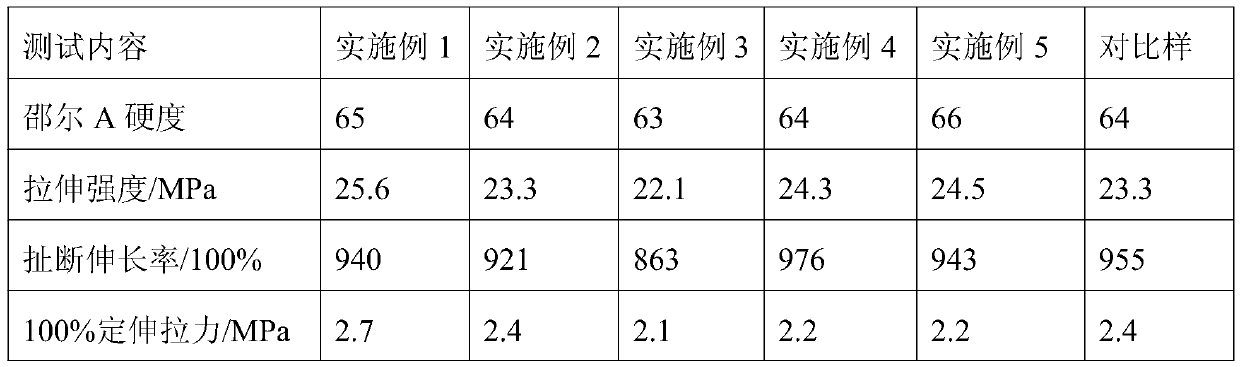

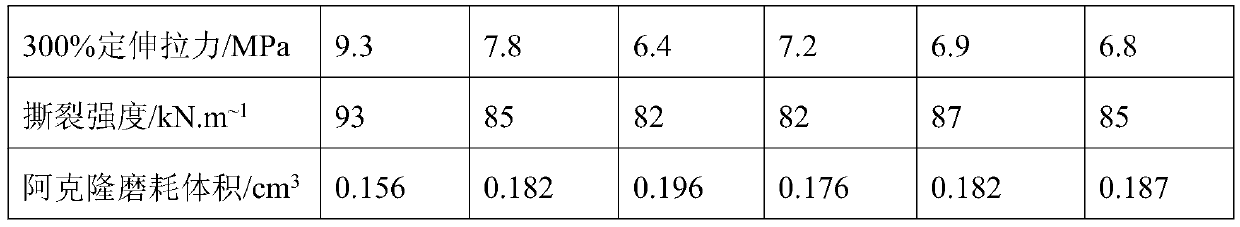

A kind of vulcanization active agent for blended rubber and preparation method thereof

The invention provides a vulcanization activator with easy dispersion and good reinforcing performance for blended rubber. The vulcanization activator comprises the following raw materials in parts byweight: 40-70 parts of nano zinc oxide, 25-60 parts of zinc methacrylate, 1-3 parts of oligomer ester, 0.5-1 part of a silane coupling agent and 0.5-2 parts of a dispersing agent. The preparation method comprises the following steps: adopting a chemical deposition method to synthesize a nano mixed material with the zinc oxide as a core and the zinc methacrylate as a shell, preparing a 20-30% solution through cleaning and filtering, adding the oligomer ester and the silane coupling agent, carrying out stirring for 0.5-1 hour, carrying out filtering, and carrying out drying for 2-4 hours to prepare the vulcanization activator for blended rubber. The vulcanization activator for the blended rubber provided by the invention has low zinc content, good dispersibility and no easy agglomeration, and can be used to substitute indirect method zinc oxide with the same amount for mixing with natural rubber, styrene-butadiene rubber and butadiene rubber to prepare the blended rubber, wherein the weight ratio of the natural rubber to the styrene-butadiene rubber to the butadiene rubber is 60:20:20. The physical and mechanical properties of the blended rubber can meet the use requirements of theblended rubber.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

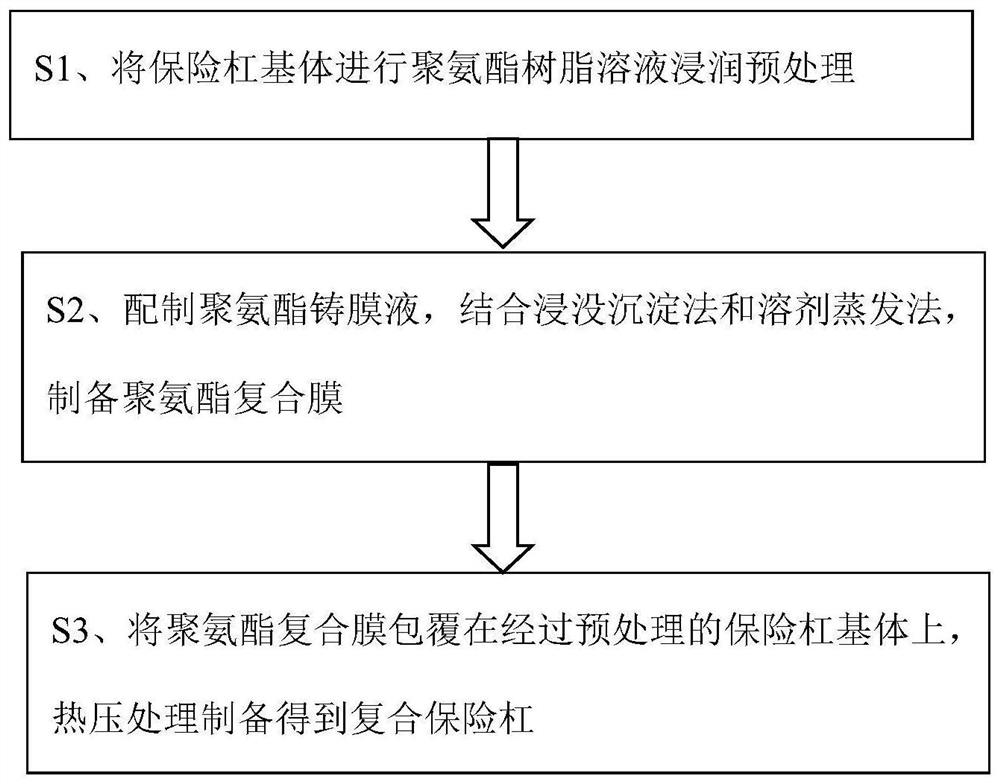

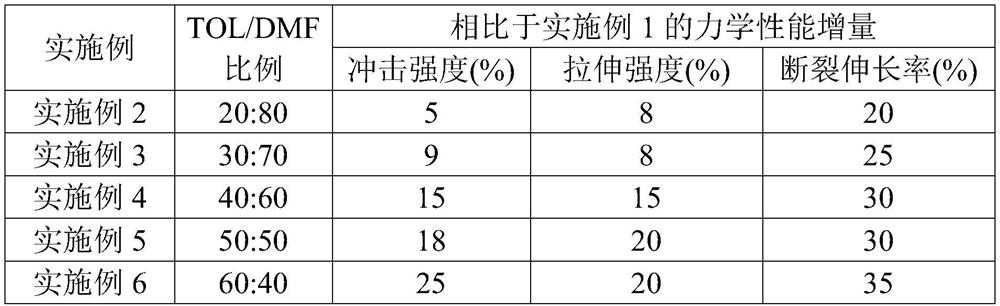

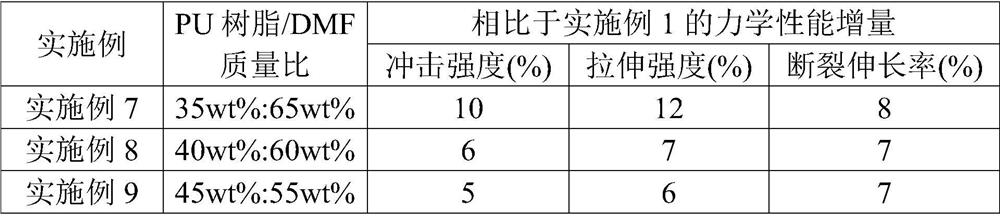

Composite bumper and preparation method thereof

ActiveCN111055798BImprove mechanical propertiesImprove impact resistanceBumpersPolymer scienceThermoplastic polyurethane

Owner:WUHAN TEXTILE UNIV

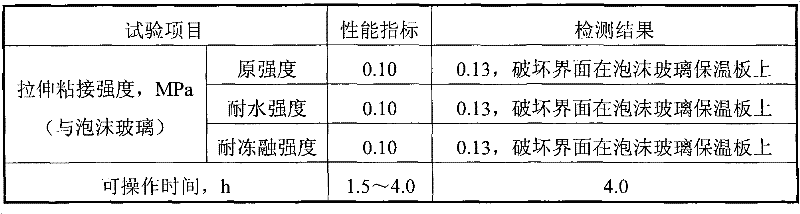

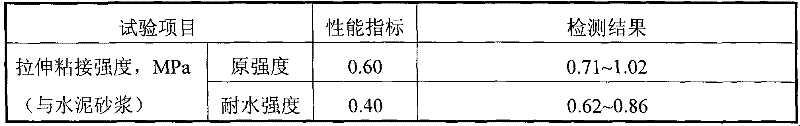

Surface mortar for heat insulation system of foam glass building

Owner:兰州鹏飞保温隔热有限公司

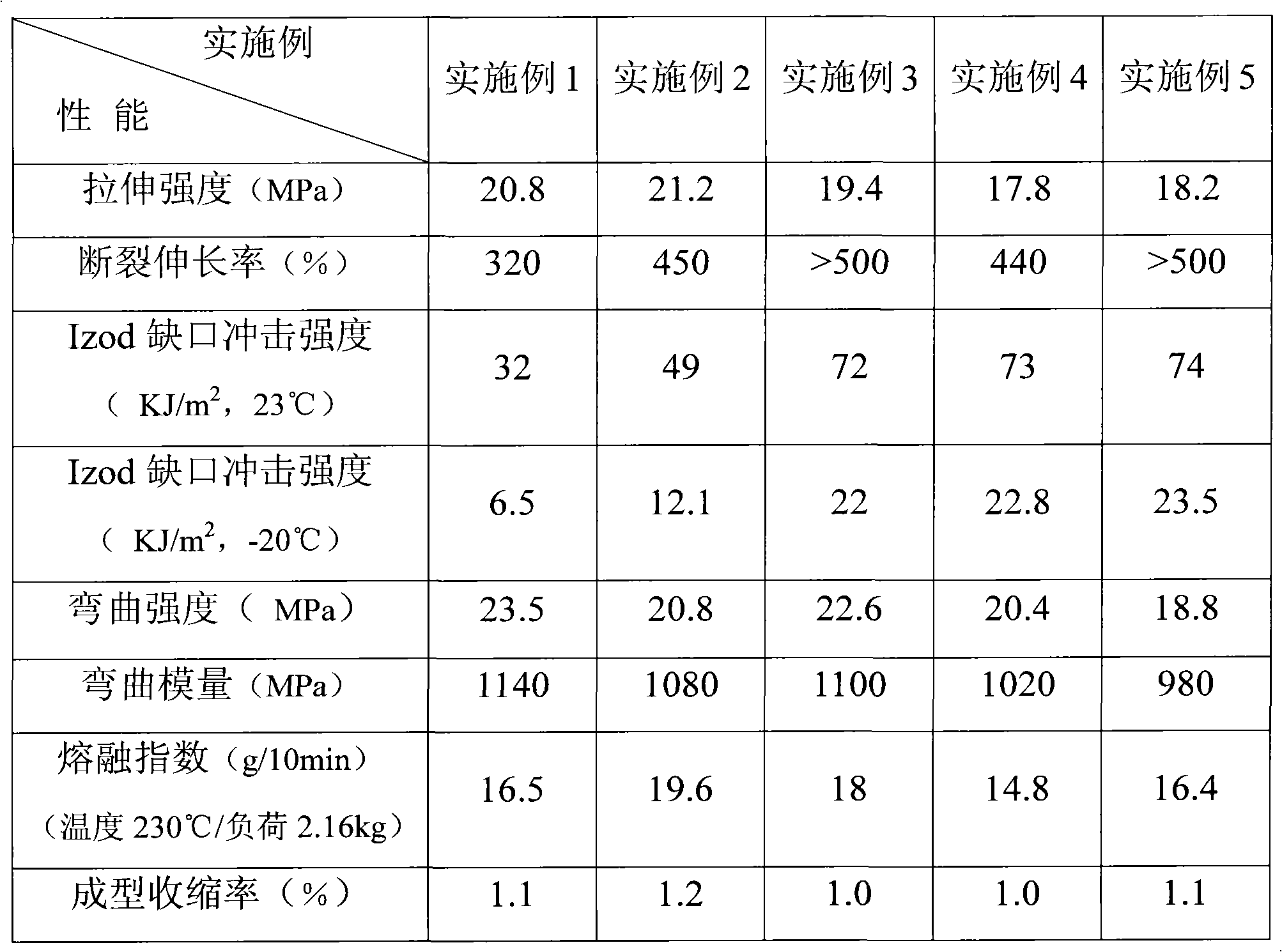

Composite material for vehicle bumper and preparation method thereof

The invention relates to a composite material for a vehicle bumper and a preparation method thereof. The composite material comprises the following ingredients: 60-80wt% of polypropylene, 5-20wt% of metallocene ethylene / hexene copolymer, 10-20wt% of nano calcium carbonate, 0.4-0.8wt% of antioxidant, 0.2-0.5wt% of lubricant. The preparation method comprises the following steps: uniformly mixing the ingredients according to the ratio in a mixer, mixing, extruding, cooling and dicing the mixture in a double screw extruder to obtain the composite material for the vehicle bumper. According to the invention, the polypropylene / metallocene ethylene / hexene copolymer / nano calcium carbonate composite material is prepared by using metallocene ethylene / hexene copolymer as an elastomer component and nano calcium carbonate with a particle size of less than 100nm as an enhancing toughening component, with the advantages of good impact resistance, good low temperature resistance, good weatherability, and good rigid, being capable of being sprayed, and being suitable for ornaments with high requirement of toughness such as the vehicle bumper.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

Bonding mortar used in foam glass building heat insulation system

Owner:兰州鹏飞保温隔热有限公司

Matt composite film with high heat sealability

PendingCN113002083AImproved heat sealing performance and chemical resistanceIncrease typeSynthetic resin layered productsLi-accumulatorsThin membranePolypropylene

The invention belongs to the technical field of shell packaging, and particularly relates to a matte composite film with high heat sealability. The matte composite film comprises a plain foil layer, a protective layer is arranged on the matte surface of the plain foil layer, the protective layer is made of a metal surface treating agent, a film is arranged on the protective layer, and the film and the protective layer are connected through a modified polyurethane adhesive; a special protective layer is arranged on the bright surface of the plain foil layer, an improved surface film-forming agent is adopted in the special protective layer, a multifunctional inner layer is arranged on the protective layer, and the overall thickness of the aluminum-plastic film is 111-155 [mu]m. By manufacturing the special protective layer, corrosion of a low-molecular-weight strong solvent in the electrolyte can be blocked, and the composite strength of the inner layer is improved. And due to the use of the swelling-resistant modified polypropylene or polyethylene, the heat-sealed bonding structure does not have great structural change in a strong solvent soaking environment of electrolyte, so that the heat sealing performance and the chemical resistance of the heat-sealed bonding structure are improved.

Owner:武汉欣宏创塑料印刷包装有限公司

A spar cap connection method for lengthening wind turbine blades

InactiveCN103573563BSafe and reliable structureImproved stiffness distributionFinal product manufactureMachines/enginesTurbine bladeWind force

The invention relates to the method of beam cap connection for lengthening wind turbine generator blades. The method is particularly adopted for connecting beam caps of the blades in the lengthening and improving process of existing wind turbine generator blades. Each reinforced beam cap is manufactured in a beam cap reserved zone between one existing beam cap of one blade and the corresponding beam cap of one blade tip lengthening section, so that the problem of connection of every two existing beam caps is solved. The blades which are lengthened and improved through the method for connecting the beam caps of the wind turbine generator blades are safe and reliable in structure.

Owner:BEIJING KHANWIND TECH

Optical cover plate with improved solder mask dam on glass for image sensor package and fabrication method thereof

ActiveUS9653500B2Improve reliabilityImprove image qualitySemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

Owner:XINTEC INC

A kind of repair mortar, its preparation method and construction method

The invention provides a repair mortar, its preparation method and construction method. The repair mortar includes raw materials: Portland cement, expansion agent, polymer emulsion, viscosity modifier, water, powder water reducer, composite fiber , super absorbent resin and sand. The preparation method includes step S1, mixing wollastonite needle powder, potassium feldspar powder and polymer emulsion to obtain mixture A; step S2, mixing portland cement, magnesium oxide, viscosity modifier, powder The water reducer, the composite fiber, the superabsorbent resin and the sand are mixed uniformly to prepare a mixture B; in step S3, water is uniformly mixed with the mixtures A and B to prepare a repair mortar. The construction method includes step W1, pretreating the construction surface of the concrete matrix to be repaired; step W2, directly forming the repair mortar prepared in step S3 on the pretreated construction surface. The repair mortar described in the invention has better thixotropy.

Owner:NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com