High rigidity high toughness polypropylene anti-static composite material and preparation method thereof

A composite material and high-toughness technology, applied in the field of composite materials, can solve the problems of poor material performance and high material cost, and achieve the effect of easy industrial production and application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

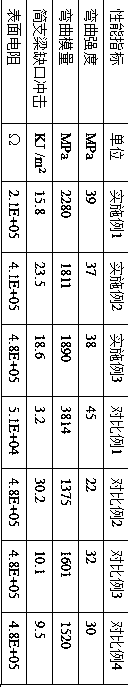

Examples

preparation example Construction

[0051] A method for preparing a high-rigidity and high-toughness polypropylene antistatic composite material as described above comprises the following steps:

[0052] Step 1, dispersing the nano-reinforcing agent in ethanol with a high-speed mixer to obtain a nano-reinforcing agent dispersion;

[0053] Step 2: Coupling the talc powder with a coupling agent in a high-speed mixer for 5-10 minutes, then adding the nano-enhancement agent dispersion liquid and stirring at a high speed, and making the temperature in the mixer gradually reach 70-80 degrees, and the stirring time is 20-30 minutes. Use pulse filter bag exhaust to make more than 90% of ethanol volatilize from the material;

[0054] Step 3. Put homopolymerized PP, copolymerized PP, compatibilizer, toughening agent and other additives into the mixer and mix for 5-10 minutes, then feed the material into the main feed of the extruder; The side of the cylinder is fed and added.

[0055] Step 4. Extrude the material.

[0...

Embodiment 1

[0064] A high-strength and high-toughness antistatic polypropylene composite material comprises the following components in parts by mass: 50 parts of homopolymerized PP, 30 parts of copolymerized PP, 20 parts of talcum powder, 0.5 parts of silane coupling agent, 2 parts 1 part of montmorillonite nano reinforcement, 1 part of silica nano reinforcement, 1 part of compatibilizer, 15 parts of carbon black, 3 parts of toughening agent, and 1 part of other additives.

[0065] The copolymerized PP is K8009 produced by Taiwan Chemical.

[0066] The homopolymer PP is Sinopec Maoming S1003.

[0067] The compatibilizer is Shenyang Ketong maleic anhydride grafted PP KT-1.

[0068] The toughening agent is Dow Corning ENGAGE 8150.

[0069] The talcum powder is Dongguan Yifeng 3000H.

[0070] The nano-montmorillonite is Zhejiang Fenghong nano-montmorillonite DK4.

[0071]The nano-silica is Degussa fumed nano-silica AEROSIL200.

[0072] The other auxiliary agents include 0.4 part of ant...

Embodiment 2

[0080] A high-strength and high-toughness antistatic polypropylene composite material includes the following components in parts by mass: a high-strength and high-toughness antistatic polypropylene composite material includes the following components in parts by mass: 20 parts of PolyPP, 50 parts of copolymerized PP, 25 parts of talc, 0.5 parts of silane coupling agent, 2 parts of montmorillonite nano-enhancer, 1 part of silica nano-enhancer, 1 part of compatibilizer, 18 parts carbon black, 3 parts of toughening agent, and 1 part of other additives. The preparation method is as follows: the copolymerized PP is K8009 produced by Taiwan Chemical. The homopolymer PP is Sinopec Maoming S1003.

[0081] The compatibilizer is maleic anhydride grafted PP KT-1.

[0082] The toughening agent is Vistamaxx 6102FL.

[0083] The talcum powder is Dongguan Yifeng 5000H.

[0084] The nano-montmorillonite is Zhejiang Fenghong nano-montmorillonite DK4.

[0085] The nano-silica is Degussa fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com