A spar cap connection method for lengthening wind turbine blades

A technology of wind power generators and connection methods, which is applied to wind power generators, wind power generators consistent with the wind direction, wind power generation, etc., and can solve the problem of reducing the clearance between blades and towers, increasing the risk of blades hitting the tower, and stress concentration at the bonding interface To avoid the risk of beating the tower, optimize the stiffness distribution, and improve the effect of the bonding interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1: Prefabrication of the reserved area of the existing blade spar cap

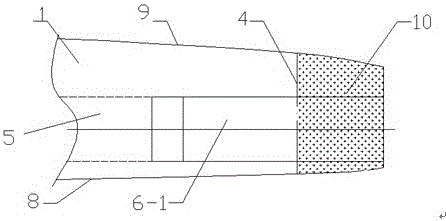

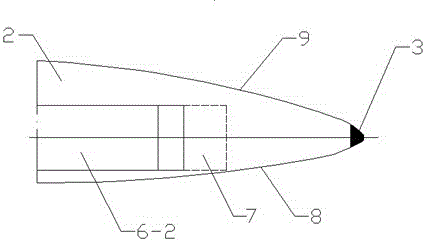

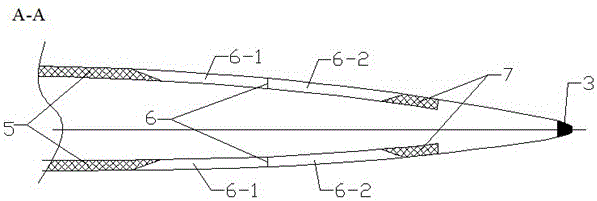

[0046] 1a. If figure 1 As shown, the identification of the cutting and grinding area of the existing blade, referring to the structure and process requirements of the lengthened wind power blade, identifies the lengthened connecting surface 4, the reserved area of the existing blade spar cap 6-1, and the grinding and bonding area of the blade tip shell 10;

[0047] 1b. For the grinding of the reserved area 6-1 of the existing blade spar cap, the grinding process shall be carried out with reference to the marking line of 1a. In the staggered transition zone of the blade spar cap 5, the single-layer staggered distance in the transition zone is greater than 100mm, the grinding width is the same as the width of the existing blade spar cap glass fiber layup, and the grinding thickness is the same as the existing spar cap glass fiber layup at the 4 extended joints thickness;

[0048] 1c. G...

Embodiment 2

[0065] Step 1: Prefabrication of the reserved area of the existing blade spar cap

[0066] 1a. Marking of the cutting and grinding area of the existing blades. Referring to the structure and process requirements of the lengthened wind power blades, mark the lengthened connecting surface 4, the reserved area of the beam cap of the existing blade 6-1, and the grinding and bonding area of the blade tip shell 10 ;

[0067] 1b. For the grinding of the reserved area 6-1 of the existing blade spar cap, the grinding process shall be carried out with reference to the marking line of 1a. In the staggered transition zone of the blade spar cap 5, the single-layer staggered distance in the transition zone is greater than 100mm, the grinding width is the same as the width of the existing blade spar cap glass fiber layup, and the grinding thickness is the same as the existing spar cap glass fiber layup at the 4 extended joints thickness;

[0068] 1c. Grinding of the bonding area 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com