Honeycomb sandwich layer structure and preparation method thereof

A technology of honeycomb interlayer and honeycomb core material, which is applied in the field of material forming to achieve the effects of stable and reliable honeycomb quality, avoiding collapse and good bonding interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

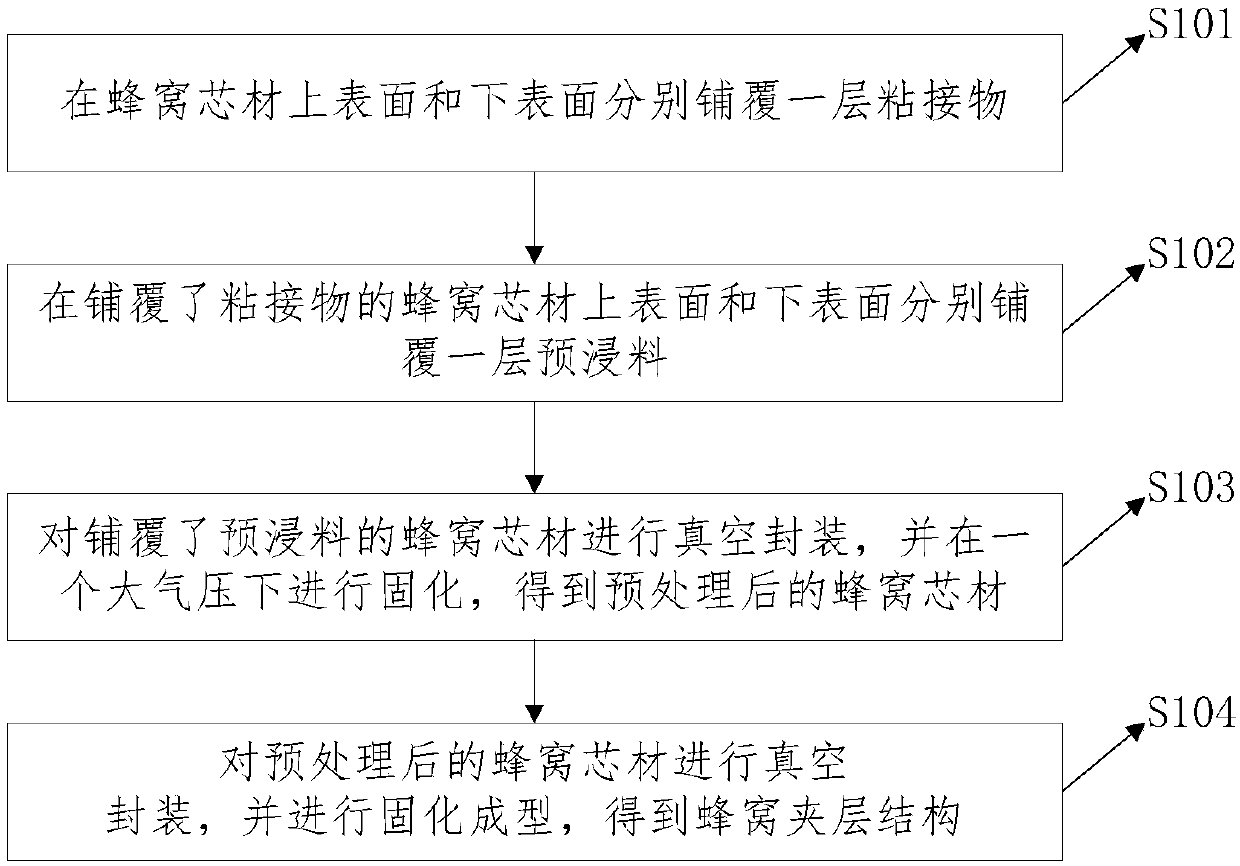

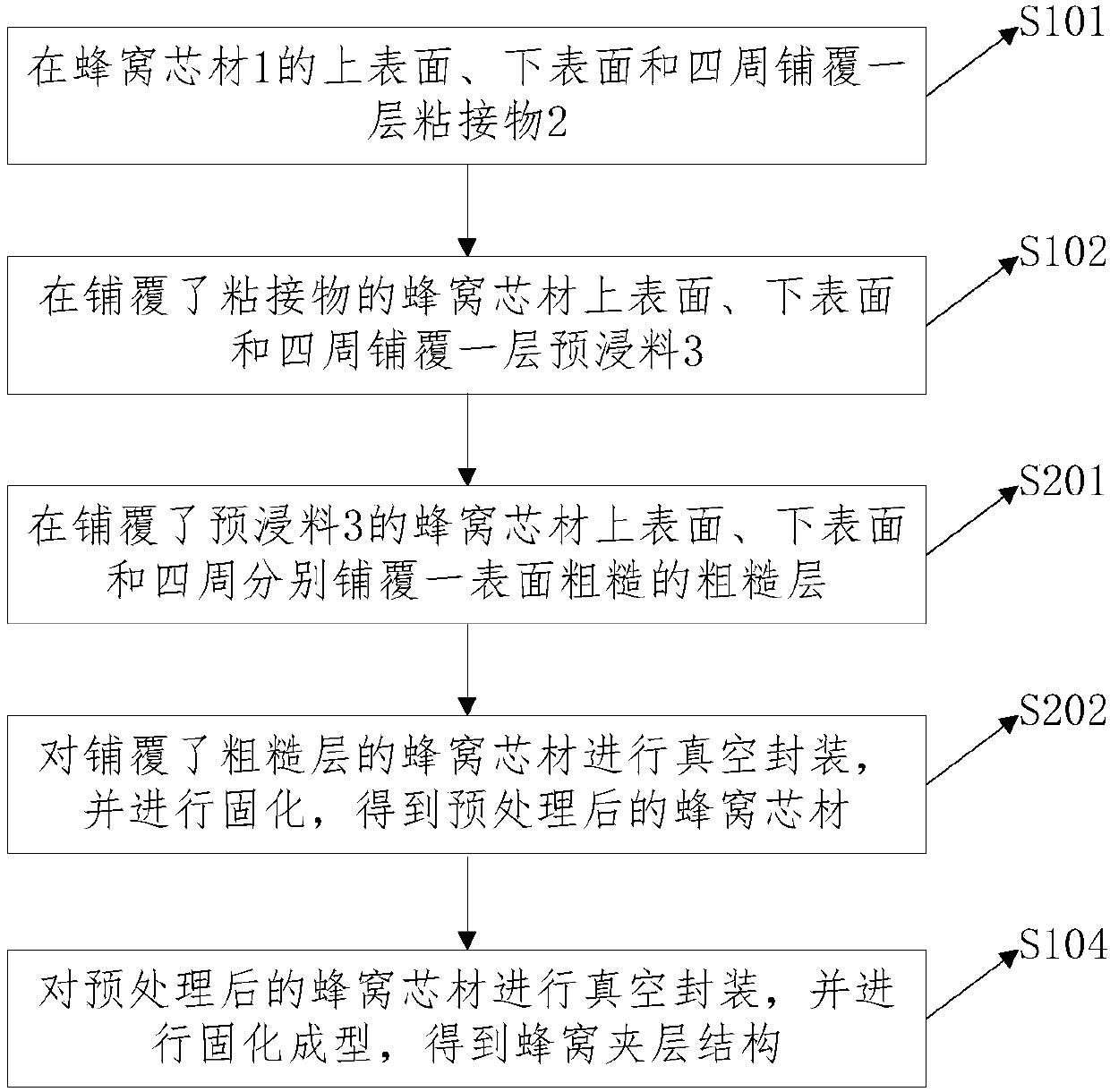

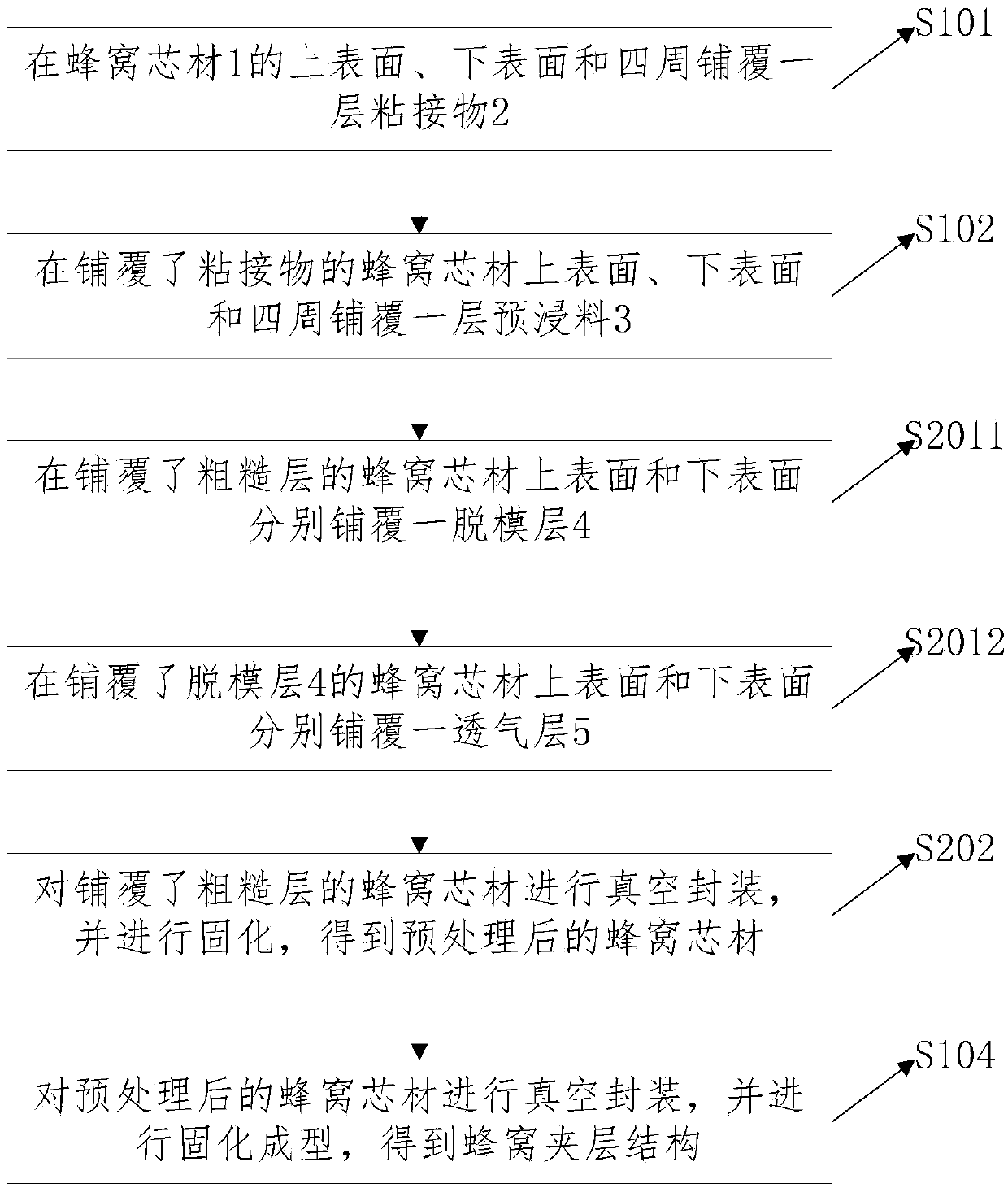

[0039] Such as figure 1 As shown, the preparation method includes the following steps S101-S104:

[0040] S101, laying a layer of adhesive 2 on the upper surface, lower surface and surroundings of the honeycomb core material 1;

[0041] Specifically, the adhesive can be an adhesive film. Since both the skin panel material of the honeycomb core material and the adhesive film are made of resin, in order to ensure the compatibility between the resins, the material of the adhesive should be selected to be compatible with the honeycomb core material. The resin material of the skin panel is the adhesive film and prepreg of the same resin system, and the material with the same curing temperature level is selected, such as low temperature curing material, medium temperature curing material or high temperature curing material; optionally, the adhesive film material can be Henkel The company's HYSOL EA 9628, PL7000, METLBOND 1515, etc.

[0042] S102, laying a layer of prepreg 3 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com