Patents

Literature

76results about How to "Reduced zinc content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

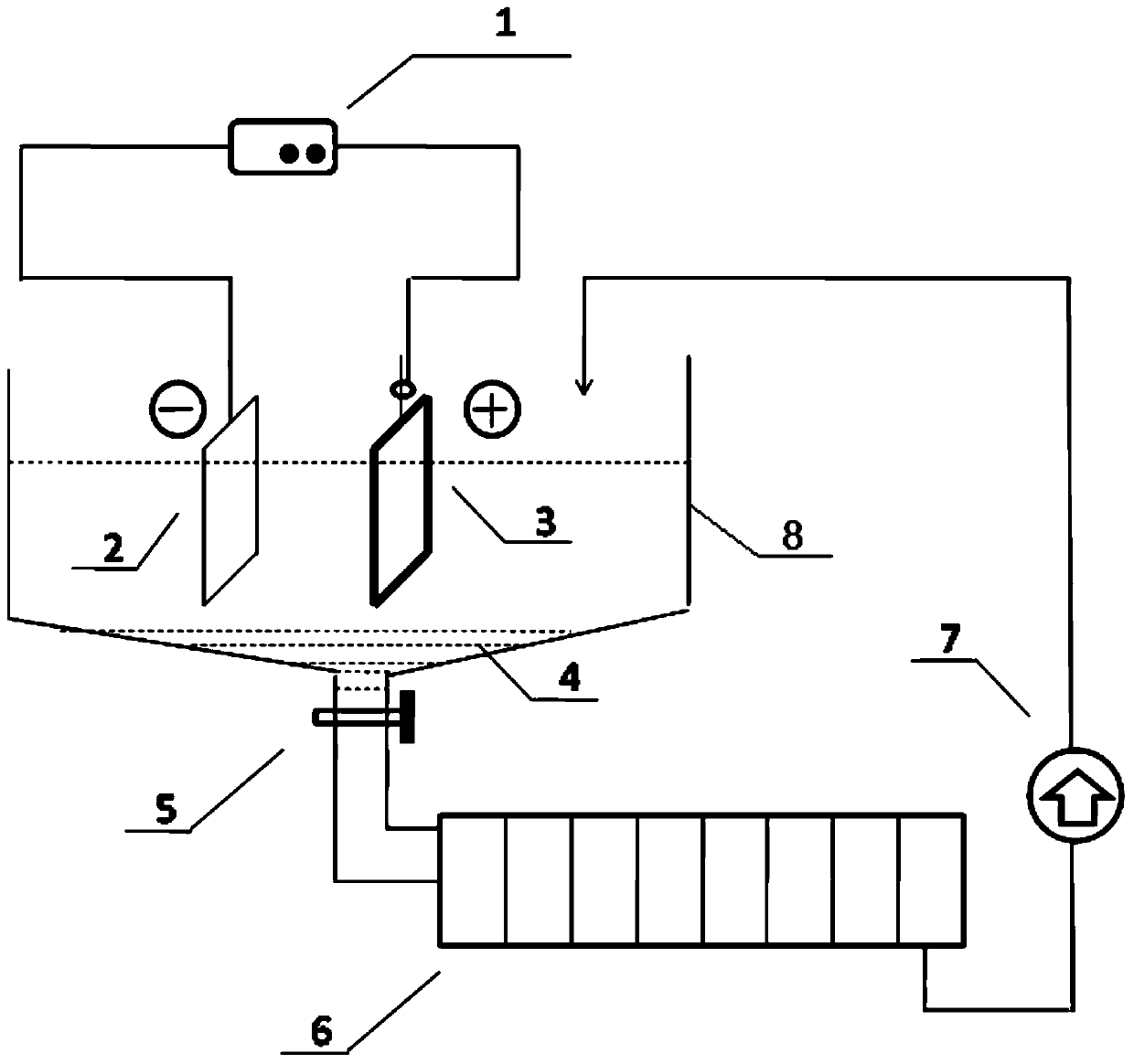

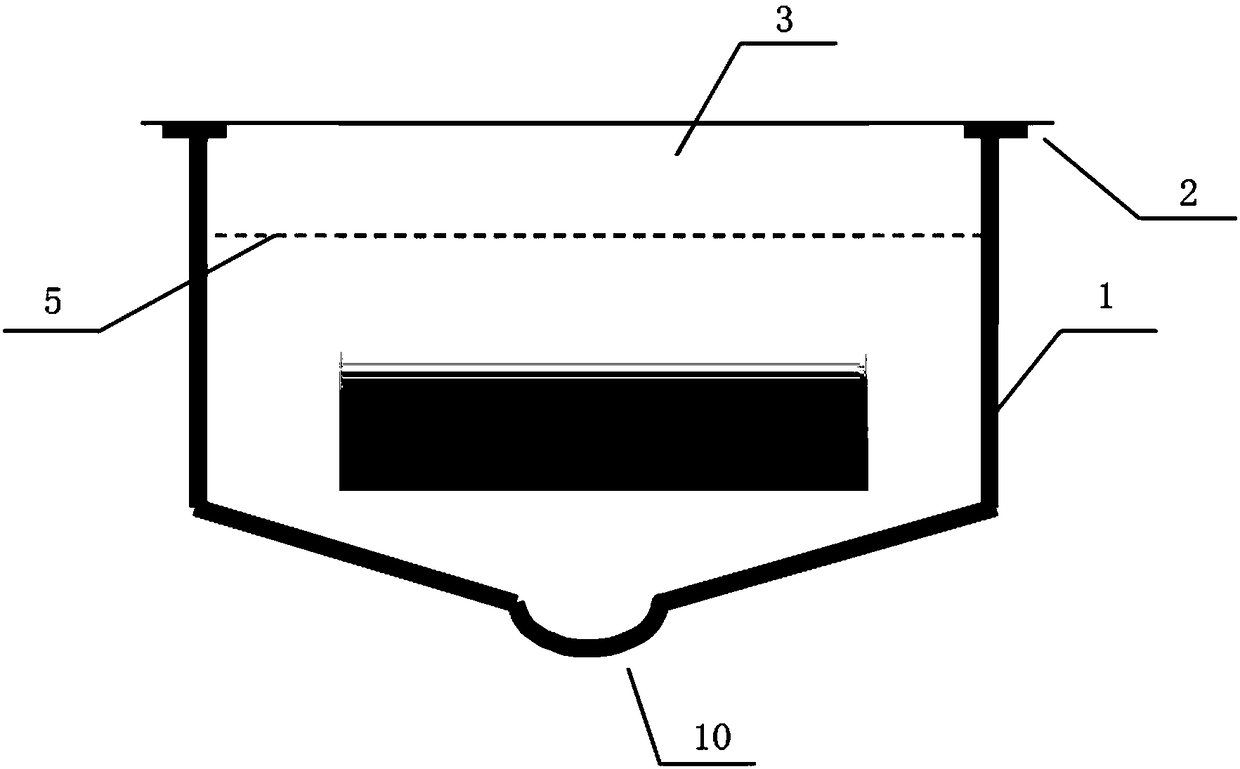

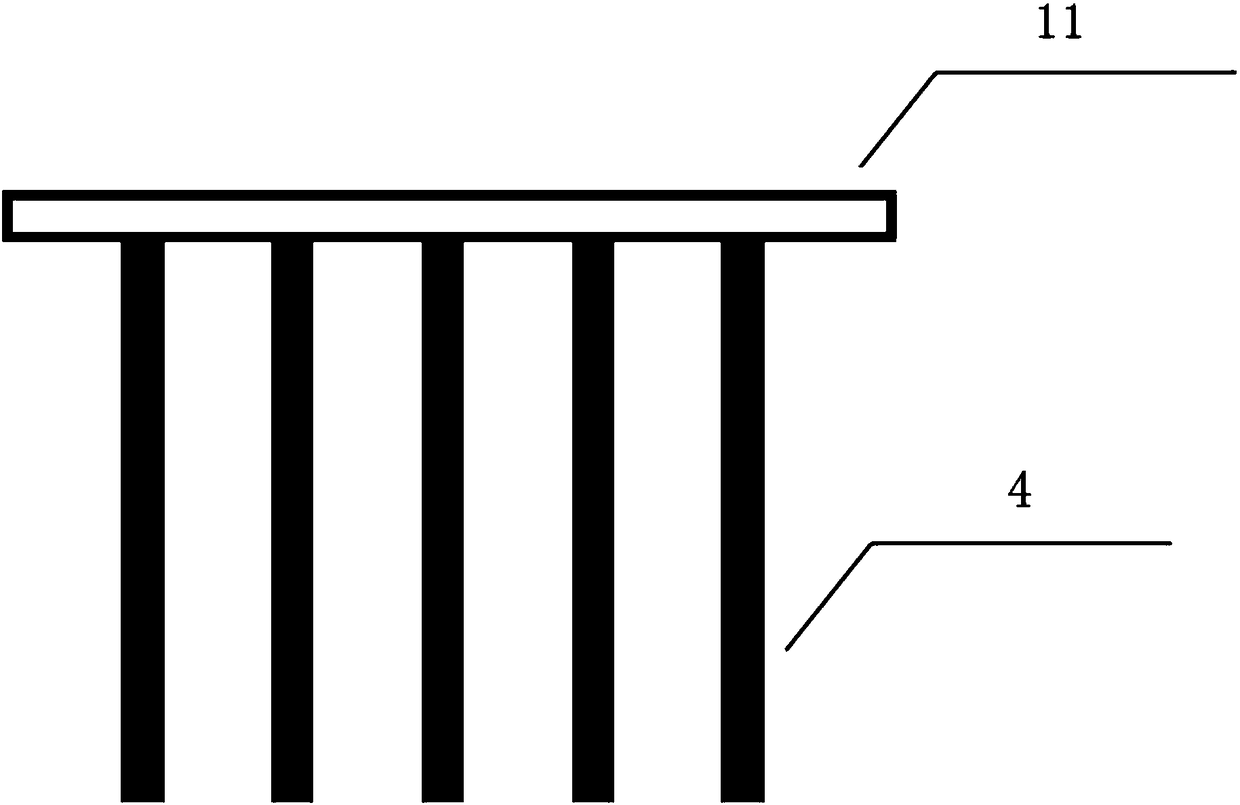

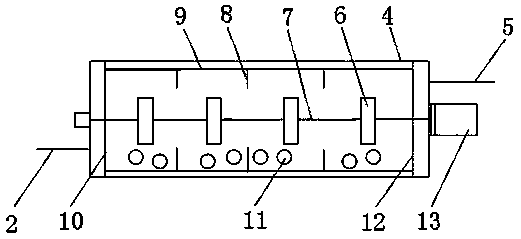

Method for recovering copper and cadmium from copper and cadmium slag and device for recovering cadmium from zinc sulfate solution rich in cadmium

ActiveCN103556180APromote leachingImprove leaching ratePhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for recovering copper and cadmium from copper and cadmium slag and a device for recovering cadmium from a zinc sulfate solution rich in cadmium. The method comprises the following steps of firstly mixing copper and cadmium slag with a gas carrier substance uniformly; then using a sulfuric acid solution to carry out acid leaching on the copper and cadmium slag under certain conditions to leach all copper, cadmium and zinc in the copper and cadmium slag into the solution; then adopting zinc powder as a reducing agent to preferably reduce copper ions in the acid leachate into elemental copper to be precipitated under certain conditions, and adopting the device for recovering cadmium from a zinc sulfate solution rich in cadmium to selectively extract cadmium from the obtained zinc sulfate solution rich in cadmium, thus obtaining a high-grade sponge cadmium and zinc sulfate solution, wherein sponge cadmium can be directly subjected to casting-electrorefining or rectifying to obtain high-purity cadmium, and the zinc sulfate solution can be directly returned to an electrolytic zinc system to produce electrolytic zinc.

Owner:CENT SOUTH UNIV +1

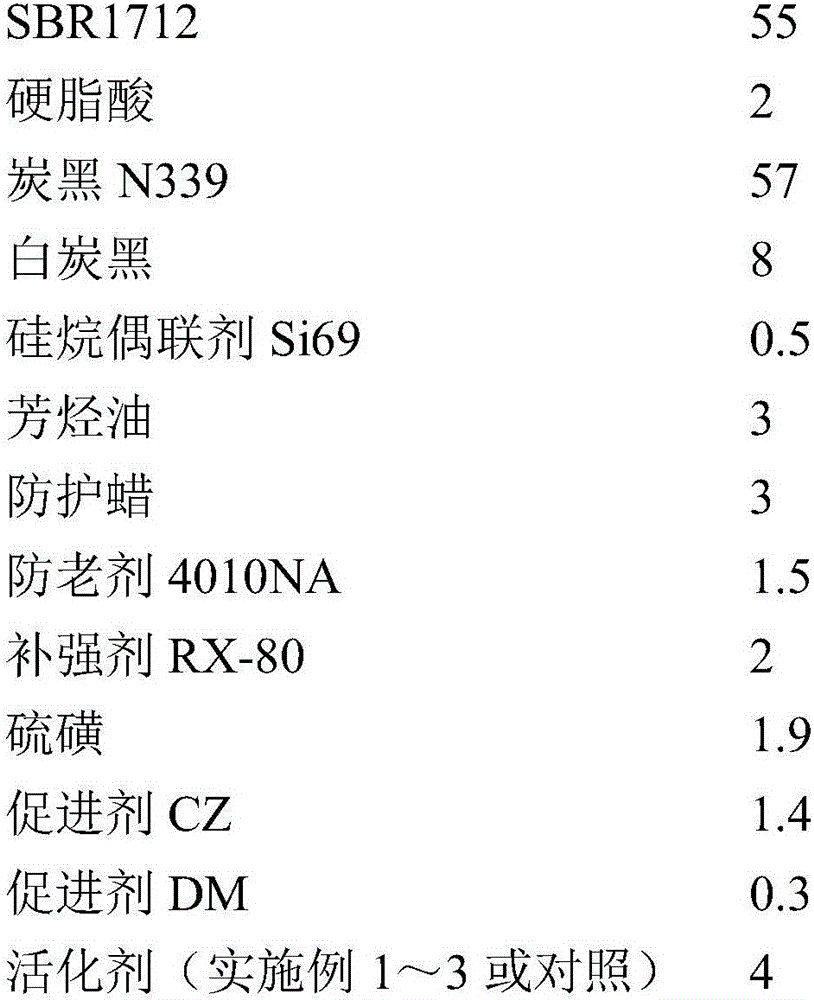

Novel rubber activator and preparation method thereof

The invention discloses a novel rubber activator and a preparation method thereof. The rubber activator particularly comprises 20 to 80 percent of aromatic group-containing formic acid type metal salt and 20 to 80 percent of zinc oxide, wherein the aromatic group-containing formic acid type metal salt is mixed with the zinc oxide at normal temperature and the two are stirred for 5 to 15 minutes at the rotation speed of between 2,000 and 3,500rpm. Compared with the prior art, the problems of high zinc content and high heavy metal element content in the zinc oxide can be effectively solved, density is reduced, dispersibility is improved, and the novel rubber activator improves rubber tensile property, broken chain elongation rate and rubber cross-linking effect.

Owner:江苏爱特恩高分子材料有限公司

Novel zinc oxide rubber vulcanization activator, and preparation method and application thereof

The invention belongs to the field of rubber assistants, and concretely relates to a novel zinc oxide rubber vulcanization activator, and a preparation method and an application thereof. The preparation method comprises the following steps: adding a soluble metal salt to an unsaturated carboxylic acid and alkali solution mixed solution to obtain a nanometer unsaturated carboxylic acid metal salt, carrying out a direct chemical precipitation technology to prepare a composite microsphere adopting the nanometer unsaturated carboxylic acid metal salt as a core and a zinc oxide nanoparticle as a shell, and modifying the surface of the zinc oxide nanoparticle on the surface of the composite microsphere to obtain the novel zinc oxide rubber vulcanization activator. The unsaturated carboxylic acid metal salt introduced to the activator has excellent cross-linking, reinforcing, lubricating and dispersion-aiding effects. Nanometer zinc oxide is grafted with a coupling agent, and the steric hindrance effect of the coupling agent of the organic long chain of the coupling agent makes nanometer composite microspheres effectively agglomerated, so the nanometer composite microspheres are uniformly dispersed. The activator is added to substantially improve the mechanical performances, the ageing resistance and the ultraviolet resistance of rubber.

Owner:GUANGZHOU KAIYAO ASSET MANAGEMENT CO LTD

Zinc-carrying nano organic montmorillonite antimicrobial agent and preparation method thereof

The invention discloses a zinc-carrying nano organic montmorillonite antimicrobial agent which is prepared from the following components in percentage by weight: 8-15% of zinc chloride, 13-16% of organized intercalation treating agent and 69-79% of montmorillonite. The preparation method comprises the following steps: preparing 69-79% of montmorillonite and deionized water into a 10% suspension, adding 8-15 wt% of zinc chloride, stirring at 60-70 DEG C for 3-4 hours, adding 13-16% of organized intercalation treating agent, heating while stirring, continuing stirring at 70-80 DEG C for 4-5 hours, carrying out vacuum filtration, repeatedly washing with distilled water, carrying out vacuum drying at 65 DEG C for 48 hours, grinding, and passing through a 300-mesh screen to obtain the zinc-carrying nano organic montmorillonite antimicrobial agent. The antimicrobial agent has the advantages of high efficiency and broad antibacterial spectrum.

Owner:LONGYAN UNIV

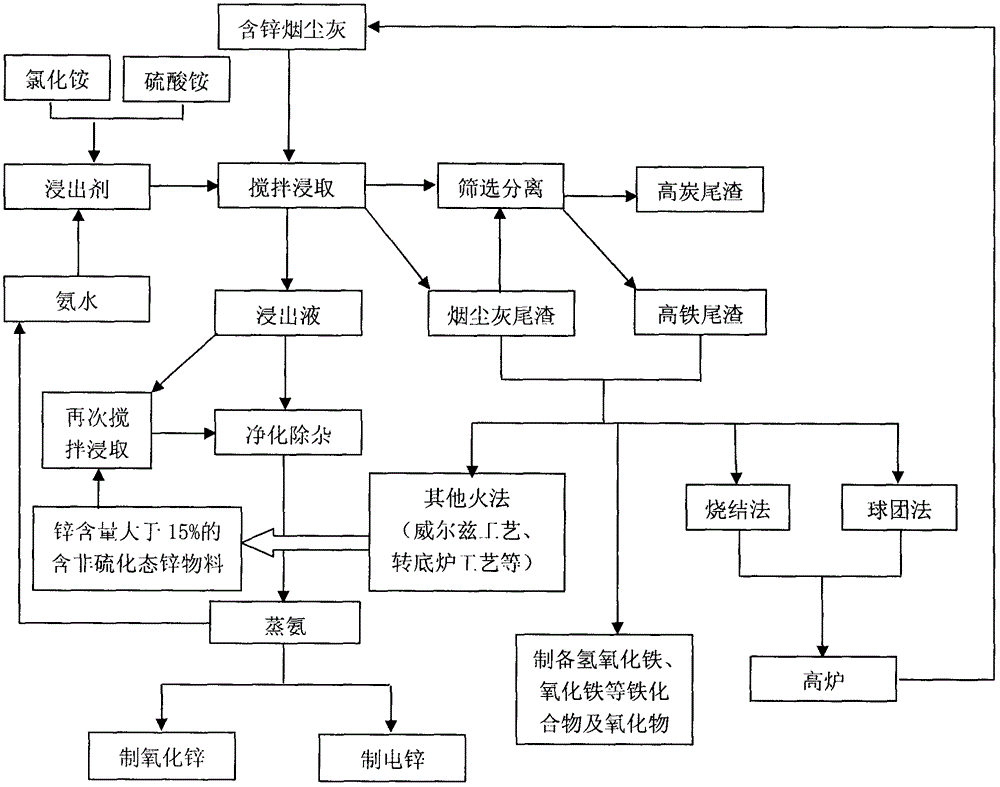

Utilizing method of zinc-containing dust ash of steel plant

InactiveCN106119556AIncrease concentrationSolve the problem of continuous enrichmentPhotography auxillary processesZinc oxides/hydroxidesEnvironmental resistanceAmmonia

The invention relates to a utilizing method for producing zinc oxide products by utilizing zinc-containing dust ash of a steel plant and recycling ferric carbon for returning to smelting. Zinc in the dust ash is leached by use of an ammonia method; materials which have the zinc content greater than 15% and contain non-vulcanized zinc are added for increasing the concentration of a zinc solution; leachate is purified, cleaned and subjected to ammonia distilling, and zinc oxide is prepared after electrolytic zinc preparation or zinc deposition; and original dust ash tailings or screened dust ash tailings are sent into a blast furnace for smelting, or a conventional pyrogenic process is adopted for recycling ferric carbon from the original dust ash tailings or the screened dust ash tailings, and collected secondary zinc oxide dust ash is used for the front end leaching, so that the zinc concentration of the leachate is increased. The utilizing method can be applicable to dust ash, with the zinc content as lower as 4% or even lower, of the steel plant; by use of a conventional method, the zinc extraction rate and the removing rate of harmful substances including alkali metal, fluorine and chlorine are both above 90%; the dust ash tailing recovery process is high in equipment adaptability, and appropriate treatment processes can be chosen according to existing equipment; and efficiency is high, the environment is protected, and comprehensive cyclic utilization of the zinc-containing dust ash is achieved.

Owner:李果

Low-zincium organophosphor scale inhibitor for recirculated cooling water process

ActiveCN101244872AEliminate environmental pollutionReduced zinc contentScale removal and water softeningPhosphoric acidCorrosion

The invention relates to an environment-friendly low-zinc organic phosphorus corrosion and scale inhibitor, which comprises the following components in percentages by weight: organic phosphono-carboxylic acid (PBTC) 20 to 25%, organic phosphoric acid (HEDP) 10 to 12%, organic phosphoric acid ester 5 to 8%, zinc salt 3 to 4%, macromolecular dispersing agent with sulfonic group, mildew inhibitor 0.5%, and pure water accounting for the rest percentage. The corrosion and scale inhibitor in the invention has the advantages that: the zinc content in circulating water and sewer water is less than 1.5mg / L, and desirable corrosion and scale resistant effects can be achieved at the same time of reducing the pollution to the environment.

Owner:BAOSHAN IRON & STEEL CO LTD

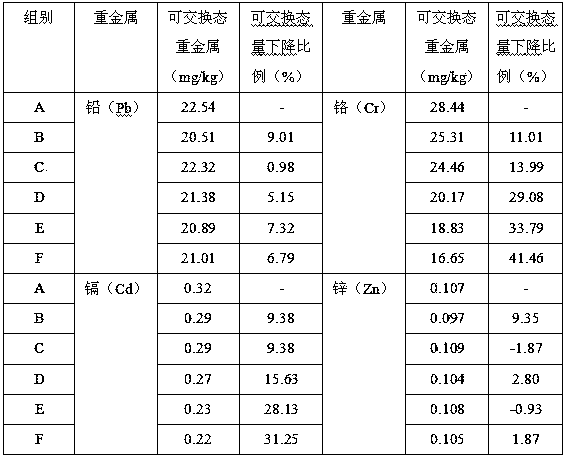

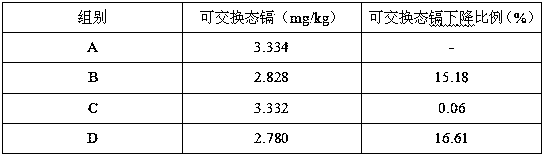

Soil heavy metal repairing agent and application thereof to jointly contaminated soil

InactiveCN104119925AReduce manufacturing costRepair pollutionAgriculture tools and machinesOrganic fertilisersPollution soilSoil heavy metals

The invention provides an application of a repairing composition used in heavy metal contamination of soil. The composition comprises lentinan and chitosan and can be used for increasing the yields of plants such as peppers and the like on the heavy metal jointly contaminated soil. Besides, the invention also provides a preparation and the like based on the composition.

Owner:CHENGDU NEWSUN CROPSCI

Combined application of zinc-selenium agricultural preparation and soil heavy metal repairing agent

ActiveCN104117534AImprove qualityResidue reductionContaminated soil reclamationLowering plantsSoil heavy metals

The invention provides combined application of an agricultural preparation containing zinc-selenium and a soil heavy metal repairing agent. The soil heavy metal repairing agent comprises lentinan and chitosan. With the combined application, the effect of the soil heavy metal repairing agent is enhanced while the plane yield is improved, and the content of heavy metal, such as cadmium, in plants (especially in plant seeds) is obviously reduced.

Owner:CHENGDU NEWSUN CROPSCI

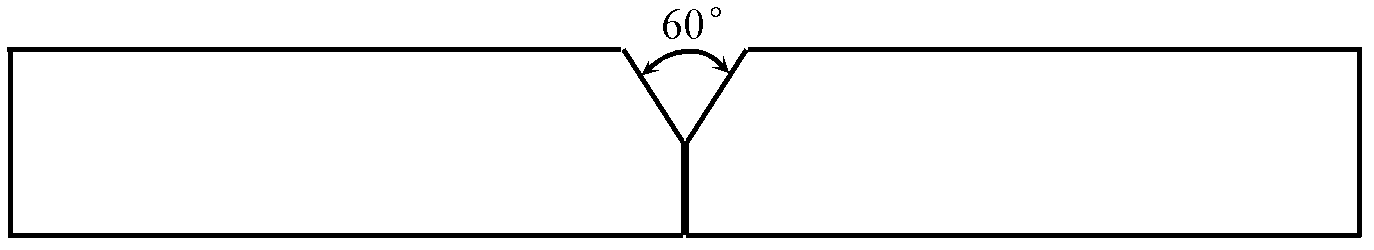

Low-pollution magnesium alloy welding material and preparation process thereof

ActiveCN102554492AHigh melting pointHigh strengthWelding/cutting media/materialsSoldering mediaChemical compositionBoiling point

The invention discloses a low-pollution magnesium alloy welding material and a preparation process of the low-pollution magnesium alloy welding material. The low-pollution magnesium alloy welding material comprises the following chemical compositions in percentage by weight: 5.5-6.5% of Zn, 0.1-0.8% of Nd, 0.20-1.0% of Ca, 0.1-0.9% of Mn, 0.1-0.4% of Al, 90.0-93.5% of Mg, a small amount of metal impurities, including Cu, Ni, Fe and Si. The low-pollution magnesium alloy welding material is prepared by a process comprising the following steps of: (1) smelting and casting; (2) homogenizing; and (3) hot extrusion and pulling and extracting. The low-pollution magnesium alloy welding material has the advantages of low pollution, high strength, simple preparation technology and low cost. By improving the boiling point of the magnesium alloy material, the welding dust can be reduced by more than 50% when being compared with the common magnesium alloy welding materials, and the melting deposition efficiency is higher than 80%.

Owner:DALIAN UNIV OF TECH

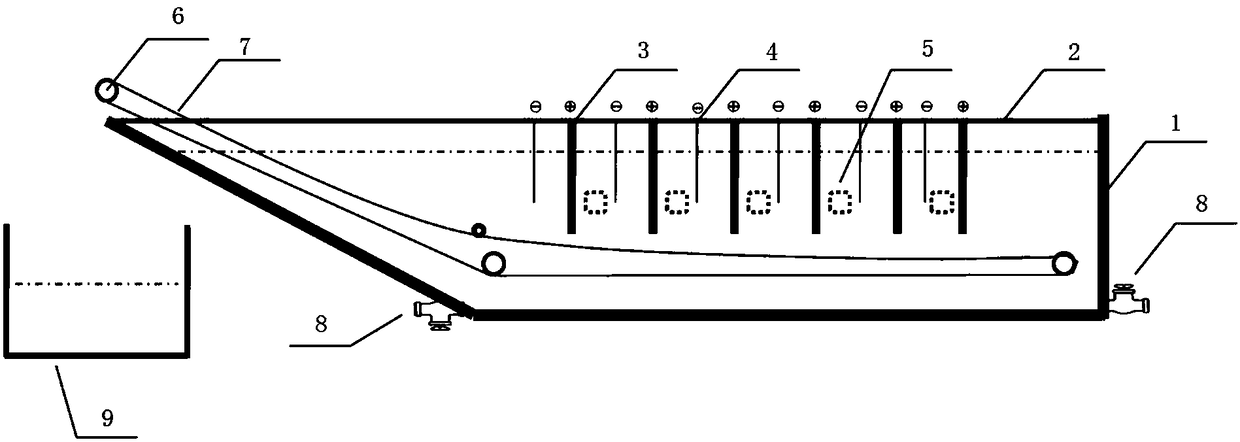

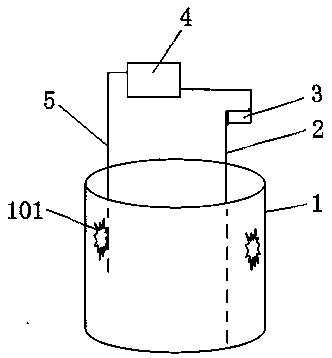

Method for recycling cadmium from metallurgical cadmium-contained dust and device for recycling cadmium from cadmium-ammonia solution

ActiveCN108220999AReduce cleaning burdenImprove qualityPhotography auxillary processesElectrolysis componentsDistillationImpurity ions

The invention discloses a method for recycling cadmium from metallurgical cadmium-contained dust and a device for recycling cadmium from a cadmium-ammonia solution. The metallurgical cadmium-containeddust is subject to ammoniacal circular leaching, when the lead / cadmium molar ratio in the solution is smaller than 0.01, the circular leaching process is ended; after leaching is finished, liquid solution separation is carried out, and the cadmium-ammonia solution is obtained; the proper amount of vulcanizing agent is added to enable impurity ions in the cadmium-ammonia solution to be subject tovulcanization precipitation separation. After impurity removal, liquid is placed in an ultrasonic enhancing electric strengthening replacement cadmium extraction key device to be subject to efficientcadmium extraction, and high-grade sponge cadmium and zinc-ammonia solution can be obtained. The sponge cadmium can be directly used for briquetting distillation or fusion casting-electrolytic refining to obtain high-purity cadmium. The zinc- ammonia solution can be directly turned into an electric zinc system to produce electric zinc.

Owner:CENT SOUTH UNIV

Environment-friendly rubber vulcanizing activator, and preparation method and application thereof

The invention discloses an environment-friendly rubber vulcanizing activator, and a preparation method and application thereof. The vulcanizing activator comprises, by mass, 1-6 parts of C2-C6 polyalcohol, 1-5 parts of C2-C6 fatty acid polyol ester, 2-5 parts of C8-C18 fatty acids and 1-4 parts of zinc oxide. The prepared vulcanizing activator is added to rubber instead of the zinc oxide, so thatthe crosslinking density and tensile strength of the vulcanized rubber are improved, the Mooney viscosity thereof is lowered, and the processing property and wear resistance thereof are improved; meanwhile, the zinc content is reduced by 50-62% as compared with that of a zinc oxide vulcanizing system.

Owner:SOUTH CHINA UNIV OF TECH

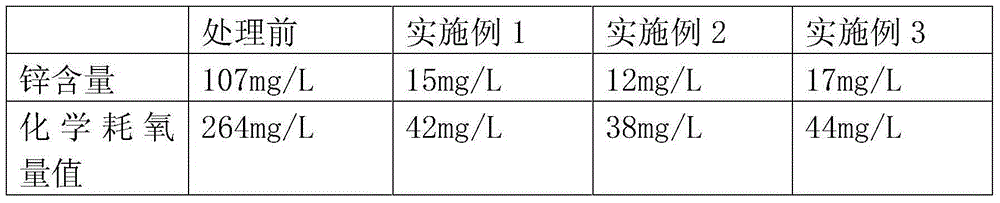

Method for treating galvanization sewage

ActiveCN103951127AReduced zinc contentWaste water treatment from metallurgical processMultistage water/sewage treatmentFlocculationChemical oxygen demand

The invention provides a method for treating galvanization sewage. The method comprises the following steps: (1) putting ferrous sulfate and ferric trichloride in the galvanization sewage to carry out flocculation; (2) after flocculation, carrying out ultrasonic treatment on the sewage; (3) after the ultrasonic treatment is finished, carrying out standing and clarifying, and removing the precipitate of the bottom layer, thereby obtaining the liquid supernatant of the galvanization sewage; (4) enabling the liquid supernatant of the galvanization sewage subjected to the ultrasonic treatment and the flocculation treatment to pass through a D751 chelating ion exchange resin; (5) collecting a sewage effluent after exchange and enabling the sewage effluent to pass through an SP825 macroporous adsorption resin; (6) finally, collecting the treated galvanization sewage. The content of zinc ions in the treated galvanization sewage is reduced to the range of 12-17mg / L from 107mg / L and the chemical oxygen demand value of the sewage is reduced to the range from 38mg / L to 44mg / L from 264mg / L, and therefore, the zinc content of the sewage and the chemical oxygen demand are remarkably reduced.

Owner:SUZHOU GANNZ ELECTRONICS TECH CO LTD

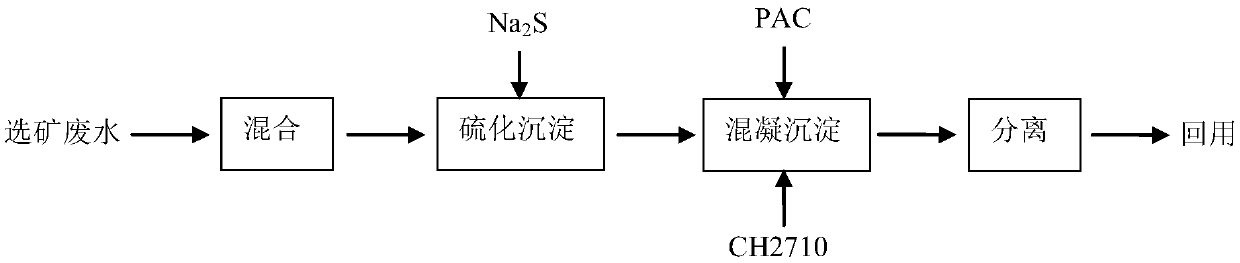

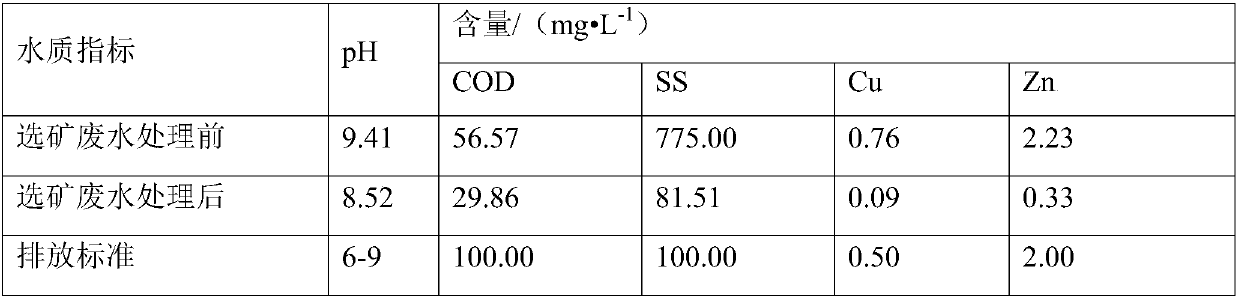

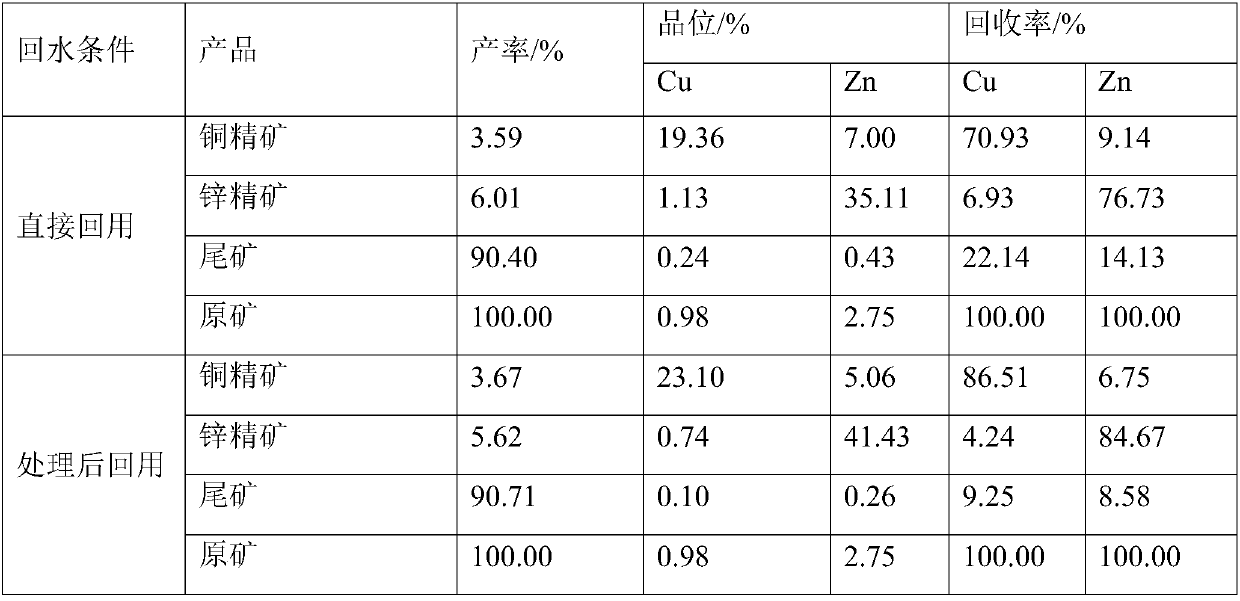

Method for treating and recycling copper-zinc sulphide ore separation waste water

PendingCN109607720AReduced zinc contentHigh recovery rateWaste water treatment from quariesWater contaminantsVulcanizationHazardous substance

The invention relates to a method for treating and recycling copper-zinc sulphide ore separation waste water. Aiming at the copper-zinc sulphide ore separation waste water, the mode of combining a vulcanization sedimentation method and a coagulating sedimentation method is adopted, that is, the waste water is fast stirring through a precipitator sodium sulphide and a flocculant PAC, then a flocculant CH2710 is added, slow stirring is carried out, after coagulating sedimentation is carried out, toxic and harmful substances in the ore separation waste water are greatly reduced, and on the contrary, the zinc concentrate recycling rate can be increased, and the zinc content in copper concentrate can be reduced. Meanwhile, consumption of part of flotation reagents can be reduced, and the production cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Zinc active agent composition for rubber vulcanization

The invention discloses a zinc active agent composition for rubber vulcanization. The zinc active agent composition comprises an aromatic compound with a plurality of COOH groups, wherein part of the COOH groups of the compound is neutralized by zinc. The zinc active composition comprises a mixture of the aromatic compounds with single or a plurality of-COOH groups, as well as zinc salt mixture of the aromatic compounds, wherein the content of the zinc salt compound is 20-100%. In comparison with the zinc oxide used as the rubber vulcanization activator, the zinc active agent composition disclosed by the invention has low zinc content, and the zinc active agent composition used as a vulcanization activator has the same effect as the conventional zinc oxide.

Owner:EAST CHINA UNIV OF SCI & TECH

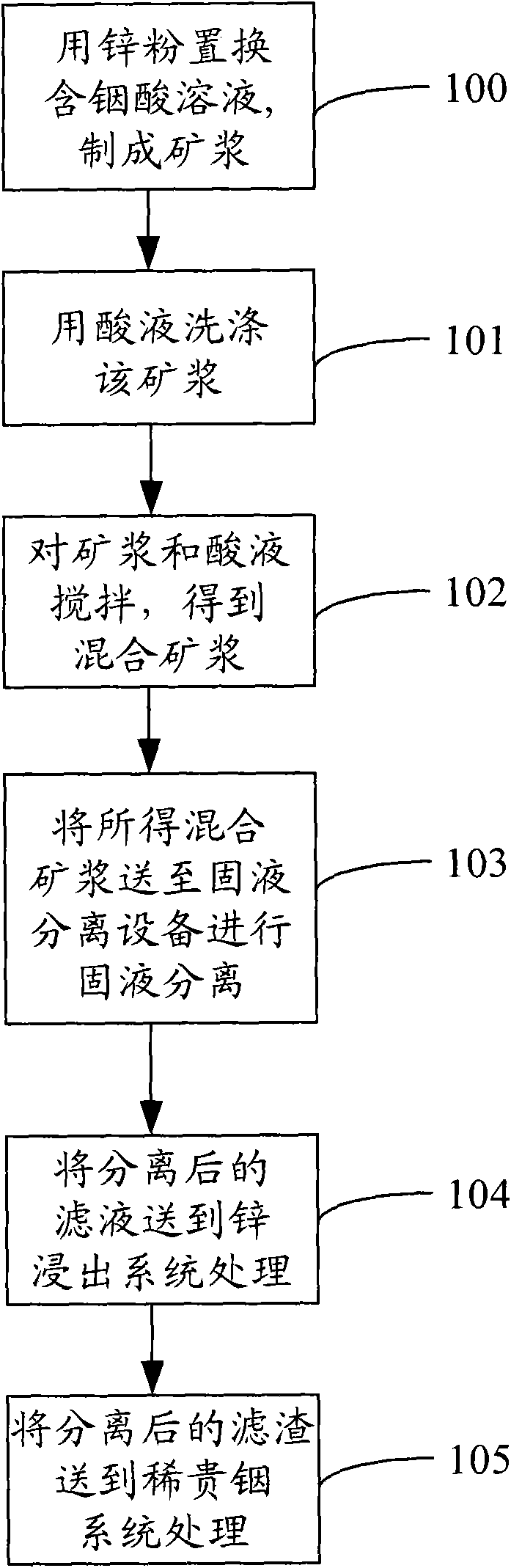

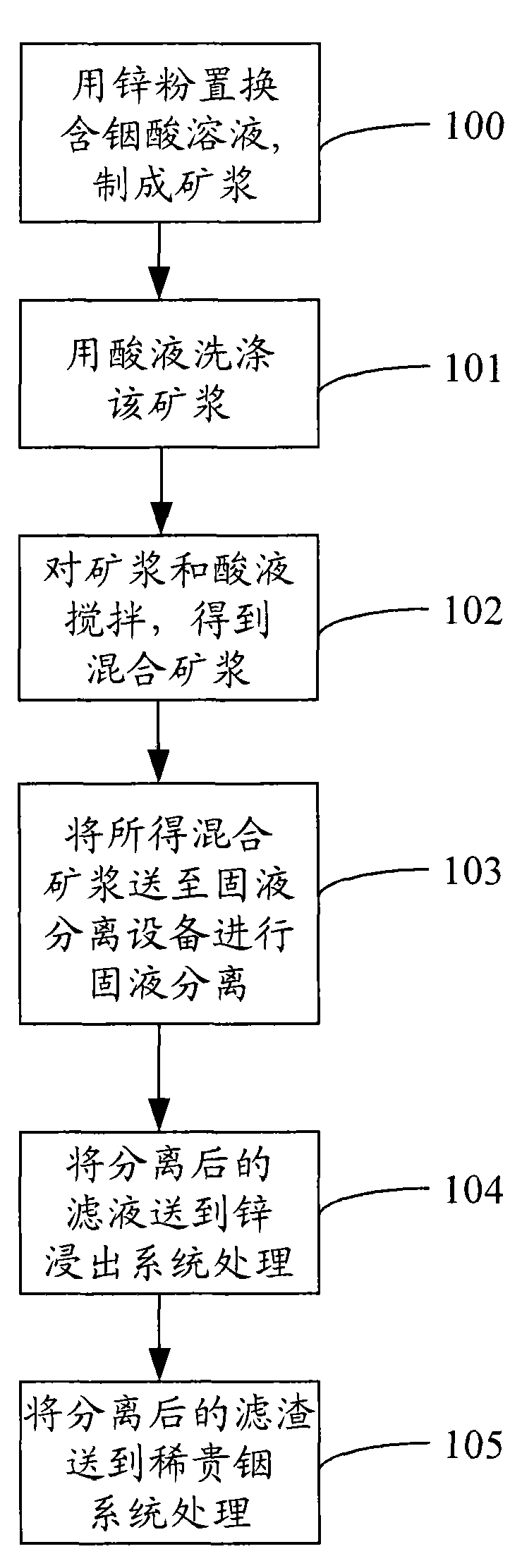

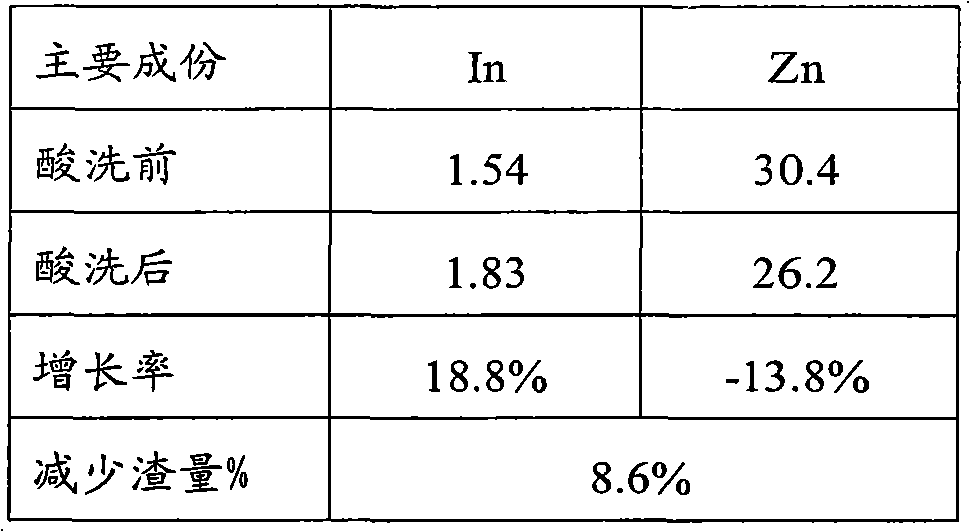

Method for improving indium grade of enriched indium slag

The invention discloses a method for the indium grade of an enriched indium slag in the process of lead and zinc smelting by-product zinc oxide. The method comprises the following steps: continuously adding acidic liquid into ore pulp after indium-containing acidic solution is replaced by zinc powder and stirring; stirring the ore pulp to perform a reaction for a certain time to form the mixed ore pulp; transporting the mixed ore pulp to a solid-liquid separator to perform solid-liquid separation; and conveying the separated filter residue to a rare indium system for processing, and then recycling the indium and zinc of the separated filter liquid. The main metal such as zinc and the like is reduced and recycled through a new process of increasing and reducing the slag quantity of the enriched indium slag, so that the quantity of the enriched indium slag is reduced and the indium grade of the enriched indium slag is improved.

Owner:ZHUZHOU SMELTER GRP

Corrosion proof fluoride welding agent containing magnesium-aluminium alloy

InactiveCN1175957CEfficient removalReduced zinc contentWelding/cutting media/materialsSoldering mediaSolderingFluoride

Owner:TSINGHUA UNIV

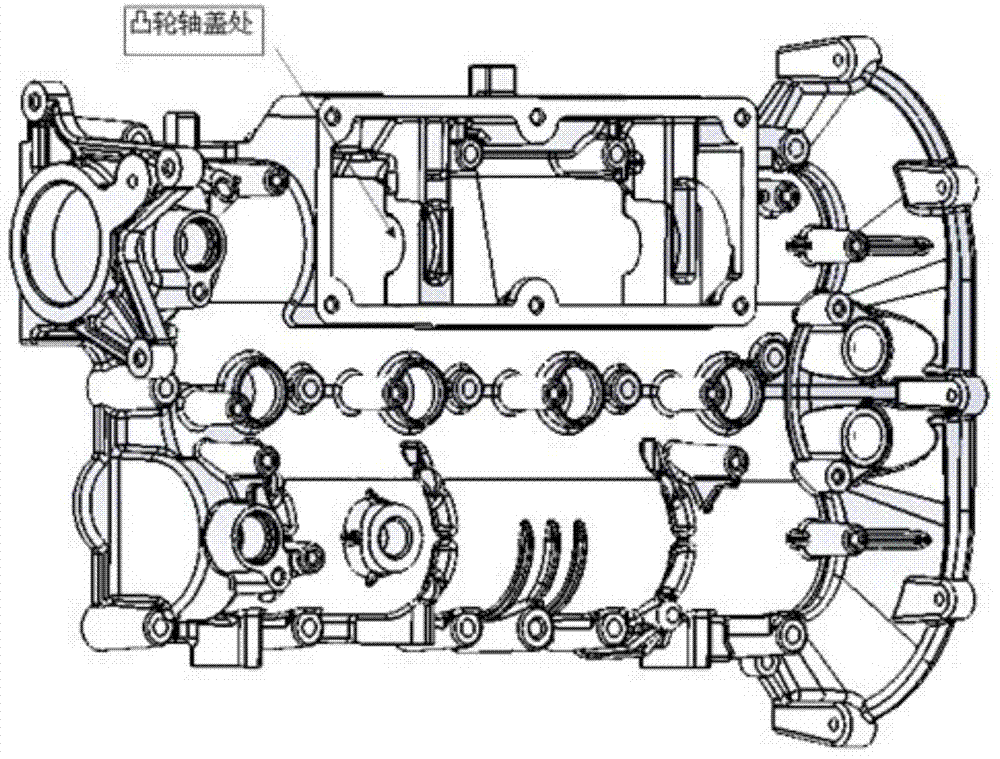

Aluminum alloy for manufacturing die-casting cylinder head covers and die-casting cylinder head cover

InactiveCN104498781AImprove liquidityReduced zinc contentCasingsMachines/enginesCylinder headUltimate tensile strength

The invention discloses an aluminum alloy for manufacturing a die-casting cylinder head covers, which comprises the following compositions in percentage by weight: 10.5-12% of Si, 1.5-2.5% of Cu, 0.8-1.1% of Fe, 0.15-0.3% of Mg, less than or equal to 1.0% of Zn, less than or equal to 0.5% of Mn, less than or equal to 0.3% of Ti, and the balance of AL and unavoidable impurities. The aluminum alloy is particularly applicable to the manufacturing of die-casting cylinder head covers, can improve the stability of the production process and the quality of products; and a die-casting cylinder head cover manufactured by using the aluminum alloy disclosed by the invention is bright in appearance, high in strength, good in toughness and long in service life, and has no mold sticking.

Owner:GUIYANG GUANGHANG CASTING

Green recovering technique for pickled vegetables

InactiveCN105231161ARestore colorReduce Zn2+ contentFood ingredient functionsFood preparationPickled vegetablesIon

The invention discloses a green recovering technique for pickled vegetables, which comprises the following steps: cleaning the pickled vegetables, preprocessing with the dilute alkali and the solution containing Ca<2+>, processing with a green recovering solution containing Zn<2+>, rinsing, packaging, sterilizing and cooling. According to the green recovering technique provided by the invention, the color of the pickled green vegetables can be effectively recovered, the excellent color and appearance can be kept and the heavy metal ion Zn<2+> is prevented from exceeding standard.

Owner:HUNAN ER KANG PHARMA

Process for the recovery of zinc from aqueous process streams

InactiveUS6036929AReduced zinc contentReduce concentrationZinc halidesZinc oxides/hydroxidesZinc compoundsChloride

The invention provides a process for the removal and recovery of zinc from an aqueous process stream. In particular, the process of the invention is useful in the removal and recovery of zinc compounds such as zinc chloride from an aqueous effluent stream produced in various manufacturing processes such as the manufacture of sorbic acid.

Owner:EASTMAN CHEM CO

Method for effectively removing magnesium ions in zinc sulfate solution of electrolytic zinc

ActiveCN109592706AReduced zinc contentReduce lossesMagnesium fluoridesZinc sulatesHydrofluoric acidSulfate

The invention provides a method for effectively removing magnesium ions from a zinc sulfate solution of electrolytic zinc. The method comprises the following steps: adding hydrofluoric acid in the zinc sulfate solution for producing electrolytic zinc according to a mass ratio of Mg to HF being 24:(35-38), adding an alkaline zinc-containing material until the pH value of the zinc sulfate solution is 3-5.2, and performing fluorination precipitation to remove magnesium; introducing saturated vapor at the pressure of 0.1-0.6Mpa, or heating to 110-160 DEG C, and boosting to 0.1-0.6Mpa, and insulating for 2-6 hours to condense, agglomerate and grow the magnesium fluoride precipitate in the mixture into particles by heating and pressurizing; decompressing, cooling and separating to obtain magnesium fluoride particles which cannot block a filter cloth or filter screen in the separating process. The method can solve the problem that magnesium fluoride precipitate which is a colloidal substanceblocks a filter cloth or filter screen and cannot realize solid-liquid separation and enables zinc fluoride to break coating of the magnesium fluoride, so that zinc loss can be reduced, and cost can be reduced.

Owner:张华

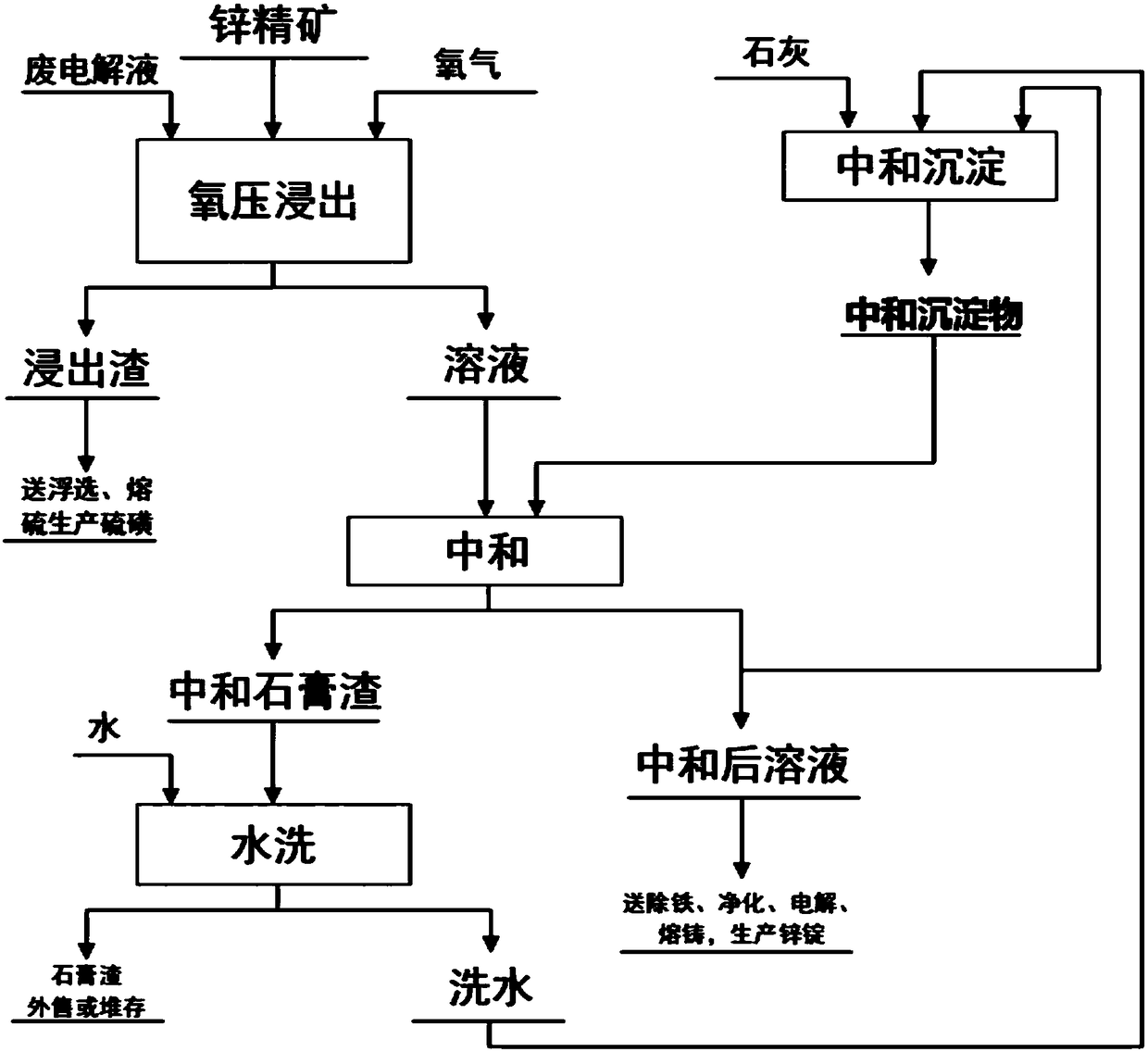

Treatment method for zinc oxygen pressure leaching solution

The invention relates to a treatment method for zinc oxygen pressure leaching solution. The treatment method includes the steps that neutralizing precipitate is added to the zinc oxygen pressure leaching solution, reaction is carried out until the pH value of the solution is 4-5, and the neutralized solution and gypsum slag are obtained; the gypsum slag is washed to obtain washing water; a mixtureis obtained by mixing partial neutralized solution with the washing water, then lime is added to the mixture, reaction is carried out until the pH value of the mixture is 7-8, and neutralized precipitate is obtained; and wherein, the neutralized precipitate comprises a hydroxide containing CaSO4 and zinc. According to the treatment method for the zinc oxygen pressure leaching solution, neutralizer (hydroxide of zinc) is self-circulation, additional zinc-containing materials adding to a production system is not required, the zinc content used as the zinc hydroxide neutralizer is approximately10% of that of the main production system, the zinc-containing content of the gypsum slag is greatly reduced, the required lime quantity is little, the neutralized precipitate is prepared by mixing the lime with the neutralized solution and the washing water, and the problem of zinc enriching and recovering in the washing water is solved.

Owner:CINF ENG CO LTD

Refining fluxing medium for zinc-based alloy smelting and preparation method of refining fluxing medium

ActiveCN106222466AIncrease slag temperatureReduced zinc contentAfter treatmentPotassium chloride 10%

The invention discloses a refining fluxing medium for zinc-based alloy smelting and a preparation method of the refining fluxing medium and aims at providing the refining fluxing medium for zinc-based alloy smelting and the preparation method of the refining fluxing medium. The refining fluxing medium is characterized by comprising the raw materials in parts by weight: 20-30 parts of sodium chloride, 10-20 parts of potassium chloride, 18-30 parts of sodium nitrate, 10-15 parts of calcium fluoride, 10-20 parts of sodium sulfate and 3-5 parts of charcoal powder and comprising the following steps of A, adding sodium chloride, potassium chloride, calcium fluoride and sodium sulfate into a heating stirrer according to the weight ratio, heating and stirring at the temperature of 95-110 DEG C for 50min, and then, stopping heating to form a uniformly dried primary mixture; B, adding 18-30 parts of sodium nitrate and 3-5 parts of charcoal powder into the uniformly dried primary mixture, and stirring for 10min in the heating stirrer to obtain a secondary mixture; and C, discharging the secondary mixture in the step B to a holding tray, naturally cooling to the room temperature, and subpackaging finished products into 2kg / bag and 20kg / box. The refining fluxing medium is mainly used for after-treatment of zinc-based alloy smelting.

Owner:ZHUZHOU CHUANGLIN ALLOY

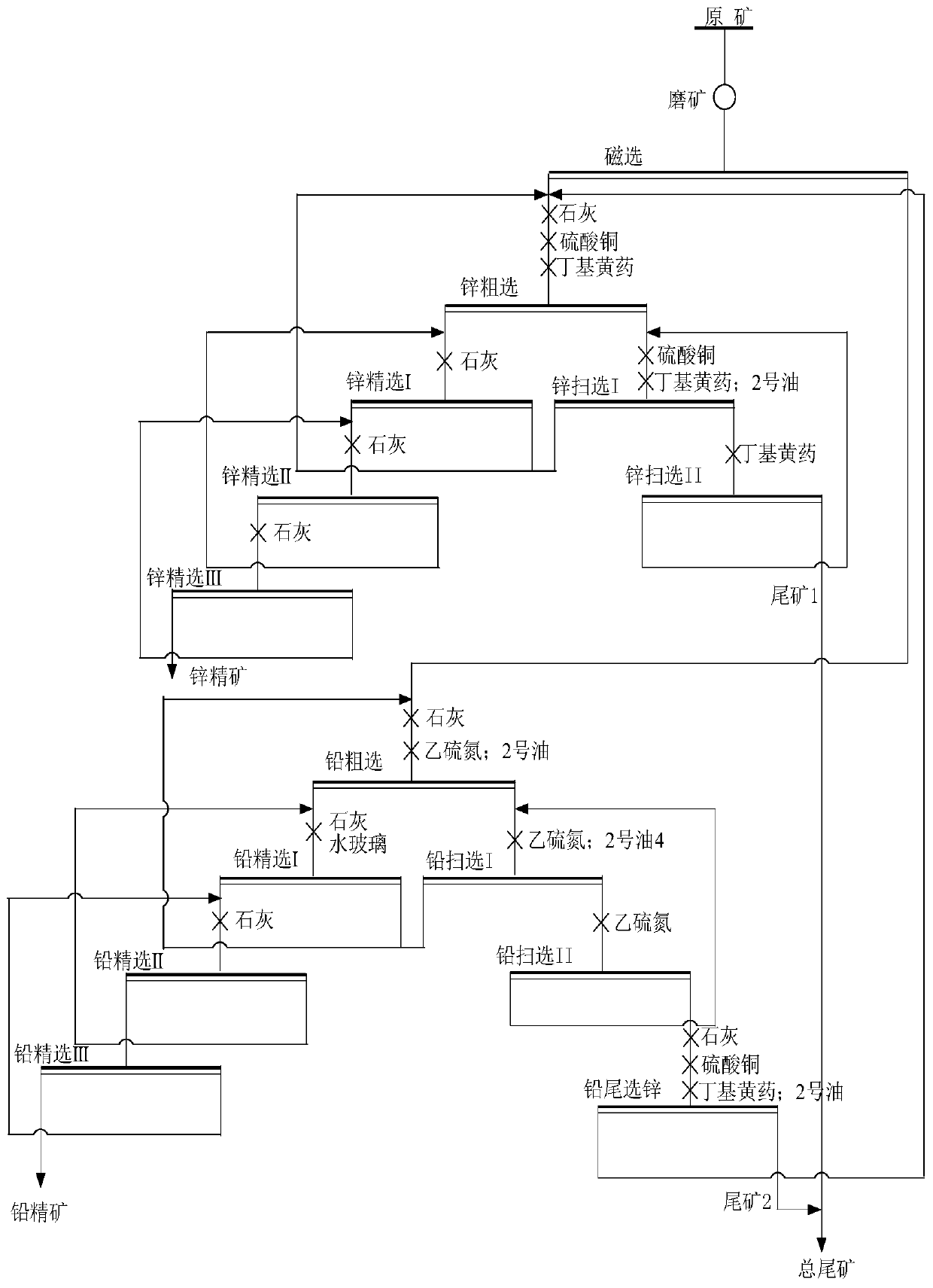

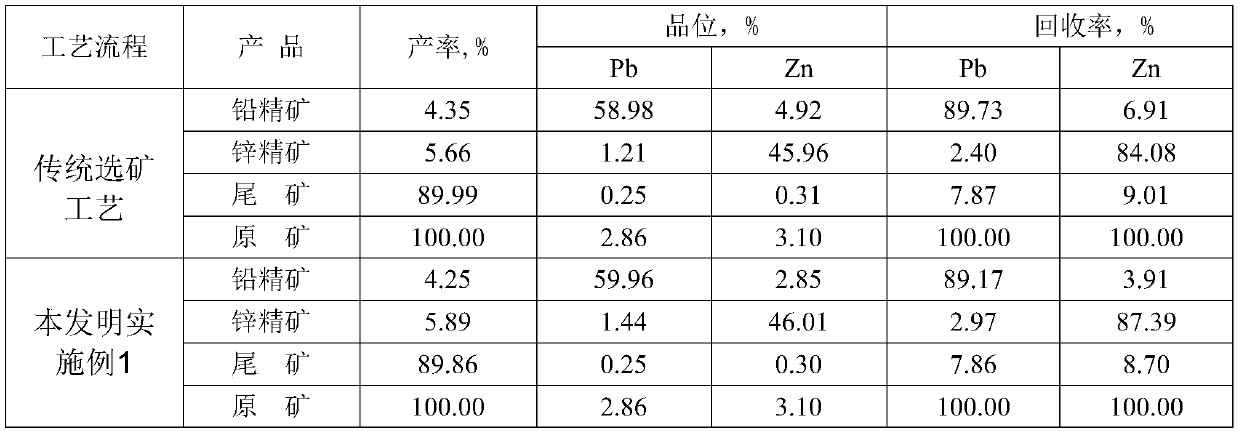

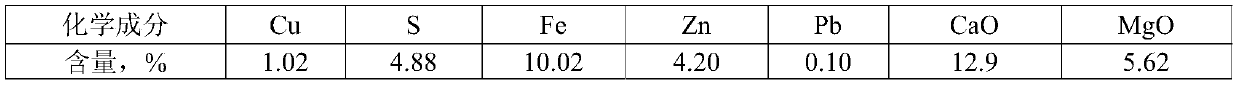

Beneficiation method for complex sulfide ore containing marmatite

InactiveCN110180673AReduced zinc contentHigh recovery rate of zincWet separationBeneficiationZincite

The invention discloses a beneficiation method for a complex sulfide ore containing marmatite. The beneficiation method comprises the following steps that a raw ore is ground and subjected to magneticseparation, so that the marmatite and magnetic separation tailings are obtained; zinc flotation is carried out on the marmatite so as to obtain a zinc concentrate; and sequential priority flotation is conducted on the magnetic separation tailings. According to the method, not only the zinc content in a copper (lead) concentrate is greatly reduced, the zinc recovery rate is improved, but also theusing amount of a flotation reagent is reduced, and the pollution to the environment is reduced.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

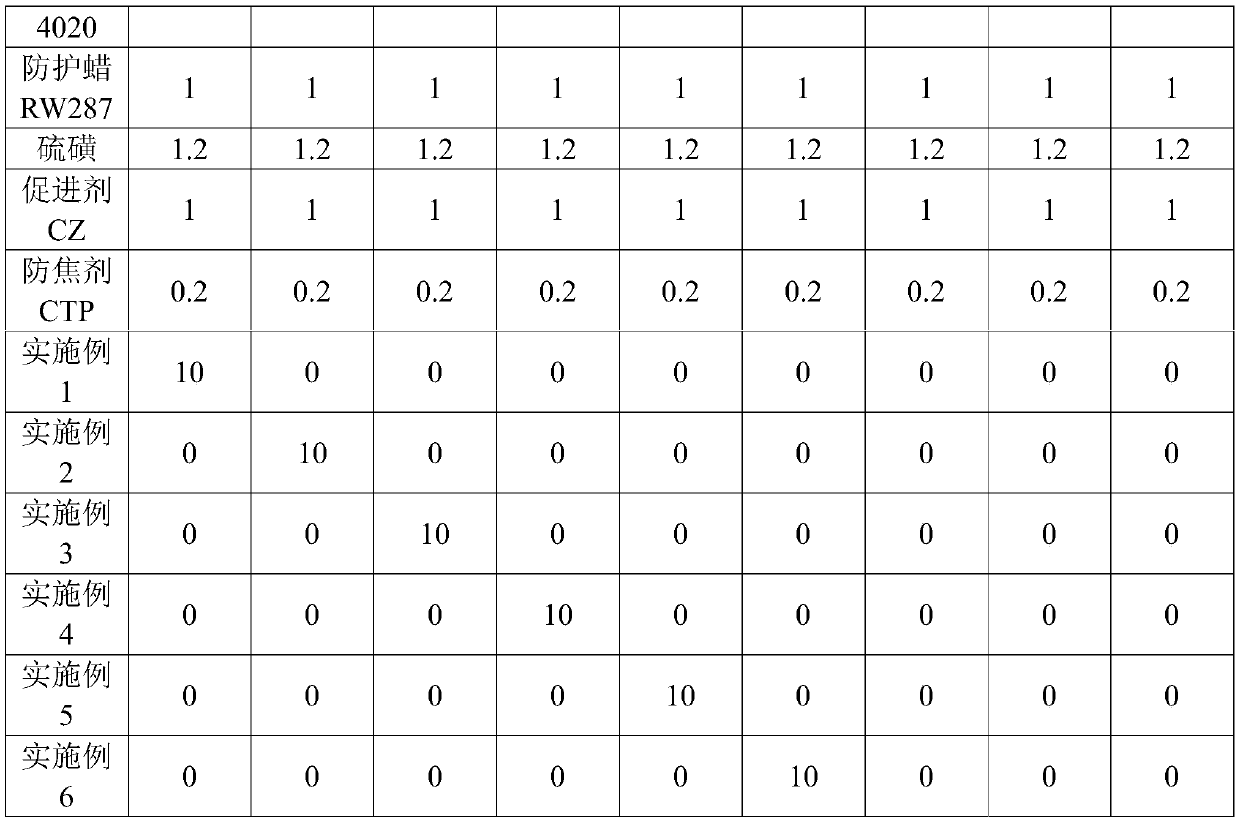

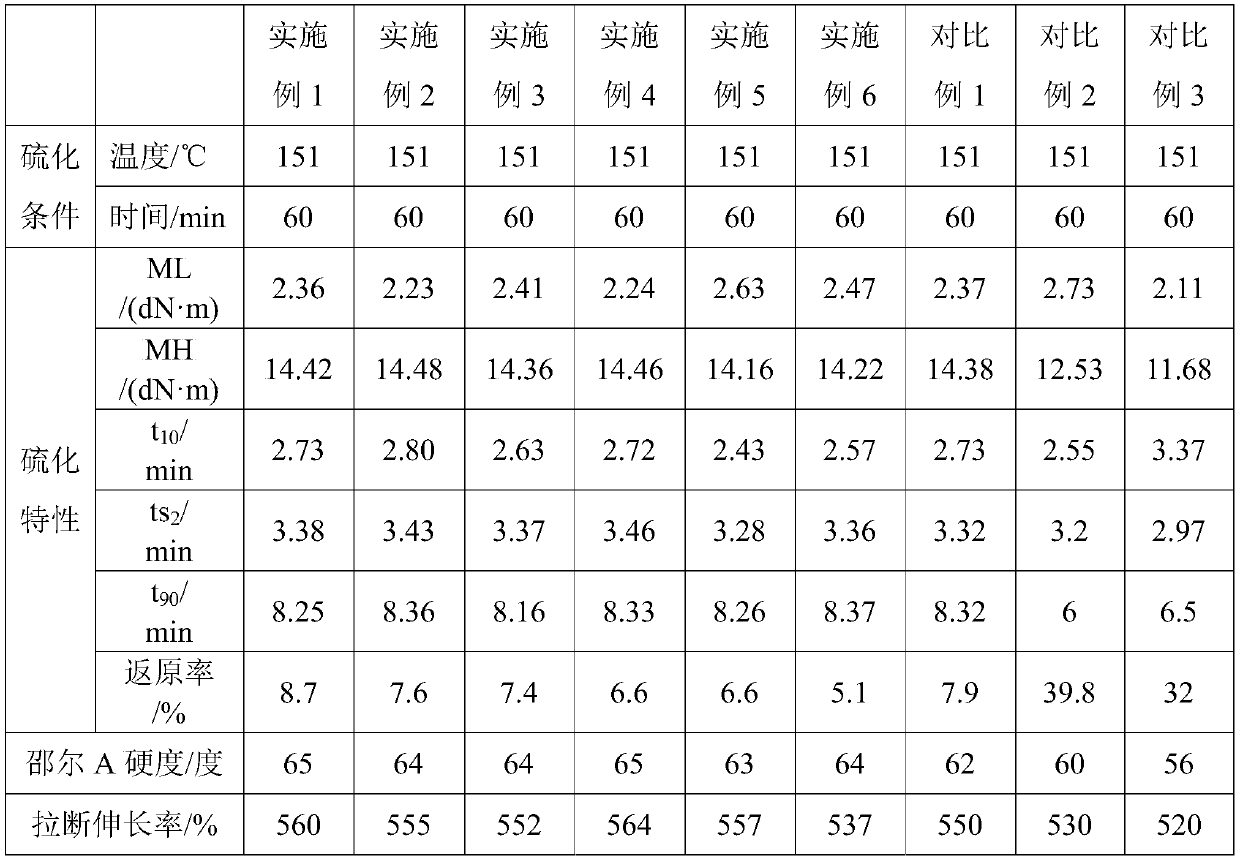

Vulcanization-promoted comprehensive protective material and preparation method thereof

The invention discloses a vulcanization-promoted comprehensive protective material and a preparation method thereof. The protective material is composed of an anti-aging agent RD, an anti-aging agent4020, an anti-aging agent 4030 and zinc terephthalate according to a weight part ratio of (25-30):(20-25):(20-25):(20-35). The preparation method of the protective material comprises the following steps: (1) adding an anti-aging agent RD, an anti-aging agent 4020, an anti-aging agent 4030 and an emulsifier into acetone, and stirring to obtain an emulsion system A; (2) dispersing zinc terephthalateand an emulsifier into acetone to obtain an emulsion system B; and (3) mixing the system A and the system B in a homogenizer, distilling to recover acetone, cooling the remaining substances, and granulating to obtain the target product. The protective material disclosed by the invention has excellent protective effects of thermal oxidation resistance, ozone resistance in dynamic and static states, metal toxicity resistance and the like, and can promote rubber vulcanization process.

Owner:常州市五洲化工有限公司

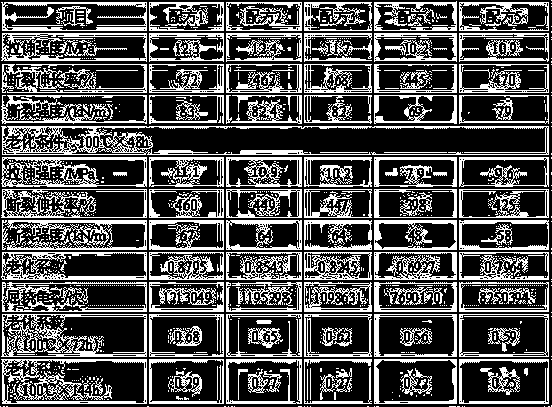

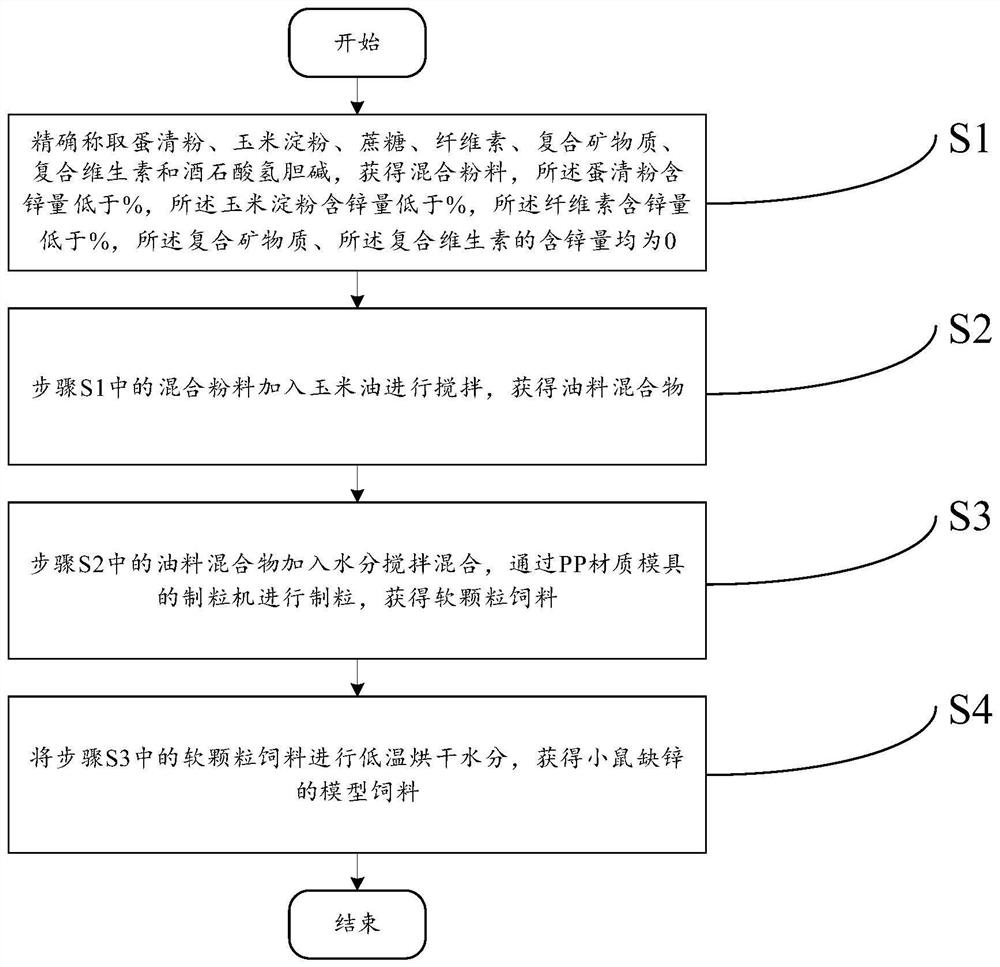

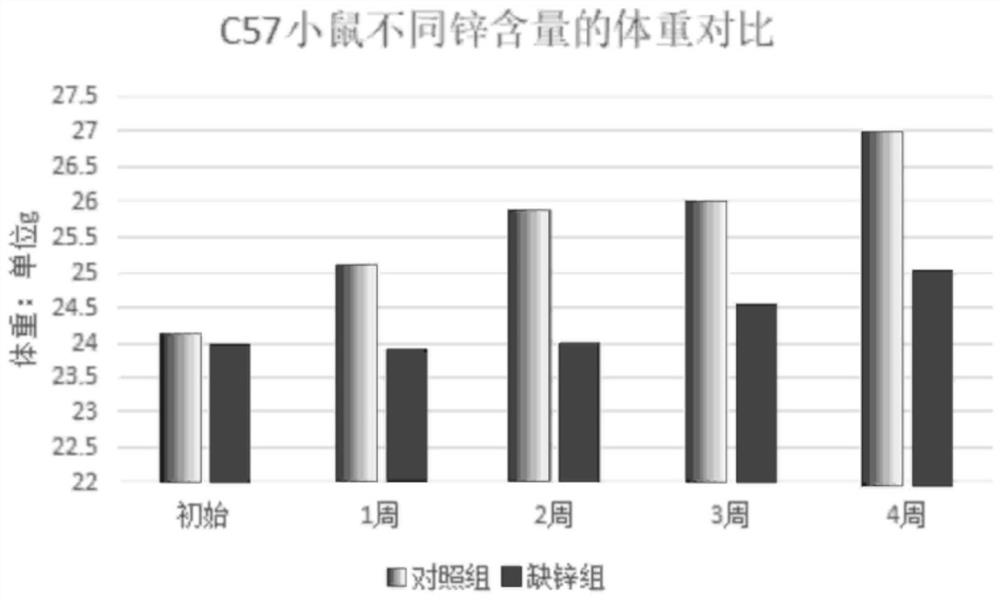

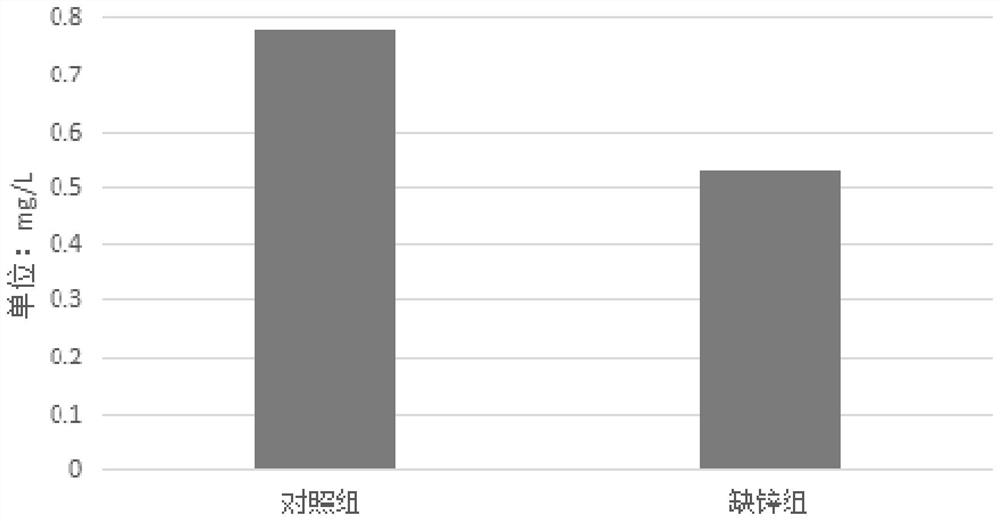

Mouse zinc deficiency model feed and preparation method and application thereof

PendingCN111728095AReduced zinc contentEthicalAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

The invention belongs to the technical field of experimental animals and particularly relates to a preparation method of mouse zinc deficiency model feed. The method comprises: weighing basal feed accurately and 2% cholesterol for mixing; adding grease with a heat ratio of 40% for stirring; adding moisture for stirring and mixing, and carrying out granulation with a granulation machine to obtain soft particle feed; and carrying out low-temperature moisture drying to obtain the model feed of mouse zinc deficiency. The invention also provides the mouse zinc deficiency model feed and applicationthereof. In the research, through analysis of raw material components and process improvement, the zinc deficiency feed nearly containing no zinc is prepared, and the model feed in current zinc deficiency disease research is solved. A mouse is fed only with the pure feed without use of a gavage method, so a mouse zinc deficiency model is obtained. Animal ethics are satisfied.

Owner:常州鼠一鼠二生物科技有限公司

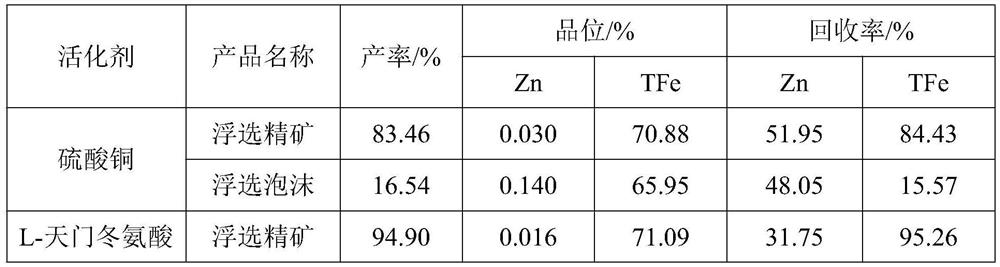

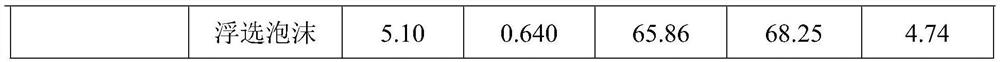

Beneficiation activating agent for sphalerite and marmatite and method for reducing zinc in iron ore concentrate through flotation

ActiveCN113477405ASolve activation problemsImprove adsorption capacityFlotationFoaming agentMining engineering

The invention relates to a beneficiation activating agent for sphalerite and marmatite and a method for reducing zinc in iron ore concentrate through flotation. The activating agent is amino acid or a mixture containing the amino acid, wherein the amino acid is one or more of asparaginic acid, asparaginic acid hydrochloride, glutamic acid, glutamic acid hydrochloride, threonine and serine. According to the method for reducing zinc in iron ore concentrate through flotation by using the activating agent, the activating agent is added into low-intensity magnetic separation iron ore concentrate pulp, then a collecting agent and a foaming agent are added, one-time roughing and one-time concentration are carried out, sphalerite and marmatite are floated out, the zinc content in the obtained iron ore concentrate is as low as 0.02% or below, and the iron loss amount is smaller than 5%. According to the invention, the problems that conventional activating agents of sphalerite and marmatite are poor in activating selectivity, zinc impurities in the iron ore concentrate are difficult to deeply remove, and the iron loss in the zinc reducing process is large are solved, the method is simple, easy to operate and good in zinc reducing effect, the zinc content can be reduced to 0.02% or below, and the requirement of the high-purity iron ore concentrate for the content of the zinc impurities is met.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Environment-friendly treating agent for wastewater containing zinc and nickel and preparation method of treating agent

InactiveCN105253930AReduce heavy metal contentHigh removal rateOther chemical processesWater contaminantsCalcium silicateSilicic acid

The invention discloses an environment-friendly treating agent for wastewater containing zinc and nickel and a preparation method of the treating agent. The treating agent for the wastewater comprises 4-10 parts of polyethylenimine, 3-8 parts of calcium silicate, 2-5 parts of barium chloride, 5-10 parts of hectorite, 3-7 parts of sodium polyacrylate, 4-12 parts of hydroxysodalite and 3-6 parts of sodium lignin sulfonate. The preparation method comprises following steps: (1), calcium silicate, barium chloride and hydroxysodalite are ground by a grinder; (2), 4-10 parts of polyethylenimine, 3-8 parts of calcium silicate, 2-5 parts of barium chloride, 5-10 parts of hectorite, 3-7 parts of sodium polyacrylate, 4-12 parts of hydroxysodalite and 3-6 parts of sodium lignin sulfonate are weighed and stirred uniformly, and the environment-friendly treating agent for the wastewater containing zinc and nickel is obtained. The zinc and nickel reducing rate of the prepared environment-friendly treating agent for the wastewater is higher than 75%.

Owner:苏州书瑞环保科技有限公司

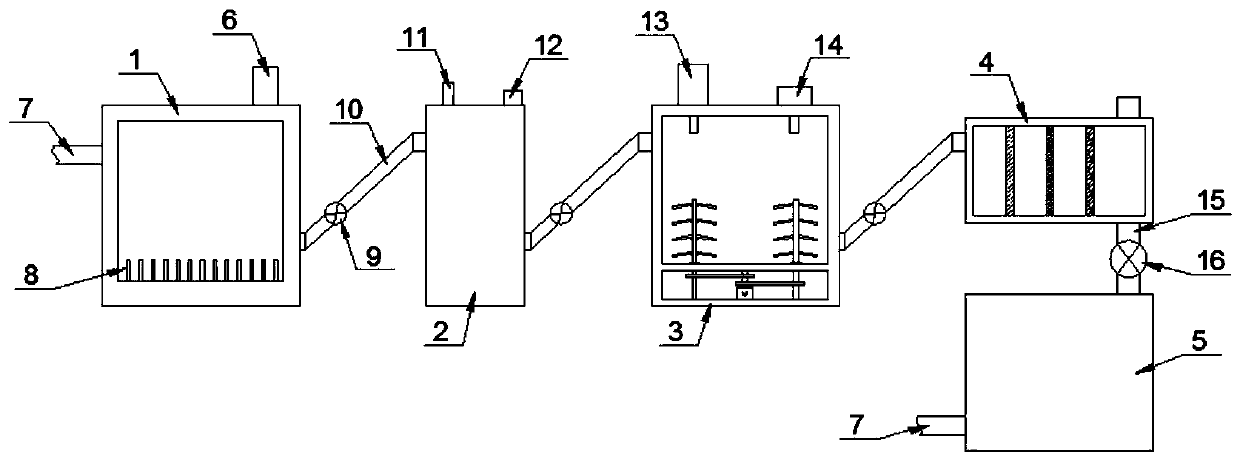

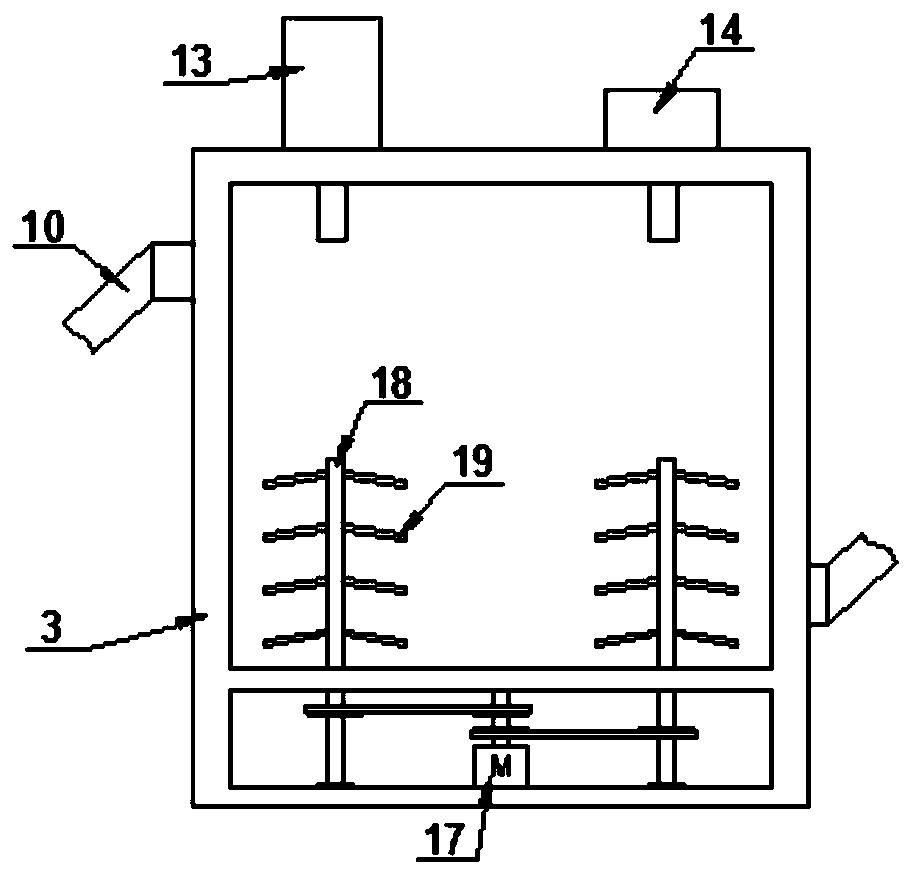

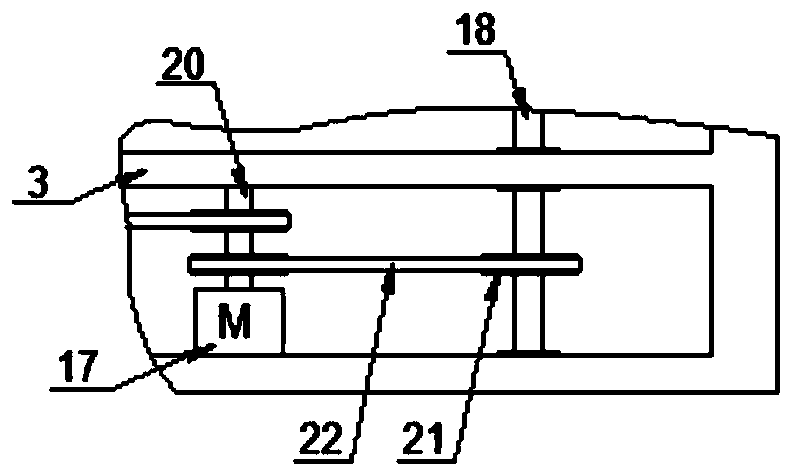

Sewage circulation treatment system for electrogalvanizing and operation method

InactiveCN110156207AImprove responseFully integratedWater contaminantsTreatment involving filtrationEmission standardSewage

The invention discloses a sewage circulation treatment system for electrogalvanizing and an operation method. The system comprises a setting tank, a neutralization tank, a reaction tank, a filtering tank and a collection tank, wherein a water inlet tube is communicated with a side wall of the settling tank; a first dosing tube and a detector are fixedly connected with a side wall of the neutralization tank; a cavity is formed in the bottom inside the reaction tank; two rotating rods are rotationally connected in symmetry inside the cavity; upper ends of the two rotating rods both extend into the reaction tank; a plurality of stirring rods are fixedly connected in symmetry on the side wall of one end inside the reaction tank, of each rotating rod; a driving device is arranged inside the cavity; the driving device is connected with the two rotating rods; a filtering device is arranged inside the filtering tank; and a first communicating tube is communicated with a side wall of the filtering tank. The system has the advantages that by adopting the system, sewage can be effectively treated, the content of zinc can be greatly reduced, and emission standards can be met.

Owner:YUEXI COUNTY CHUANGQI ELECTRIC APPLIANCE

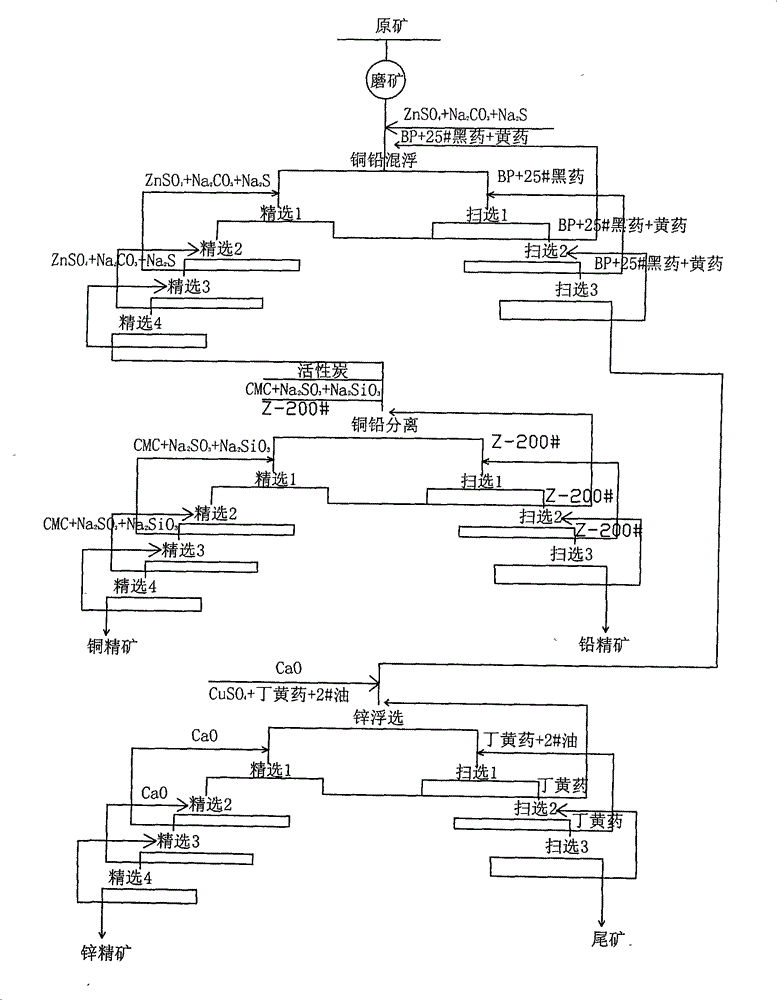

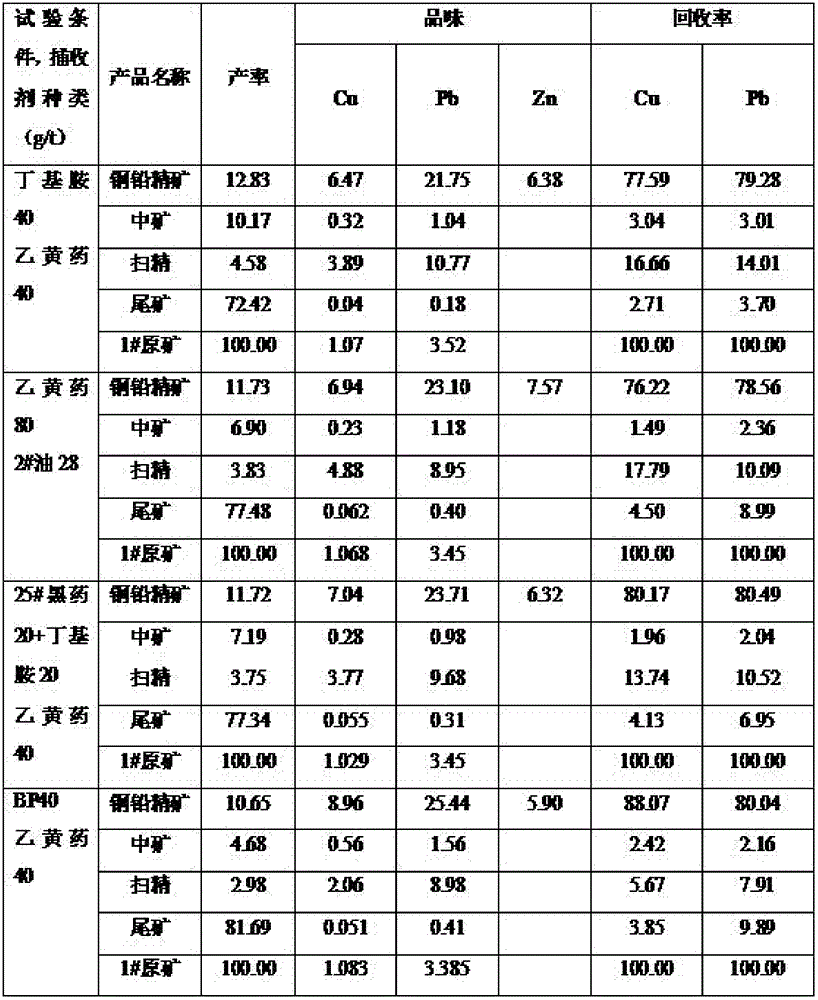

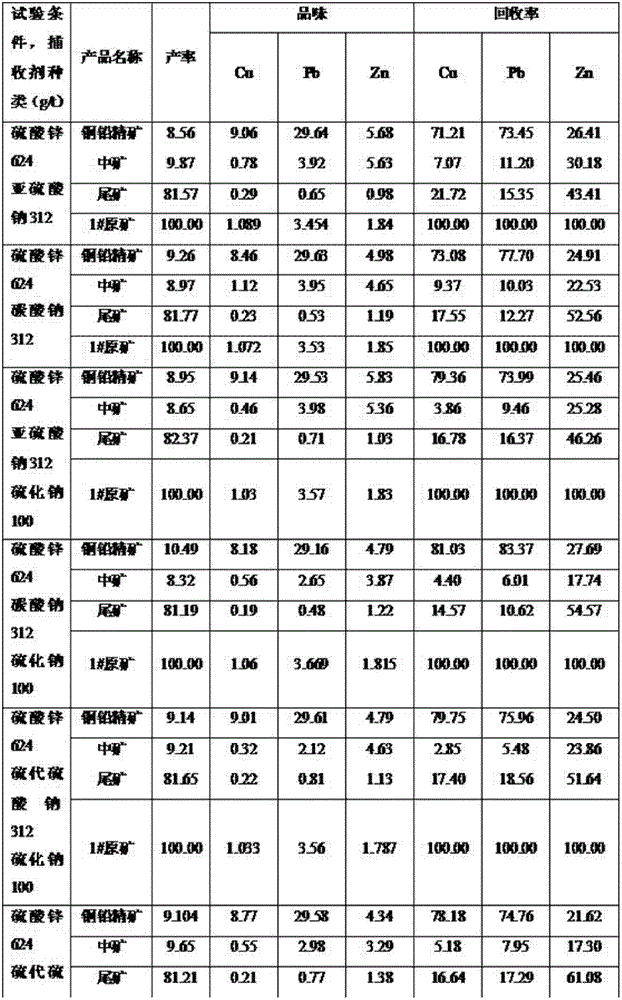

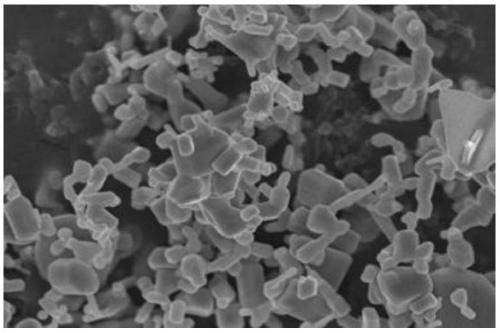

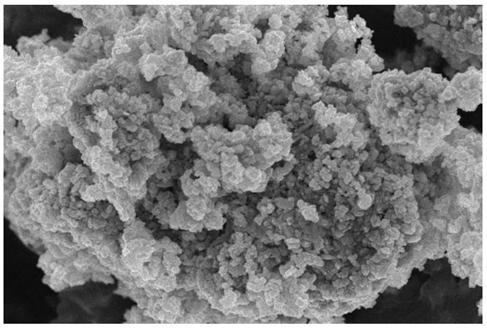

Mineral separation process capable of separating copper, lead, zinc polymetal sulphide ore

The invention relates to a method for ore dressing, in particular to a method for the ore dressing of a copper-lead-zinc poly-metallic sulfide ore. The method consists of crude ore dressing, ore grinding, copper-lead bulk flotation, copper-lead separation and zinc flotation, wherein in the process of the copper-lead bulk flotation, ore dressing reagents BP, No.25 aerofloat and ethylic-butyl xanthate are adopted as collecting agents for copper and lead ores, and zinc sulfate, sodium carbonate and sodium sulfide are adopted as inhibitors for zinc ores; and in the process of the copper-lead separation, active carbon is adopted to perform reagent removal, sodium sulfite, CMC and water glass are adopted as the inhibitors for lead ores, and No.Z-200 as the collecting agent for copper ores. The method has good metallic mineral separation effect and high metal recovery rate, is simple, is easy to operate, and is suitable for popularization and application.

Owner:XIZANG ZHONGKAI MINING IND

Low zinc rubber composition

The invention discloses a low zinc rubber composition which is characterized by comprising a rubber composition of at least one diene elastomer containing zinc, the zinc content is 0.5-1 phr, and phrmeans per hundred parts of rubber. The rubber composition is based on at least one filler system and a sulfur-based crosslinking system comprising high specific surface area nano zinc oxide supportedby zinc hydroxide particles as a vulcanization activator. An auxiliary system is further included. The vulcanization activator is characterized in that nano zinc oxide is evenly supported on the surfaces of the zinc hydroxide particles during the decomposition process of a precipitate, has high chemical activity and good dispersibility, and can ensure good performance of a product under reduced use and reduce the residual amount of zinc in rubber products. The rubber composition is applied to tire products to improve environmental performance and reduce zinc pollution caused by tires.

Owner:SAILUN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com