Novel zinc oxide rubber vulcanization activator, and preparation method and application thereof

A technology of rubber vulcanization and zinc oxide, applied in the field of rubber additives, can solve the problems of poor compatibility with polymers, easy agglomeration, low reactivity, etc., and achieve the effects of short production cycle, reduced pollution and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

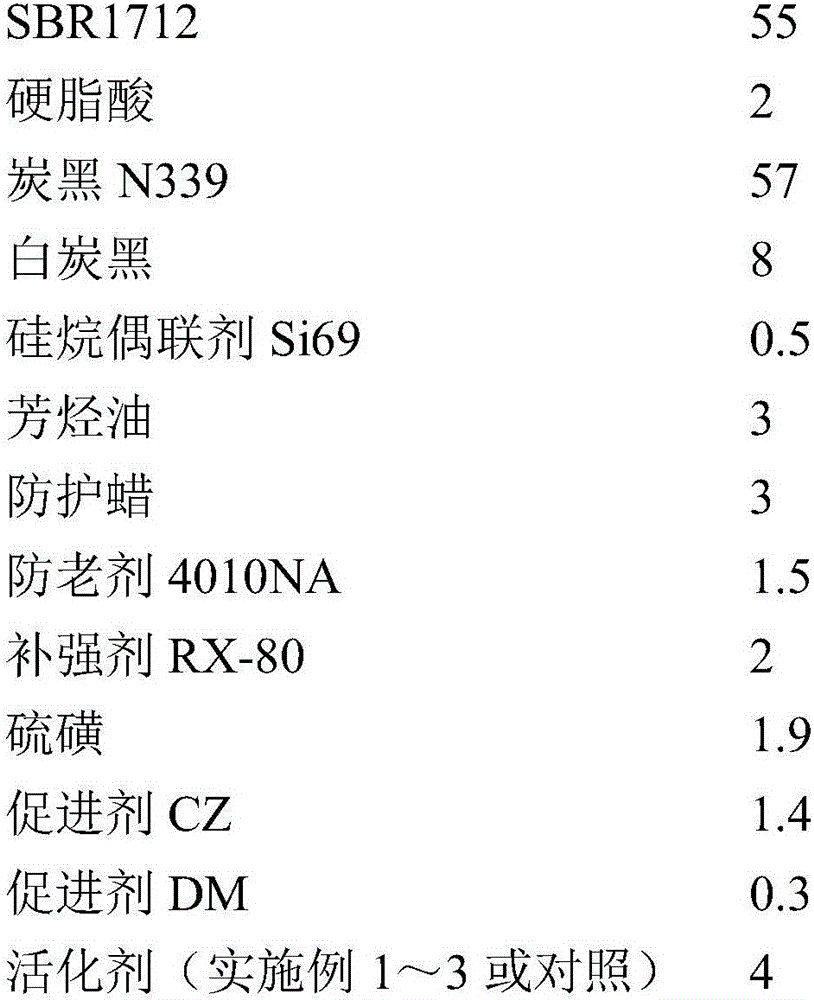

Examples

Embodiment 1

[0039] (1) Mix methacrylic acid and sodium hydroxide solution evenly, and adjust the pH to 9.0; then slowly add zinc chloride solution with an initial concentration of 276mg / ml, wherein the molar ratio of zinc chloride to methacrylic acid in the reaction system 1:2, the mol ratio of zinc chloride to the hydroxide ion in the sodium hydroxide solution is 1:2; after the zinc chloride solution is added, stir and react for 40min, filter and separate to obtain the crude product, then wash, Obtain nano zinc methacrylate;

[0040] (2) Mix the nano-zinc methacrylate prepared in step (1) with sodium hydroxide solution and ultrasonically treat it for 40min, then slowly add the zinc chloride solution whose initial concentration is 63.4mg / ml, wherein, the chlorine in the reaction system The molar ratio of zinc chloride to zinc methacrylate is 2:1, and the molar ratio of zinc chloride to hydroxide ions in sodium hydroxide solution is 1:1; Stir and react for 80 minutes; filter and separate ...

Embodiment 2

[0043] (1) Mix 2-butenoic acid and sodium hydroxide solution evenly, and adjust the pH to 10.0; then slowly add zinc chloride solution with an initial concentration of 74mg / ml, wherein, in the reaction system, zinc chloride and 2-butene The molar ratio of the acid is 1:1, and the molar ratio of the hydroxide ion in the zinc chloride to the sodium hydroxide solution is 1:1; after the addition of the zinc chloride solution, stir and react for 30 minutes, filter and separate to obtain the crude product , and then washed to obtain nano-zinc 2-butenoate;

[0044](2) Mix the nano-zinc 2-butenoate prepared in step (1) with sodium hydroxide solution and ultrasonically treat it for 30min, then slowly add the zinc nitrate solution whose initial concentration is 33.2mg / ml, wherein, in the reaction system The molar ratio of zinc nitrate to zinc 2-butenoate is 3:1, and the molar ratio of zinc nitrate to hydroxide ions in the sodium hydroxide solution is 1:2; Stir and react for 100 minutes...

Embodiment 3

[0047] (1) Mix methacrylic acid and sodium hydroxide solution evenly, and adjust the pH to 8.0; then slowly add calcium chloride solution with an initial concentration of 111mg / ml, wherein the molar ratio of calcium chloride to methacrylic acid in the reaction system It is 1:1.5, and the mol ratio of calcium chloride and the hydroxide ion in the sodium hydroxide solution is 1:1.5; After the calcium chloride solution is added, stir and react for 60min, filter and separate, obtain the crude product, then wash, Obtain nanometer calcium methacrylate;

[0048] (2) Mix the nano-calcium methacrylate prepared in step (1) with sodium hydroxide solution and ultrasonically treat it for 50min, then slowly add the zinc chloride solution whose initial concentration is 63.4mg / ml, wherein, the chlorine in the reaction system The molar ratio of zinc chloride to calcium methacrylate is 1:1, and the molar ratio of zinc chloride to hydroxide ions in sodium hydroxide solution is 1:1.5; Stir and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com