Beneficiation method for complex sulfide ore containing marmatite

A sphalerite and ore dressing method technology, which is applied to chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of unfavorable environmental protection, increased dosage of chemicals, and high zinc content, so as to reduce environmental pollution and improve Zinc recovery rate, effect of reducing zinc content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

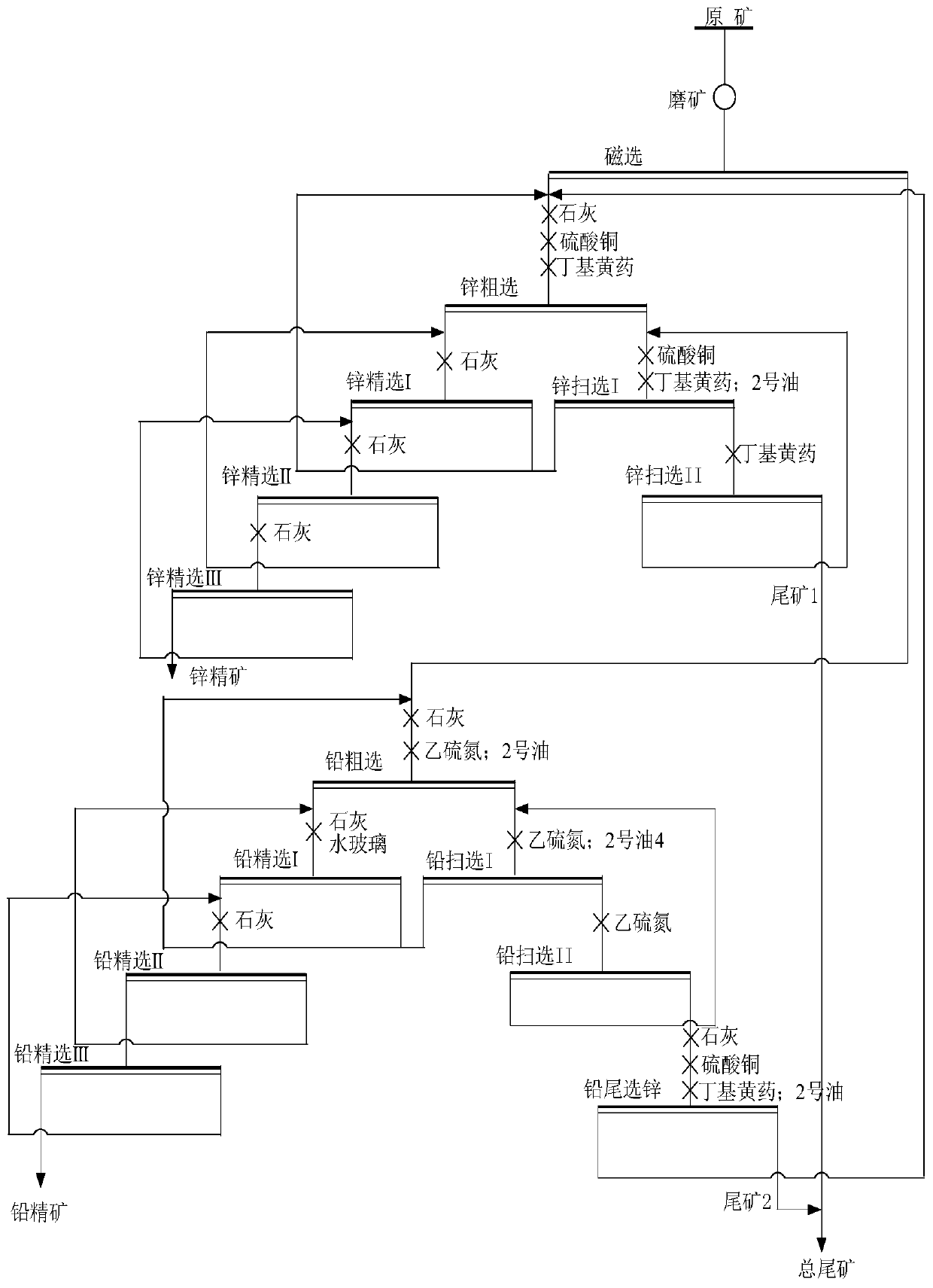

[0023] (1) The described sequence priority flotation of the magnetic separation tailings includes: performing copper flotation and / or lead flotation on the magnetic separation tailings, thereby obtaining copper concentrate and / or lead concentrate; Zinc beneficiation of copper flotation tailings and / or lead flotation tailings to yield low-iron or iron-free sphalerite.

[0024] (2) The magnetic field strength of the magnetic separation is 0.1-2T.

[0025] (3) combining the sphalerite with the low-iron or non-iron sphalerite for zinc flotation comprises: combining the sphalerite with the low-iron or non-iron sphalerite in Carry out zinc roughing together to obtain zinc roughing concentrate and zinc roughing tailings. Carry out zinc sweeping for zinc roughing tailings twice to obtain zinc sweeping ore and tailings; zinc sweeping ore selection returns to the previous operation in sequence. Carry out three times of zinc concentration on the zinc roughing concentrate to obtain the ...

Embodiment 1

[0034] Taking lead-zinc mine as an example, such as figure 1 As shown, a complex sulfide ore beneficiation method containing sphalerite is used for beneficiation of ores whose sphalerite content accounts for at least 50% of the total amount of sphalerite, and may include the following steps:

[0035] Step 1. Put the raw ore into the ball mill, add water into the ball mill for grinding according to the liquid-solid ratio of 1:1, and the grinding fineness reaches -0.074mm, accounting for at least 70%.

[0036] Step 2, import the ground pulp into a magnetic separator (add water to adjust the concentration to about 35 wt%), and perform magnetic separation operation, thereby obtaining magnetic separation concentrate and magnetic separation tailings.

[0037] Step 3: Add lime 2000g / t to the magnetic separation concentrate to adjust the pH value to 10-13, and stir for 2 minutes, add activator copper sulfate 150g / t, and stir for 2 minutes, then add collectors in turn Butyl xanthate 5...

Embodiment 2

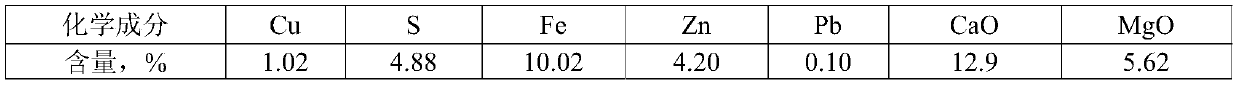

[0051] A lead-zinc ore mainly contains galena, sphalerite (part of sphalerite does not contain iron), pyrite, siderite, arsenopyrite, etc., and trace amounts of chalcopyrite, copper blue, limonite Wait. Most of the non-metallic minerals in the ore are quartz, followed by sericite, a small amount of orthoclase, kaolinite, chlorite, albite, and trace amounts of calcite, carbonaceous, rutile, etc. The main chemical composition analysis results of the ore are shown in Table 1 below:

[0052] Table 1

[0053] chemical composition Cu Pb Zn S Fe As SiO 2

content,% 0.092 2.86 3.10 8.87 10.95 1.22 54.15 chemical composition Al 2 o 3

MgO CaO Na 2 o

K 2 o

P - content,% 10.65 1.32 0.59 0.29 3.67 0.61 -

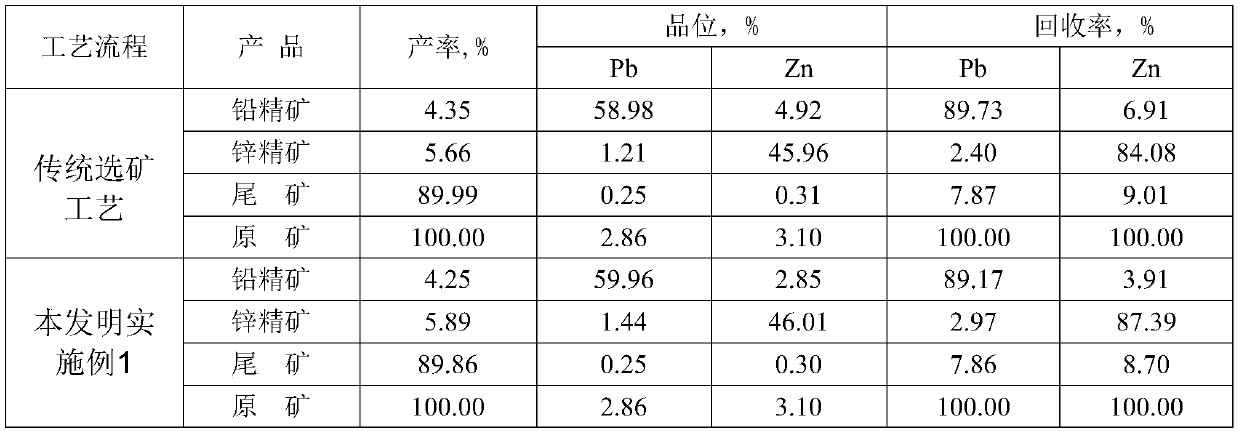

[0054] The complex sulfide ore beneficiation method of iron-containing sphalerite provided by the traditional mineral processing technology and the embodiment of the present invention 1 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com