Method for treating and recycling copper-zinc sulphide ore separation waste water

A technology for beneficiation wastewater and sulfide ore, which is applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of less research on the treatment process of copper-zinc sulfide ore beneficiation wastewater, and save the consumption of flotation reagents , The process is simple and the effect of less slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

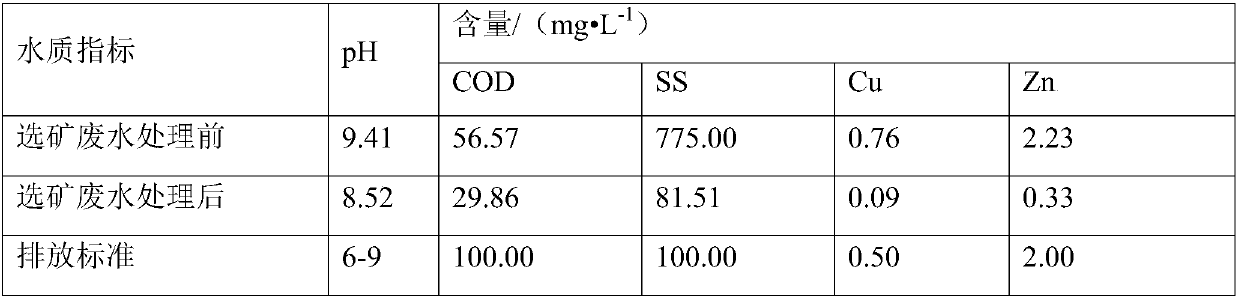

[0024] Table 1 shows the water quality of copper-zinc sulfide ore dressing wastewater before and after comprehensive treatment by sulfide precipitation method and coagulation sedimentation method.

[0025] Table 1 Water quality status of beneficiation wastewater

[0026]

[0027] Note: The discharge standard refers to the primary sewage discharge standard in GB8978-1996

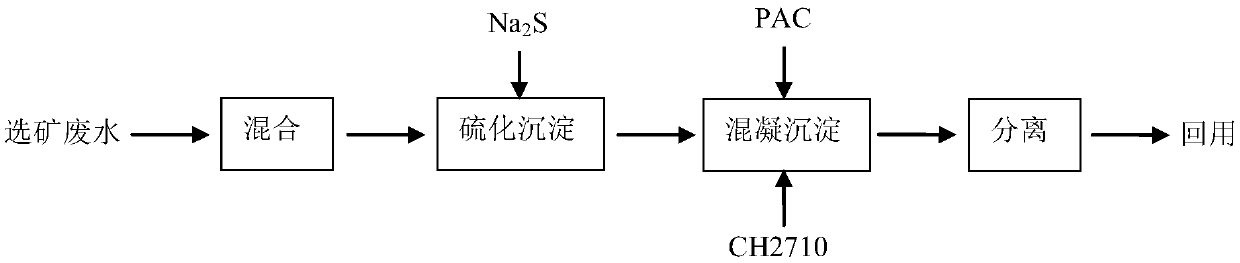

[0028] The integrated process such as figure 1 As shown, that is to add a certain amount of precipitant to the copper-zinc mineral processing wastewater, so that the soluble heavy metal ions in the wastewater are precipitated in the form of sulfide; destabilization; then continue to add flocculant to the destabilized wastewater, stir, and carry out coagulation and precipitation reaction; after the coagulation and precipitation reaction is completed, settle naturally, and take the supernatant for copper-zinc flotation separation test.

[0029] Table 1 shows that after the precipitant sodium sulfide, coagu...

Embodiment 2

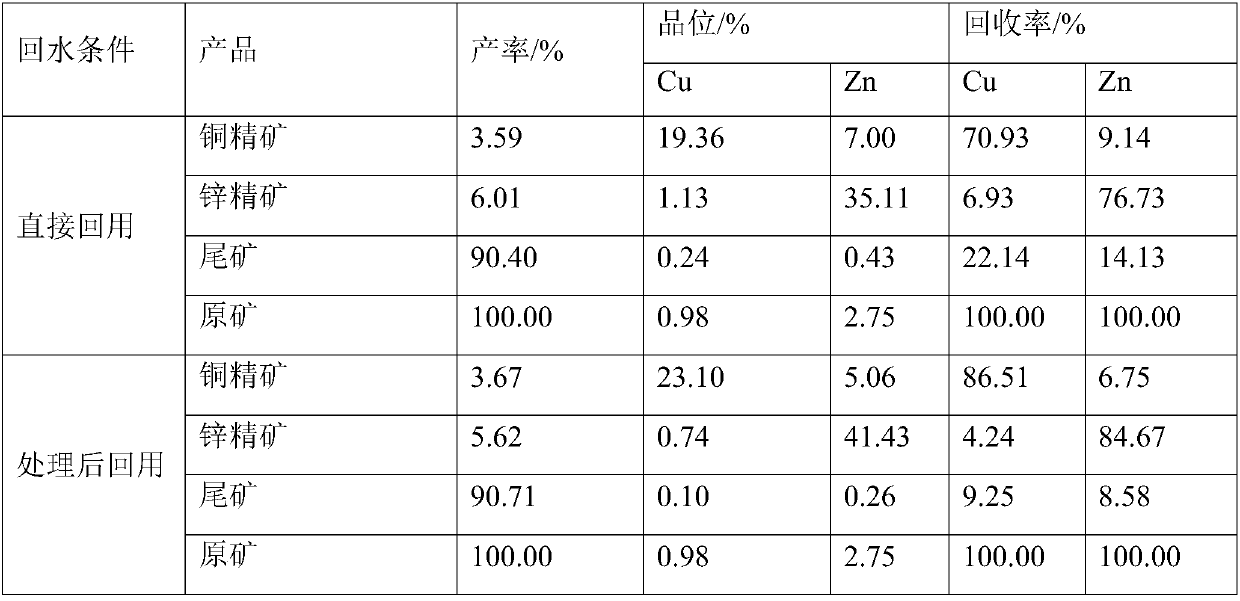

[0031] The comparison test of the flotation closed-circuit process of the direct reuse of mineral processing wastewater and the reuse of mineral processing wastewater after treatment with sodium sulfide, coagulant PAC and flocculant CH2710 was carried out. The impact of the indicators is shown in Table 2.

[0032] Table 2 Comparison of flotation closed-circuit test results

[0033]

[0034] Table 2 shows that the mineral processing wastewater is directly reused without treatment, and the copper concentrate grade, recovery rate and zinc concentrate grade and recovery rate are not as good as the mineral processing index obtained after the mineral processing wastewater is reused, indicating that the suspended solids in the mineral processing wastewater , heavy metal ions and other toxic and harmful substances do have adverse effects on the beneficiation process, and coagulation and sedimentation of wastewater by adding sodium sulfide, coagulant PAC and flocculant CH2710 can ef...

Embodiment 3

[0036] Select a copper-zinc mine in Xinjiang in July, August, and September of 2017 in the normal production stage of using fresh water, in April 2018 in the stage of direct reuse of mineral processing wastewater without treatment, in May and June of 2018 in the stage of wastewater treatment and reuse of the dressing plant And in July and August 2018, the production indicators and chemical consumption of the wastewater treatment and reuse in the normal production stage of the dressing plant are compared as follows, see Tables 3 and 4.

[0037] Table 3 Concentrator using different water beneficiation production indicators

[0038]

[0039]

[0040] Table 4 Comparison of chemical consumption in dressing plants

[0041]

[0042] Comparing the beneficiation production indicators in July, August, September 2017 and April 2018 in Table 3, it can be seen that the direct reuse of wastewater without treatment has a serious impact on the grade of copper concentrate, zinc concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com