Aluminum alloy for manufacturing die-casting cylinder head covers and die-casting cylinder head cover

A cylinder head cover and aluminum alloy technology, which is applied in the field of aluminum alloy materials, can solve the problems of unstable process, deformation, under-casting and other problems of content deviation, and achieve the effects of bright appearance, good toughness and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The aluminum alloy used to manufacture the die-casting cylinder head cover in this embodiment includes the following components by weight percentage: Si: 10.5%, Cu: 1.5%, Fe: 0.8%, Mg: 0.15%, Zn: ≤ 1.0%, Mn: ≤0.5%, Ti≤0.3%, the rest is Al and a small amount of unavoidable impurities.

[0032] The aluminum alloy used to manufacture the die-cast cylinder head cover in this embodiment is made by the following method: put pure aluminum into an aluminum melting furnace, and then add a specified amount of alloy into the aluminum melting furnace after the pure aluminum is melted.

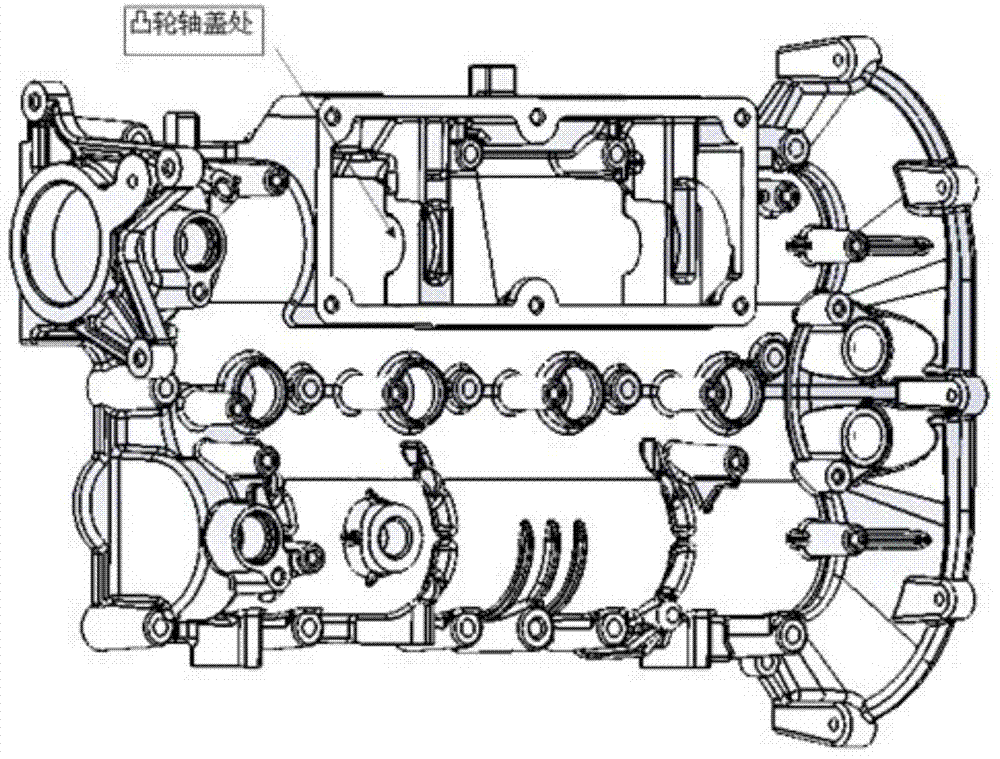

[0033] The aluminum alloy of the present invention is suitable for the manufacture of die-cast cylinder head covers, especially as figure 1 Manufacture of die-cast cylinder head cover with camshaft cover function shown. The finished product has bright appearance, no sticky mold, high strength, good toughness and long service life.

Embodiment 2

[0035] The aluminum alloy used to manufacture the die-casting cylinder head cover in this embodiment includes the following components by weight percentage: Si: 12%, Cu: 2.5%, Fe: 1.1%, Mg: 0.3%, Zn: ≤ 1.0%, Mn: ≤0.5%, Ti≤0.3%, the rest is Al and a small amount of unavoidable impurities.

Embodiment 3

[0037] The aluminum alloy used to manufacture the die-casting cylinder head cover in this embodiment includes the following components by weight percentage: Si: 11%, Cu: 2.0%, Fe: 1%, Mg: 0.2%, Zn: ≤ 1.0%, Mn: ≤0.5%, Ti≤0.3%, the rest is Al and a small amount of unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com