Method for improving indium grade of enriched indium slag

A technology for enriching indium slag, which is applied to the field of improving the indium content of enriched indium slag in the process of producing enriched indium slag, can solve the problems of low ability to reduce slag amount, reduce slag amount, increase labor intensity, etc., and achieve reduction The effect of production cost, improvement of processing capacity, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

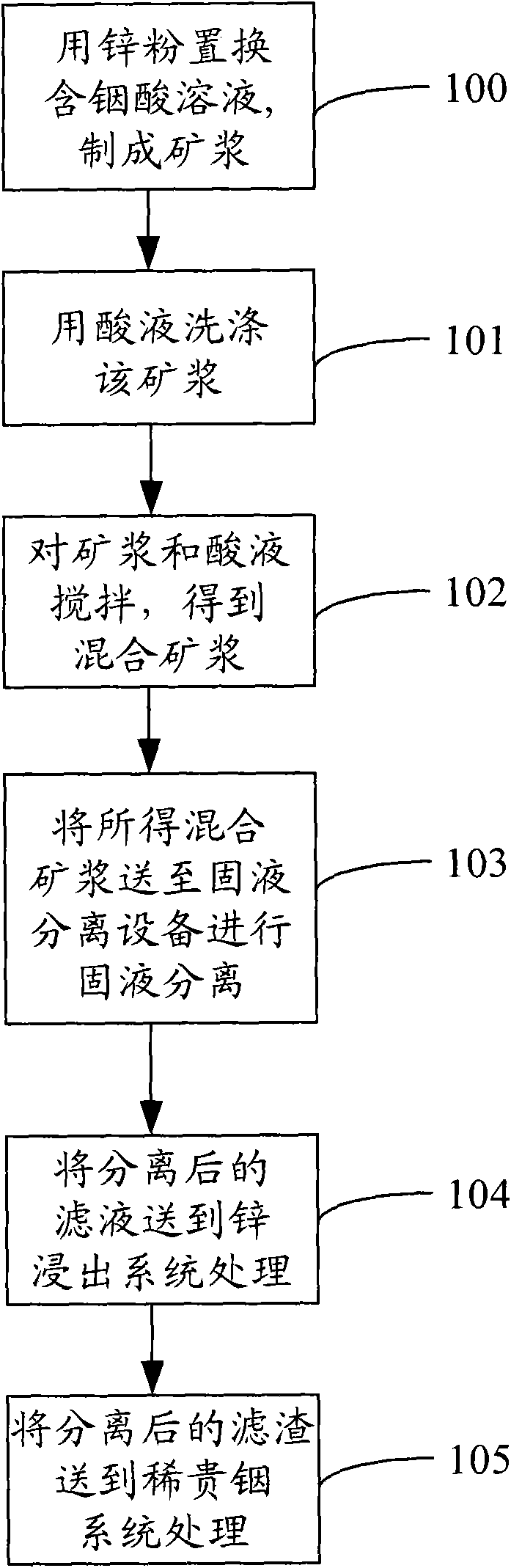

Method used

Image

Examples

Embodiment 1

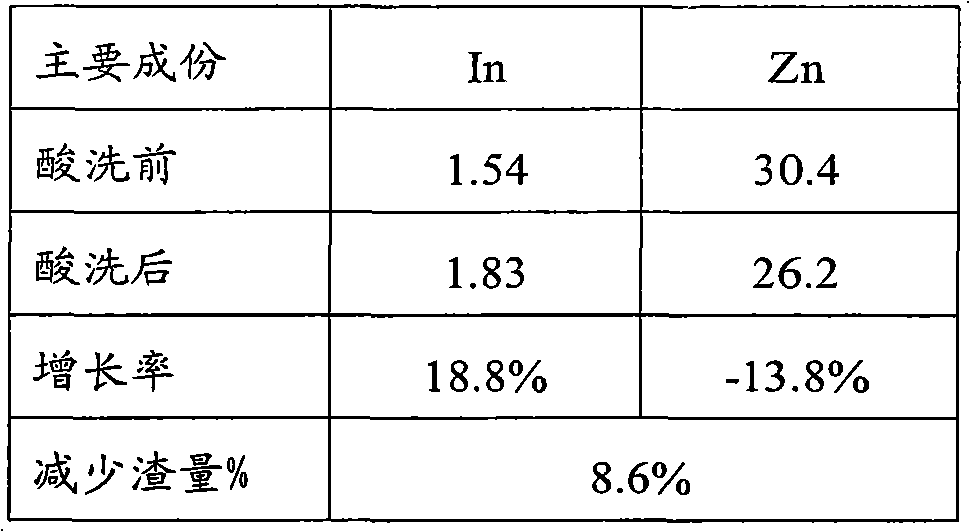

[0027] In the slurry tank, replace the indium-containing acid solution with zinc powder. After stirring evenly, its dry weight is 1 ton. Add zinc electrolytic waste solution to it. The acid content of the electrolyte is 140 grams per liter of acid. Stir the acid Wash for 10 minutes, use a pH tester or pH test paper to measure the pH value at the end of pickling to 4.5, and finally send it to a filter press for liquid-solid separation, and recover the filtered filtrate to the zinc smelting production leaching process, and send the filtered residue to To the rare and precious indium system, the final slag volume obtained is 0.914t. The indium in the enriched indium slag was analyzed by the atomic absorption instrument analysis method, and the zinc content was analyzed by the chemical analysis method. The pickling results are shown in Table 1.

[0028] Table 1

[0029]

[0030] Note: growth rate = (after pickling - before pickling) / before pickling

[0031] Reduce slag amou...

Embodiment 2

[0033]Experimental operation process is identical with embodiment 1, and the acid solution that adopts is zinc electrolytic waste solution, and concentration is 160 g / liter, and stirring pickling time is 20 minutes, and pickling terminal pH value is 4.5, and pickling result is shown in Table 2.

[0034] Table 2

[0035]

Embodiment 3

[0037] The experimental operation process is the same as in Example 1, the acid solution used is zinc electrolysis waste solution, the concentration is 175 grams per liter, the stirring pickling time is 40 minutes, the pH value of the pickling end point is 4.5, and the pickling results are shown in Table 3.

[0038] table 3

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com