Vulcanization-promoted comprehensive protective material and preparation method thereof

A protective material and vulcanization-promoting technology, applied in the field of vulcanization-promoted comprehensive protective materials for rubber and their preparation, can solve the problems of lack of dynamic protective effect, influence on protective effect, insufficient dynamic performance, etc., and achieve excellent comprehensive protective effect and excellent resistance to Thermal oxidative aging, improve the effect of metal poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

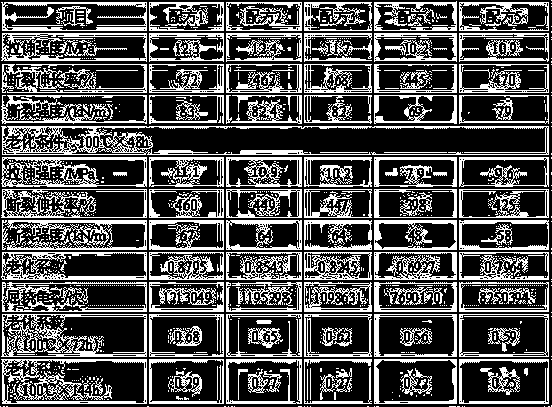

Embodiment 1

[0022] A vulcanization-promoting comprehensive protective material of the present invention comprises the following components: anti-aging agent RD, anti-aging agent 4020, anti-aging agent 4030 and zinc terephthalate.

[0023] The method for preparing the vulcanization-accelerated comprehensive protective material comprises the following steps:

[0024] (1) Add antiaging agent RD, antiaging agent 4020 and antiaging agent 4030 into acetone in proportion, stir until dissolved, and then add emulsifier to obtain emulsion system A;

[0025] (2) Disperse zinc terephthalate in acetone and add emulsifier to obtain emulsion system B;

[0026] (3) Fully mix system A of step (1) and system B of step (2) in a homogenizer, then recover acetone through distillation, and transfer the remaining substances to the storage tank under heat preservation, and reduce to a suitable After reaching a certain temperature, it is granulated by a steel belt cooling granulator to obtain the final granular ...

Embodiment 2

[0031] The difference between embodiment 2 and embodiment 1 is:

[0032] Further, the ratio of the antiaging agent RD, antiaging agent 4020, antiaging agent 4030 and zinc terephthalate is (by weight), 30:25:25:20.

[0033] Further, the emulsifier is selected from OP-10.

[0034] Further, the particle size D of zinc terephthalate 97 1.5 microns, BET specific surface area is 100m 2 / g.

Embodiment 4

[0036] The difference between embodiment 4 and embodiment 1 is:

[0037] Further, the ratio of the antiaging agent RD, antiaging agent 4020, antiaging agent 4030 and zinc terephthalate is (by weight), 28:23:23:26.

[0038] Further, the emulsifier is selected from a mixture of sodium palmitate and OP-20.

[0039] Further, the particle size D of zinc terephthalate 97 0.8 micron, BET specific surface area is 150m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com